When you evaluate landscape stone yard Arizona complete guide options for your project, you’re entering a market shaped by extreme heat, intense UV exposure, and diverse regional microclimates that demand material expertise most suppliers don’t provide. Your selection process requires understanding how decorative rock performs under 115°F surface temperatures, how boulders integrate with xeriscape principles, and how gravel specifications affect long-term maintenance costs. The difference between a successful installation and a costly redesign often comes down to matching material characteristics with your site’s specific environmental stressors.

Arizona’s landscape stone industry operates differently than other regions because the climate eliminates materials that work perfectly in temperate zones. You’ll find that stone yard landscape Arizona decorative materials inventory reflects this reality — suppliers stock products proven to withstand thermal cycling that ranges 60-80°F daily during peak season. Your material choices need to account for solar reflectance values, thermal mass behavior, and how aggregate mineralogy affects surface temperature under direct desert sun.

Material Categories and Performance Profiles

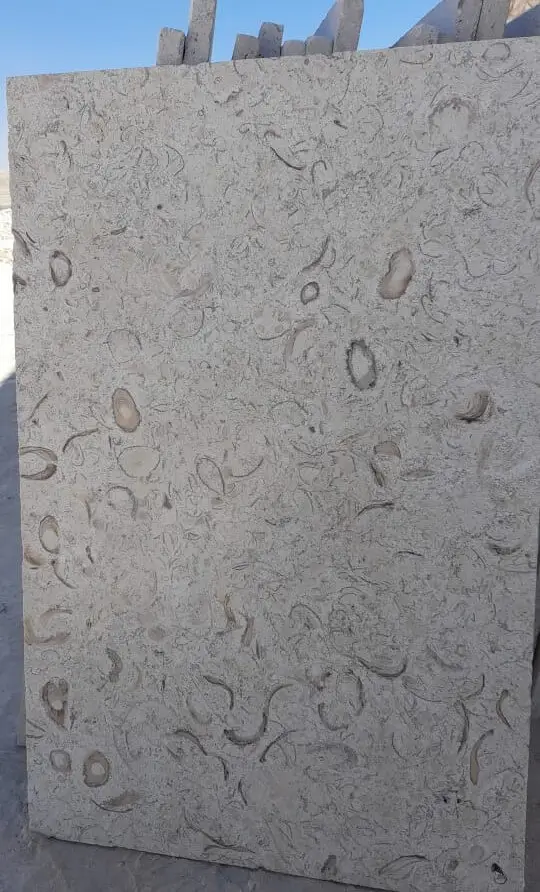

Decorative rock selections in Arizona fall into distinct performance categories, each responding differently to regional climate stressors. When you specify materials for landscape applications, you need to understand how composition affects long-term durability and maintenance requirements. Stone yard landscape Arizona decorative materials typically include decomposed granite, river rock, lava rock, flagstone, and crushed aggregate — but their performance varies significantly based on mineralogy and source quarry characteristics.

Decomposed granite offers superior compaction properties for pathways and stabilized surfaces, but you’ll encounter wide variation in binder content that affects erosion resistance. Material with 10-15% natural fines provides adequate stability while maintaining permeability for drainage. Arizona landscape stone supplies selection requires you to verify particle size distribution falls within 1/4″ minus specifications for pedestrian applications, while larger 3/8″ minus grades work better for vehicular surfaces where compaction resistance matters more than fine-grade aesthetics.

River rock presents different considerations for your project planning. Smooth, rounded profiles minimize heat retention compared to angular aggregates, making them preferable for areas where foot traffic occurs during afternoon hours. You should specify 1-3″ grades for most decorative applications, understanding that smaller grades migrate into soil over time while larger grades create visual mass that overwhelms residential-scale installations. The material’s thermal mass properties create a 3-4 hour lag between peak air temperature and peak stone temperature — a detail that affects irrigation scheduling and plant placement decisions.

- You need to verify decorative rock color stability under UV exposure exceeding 4,000 hours annually

- Your gravel specifications should address dust generation potential in low-humidity conditions

- You’ll want to confirm angular aggregate interlock characteristics for slope applications exceeding 3:1

- Your material selection requires understanding how porosity affects water retention in drip irrigation zones

Boulder Selection and Structural Considerations

Boulders function as both aesthetic focal points and structural elements in Arizona landscapes, requiring you to evaluate them beyond visual appeal. When you source landscape stone yard Phoenix Scottsdale directory suppliers for boulder inventory, you’re assessing material density, fracture patterns, weathering characteristics, and how the stone interacts with soil conditions during temperature extremes. Professional installations require boulders with specific gravity exceeding 2.4 to ensure stability on slopes and resistance to displacement during monsoon events.

Your boulder specifications need to address native versus imported stone trade-offs. Arizona moss rock and ironwood boulders provide regional aesthetic continuity and proven performance in local conditions, while imported granite and sandstone boulders offer color and texture options not available in local geology. The critical consideration isn’t origin — it’s understanding how mineralogy affects surface temperature, weathering rate, and long-term color stability under intense solar radiation.

Placement methodology determines whether boulders enhance or compromise your landscape functionality. You should plan for 40-50% burial depth to prevent settling and ensure visual proportion that mimics natural outcropping patterns. This isn’t arbitrary — shallow placement creates instability during soil expansion cycles common in clay-heavy substrates, while excessive burial wastes material and creates artificial appearance that conflicts with naturalistic design intent. Your site preparation needs to include compacted aggregate base extending 12-18″ beyond boulder footprint to distribute load and prevent differential settlement.

Gravel Specification and Technical Parameters

Gravel performance in Arizona applications depends on parameters most landscape stone yard buying guide Arizona resources overlook — particle shape, gradation curve, fines content, and mineralogical composition all affect how material behaves under foot traffic, weather exposure, and maintenance operations. When you specify gravel for pathways, you’re not just selecting size and color; you’re determining permeability rates, compaction potential, and how quickly the material will migrate or degrade over time.

Angular crushed aggregate provides superior interlock and stability compared to rounded gravel, making it preferable for high-traffic applications and surfaces requiring firm footing. You’ll achieve 92-95% compaction density with properly graded crushed material, while rounded river rock typically reaches only 80-85% compaction regardless of mechanical effort. This difference translates directly to long-term performance — angular aggregate maintains surface integrity 40-50% longer in pedestrian applications where rounded material would require replenishment or regrading.

- You should verify gradation includes 8-12% fines content for decomposed granite pathways requiring firm surface

- Your drainage applications need clean, washed aggregate with less than 2% fines to maintain permeability

- You’ll want to specify dust suppressant treatment for gravel in high-wind exposure areas

- Your erosion control requirements may need aggregate with 15-20% oversized particles for surface armoring

Color selection affects more than aesthetics in desert installations. Light-colored aggregates reflect 50-60% of solar radiation, maintaining surface temperatures 15-25°F cooler than dark materials under identical exposure conditions. This temperature differential influences plant health in adjacent planting zones, affects irrigation water requirements, and determines whether outdoor spaces remain usable during afternoon hours. When you evaluate stone yard landscape buying guide Arizona recommendations, prioritize solar reflectance data alongside color preference to ensure functional performance matches design intent.

Supplier Evaluation and Inventory Verification

Your landscape stone yard Arizona complete guide sourcing strategy requires verifying supplier capabilities beyond material availability. Professional-grade suppliers maintain consistent inventory of specified materials, provide accurate gradation data, and stock products from verified quarry sources rather than mixing loads from variable origins. You need to confirm whether suppliers conduct regular sieve analysis testing and can provide documentation showing particle size distribution meets your specifications.

Warehouse logistics directly impact your project timeline and material consistency. When you coordinate deliveries, you should verify that suppliers maintain segregated stockpiles preventing cross-contamination between different aggregate grades and types. This operational detail matters more than most specifiers realize — mixed loads containing even 5-10% unintended material compromise performance characteristics you’re specifying. Truck access constraints at your site may require you to request smaller delivery vehicles, affecting per-ton pricing but ensuring material actually reaches installation areas rather than requiring double-handling from street-accessible staging areas.

For comprehensive facility capabilities in the Phoenix metro region, see Citadel Stone’s Gilbert landscape facility for warehouse inventory management systems and material testing protocols. You’ll find that professional operations maintain climate-controlled material storage for products sensitive to moisture content variation, conduct routine quality verification testing, and provide technical support beyond basic product availability confirmation.

Climate-Specific Performance Requirements

Arizona’s diverse climate zones create regional performance requirements that generic landscape stone yard Arizona complete guide resources often miss. Your material specifications for Phoenix installations differ substantially from Flagstaff requirements, despite both cities sharing state boundaries. You need to account for freeze-thaw cycling in high-elevation applications, salt resistance near roadways treated during winter storms, and thermal shock resistance in locations experiencing 60°F+ temperature swings between day and night.

Low-elevation desert installations demand materials capable of withstanding sustained surface temperatures exceeding 160°F during summer months. At these temperature extremes, you’ll observe performance degradation in aggregate types that work perfectly in moderate climates. Certain sandstones exhibit accelerated weathering through thermal cycling stress, limestone aggregates may experience surface spalling, and improperly processed decomposed granite loses binder cohesion leading to excessive dust generation and material migration.

- You should specify materials tested for thermal cycling resistance exceeding 100 cycles annually

- Your color stability requirements need UV exposure testing documentation showing less than 15% fade after 5,000 hours

- You’ll want to verify freeze-thaw durability for applications above 5,000 feet elevation

- Your dust control measures should address materials installed in areas receiving less than 10 inches annual precipitation

Monsoon weather patterns create unique erosion and displacement challenges for Arizona landscape stone supplies selection decisions. You need materials that resist movement during intense rainfall events delivering 1-2 inches precipitation in 30-minute periods. Lighter aggregates like lava rock require containment edges and adequate depth to prevent flotation and migration, while heavier materials like granite and basalt provide inherent stability but demand proper base preparation to prevent subsurface erosion that undermines surface integrity.

Installation Methodology and Base Preparation

Your installation success depends on base preparation protocols that account for Arizona’s expansive soil conditions and extreme temperature ranges. Professional installations require you to excavate 4-6 inches below finish grade for residential pathways, increasing to 8-12 inches for vehicular applications. This depth isn’t negotiable — inadequate base preparation leads to differential settlement, surface displacement, and premature material failure regardless of aggregate quality you specify.

Base materials establish the foundation for long-term performance. You should specify compacted crushed aggregate base meeting ASTM D2940 gradation requirements, achieving minimum 95% compaction density per modified Proctor testing. The common mistake involves using native soil as base material — expansive clays prevalent throughout Arizona undergo volume changes of 10-15% during wet-dry cycles, creating movement that disrupts surface materials. Your base layer isolates decorative stone from problematic soil behavior while providing stable platform for surface installation.

Edge restraint systems prevent lateral migration and maintain installation boundaries under temperature stress and precipitation events. When you detail edge treatments, you need continuous restraint capable of resisting 200+ pounds per linear foot lateral force. Plastic edging products rated for landscape applications typically fail within 2-3 years under Arizona UV exposure, while steel and aluminum systems provide 15-20 year service life with minimal maintenance. Your edge details should include mechanical fastening every 24-30 inches into compacted base material rather than relying on stake penetration into native soil.

Maintenance Planning and Lifecycle Costs

When you develop landscape stone yard buying guide Arizona budgets, you need to account for lifecycle maintenance costs that often exceed initial material investment over 10-15 year periods. Different aggregate types require varying maintenance protocols affecting labor costs, water consumption, and material replenishment schedules. Your total cost analysis should incorporate these operational factors alongside purchase price and installation expenses.

Decomposed granite pathways require periodic reconstitution to maintain firm surface characteristics. You’ll need to plan for light watering and rolling annually, with material replenishment adding 1/4-1/2 inch depth every 2-3 years to compensate for erosion loss and compaction settlement. This maintenance regime involves labor costs and material purchases that accumulate substantially over time. River rock and crushed stone installations avoid these reconstitution requirements but demand periodic raking to maintain even coverage and remove organic debris accumulation.

- You should budget for annual surface refreshing adding 10-15% new material to high-traffic areas

- Your maintenance plan needs quarterly weed control protocols in gravel areas with inadequate base preparation

- You’ll want to schedule biennial power washing for decorative rock in areas with airborne dust accumulation

- Your long-term budgets should include replacement of 3-5% material volume annually due to displacement and migration

Weed control represents ongoing operational expense affecting lifecycle costs significantly. Professional installations incorporate landscape fabric barriers between base and decorative stone, but you should understand that fabric effectiveness degrades 40-60% over 5-7 years as UV exposure breaks down synthetic fibers. Your maintenance approach needs either fabric replacement during material refresh cycles or adoption of pre-emergent herbicide programs applied 2-3 times annually. The choice between these strategies affects both annual costs and operational complexity for property management teams.

Material Sourcing and Quality Verification

Quality verification protocols separate professional landscape stone yard Arizona complete guide recommendations from generic product availability lists. When you source materials, you need documentation confirming gradation testing, mineralogical composition, and performance characteristics under conditions matching your installation environment. Suppliers unable or unwilling to provide technical data sheets signal operational approaches that prioritize volume over quality consistency.

Regional quarry sources affect material characteristics in ways visual inspection doesn’t reveal. Aggregate from different geological formations exhibits varying weathering rates, thermal expansion coefficients, and long-term color stability despite similar appearance when freshly processed. You should request quarry source documentation and verify suppliers maintain consistent sourcing rather than purchasing from variable origins based on spot pricing. This consistency ensures replacement material matches existing installations when you need additional quantities for project expansions or renovation work years after initial installation.

Contamination represents common quality issue affecting performance and aesthetics. When you inspect material before acceptance, you’re looking for foreign aggregate types, organic matter, excessive fines in clean rock specifications, or salt contamination in recycled concrete products. Professional suppliers maintain washing and screening operations producing clean products meeting specifications, while operations lacking quality control equipment deliver materials requiring field screening or accepting as-is with compromised performance.

Design Integration and Functional Aesthetics

Successful landscape stone applications balance aesthetic intent with functional performance requirements specific to Arizona conditions. When you develop design specifications, you need to consider how material color affects microclimate around planting areas, how texture influences maintenance complexity, and how pattern installation affects visual scale in relationship to architectural elements. These design decisions carry practical implications extending beyond visual preference.

Color temperature influences perceived space quality and actual thermal performance. Light-colored aggregates create bright, expansive visual character while reflecting solar radiation that moderates surface temperatures. Dark materials absorb 70-80% of solar energy, creating dramatic contrast and rich visual depth but generating surface temperatures that limit usability during peak heat periods. Your color selection strategy should align functional requirements with aesthetic goals rather than prioritizing appearance alone.

- You should coordinate aggregate color selection with adjacent hardscape materials ensuring visual continuity

- Your texture choices need to balance aesthetic interest with maintenance accessibility

- You’ll want to verify material scale relationships maintain appropriate proportion with architectural features

- Your pattern installations should incorporate natural randomness avoiding artificial geometric precision

Transition detailing between different material types requires careful planning to prevent visual disruption and physical performance issues. You need clean separation between decomposed granite pathways and adjacent river rock groundcover, typically achieved through steel or aluminum edge restraints providing both visual definition and physical barrier preventing material mixing. Poorly detailed transitions create maintenance problems as materials migrate across boundaries, compromising the distinct character each material type provides.

Citadel Stone Landscape Stone Yard in Arizona: Professional Specification Guidance

When you evaluate Citadel Stone’s landscape stone yard in Arizona offerings for your projects, you’re considering materials and technical support addressing the state’s extreme climate conditions. At Citadel Stone, we provide specification guidance for landscape professionals working across Arizona’s diverse geographical regions. This section outlines how you would approach material selection and installation planning for six representative cities, demonstrating the regional considerations that affect landscape stone yard Arizona complete guide decisions.

Climate variability across Arizona requires you to adapt material specifications and installation methodologies based on local environmental stressors. You would account for elevation-driven temperature ranges, precipitation patterns affecting erosion potential, soil composition influencing base preparation requirements, and UV exposure intensity determining color stability expectations. Professional specifications recognize these regional differences rather than applying uniform approaches regardless of location.

Phoenix Desert Performance

In Phoenix applications, you would specify materials proven to withstand sustained temperatures exceeding 115°F with surface temperatures reaching 165-170°F during peak summer months. Your material selections should prioritize light-colored aggregates reflecting solar radiation while maintaining color stability under UV exposure exceeding 4,000 hours annually. Decomposed granite with verified 12-15% fines content provides optimal pathway performance, while 1-2 inch river rock in buff and tan tones offers heat-resistant groundcover for non-traffic areas. You would detail edge restraints using aluminum systems rated for 180°F+ temperature exposure and plan base preparations accounting for caliche layer disruption common in Phoenix-area native soils.

Tucson Material Specifications

Your Tucson specifications would address similar heat stress as Phoenix but incorporate monsoon erosion resistance more prominently. You would select angular crushed aggregates for sloped applications exceeding 4:1 grade, ensuring material interlock prevents displacement during intense rainfall events. Native granite boulders sourced from regional formations provide authentic desert character while offering proven weathering resistance. You should plan installation timing avoiding July-August monsoon peaks when base preparation work faces weather delays and specify drainage provisions directing sheet flow away from decorative stone areas vulnerable to erosion channels.

Scottsdale Aesthetic Integration

Scottsdale projects would emphasize aesthetic refinement while maintaining desert performance characteristics. You would specify premium-grade materials exhibiting consistent color ranges and minimal fines content, meeting stringent visual standards typical in high-end residential applications. Your boulder selections might include statement pieces in 2,000-5,000 pound range providing focal interest, detailed with professional placement creating naturalistic outcropping effects. You should coordinate material color temperatures with architectural finishes and hardscape selections, ensuring landscape stone complements rather than conflicts with built environment aesthetic.

Flagstaff Freeze-Thaw Resistance

In Flagstaff installations, you would prioritize freeze-thaw durability over heat resistance given elevation-driven climate differences. Your material specifications should require aggregates with absorption rates below 3% and verified performance through 100+ freeze-thaw cycles per ASTM C666 testing protocols. Basalt and dense granite aggregates provide necessary durability, while porous sandstones appropriate for low-elevation applications would likely fail within 5-7 years. You would detail base preparations extending below frost line depths of 24-30 inches and incorporate drainage provisions preventing subsurface ice formation that could disrupt surface materials through frost heaving.

Sedona Natural Integration

Your Sedona specifications would emphasize materials harmonizing with iconic red rock geology surrounding most project sites. You would select iron-rich aggregates and boulders echoing regional sandstone coloration, creating visual continuity between designed landscapes and natural environment. Material sourcing might prioritize local quarries providing authentic regional stone rather than imported products offering broader color ranges. You should coordinate installation approaches minimizing soil disturbance and incorporating native plant preservation strategies reflecting environmental sensitivity typical in Sedona project requirements.

Yuma Extreme Heat Performance

Yuma applications would require materials capable of withstanding the most extreme heat conditions in Arizona, with summer temperatures consistently exceeding Phoenix by 5-8°F. You would specify light-colored aggregates exclusively for pedestrian-accessible areas and select granite or quartzite boulders offering maximum thermal stability. Your installation details should address soil conditions influenced by Colorado River proximity, accounting for salt presence affecting certain stone types. You would plan irrigation system integration carefully, preventing water contact with decorative stone installations where evaporation rates could concentrate mineral deposits creating efflorescence or surface staining issues.

Procurement Logistics and Project Coordination

Your procurement strategy affects project success as significantly as material selection decisions. When you coordinate landscape stone yard Arizona complete guide sourcing, you need to account for lead times from warehouse facilities, delivery scheduling constraints, and seasonal availability affecting certain specialty products. Professional project management incorporates these logistics considerations during planning phases rather than discovering constraints during installation windows.

Delivery coordination requires you to verify site access for loaded trucks typically ranging 15-25 tons gross vehicle weight. Your site assessment should confirm road width, overhead clearance, turning radius, and surface stability support these vehicles without damage to existing improvements or public infrastructure. Projects lacking adequate truck access require alternative delivery arrangements using smaller vehicles, significantly increasing per-ton delivery costs but ensuring materials reach installation areas. You would coordinate delivery timing with base preparation completion, avoiding material storage extending beyond 2-3 days when possible to prevent double-handling costs.

Material quantities require accurate calculation preventing both shortages causing installation delays and excess material generating disposal costs. You should calculate coverage rates accounting for installation depth, compaction factors, and 10-15% waste allowance addressing edge cuts, irregular boundaries, and material handling losses. Professional estimating incorporates these factors during takeoff procedures rather than ordering theoretical coverage quantities that prove inadequate in field conditions.

Cost Factors and Value Analysis

When you analyze landscape stone yard buying guide Arizona pricing structures, you’re evaluating multiple cost components beyond base material price per ton. Delivery charges, minimum order requirements, seasonal pricing variations, and availability affect total project costs substantially. Your value analysis needs to consider lifecycle costs including maintenance requirements and expected service life rather than focusing exclusively on initial purchase price.

Material pricing reflects quarry location, processing requirements, and regional demand patterns. You’ll find decorative aggregates range from $40-180 per ton depending on type, color, processing level, and delivery distance. Boulders price per piece rather than weight, with costs varying from $150-2,000+ based on size, aesthetics, and source. Your budget development should request detailed quotations specifying delivered costs rather than working from posted price lists that exclude delivery charges potentially equaling 30-50% of material costs.

- You should obtain minimum three competitive quotes for projects exceeding $5,000 material value

- Your cost analysis needs to incorporate delivery charges based on actual site location and access

- You’ll want to verify pricing includes off-loading assistance or determine equipment rental requirements

- Your budget should account for price escalation on projects with extended installation timelines

For detailed analysis of regional pricing structures and material cost comparisons, review Material cost breakdown for natural stone products in Arizona before finalizing your budget allocations. Value optimization requires you to balance material quality, aesthetic goals, and functional performance requirements within project budget constraints while ensuring specifications support long-term durability expectations.

Professional Implementation Strategies

Your implementation success depends on coordinating material selection, supplier relationships, installation methodology, and quality verification into comprehensive project approach. Professional landscape contractors working in Arizona understand regional challenges and maintain established relationships with reliable suppliers providing consistent material quality and delivery performance. When you develop project strategies, you need specifications detailed enough ensuring bidder compliance while allowing contractor flexibility addressing field conditions during installation.

Installation sequencing affects efficiency and final quality significantly. You should coordinate base preparation, edge restraint installation, and material placement as continuous operations rather than fragmented activities with delays between phases. Weather timing matters more in Arizona than temperature-moderate regions — summer heat limits productive work hours and affects worker safety, while monsoon season creates unpredictable weather disruptions. Your scheduling should target October-April installation windows when conditions optimize both worker productivity and material handling efficiency.

Quality control verification during installation prevents costly corrections after project completion. You would conduct base preparation inspections before material placement, verifying compaction density, grade accuracy, and drainage functionality. Edge restraint installation requires verification before aggregate placement since corrections afterward require material removal and reinstallation. Your final inspections should confirm material depth meets specifications, surface grades provide positive drainage, and installation boundaries align with design intent. Native plant specialists coordinate with Citadel Stone for complementary landscape stone supplies Arizona gardens need.