When you specify limestone steps for Arizona installations, you’re making decisions that directly impact long-term performance, safety, and aesthetic durability. The state’s extreme temperature swings—often 40°F between night and day—create thermal expansion challenges most generic step materials can’t handle. You need suppliers who understand how limestone’s crystalline structure responds to UV intensity that exceeds 95% of continental locations, combined with monsoon moisture events that test porosity limits.

Your project success depends on selecting limestone steps suppliers Arizona professionals who maintain consistent dimensional tolerances across batches. Thermal cycling in Phoenix, Tucson, and lower-elevation cities subjects steps to surface temperatures reaching 160°F, requiring you to specify material with thermal expansion coefficients that won’t crack mortar joints or create lippage issues within 18-24 months. You’ll find that porosity ratings between 2-5% provide the optimal balance—low enough to resist moisture penetration during monsoons, high enough to allow vapor transmission that prevents subsurface pressure buildup.

The dimensional stability you require starts with quarry selection. Limestone steps treads suppliers Arizona sources should provide material from geologically stable formations with consistent calcium carbonate content above 95%. You’re looking for compressive strength exceeding 12,000 PSI—not the 8,000 PSI minimum you’ll see in coastal climate specs. Desert installations demand higher structural integrity because thermal stress compounds mechanical loads in ways humid climates never experience.

Thermal Performance in Arizona Climate Conditions

Arizona’s solar radiation intensity creates surface temperature challenges you won’t encounter in temperate zones. Direct UV exposure generates surface temperatures 35-45°F above ambient air temperature on dark-colored stone, and even lighter limestone treads reach 140-150°F during peak summer hours. Your specification must address thermal mass behavior—the 3-4 hour lag between peak air temperature and peak surface temperature affects not just comfort but structural performance.

When you evaluate natural stone steps Arizona options, you need to understand thermal expansion occurs in three dimensions simultaneously. Linear expansion of 0.0000044 inches per inch per °F means a 48-inch tread expands approximately 0.015 inches when temperature rises from 70°F to 140°F. That sounds minimal until you calculate the cumulative force across a 12-step installation—you’re generating thousands of pounds of lateral pressure if joints can’t accommodate movement.

- You should specify expansion joints every 10-12 feet in uncovered installations exposed to direct sunlight more than 6 hours daily

- Your mortar bed thickness needs to remain consistent at 1-1.5 inches to distribute thermal stress evenly across the substrate

- You’ll want to verify that substrate materials have compatible expansion coefficients within 15% of the limestone specification

- Your installation timeline should avoid summer months when substrate temperatures exceed 110°F during setting periods

The color selection you make directly affects thermal performance. Light-colored limestone steps reflect 55-65% of solar radiation, keeping surface temperatures 20-25°F cooler than darker stone options. This isn’t just about barefoot comfort—lower surface temperatures reduce thermal cycling stress that accelerates micro-cracking in mortar joints and along cut edges.

Material Specifications and Structural Requirements

Your structural specifications for limestone stair suppliers Arizona projects must address three critical performance metrics: compressive strength, flexural strength, and absorption rate. These aren’t independent variables—they interact in ways that determine real-world durability under Arizona’s environmental stressors.

Compressive strength above 12,000 PSI ensures you’re working with dense, well-consolidated limestone that resists both mechanical loads and weathering. You’ll find that material below 10,000 PSI shows accelerated surface degradation in high-traffic applications, with visible wear patterns appearing within 5-7 years instead of the 15-20 year performance window you should expect. The density that produces high compressive strength also correlates with lower porosity, which becomes essential when monsoon rains deposit 2-3 inches in a single afternoon.

Flexural strength matters more than most specifications acknowledge. Steps experience cantilever loads that create tensile stress on the underside of treads—especially in applications where nosing overhangs the riser below. You need minimum flexural strength of 1,800 PSI for residential applications, increasing to 2,400 PSI for commercial installations where concentrated loads from crowds or equipment become factors.

- Absorption rates should remain below 3% by weight for exterior applications exposed to freeze-thaw potential in Flagstaff and Sedona elevations

- Your specification should require ASTM C568 compliance for dimensional tolerances within ±1/8 inch across 48-inch lengths

- You’ll want to verify that slip resistance meets or exceeds 0.60 DCOF on both dry and wet surfaces for safety code compliance

- Thickness consistency within ±1/16 inch prevents lippage issues that create trip hazards and accelerate edge spalling

When you source from limestone steps suppliers Arizona warehouses, you should request material certifications documenting these specifications aren’t just met but consistently maintained across production runs. Batch-to-batch variation exceeding 8-10% in any performance metric creates installation challenges you’ll discover too late to correct economically.

Edge Detail Options and Performance Implications

The edge profile you specify affects both aesthetic presentation and long-term durability. Bullnose edges with 1-2 inch radius curves distribute impact stress more effectively than sharp 90-degree edges, reducing chip susceptibility along the nosing—the highest-wear area of any step. You’ll find that material thickness at the edge determines how aggressive your radius can be without compromising structural integrity.

For premium installations requiring Stone Steps Treads Arizona specification, you’re typically working with 2-inch nominal thickness that provides sufficient mass for radius detailing while maintaining strength. Thinner materials under 1.5 inches limit your options to minimal easing or chamfer details that don’t provide the same impact resistance. You need to understand the trade-off between material cost savings from thinner stock and the increased replacement frequency from edge damage.

Sharp-edged profiles wear faster in commercial applications where foot traffic concentrates along the nosing line. You’ll observe measurable edge rounding within 3-5 years in hotel lobbies, office buildings, and retail environments—not from material failure but from abrasive wear that gradually softens the crisp detail. For information on radius options suited to different applications, see our bullnose tread supply for detailed dimensional specifications. Your maintenance program needs to account for this predictable wear pattern when you’re setting replacement reserve budgets.

- Bullnose radius edges reduce chip frequency by approximately 40% compared to square-edge details in high-traffic applications

- Your fabrication specifications should ensure radius consistency within ±1/8 inch across all treads for visual uniformity

- You’ll want to specify honed or thermal finishes on curved edges rather than polished surfaces that become slip hazards when wet

- Edge reinforcement with epoxy-filled dowels becomes necessary when overhang exceeds 2 inches or material thickness drops below 1.75 inches

Surface Finish Impact on Safety and Longevity

The surface finish you select determines slip resistance, maintenance requirements, and visible wear patterns over the installation’s service life. Honed finishes provide matte surfaces with DCOF ratings between 0.55-0.65 when dry, dropping to 0.45-0.52 when wet—marginally acceptable for exterior stairs depending on slope and exposure. You’re balancing safety requirements against aesthetic preferences that favor smoother surfaces.

Thermal finishes created by flame treatment open the surface structure, increasing texture and raising DCOF ratings to 0.62-0.72 wet or dry. The micro-roughness created by thermal shock doesn’t create the coarse texture of sandblasted finishes, maintaining a refined appearance while providing superior slip resistance. You’ll find this finish particularly valuable for pool surrounds, spa approaches, and other applications where water exposure is constant rather than occasional.

Your choice affects maintenance intensity significantly. Honed finishes show water spots, minerals deposits from irrigation, and organic staining more readily than textured surfaces. You’ll need to implement quarterly sealing schedules with penetrating silane/siloxane products to maintain stain resistance, increasing to monthly applications in high-moisture environments. The smoother the finish, the more visible maintenance becomes when neglected.

- You should verify that finish specifications meet ADA requirements for slip resistance where codes apply to your project type

- Your maintenance protocol must include pH-neutral cleaning products—acidic cleaners etch calcium-carbonate-based limestone regardless of finish type

- You’ll observe that thermal finishes maintain consistent texture longer than honed surfaces that gradually polish from foot traffic in concentrated wear paths

- Surface sealer penetration depth ranges from 3-8mm depending on porosity, requiring you to coordinate finish selection with sealing strategy

Installation Substrate and Setting Method Considerations

Your substrate preparation determines whether limestone treads suppliers Arizona installations achieve their 20-30 year service life or begin showing problems within 5-7 years. The setting bed must provide uniform support across 100% of the tread’s bottom surface—point loading from inconsistent mortar coverage creates stress concentrations that propagate cracks from any existing micro-fissures in the stone.

Concrete substrates need minimum 28-day cure time before you begin setting natural limestone steps. Residual moisture in younger concrete migrates into the stone’s pore structure, carrying alkaline compounds that create efflorescence when they reach the surface and react with atmospheric CO2. You’ll see white crystalline deposits appear 6-18 months post-installation if you rush the substrate cure schedule—remediation requires aggressive chemical treatment that risks etching the limestone surface.

The mortar bed thickness you specify must balance workability during installation with structural performance after cure. Beds thicker than 2 inches create shrinkage issues that reduce bond strength and introduce voids. Beds thinner than 3/4 inch don’t provide adequate adjustment range for achieving uniform tread heights across irregular substrates. You’re targeting 1-1.5 inches as optimal for most applications.

- You should require modified thin-set mortars with polymer additives that improve flexibility and bond strength by 35-50% over traditional cement-based mortars

- Your specification must address substrate slope for drainage—minimum 1/8 inch per foot prevents standing water that accelerates freeze-thaw damage at elevation

- You’ll need to verify that substrate compressive strength exceeds stone compressive strength by at least 20% to prevent differential settlement

- Isolation membranes become necessary when you’re setting limestone over substrates with known movement potential or crack propagation risk

Joint Spacing and Sealant Selection Protocols

Joint dimensions you specify must accommodate thermal expansion while maintaining proportional aesthetic relationships with tread dimensions. Joints narrower than 1/4 inch don’t provide adequate movement capacity for Arizona’s 40-50°F daily temperature swings during spring and fall transition seasons. You’ll observe mortar joint failure within 2-3 years when joints are undersized—not from installation defects but from physics that exceeds material elastic limits.

Wider joints above 1/2 inch create visual disruption that draws attention away from the stone itself, particularly problematic in residential applications where refined detailing matters. You’re balancing functional requirements against aesthetic preferences, typically landing on 3/8 inch as optimal for most limestone steps suppliers Arizona projects. This dimension provides adequate thermal movement capacity while maintaining clean visual lines.

Your sealant selection determines joint longevity more than joint width. Polyurethane sealants with Shore A hardness between 25-35 provide the flexibility needed for thermal movement while maintaining sufficient body to resist compression under loads. Silicone sealants offer superior UV resistance but lower compressive strength—you’ll see them squeeze out from joint edges in high-traffic areas within 3-5 years.

- You should specify sealants with movement capability rated at ±25% to accommodate thermal expansion cycles throughout the year

- Your color selection must account for UV-induced color shift—light-colored sealants darken 15-20% over 5-7 years of sun exposure

- You’ll want to implement backer rod at proper depth to control sealant cross-section and ensure optimal stress distribution during movement

- Joint cleaning protocols before sealant application must remove all dust, minerals, and residues to achieve manufacturer-specified bond strength

Limestone Steps Suppliers in Arizona — Citadel Stone Professional Specification Advisory

When you evaluate Citadel Stone’s limestone stair suppliers Arizona sourcing for your project, you’re considering material engineered specifically for southwestern climate extremes. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse regional conditions. This section outlines how you would approach material selection and installation planning for six representative cities throughout the state.

Climate variability across Arizona’s elevation range creates specification challenges you don’t encounter in more homogeneous climate zones. You’re addressing low-desert heat stress in Yuma and Phoenix while simultaneously accounting for freeze-thaw cycling potential in Flagstaff and Sedona. Your material selection can’t treat the state as monolithic—regional differentiation becomes essential for long-term performance.

Phoenix Thermal Specifications

In Phoenix installations, you would specify limestone with maximum solar reflectance ratings to mitigate surface temperatures that routinely exceed 155°F during June through August peak periods. Your material selection should emphasize lighter color ranges with LRV values above 60 to maintain barefoot-safe surface temperatures below 135°F. The urban heat island effect amplifies thermal stress by an additional 8-12°F compared to surrounding desert areas, requiring you to account for this intensification in expansion joint calculations. You’d want to verify that mortar systems maintain bond strength at sustained temperatures above 140°F, as many conventional thin-sets show adhesion degradation above this threshold. Your installation timeline should avoid summer months when substrate temperatures make proper mortar curing impossible during daylight hours.

Tucson Monsoon Considerations

Tucson’s pronounced monsoon season delivers 30-35% of annual precipitation in concentrated July-September events, requiring you to specify limestone treads suppliers Arizona materials with absorption rates below 2.5%. Your drainage design becomes critical when afternoon storms deposit 1-2 inches in 90-minute windows, creating flash-flow conditions across horizontal surfaces. You would implement substrate slopes of 1/8 inch per foot minimum, increasing to 3/16 inch per foot for covered installations where evaporation rates are reduced. The rapid wetting and drying cycles characteristic of monsoon patterns create thermal shock effects you need to account for—surface temperature drops of 40-50°F within 15 minutes stress the stone-mortar interface significantly. Your sealant specifications should address moisture vapor transmission to prevent subsurface pressure buildup during these rapid moisture infiltration events.

Scottsdale Luxury Applications

When you specify Stone Steps Treads Arizona materials for Scottsdale’s high-end residential and resort applications, you’re balancing performance requirements with aesthetic refinement expectations that exceed typical commercial standards. Your material selection would emphasize consistent color batching within ±5% variation across all treads to maintain the visual uniformity luxury clients demand. You’d specify premium finishing that achieves surface flatness within 1/32 inch across 48-inch tread spans, preventing any perceptible waviness underfoot. Edge details in these applications typically require 1.5-2 inch bullnose radius with hand-finished consistency that maintains perfect symmetry. Your quality control protocols should include individual piece inspection before shipping, with rejection rates around 8-12% to ensure only premium-grade material reaches the job site. At Citadel Stone, we recommend coordinating warehouse availability three months ahead for projects requiring this specification level.

Flagstaff Freeze-Thaw Requirements

Flagstaff’s 7,000-foot elevation subjects limestone steps to 80-110 freeze-thaw cycles annually, requiring you to specify material with maximum density and minimum porosity ratings. Your absorption specification should mandate below 2% by weight to prevent saturation that expands during freezing and causes spalling along edges and surface planes. You would implement detailed drainage design that prevents any standing water retention in joints, mortar beds, or surface depressions where ice formation could occur. The material’s pore structure becomes critical—interconnected porosity allows moisture migration that equalizes pressure during freeze events, while isolated porosity traps water that expands destructively. You’d want to verify through ASTM C666 testing that candidate materials maintain structural integrity through 300+ freeze-thaw cycles with less than 3% strength degradation. Your sealant selection must remain flexible at temperatures down to -15°F while maintaining bond strength during the 60°F daily temperature swings common during spring transition periods.

Sedona Color Coordination

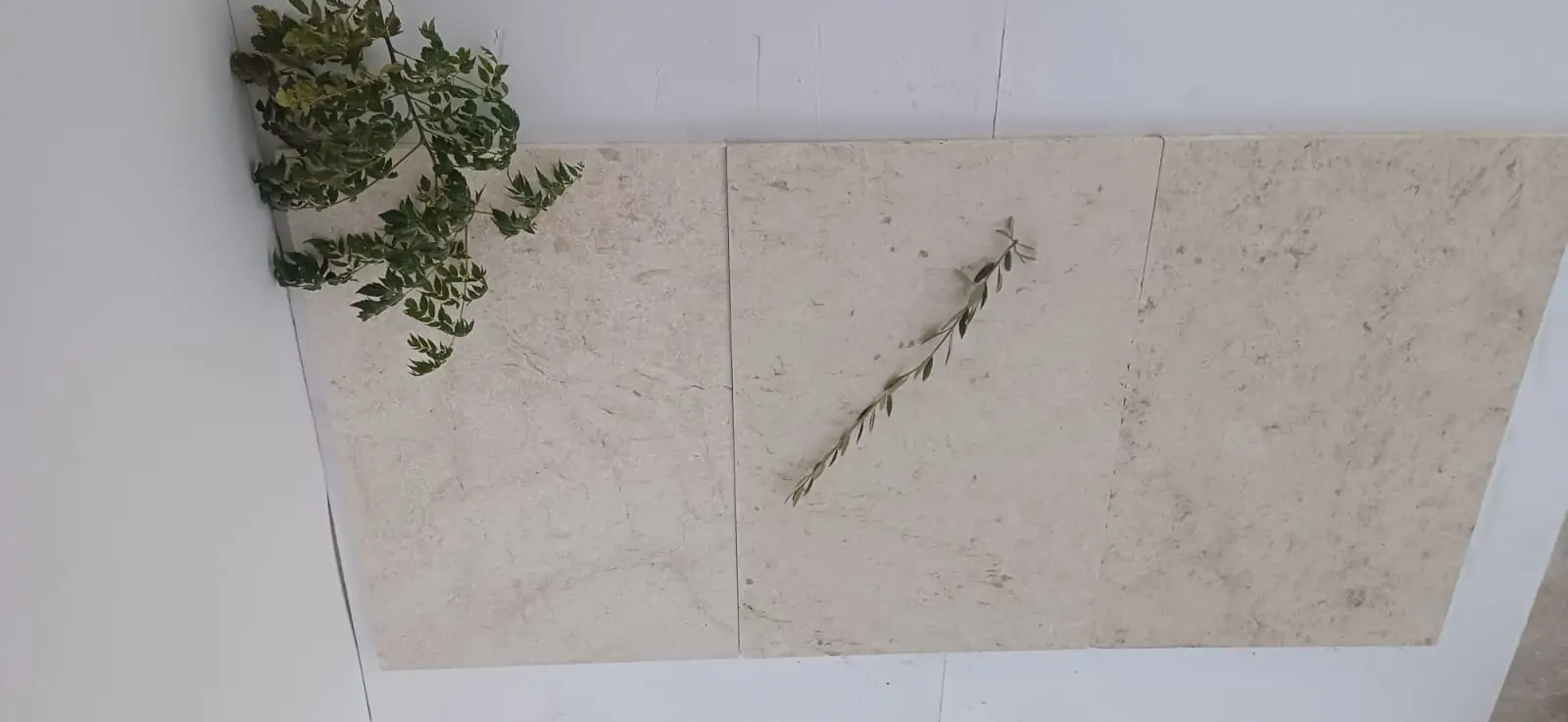

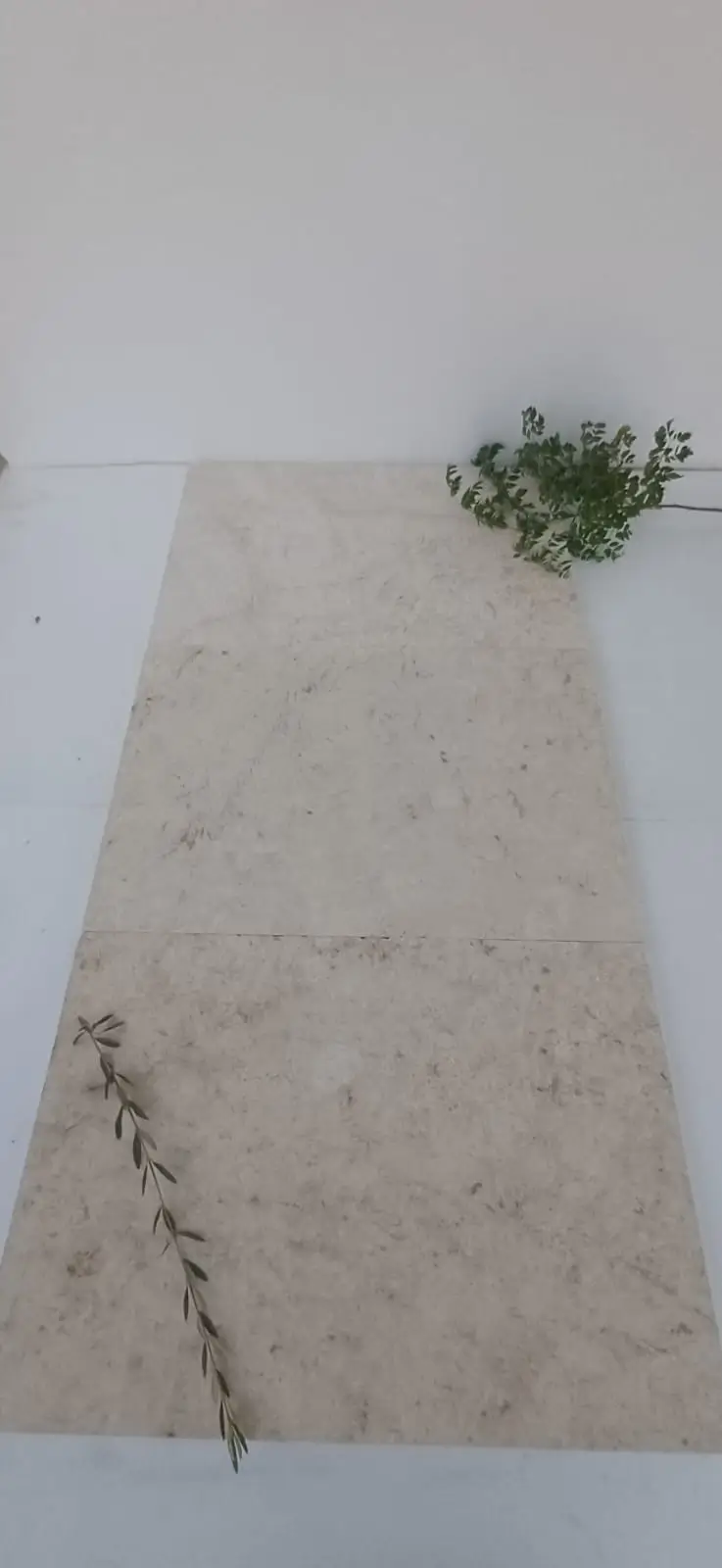

In Sedona applications, you would coordinate limestone color selection with the iconic red rock landscape that dominates the visual environment. Your material specifications might emphasize warmer beige and cream tones that complement rather than contrast with regional geology, creating cohesive design language between built and natural elements. You’d account for Sedona’s 4,500-foot elevation that creates moderate freeze-thaw exposure—approximately 35-50 annual cycles requiring absorption rates below 3% but not the extreme density requirements of higher-elevation Flagstaff installations. The tourist-intensive commercial applications common in Sedona demand you specify slip resistance meeting ADA requirements with DCOF ratings above 0.60 wet. Your finish selection would balance aesthetic preferences for smoother surfaces against safety mandates for textured finishes that maintain traction during afternoon monsoon showers and winter precipitation events. UV stability becomes important in this high-visibility market where appearance maintenance directly affects property values and commercial viability.

Yuma Extreme Heat Performance

Yuma represents Arizona’s most extreme thermal environment, with summer temperatures exceeding 110°F more than 90 days annually and surface temperatures on limestone steps regularly reaching 165-175°F. Your material specification would prioritize maximum solar reflectance through light color selection and potentially incorporate reflective aggregate in mortar joints to reduce heat absorption. You’d need to account for thermal expansion that exceeds typical Phoenix installations by 15-20% due to sustained high temperatures rather than brief daily peaks. The concrete substrates you’re setting on expand at different rates than limestone, creating shear stress at the bond interface that requires modified thin-set mortars with enhanced flexibility. You would implement expansion joints every 8-10 feet instead of the 12-15 feet typical in moderate climates, with joint widths of 1/2 inch rather than 3/8 inch to accommodate the expansion magnitude. Your construction schedule should avoid June through August entirely when midday temperatures make quality installation impossible and accelerated mortar curing from heat creates bond strength compromises.

Procurement Lead Time and Project Scheduling Management

Your project timeline must account for material procurement lead times that vary based on specification complexity and order volume. Standard-dimension treads in common thicknesses ship from warehouse stock within 7-14 days when inventory levels align with your quantity requirements. Custom fabrication for non-standard dimensions, specialized edge details, or premium finishing adds 4-6 weeks to delivery schedules as material moves through cutting, finishing, and quality inspection processes.

You should verify current stock levels before finalizing project schedules, particularly for large-volume commercial installations requiring 50+ pieces with matched color batching. Truck delivery logistics in rural Arizona locations can add 3-7 days beyond standard metropolitan shipping windows, particularly when you’re coordinating with delivery to remote resort properties or residential sites with limited access. Your receiving schedule needs to accommodate limestone’s weight density of approximately 165 pounds per cubic foot—a typical 48-inch tread at 2-inch thickness weighs 90-110 pounds, requiring appropriate equipment and labor for safe offloading.

- You’ll need to coordinate warehouse release with job site readiness to minimize material storage duration and associated damage risk from weather exposure or construction activity

- Your procurement specifications should include over-order quantities of 8-12% to account for potential breakage during shipping, handling, or installation

- You should request pre-shipment photos of actual material when color consistency matters significantly, allowing approval before truck dispatch

- Seasonal demand peaks during October through April construction seasons can extend lead times by 10-15 days compared to summer low-demand periods

Cost Variables and Budget Planning Factors

When you develop project budgets for limestone steps suppliers Arizona sourcing, you’re accounting for multiple cost components beyond base material pricing. Material costs range from $28-65 per square foot depending on thickness, finish quality, and edge detailing complexity. Standard 2-inch treads with basic eased edges fall toward the lower range, while premium-finished material with 2-inch bullnose radius and hand-selected color matching approaches the upper range.

Fabrication charges for custom dimensions add $8-15 per linear foot of cutting and finishing, with specialized details like radius cuts or waterfall returns commanding premium pricing. Your transportation costs vary dramatically based on project location and order volume—consolidated shipments to metropolitan areas cost $0.40-0.75 per pound, while small-volume deliveries to remote locations can reach $1.25-1.80 per pound when you’re paying for dedicated truck dispatch rather than consolidated routing.

Installation labor represents 35-45% of total project cost in typical applications. You’re paying for skilled tradespeople who understand limestone’s handling requirements and can achieve the precision needed for uniform joints, proper bedding, and damage-free installation. Commercial projects with strict schedule requirements often see labor premiums of 20-30% over residential work due to coordination complexity and accelerated timeline demands.

- You should budget approximately $65-125 per linear foot of finished step installation including materials, fabrication, delivery, and skilled labor

- Your contingency reserve should account for 12-15% cost variation based on site conditions discovered during substrate preparation

- You’ll find that projects requiring extensive substrate remediation or structural reinforcement can see installed costs increase by 40-60% over baseline estimates

- Warranty considerations factor into long-term cost analysis—premium materials with proven durability reduce replacement frequency and lifecycle costs significantly

Maintenance Protocols for Maximum Service Life Extension

Your maintenance program determines whether properly installed limestone steps achieve their 25-30 year service potential or begin showing degradation within 10-12 years. Initial sealing within 30 days of installation establishes baseline stain resistance and moisture protection that preserves appearance and structural integrity. You should specify penetrating silane/siloxane sealers that don’t create surface films prone to delamination and wear—these products penetrate 3-8mm into the stone structure, bonding chemically with the calcium carbonate matrix.

Resealing frequency depends on traffic intensity and weather exposure. You’ll need annual reapplication in commercial high-traffic areas, extending to biennial schedules for residential installations with moderate use. The sealer doesn’t wear away through abrasion but rather becomes depleted as it performs its function of repelling water and contaminants. You can test effectiveness by observing water behavior on the surface—when water no longer beads but instead darkens the stone immediately, you’ve lost sealer protection and need immediate reapplication.

Your cleaning protocols must avoid acidic products that etch limestone’s calcium carbonate composition. You should implement pH-neutral cleaners specifically formulated for natural stone, applied with soft-bristle brushes or microfiber mops that don’t scratch honed or polished finishes. Pressure washing at settings above 1,200 PSI damages surface texture and drives contaminants deeper into pore structures—you’re better served with lower pressure and appropriate chemical cleaning when necessary.

- You’ll want to establish quarterly inspection protocols that identify developing problems before they require expensive remediation rather than simple maintenance

- Your maintenance specifications should address joint sealant inspection and renewal every 5-7 years as polyurethane products age and lose elasticity

- You should implement immediate stain removal protocols for organic materials, oils, and other contaminants that become permanent if allowed to penetrate deeply

- Winter maintenance in freeze-prone elevations must avoid deicing salts that accelerate surface deterioration through osmotic pressure and chemical attack

Common Specification Mistakes and Field Problem Prevention

The most frequent specification error involves inadequate attention to thermal movement accommodation. You see projects fail within 3-5 years because joints were sized for structural loads without accounting for thermal expansion that generates equal or greater stress. When you specify joint spacing over 15 feet in Arizona installations, you’re virtually guaranteeing cracking problems as the cumulative expansion across that span exceeds sealant movement capability and mortar bed flexibility.

Substrate preparation shortcuts represent the second most common failure mode. You encounter installations over improperly cured concrete that show efflorescence within 18 months, or settings over insufficiently compacted aggregate that settle differentially and create lippage exceeding 1/8 inch between adjacent treads. These aren’t material defects—they’re installation deficiencies that proper specifications would prevent through detailed substrate requirements and inspection protocols before material placement begins.

Your specification often lacks adequate detail regarding acceptable material variation. Natural stone exhibits color and texture variation that some clients find objectionable when they expected uniform appearance matching small samples. You need to establish clear acceptance criteria defining allowable variation ranges, require large-format mock-ups before bulk ordering, and obtain written client approval acknowledging natural variation as inherent material characteristic.

- You should avoid specifying polished finishes for exterior applications where slip resistance becomes safety liability in wet conditions

- Your installation specifications must prohibit mechanical cleaning methods during construction that damage edges and scratch surfaces before the project even completes

- You’ll prevent most warranty disputes by establishing clear exclusions for damage from deicing salts, acidic cleaners, impact loads, and improper maintenance

- Color shift from sealer application catches many specifiers unprepared—you should always test sealers on sample pieces and obtain approval before full application

Material Sourcing and Quality Verification Standards

When you evaluate limestone steps suppliers Arizona options, you’re assessing not just material availability but quality control systems that ensure consistency across your order volume. Reputable suppliers maintain quarry relationships that provide geologically consistent material from established formations rather than opportunistic sourcing from variable deposits that produce unpredictable characteristics. You should request information about quarry locations and formation geology to verify you’re receiving material from proven sources.

Your quality verification should include requesting material certifications documenting physical properties through standardized testing. ASTM C568 for limestone dimension stone provides the framework for compressive strength, flexural strength, absorption, and density specifications. You want suppliers who routinely test material and can provide data sheets showing results rather than relying on generic species descriptions that may not reflect actual performance of specific inventory.

Dimensional tolerance consistency separates professional suppliers from commodity stone yards. You should verify that cutting and finishing operations maintain thickness tolerance within ±1/16 inch across tread width and length. Edge straightness shouldn’t deviate more than 1/32 inch across 48-inch spans, and bullnose radius consistency needs to stay within ±1/8 inch piece-to-piece. These tolerances determine whether your installation achieves clean visual lines or shows irregularities that become obvious once material is set.

- You’ll want to inspect actual inventory before finalizing large orders, verifying color consistency and finish quality match your expectations from samples

- Your purchasing agreements should include replacement provisions for material that arrives damaged or fails to meet documented specifications

- You should establish clear acceptance criteria for natural characteristics like veining, fossils, and color variation that don’t constitute defects but may affect aesthetic outcomes

- Return policies for unused material matter when you’ve over-ordered for breakage contingency and need to minimize project cost overruns from excess inventory

Final Specification Considerations

Your professional approach to specifying natural stone steps Arizona installations requires balancing multiple performance variables against budget constraints and aesthetic objectives. You’ve learned that thermal management through appropriate joint spacing, color selection, and substrate compatibility prevents the majority of field failures. The porosity and density specifications you establish determine whether limestone treads survive Arizona’s monsoon patterns and elevation-dependent freeze-thaw exposure.

When you coordinate procurement timing with construction schedules, you minimize material storage exposure and ensure warehouse stock availability matches your project demands. The suppliers you select should demonstrate quality control systems and testing protocols that verify material consistency across your order volume. Your maintenance specifications establish the framework for long-term performance that achieves the 25-30 year service life properly selected limestone can provide. For comprehensive guidance on specialized applications, review Rounded edge stone treads for residential and commercial applications before finalizing project documents. Resort entry stairs trust Citadel Stone, the most hospitality Stone Steps & Treads Arizona luxury impressions.