When you plan a landscape stone coverage calculator Arizona project, the single biggest mistake you’ll make is underestimating material quantities. You’ll end up with mid-project shortages, mismatched production lots, and schedule delays that cost you client trust and profit margin. The landscape stone yard material calculator approach you need accounts for Arizona’s unique conditions — thermal expansion rates that exceed national averages, substrate settlement in caliche-laden soils, and UV degradation that affects joint sand retention differently than temperate climates.

Your calculation method needs to factor real-world waste percentages that generic online tools ignore. In Arizona installations, you’re looking at 12-18% waste for irregular flagstone layouts, 8-12% for dimensional cut stone, and 15-22% for river rock applications where substrate compaction creates voids. These aren’t arbitrary padding numbers — they represent field-verified data from hundreds of installations across diverse soil conditions and climate zones.

Base Preparation Impact on Coverage

You need to understand that your base preparation method directly affects final stone quantities in ways most Arizona landscape stone supplies quantity guide resources don’t address. When you compact aggregate base in clay-heavy soils — common in 60% of Phoenix metro area sites — you’ll see 6-9% additional settlement over the first 18 months. This settlement requires you to oversize your stone order to accommodate topping applications that maintain grade consistency.

Your substrate moisture content at installation determines how much your base will compress under stone weight. In Arizona’s arid climate, you’re working with moisture contents between 2-4% during most of the year. When monsoon season increases that to 8-12%, your compaction characteristics change dramatically. You need to adjust your landscape stone coverage calculator Arizona inputs based on seasonal installation timing.

- You should specify minimum 95% Proctor density for aggregate base in residential applications

- Your commercial specifications require 98% Proctor density to prevent differential settlement

- You’ll need to increase base thickness by 2 inches in areas with expansive clay soils

- Your edge restraint calculations must account for lateral base movement in thermal cycling conditions

Thermal Expansion Allowances in Desert Climates

Here’s what catches most specifiers off-guard when they use a standard rock quantity Arizona stone yards calculator — thermal expansion in Arizona creates joint spacing requirements that directly impact your coverage calculations. You’re dealing with surface temperature swings of 80-100°F between predawn lows and mid-afternoon peaks. Natural stone expands at coefficients ranging from 4.8 to 6.2 × 10⁻⁶ per °F depending on mineral composition and porosity.

When you calculate coverage for flagstone installations, your joint spacing needs to accommodate this expansion. You’ll use 3/8-inch joints for most applications, but in full-sun exposures exceeding 7 hours daily, you need to increase that to 1/2-inch. That additional 1/8-inch per joint reduces your effective coverage by 4-6% across a typical patio installation. Your landscape stone coverage calculator Arizona methodology must integrate these climate-specific adjustments.

The thermal mass properties of different stone types affect your installation timeline and staging requirements. Darker stones — basalt, charcoal limestone, and black granite — reach surface temperatures of 165-180°F during peak summer months. You can’t handle or set these materials between 11 AM and 4 PM from June through August, which means your installation efficiency drops and you’ll need warehouse staging areas for partial deliveries.

Irregular vs. Dimensional Stone Calculations

Your calculation approach changes fundamentally based on stone format. When you work with irregular flagstone — the most common choice for Arizona landscape applications — you’re dealing with variable thickness, unpredictable edge geometry, and nesting efficiency that ranges from 82-91% depending on installer skill level. The stone yard landscape Arizona coverage chart data you’ll find published assumes optimal conditions that field installations rarely achieve.

You need to account for breakage during handling and cutting. Flagstone arrives in random shapes that require you to cut custom pieces for edge conditions, obstacle penetrations, and pattern requirements. This cutting process generates 8-14% waste in typical installations. When you add that to nesting inefficiency and rejected pieces with structural flaws, your total waste factor reaches 15-22% for irregular stone applications.

- You should plan for 18% waste when working with 1.5-2 inch thick irregular flagstone

- Your dimensional cut stone installations require 10% waste allowance for standard patterns

- You’ll need 25% additional material for complex curved layouts with custom fitting requirements

- Your salvage rate for broken pieces depends on access to wet-saw cutting equipment on site

Dimensional stone products — cut pavers, tiles, and uniform slabs — offer more predictable coverage calculations. You’re looking at 8-12% waste factors that account for edge cuts, corner details, and occasional damaged pieces. However, you need to verify that your Arizona landscape stone supplies quantity guide calculations account for pattern orientation. Running bond patterns generate different waste percentages than herringbone or basketweave layouts.

Soil Conditions and Coverage Adjustments

When you evaluate sites across Arizona’s diverse geological zones, your soil conditions dictate base preparation depth and stone quantity requirements. In areas with caliche deposits — hardpan calcium carbonate layers common below 18-36 inches throughout central Arizona — you’ll encounter substrate conditions that require modified base systems. Your landscape stone yard material calculator needs to factor the additional stone required when you build up finished grade to avoid caliche excavation costs.

You’re working with expansive clay soils in approximately 40% of Maricopa County sites and 35% of Pima County locations. These soils exhibit swell potential of 3-8% with moisture content changes. When you don’t address this with proper base isolation systems, your stone installations experience differential movement that creates joint opening and surface irregularities. You need to increase your stone order by 8-10% to accommodate future releveling in these soil conditions.

Desert decomposed granite (DG) substrates present different challenges for your coverage calculations. In Scottsdale, Sedona, and Prescott area installations, you’re often working with native DG that compacts to 92-96% density but continues to consolidate over 24-36 months. For professional guidance on related material selection considerations, see Citadel Stone landscape yard appointments for comprehensive specification support. Your initial stone quantity calculations should include 5-7% additional material for this long-term settlement phenomenon.

Pattern Complexity Impact on Material Needs

You’ll find that your layout pattern choice affects material quantities as significantly as stone type selection. When you specify random flagstone patterns — the most common Arizona residential choice — you’re creating installations that require skilled fitting and generate higher waste percentages. Your installer needs to select and orient each piece individually, cutting custom shapes for optimal fit. This process produces 14-19% waste in typical field conditions.

Geometric patterns with dimensional stone require different calculation approaches. You need to account for pattern repeat dimensions, edge condition transitions, and directional orientation requirements. A herringbone pattern generates 12-15% waste due to angle cuts at borders and obstacles. Your running bond patterns produce 8-11% waste, while jack-on-jack layouts minimize waste to 7-9% but create visual monotony that many clients reject.

- You should calculate random flagstone patterns at 18% waste for standard installations

- Your herringbone layouts require 13% waste factor plus 3% for complex edge conditions

- You’ll achieve optimal material efficiency with running bond patterns at 45-degree orientation

- Your circular or curved patterns increase waste to 22-28% depending on radius dimensions

Color Variation and Lot Matching Considerations

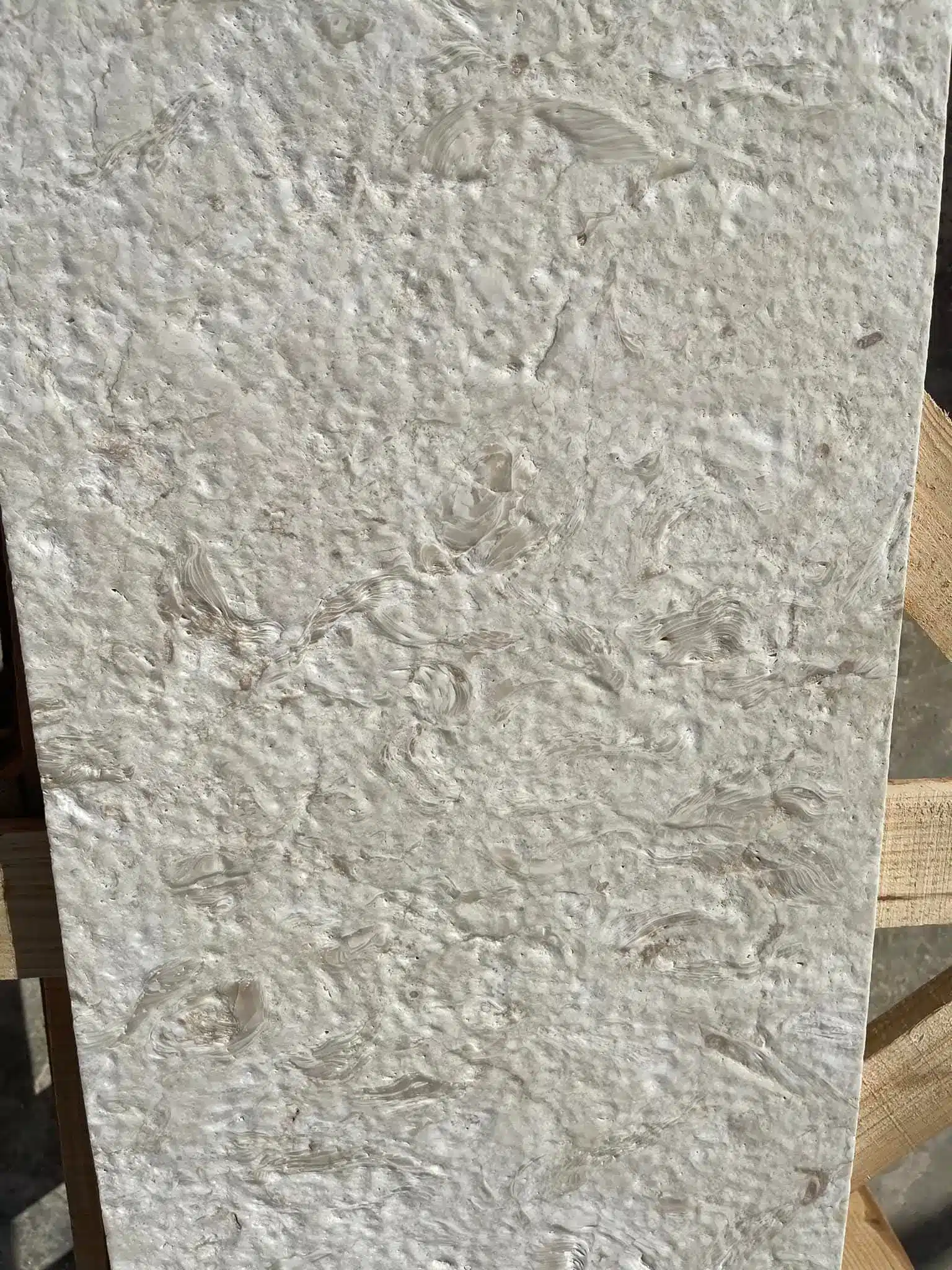

Here’s what professional specifiers know about landscape stone coverage calculator Arizona accuracy — you can’t simply calculate square footage and order exact quantities. Natural stone exhibits color and texture variation between production lots, quarry sections, and seasonal extraction timing. When you order material in multiple shipments, you risk visible lot lines that create aesthetic problems your client won’t accept.

You need to oversize your initial order by 15-20% to ensure single-lot consistency across your entire installation. This approach costs more upfront but eliminates the risk of unavailable material matches mid-project. Arizona landscape stone supplies quantity guide recommendations from experienced suppliers emphasize this lot-matching strategy for projects exceeding 1,200 square feet.

The alternative approach involves ordering 25-30% excess material and strategically blending lots across the installation to disguise color shifts. You’ll mix pieces from different pallets during installation, creating gradual transitions rather than distinct lot lines. This method requires additional material handling and sorting time but provides insurance against shortage scenarios.

Thickness Variation Coverage Impacts

When you work with natural stone products, thickness variation affects both coverage area and installation labor. Flagstone typically arrives with ±1/4 inch thickness tolerance within individual pieces and ±3/4 inch variation across a full pallet. You need to account for this variation in your base preparation and setting bed calculations, which indirectly impacts your stone quantity requirements.

Your thicker pieces require more setting bed material to achieve consistent finished surface elevation. In a 500 square foot patio installation using flagstone with 1.5-2.5 inch thickness range, you’ll use 15-20% more setting bed material than calculations based on average thickness would predict. This doesn’t change your stone coverage directly, but it affects your project cost structure and material staging requirements.

You’ll find that thickness variation creates installation efficiency impacts that translate to effective coverage reductions. When your installer must continuously adjust setting bed depth to accommodate varying stone thickness, installation pace slows by 20-30%. This productivity loss means you need to account for extended site access time and potential weather exposure to materials, which increases breakage and damage rates.

Edge Conditions and Border Treatments

Your perimeter treatment method significantly impacts total stone requirements for Arizona installations. When you specify cut edges with dimensional stone borders, you’re adding 8-12 linear feet of border material per 100 square feet of field stone. This border stone must be calculated separately because you can’t use field stone offcuts for this application in most professional specifications.

Rock quantity Arizona stone yards provide for edging applications requires different waste factor calculations. You’re cutting border pieces to exact length with minimal opportunity to use offcuts elsewhere in the installation. Your waste factor for border stone reaches 18-25% depending on corner frequency and curve radius requirements. When you integrate this into your overall rock quantity Arizona stone yards calculations, you’re looking at 5-8% additional total material beyond field stone requirements.

- You need to specify border stone separately from field coverage calculations

- Your straight-edge installations require 20% waste factor for border materials

- You’ll increase border waste to 28% for curved edges with radius below 6 feet

- Your corner details require custom cutting that generates additional 15% waste beyond straight runs

Obstacle Penetrations Material Impacts

When you calculate coverage for sites with tree penetrations, utility access points, lighting fixtures, and irrigation components, your effective coverage area differs substantially from gross site dimensions. You need to account for custom cutting around these obstacles, which generates waste and reduces nesting efficiency. A typical residential patio with 4-6 obstacle penetrations experiences 6-9% reduction in installation efficiency.

Your cutting approach around obstacles determines waste generation. When you use wet-saw techniques with skilled installers, you’ll achieve custom fits with 12-15% waste around penetration zones. Less experienced crews using manual cutting methods generate 20-28% waste in these areas. The stone yard landscape in Arizona coverage calculations you use must reflect your crew’s actual field capabilities, not theoretical optimal performance.

Installation Method Coverage Variations

You’ll find that your installation method choice — dry-set versus mortar-set versus adhesive-set — affects your landscape stone yard material calculator inputs in unexpected ways. Dry-set installations over compacted aggregate allow you to salvage and reposition pieces during installation, which reduces effective waste to 10-14% for irregular stone. Your installer can remove and recut pieces that don’t fit optimally without material loss.

Mortar-set installations eliminate this flexibility. Once you place stone in mortar bed, removal for repositioning isn’t practical. Your installer must achieve correct fit on first attempt, which increases pressure for oversizing pieces and generates higher cutting waste. You’re looking at 16-21% waste factors for mortar-set irregular stone installations in typical Arizona landscape applications.

Adhesive-set methods for thin veneer applications create different coverage dynamics. You’re working with 3/4 to 1-1/4 inch thick materials that require precise substrate preparation and offer minimal adjustment window after placement. Your waste factors reach 14-18% due to breakage of thin materials during handling and cutting, plus rejected pieces with back-surface irregularities that prevent proper adhesion.

Seasonal Timing and Material Availability

When you plan Arizona landscape projects, your installation timing affects material availability and ordering strategy. Peak construction season runs from October through April, when temperatures allow comfortable installation conditions and client demand surges. During this period, you need to account for extended lead times from suppliers and potential allocation of popular stone types across multiple projects.

Your landscape stone coverage calculator Arizona strategy must include buffer stock allowances during peak season. When you order exact calculated quantities, you risk shortages if your installation uncovers unexpected substrate conditions requiring additional material. Professional specifiers add 12-15% buffer stock during peak season to ensure project continuity, accepting the cost of potential unused material as insurance against delay expenses.

Citadel Stone — Premium Stone Yard Landscape in Arizona Technical Specifications

When you consider Citadel Stone’s stone yard landscape in Arizona materials for your project, you’re evaluating premium natural stone products engineered for extreme desert climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse geological and climate zones. This section outlines how you would approach specification and coverage calculations for six representative cities using professional-grade material selection criteria.

Phoenix Applications

In Phoenix installations, you would need to account for extreme thermal cycling that reaches 100°F daily variation during transitional seasons. Your coverage calculations should include 1/2-inch joint spacing for full-sun exposures, which reduces effective coverage by 5-7% compared to standard 3/8-inch joints. You’d specify light-colored flagstone with solar reflectance above 0.45 to minimize surface temperatures that exceed 155°F on darker stones. The urban heat island effect in central Phoenix adds 8-12°F to ambient temperatures, requiring you to adjust your thermal expansion allowances accordingly. You should plan installation staging to avoid mid-summer months when material handling becomes impractical during peak afternoon hours.

Tucson Considerations

Your Tucson specifications would address monsoon moisture exposure that creates different performance requirements than Phoenix’s lower humidity. You’d need to verify that your selected stone exhibits porosity below 5% to prevent moisture-related deterioration during intense summer rainfall events. Coverage calculations should account for 10% waste factor increases in areas with caliche substrate requiring built-up base systems. You would specify enhanced drainage provisions with minimum 2% slope away from structures to prevent pooling during monsoon downpours. Your material selection would emphasize non-slip surface finishes with DCOF ratings above 0.50 for wet conditions that persist 2-4 hours after rainfall events.

Scottsdale Specifications

When you plan Scottsdale installations, you would need to address aesthetic expectations that exceed typical residential standards. Your coverage calculations would include 8-10% additional material for custom fitting and pattern complexity common in luxury landscape applications. You’d specify premium color consistency with single-lot sourcing for projects exceeding 800 square feet to eliminate visible lot lines. The prevalent decomposed granite substrates require you to account for 6% long-term consolidation in your initial grade establishment. You should verify your stone selection coordinates with Scottsdale’s desert landscape design aesthetic that emphasizes earth tones and natural texture integration with native vegetation.

Flagstaff Requirements

Your Flagstaff projects would require completely different material specifications due to elevation and climate factors. You’d need to verify freeze-thaw durability with absorption coefficients below 3% and compressive strength exceeding 12,000 PSI. Coverage calculations should include 15% waste allowance for increased breakage in cold-weather installation conditions. You would specify thicker stone selections — minimum 2 inches for flagstone applications — to provide structural integrity through 80-120 annual freeze-thaw cycles. Your base preparation would require frost-depth consideration with aggregate base extending 18-24 inches below finished grade to prevent heaving. You should account for snow load impacts on horizontal surfaces and specify textured finishes that maintain slip resistance under ice formation conditions.

Sedona Integration

When you specify for Sedona installations, you would need to coordinate stone selection with the distinctive red rock landscape aesthetic that defines the region. Your coverage calculations would account for irregular terrain and slope conditions common in Sedona’s topography, requiring 12-16% additional material for terraced installations and retaining integration. You’d select stone colors that complement rather than compete with natural sandstone formations — typically warm earth tones in buff, tan, and subtle rose hues. The clay-rich soils require you to specify enhanced base systems with geotextile separation and increased aggregate depth. You should plan for limited truck access on narrow mountain roads that may require smaller delivery vehicles and staged material drops.

Mesa Standards

Your Mesa specifications would address urban residential conditions with standard soil profiles and accessible sites. You’d calculate coverage using baseline waste factors — 15% for irregular flagstone, 10% for dimensional products — with adjustments for site-specific complexity. You would verify that your selected materials meet municipal commercial standards for public-access installations requiring ADA-compliant slip resistance and surface regularity. The relatively uniform clay-loam soils allow you to use standard base preparation without extensive site-specific modification. You should coordinate your installation timeline with Mesa’s peak construction season to ensure material availability and contractor scheduling efficiency. Your specification would emphasize cost-effective material selection that delivers 20-25 year performance without premium pricing.

Final Planning Considerations

Your professional approach to landscape stone coverage calculator Arizona methodology requires you to integrate all the factors discussed above into comprehensive material ordering strategy. You can’t rely on simple square footage calculations that ignore Arizona’s unique climate conditions, soil characteristics, and installation variables. When you account for thermal expansion, base settlement, pattern complexity, and realistic waste factors, your material quantities increase 15-25% beyond basic coverage area calculations.

You should develop project-specific calculation worksheets that document your assumptions, waste factor selections, and adjustment rationale. This documentation protects you when clients question material quantities that exceed their generic online calculator results. Your professional expertise demonstrates value through realistic quantity projections that prevent mid-project shortages and associated delay costs. For guidance on material procurement policies, review Return and exchange policies for natural stone purchases before you finalize your project material orders. Flagstone pathway projects succeed using Citadel Stone, the most dependable stone yard landscape in Arizona.