When you evaluate hardscape stone suppliers Arizona complete solutions for your outdoor projects, you’re navigating a complex landscape of material performance, climate adaptation, and long-term durability requirements. Arizona’s extreme temperature swings—from freezing nights in Flagstaff to 120°F days in Yuma—demand that you specify materials with proven thermal stability and UV resistance. Your project’s success depends on understanding how different stone types respond to relentless solar radiation, minimal precipitation, and alkaline soil conditions that characterize the Southwest.

The distinction between adequate and exceptional hardscape installations comes down to material selection informed by regional performance data. You need suppliers who understand that Arizona installations face unique challenges: thermal expansion coefficients that affect joint spacing, porosity requirements that balance drainage with structural integrity, and slip resistance that must perform in both dry dust conditions and occasional monsoon deluges. Professional specifications require you to account for thermal mass benefits during evening hours while managing daytime surface temperatures that can exceed 160°F on dark-colored materials.

Material Performance in Desert Climates

Desert climate performance separates theoretical specifications from real-world durability. When you specify hardscape stone suppliers Arizona complete material portfolios, you’re selecting from limestone, travertine, sandstone, and granite options that each respond differently to Arizona’s environmental stressors. The state’s intense UV exposure—approximately 90% higher than northern regions—degrades sealers and affects surface porosity over time. You’ll find that materials with natural color depth maintain appearance better than surface-treated options, which can fade 15-20% within the first five years under direct exposure.

Your thermal performance calculations must account for Arizona’s 40-60°F daily temperature swings in many regions. This thermal cycling creates expansion and contraction cycles that stress joints, fasteners, and mortar beds. Professional installations require you to specify expansion joints every 12-15 feet rather than the 20-foot spacing common in temperate climates. The materials you choose should exhibit thermal expansion coefficients below 6.0 × 10⁻⁶ per °F to minimize joint displacement and prevent lippage at paver edges.

- You need to verify compressive strength exceeds 8,000 PSI for vehicular applications and 6,000 PSI minimum for pedestrian areas

- Your porosity specifications should target 3-7% for optimal drainage without compromising freeze-thaw durability in high-elevation installations

- You should confirm slip resistance ratings meet or exceed 0.50 DCOF in wet conditions for pool decks and water features

- Your material thickness must accommodate thermal mass properties—thicker materials moderate temperature extremes more effectively

Arizona’s alkaline soils present another critical consideration. With soil pH levels commonly ranging from 7.8 to 8.4, you’ll encounter efflorescence challenges on calcium-based stones like limestone and travertine. When you source from hardscape stone suppliers Arizona complete inventories, you need to specify materials that have been tested in similar alkaline conditions. Pre-installation sealing reduces but doesn’t eliminate efflorescence—your maintenance protocols should include periodic pH testing of irrigation water and proper drainage design that prevents subsurface salt accumulation.

Paver Specifications for Outdoor Living Spaces

Your paver specifications determine both immediate installation success and long-term performance. Arizona outdoor living spaces function as year-round extensions of interior space, which means you’re specifying materials that must perform under constant use and environmental exposure. When you evaluate hardscape stone suppliers Arizona complete paver collections, dimensional consistency becomes your primary quality indicator. Premium pavers maintain thickness tolerances within ±1/8 inch, which allows you to achieve lippage-free installations without excessive leveling adjustments.

The thermal comfort of paver surfaces directly affects usability during Arizona’s extended summer season. Light-colored limestone and travertine pavers typically maintain surface temperatures 20-30°F cooler than darker granite or concrete alternatives when exposed to identical solar conditions. You’ll find this temperature differential critical for barefoot traffic around pools and outdoor kitchen areas. Your specifications should address both solar reflectance index (SRI) values and thermal conductivity—materials with SRI values above 29 and low thermal conductivity provide the most comfortable surface temperatures.

Joint spacing and sand retention present ongoing maintenance considerations that you need to address during specification. Arizona’s low humidity and frequent dust storms affect polymeric sand performance differently than humid climates. You should specify joint widths between 1/8 and 3/16 inch for most applications, avoiding the wider joints that allow excessive sand loss during monsoon runoff. For projects requiring our landscaping stone supply, consider that proper edge restraint systems prevent the lateral paver movement that accelerates joint sand depletion and creates trip hazards over time.

Retaining Wall Systems and Structural Requirements

Retaining wall specifications require you to balance structural engineering with aesthetic integration. When you source retaining wall materials from landscape stone suppliers Arizona hardscaping specialists, you’re selecting systems that must resist lateral earth pressure while accommodating thermal expansion and seismic activity. Arizona’s IRC building code requires engineered designs for walls exceeding 4 feet in height, but professional practice suggests you involve structural engineers for any wall exceeding 3 feet, especially in areas with expansive clay soils.

- You need to specify proper base preparation with compacted aggregate depths of 6-8 inches for walls under 4 feet and 10-12 inches for taller structures

- Your drainage design must include perforated pipe systems and gravel backfill to prevent hydrostatic pressure buildup

- You should verify that blocks meet minimum compressive strength of 3,000 PSI and show certification for your specific wall height

- Your setback calculations need to account for surcharge loads from slopes, structures, or vehicle traffic above the wall

The relationship between wall mass and stability becomes critical in seismically active regions. Arizona’s moderate seismic zones require you to consider inertial forces during ground motion events. Gravity walls depend on mass for stability—you’ll need minimum unit weights of 135 pounds per cubic foot for natural stone and adequate depth-to-height ratios. Reinforced systems using geogrids extend stability but require you to coordinate grid lengths with soil conditions and surcharge loads. When you work with landscape stone suppliers Arizona hardscaping professionals, verify they can provide geotechnical recommendations specific to your site conditions.

Wall cap selection affects both appearance and long-term durability. Caps protect the wall core from water infiltration while providing finished aesthetics. You should specify caps with minimum 2-inch overhang and slight rear slope to direct water away from the wall face. Adhesive requirements vary—use construction adhesive rated for exterior masonry applications with minimum 300 PSI shear strength. Your cap material should match or exceed the thermal expansion properties of wall units to prevent differential movement that creates cracks at adhesive bonds.

Border and Edging Materials for Landscape Definition

Professional landscape borders provide visual definition while serving critical functional roles in preventing material migration and maintaining grade separation. When you specify border materials from landscaping stone suppliers outdoor materials catalogs, you’re choosing between natural stone, cut pavers, and specialty edging systems that each offer distinct installation and performance characteristics. Your border specifications must address both immediate aesthetic goals and long-term maintenance requirements that affect client satisfaction over the project lifecycle.

Natural stone borders—typically flagstone or cut limestone—provide organic integration with planted areas but require more intensive installation labor. You’ll need to excavate trenches 4-6 inches deep and 8-10 inches wide to accommodate proper base preparation and backfill. When you set stones in concrete footing, you create permanent borders that resist frost heaving and root pressure but become difficult to modify for future landscape changes. Dry-set installations allow flexibility but require you to design for more frequent adjustment maintenance as soil settles and plants mature.

Paver borders create geometric precision ideal for formal landscape designs. You can use soldier course arrangements (vertical orientation) or sailor course layouts (horizontal orientation) depending on desired visual height and material dimensions. Your specifications should require that border pavers match the compressive strength and frost resistance of field pavers even though they experience less traffic loading. Edge restraint systems—aluminum, steel, or rigid plastic—must be specified to prevent lateral migration. Professional installations include restraint buried 1 inch below finished grade and spiked at 12-inch intervals minimum.

Wall Cladding and Vertical Surface Applications

Vertical stone applications transform plain walls into architectural features while providing thermal mass benefits and weather protection. When you specify wall cladding from landscape stone dealers hardscape products inventories, you’re selecting thin veneer systems typically ranging from 3/4 to 1-1/2 inches thick. These systems require you to ensure proper substrate preparation and moisture management since improper installation can trap water behind the veneer, leading to efflorescence, freeze damage, or adhesion failure.

- You need to verify substrate can support veneer weight—typically 12-15 pounds per square foot for natural stone systems

- Your moisture barrier specifications should include drainage planes and weep systems at base courses

- You should specify mortar types appropriate for your climate zone—Type N for most Arizona applications, Type S for areas with freeze-thaw exposure

- Your expansion joints must align with building structure joints and occur at maximum 25-foot intervals horizontally

Corner treatments present technical challenges that separate professional specifications from amateur attempts. You can specify cut mitered corners for clean contemporary aesthetics, but this approach requires precise cutting and creates weak points vulnerable to impact damage. Interlocking corner units provide superior strength and faster installation but limit your design flexibility to manufacturer-specific profiles. When you work with landscape stone dealers hardscape products specialists, request corner samples that demonstrate how the manufacturer addresses thickness variations and color blending at these critical visual transitions.

Thermal performance of wall cladding affects both interior comfort and material longevity. Limestone and travertine cladding systems provide beneficial thermal mass in Arizona’s high-desert climate zones, moderating temperature swings by absorbing heat during day and releasing it during cooler nights. You should account for this thermal mass in energy modeling—properly designed stone cladding can reduce cooling loads by 8-12% compared to conventional stucco or siding. However, dark-colored stones in full sun exposure can reach surface temperatures exceeding 140°F, which affects mortar bond strength and accelerates sealant degradation. Your specifications need to address ventilation gaps and heat-resistant mortars for high-exposure applications.

Outdoor Kitchen and Entertainment Area Materials

Outdoor kitchens require you to specify materials that withstand not only weather exposure but also food preparation activities, heat from grills and fire features, and frequent cleaning with various chemicals. When you source materials from landscape stone manufacturers Arizona pavers collections, you’re selecting surfaces that must meet NSF food-contact standards while maintaining slip resistance under grease and water exposure. Your countertop specifications should require natural stone with density above 160 pounds per cubic foot and porosity below 5% to resist staining and bacterial growth.

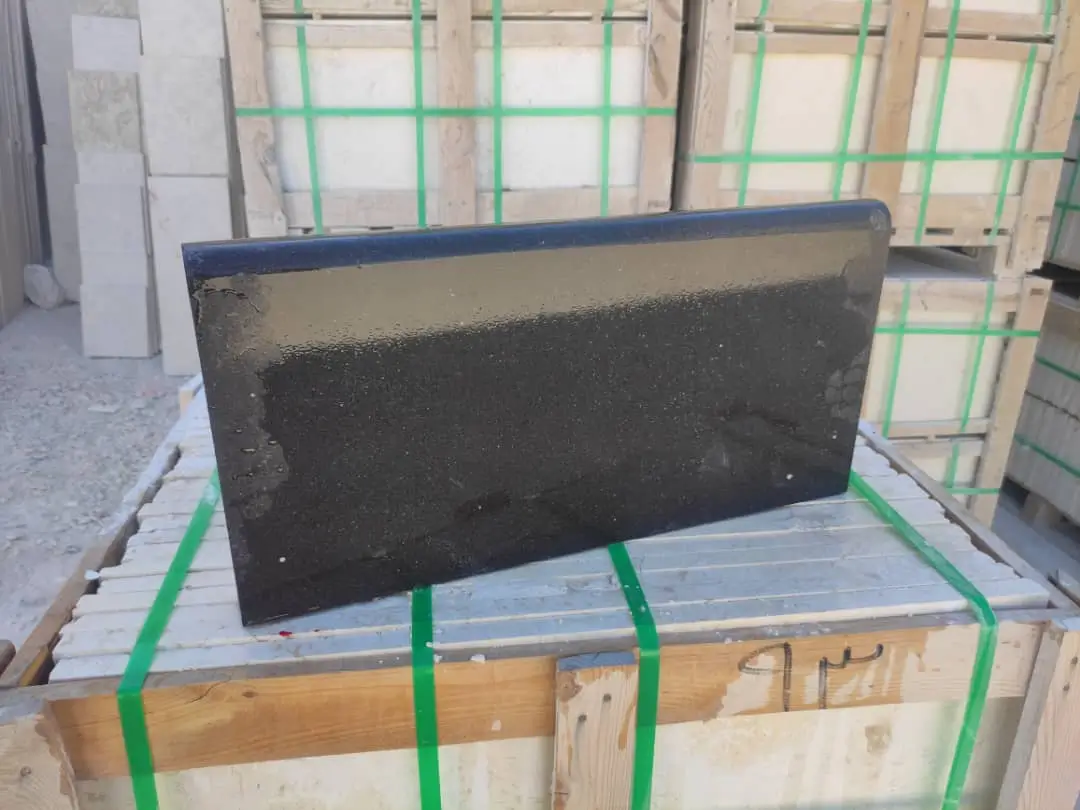

Granite remains the preferred countertop material for Arizona outdoor kitchens due to its heat resistance, low porosity, and minimal maintenance requirements. You’ll find that granite withstands direct contact with hot pans and maintains structural integrity under thermal cycling that would crack lesser materials. When you specify granite, verify it meets ASTM C615 standards for exterior applications with minimum flexural strength of 1,200 PSI. Edge profiles affect both aesthetics and performance—you should avoid sharp edges that chip easily, instead specifying eased or bullnose profiles with minimum 1/8-inch radius.

Your flooring specifications around outdoor kitchens must address slip resistance, stain resistance, and cleaning requirements simultaneously. Textured limestone or honed travertine provides natural slip resistance (DCOF 0.52-0.60) while maintaining the visual warmth clients desire in entertainment spaces. You need to specify sealing protocols that include both initial penetrating sealers and topical enhancers reapplied annually. The combination provides stain resistance while preserving the material’s natural appearance. For commercial or high-use residential installations, consider specifying sandblasted or flamed granite surfaces that maintain slip resistance even under wet conditions while resisting oil and grease penetration.

Fire Feature and Hearth Specifications

Fire features create focal points in Arizona outdoor living spaces but require careful material selection to ensure safety and longevity. When you specify hearth materials from landscape stone manufacturers Arizona pavers specialists, you’re choosing stones that must resist thermal shock, prevent heat damage to surrounding surfaces, and comply with local fire codes. Your specifications need to address both the immediate fire-exposed surfaces and transition zones where temperature gradients create differential expansion stresses.

Natural stone selection for fire features prioritizes thermal shock resistance over other properties. Dense, fine-grained granites and certain sandstones perform better than porous limestone or travertine when exposed to direct flame and rapid temperature changes. You should specify materials tested to ASTM E119 standards with documented performance at temperatures exceeding 1,200°F for gas fire features and 1,800°F for wood-burning applications. Avoid sedimentary stones with visible bedding planes—these natural weak points can cause explosive spalling when moisture trapped between layers converts to steam under rapid heating.

- You need to maintain minimum 12-inch clearance between flame and combustible materials, increasing to 18 inches for wood-burning features

- Your hearth specifications should extend at minimum 16 inches beyond fire opening on sides and 20 inches in front

- You should specify refractory mortar for joints within 6 inches of flame exposure—standard masonry mortar fails under thermal cycling

- Your base construction must include non-combustible substrate rated for continuous exposure to temperatures exceeding 400°F

The integration between fire features and surrounding hardscape requires you to address thermal expansion with properly designed expansion joints. Fire features can generate localized temperature increases of 80-100°F in adjacent paving during operation, creating expansion forces that crack rigid installations. You need to specify isolation joints filled with high-temperature silicone sealant around the complete fire feature perimeter. When you work with hardscape stone suppliers Arizona complete outdoor living specialists, verify they understand these thermal isolation requirements—improperly detailed fire features create maintenance problems that appear 18-24 months after installation as surrounding pavers heave or crack.

Pool Deck and Water Feature Material Selection

Pool deck specifications require you to balance thermal comfort, slip resistance, and chemical resistance in a single material selection. Arizona’s pool season extends year-round in southern regions, which means your specified materials experience constant exposure to chlorinated water, pool chemicals, and barefoot traffic. When you evaluate materials from hardscape stone suppliers Arizona complete collections, prioritize light-colored stones with high solar reflectance—surface temperatures directly affect usability and client satisfaction during the extended summer season.

Travertine has become the preferred pool deck material in Arizona due to its natural slip resistance, thermal properties, and aesthetic versatility. The material’s cellular structure creates textured surfaces that maintain DCOF ratings of 0.55-0.62 wet, well above the 0.42 minimum for pool decks. You’ll find that travertine’s thermal properties keep surface temperatures 20-25°F cooler than concrete alternatives under identical sun exposure. When you specify travertine, require tumbled or brushed finishes rather than honed surfaces—the additional texture improves wet slip resistance while the softer edges reduce injury risk from falls.

Chemical resistance becomes critical around salt-chlorine generators and areas where pool chemicals are handled. Acidic conditions from improper pH levels or spilled muriatic acid can etch calcium-based stones like limestone and marble. Your specifications should require initial sealing with penetrating sealers designed specifically for pool deck applications—these products resist chlorine degradation better than standard stone sealers. You need to establish maintenance protocols that include pH monitoring and immediate neutralization of chemical spills to prevent permanent damage. For areas with chronic pH issues or salt-chlorine systems, consider specifying granite or other silica-based stones that resist acid etching.

Pathway and Walkway Design Considerations

Pathway design requires you to integrate functional requirements with aesthetic goals while addressing accessibility standards and long-term maintenance realities. When you specify pathway materials from landscaping stone suppliers outdoor materials catalogs, you’re making decisions that affect traffic flow, user safety, and landscape character for decades. Your design must accommodate the specific traffic patterns and user demographics while responding to site conditions like slope, drainage, and existing vegetation.

Flagstone pathways provide informal character suited to naturalistic Arizona landscapes but require careful attention to installation details. You need to specify flagstones with minimum 1-1/2 inch thickness for pedestrian traffic and 2-inch minimum for areas that might experience occasional vehicle crossings. Joint width affects both appearance and weed control—specify 1/2 to 3/4 inch joints for formal installations with mortared joints, or 1 to 2 inch joints for informal dry-laid paths with planted joints. When you design dry-laid paths, include 4-inch minimum crushed aggregate base compacted to 95% density to prevent settling and reduce weed emergence.

- You should maintain minimum 36-inch width for primary pathways to accommodate comfortable two-way traffic

- Your grade specifications must not exceed 5% slope for accessible routes—steeper grades require handrails or alternative routing

- You need to specify edge restraint for all flexible paving systems to prevent lateral migration and maintain defined edges

- Your drainage design should create minimum 2% cross-slope to prevent water ponding on walking surfaces

Paver pathways offer geometric precision and long-term dimensional stability superior to flagstone alternatives. You can specify standard rectangular pavers in running bond patterns for traditional appearance, or create custom patterns using multiple sizes for added visual interest. When you design paver paths, consider that 90-degree herringbone patterns provide 40% greater interlock than running bond, making them ideal for sloped paths or areas with vehicle crossings. Your base preparation specifications remain critical—6-inch aggregate base compacted in 2-inch lifts, topped with 1-inch setting bed of concrete sand screeded to uniform thickness.

Citadel Stone: Best local landscape stone suppliers in Arizona — Regional Specification Strategies

When you consider Citadel Stone’s local landscape stone suppliers in Arizona expertise, you’re evaluating comprehensive material knowledge developed across Arizona’s diverse climate zones. At Citadel Stone, we provide technical guidance for hypothetical applications throughout the state’s varied regions, from low desert heat zones to high-elevation freeze-thaw environments. This section outlines how you would approach specification decisions for six representative cities, each presenting distinct environmental challenges that affect material selection and installation protocols.

Phoenix Heat Management

In Phoenix applications, you would prioritize materials with proven thermal performance under extreme heat exposure exceeding 115°F for extended periods. Your specifications should focus on light-colored limestone or travertine with solar reflectance index values above 35 to maintain manageable surface temperatures around pools and entertainment areas. You need to account for the urban heat island effect that elevates nighttime temperatures 8-12°F above surrounding areas, which affects thermal cycling calculations and mortar curing protocols. Typical installations would specify expanded joint spacing at 12-foot intervals rather than standard 15-foot spacing to accommodate thermal expansion in this extreme environment. You should verify that warehouse stock levels support summer installation schedules when material demand peaks across the metropolitan region.

Tucson Monsoon Considerations

Your Tucson specifications would address the region’s intense monsoon season with rainfall events that can deliver 2-3 inches in single storms. You need to design drainage systems that handle rapid runoff without eroding joint sand or undermining paver bases. Material selection should emphasize porosity in the 4-6% range to facilitate drainage while maintaining structural integrity. You would specify polymeric sand systems with proven performance in wet-dry cycling conditions typical of monsoon patterns. Installation timing recommendations would avoid July through September when afternoon thunderstorms disrupt mortar curing and create challenging working conditions. Your base preparation specifications need to account for Tucson’s caliche layers that require mechanical excavation and proper compaction testing before material installation.

Scottsdale Luxury Applications

Scottsdale projects typically demand premium aesthetics combined with exceptional durability for high-value residential installations. You would specify select-grade materials with enhanced color consistency and minimal natural variation to meet client expectations for refined appearance. Your material recommendations would emphasize honed travertine or premium limestone with consistent vein patterns and color matching across multiple pallets. Installation protocols would include enhanced sealing treatments and ongoing maintenance programs to preserve appearance in showcase outdoor living environments. You need to coordinate with luxury appliance and lighting vendors to ensure hardscape materials complement high-end equipment finishes. Typical specifications would include thicker materials—2-inch pavers rather than standard 1-1/4 inch—to convey substantial quality through increased mass and improved thermal performance.

Flagstaff Freeze-Thaw Performance

Your Flagstaff specifications must address freeze-thaw cycling that occurs 120-140 times annually at 7,000-foot elevation. You would prioritize dense materials with porosity below 4% and verified ASTM C1026 testing showing no deterioration after 50 freeze-thaw cycles. Material thickness requirements increase to minimum 2 inches for all applications due to enhanced structural demands from ice formation within pores. You need to specify modified mortars with air-entraining additives that maintain bond strength through winter temperature extremes. Installation timing becomes critical—you would recommend completion before mid-October to allow proper curing before first hard freeze. Your drainage design must prevent water ponding on any horizontal surfaces where freeze damage could occur, requiring minimum 3% slope on all paved areas rather than the 2% adequate for lower elevations.

Sedona Aesthetic Integration

Sedona’s distinctive red rock landscape requires you to specify materials that harmonize with natural surroundings while meeting design guidelines that preserve visual character. You would recommend warm-toned sandstones and Arizona flagstone that complement rather than contrast with the region’s iconic geology. Material color selection should incorporate earth tones—buffs, tans, and warm grays—that recede visually into the landscape. Your installation recommendations would emphasize naturalistic patterns and irregular joint widths that mirror the organic character of native rock formations. You need to address local zoning requirements that often restrict reflective surfaces and require natural material palettes. Typical Sedona specifications would minimize formal geometric patterns in favor of random layouts that integrate with the relaxed, nature-focused design aesthetic prevalent throughout the region.

Yuma Extreme Conditions

Yuma presents the most extreme heat exposure in Arizona with summer temperatures consistently exceeding 110°F and peak readings approaching 125°F. Your material specifications would focus exclusively on light-colored stones with maximum solar reflectance to maintain usable surface temperatures. You need to account for minimal precipitation—less than 3 inches annually—which affects sealer performance and cleaning protocols differently than higher-rainfall regions. Installation timing recommendations would avoid June through August when midday surface temperatures can exceed safe working conditions. Your specifications should address wind-blown sand accumulation that affects joint stability and requires modified polymeric sand formulations with enhanced binding properties. Material delivery and storage protocols need to prevent thermal shock from warehouse-temperature materials being exposed suddenly to extreme outdoor heat during summer installations.

Installation Best Practices and Common Specification Errors

Your specifications determine installation success, but common specification errors create field problems that compromise performance and generate expensive callbacks. When you work with hardscape stone suppliers Arizona complete project support, you need to provide installation details that address base preparation, setting methods, joint specifications, and edge restraint with sufficient precision that competent contractors can execute properly without interpretation gaps. Ambiguous specifications create installation variations that affect long-term performance and appearance consistency.

Base preparation failures account for 60-70% of hardscape performance problems. You must specify aggregate type, depth, and compaction standards with precision. Crushed angular aggregate compacts more effectively than rounded river rock—your specifications should require minimum 80% fractured faces for base materials. Compaction standards need to specify 95% density per modified Proctor test, verified by nuclear densometer testing at 2,500 square foot intervals minimum. When you specify compaction depths, require lifts of 2-3 inches maximum—attempting to compact full 6-inch base depths in single pass creates loose lower layers that settle over time and cause paver subsidence.

- You should specify concrete sand meeting ASTM C144 gradation for setting beds—masonry sand contains excessive fines that prevent proper paver interlock

- Your edge restraint details must specify restraint type, spike spacing, and concrete backfill where appropriate for site conditions

- You need to provide joint sand specifications that address whether polymeric or conventional sand is required based on slope, traffic, and climate factors

- Your sealing specifications should clarify whether penetrating, enhancing, or topical sealers are required and establish reapplication intervals

Improper joint spacing creates long-term maintenance problems that become apparent 12-24 months after installation. You need to specify joint widths appropriate for thermal expansion in your climate zone—Arizona’s extreme temperatures require you to maintain minimum 1/8-inch joints between pavers to accommodate expansion without creating compressive forces that cause cracking or upheaval. When you detail perpendicular abutments between hardscape and structures, specify expansion joints filled with closed-cell backer rod and high-quality polyurethane sealant. These isolation joints prevent transfer of thermal expansion forces from paving to building foundations where they can cause structural damage or cosmetic cracking of adjacent materials.

Material Sourcing and Quality Verification Protocols

Your responsibility extends beyond specification writing to include quality verification that ensures delivered materials match specified performance criteria. When you source from landscape stone dealers hardscape products suppliers, you need to establish testing protocols and acceptance criteria before material orders are placed. This proactive approach prevents the costly situation where non-conforming materials arrive on site and create schedule delays while replacement materials are sourced and delivered.

Physical testing requirements should be specified for projects exceeding $50,000 in material value or where performance is critical to project success. You can require that suppliers provide certified test results for compressive strength, flexural strength, porosity, and freeze-thaw durability performed by independent laboratories following ASTM standards. These certifications verify that materials meet your specifications rather than relying on generic product literature that may not represent the specific production lot being supplied to your project. When you write these testing requirements into specifications, include provisions for who bears testing costs and what occurs if materials fail to meet specified criteria.

Visual inspection protocols should be established before delivery to address color consistency, dimensional tolerances, and surface finish quality. You need to require that full-range samples representing color variation expected in the shipment be approved before bulk delivery. Natural stone exhibits inherent variation—your specifications should define acceptable color range using approved physical samples rather than photographs or digital representations that don’t accurately convey three-dimensional appearance and texture. When materials arrive on site, inspection should occur before unloading to identify shipping damage or non-conforming materials while the delivery truck is still present, avoiding disputes about when damage occurred.

Long-Term Maintenance and Performance Expectations

Your specifications should include maintenance requirements and realistic performance expectations that inform clients about ongoing care responsibilities. Arizona hardscape installations require different maintenance protocols than humid climates due to unique environmental conditions including alkaline water, intense UV exposure, and dust accumulation. When you establish maintenance guidelines, you’re setting expectations that affect client satisfaction and reduce future disputes about material performance.

Sealing protocols represent the most critical maintenance specification for most natural stone applications. You should establish initial sealing requirements and reapplication intervals based on material porosity, surface finish, and exposure conditions. Penetrating sealers typically require reapplication every 2-3 years for horizontal surfaces with direct sun exposure, extending to 4-5 years for vertical applications or shaded locations. Your maintenance specifications need to address proper cleaning procedures before resealing—pressure washing at 1,500-2,000 PSI removes accumulated dirt and degraded sealer residue to ensure proper penetration of fresh sealer applications.

- You need to specify appropriate cleaning products—pH-neutral stone cleaners rather than acidic or alkaline products that damage natural stone

- Your maintenance protocols should establish inspection intervals for joint sand levels—annual inspection with sand replenishment as needed prevents paver edge chipping

- You should provide guidance on efflorescence removal using appropriate methods that don’t damage stone surfaces or accelerate future occurrences

- Your specifications need to address irrigation adjustments that prevent chronic water exposure to hardscape materials which accelerates deterioration

Realistic performance expectations should be documented in your specifications to establish reasonable service life estimates. Premium natural stone installations with proper maintenance typically achieve 30-50 year service life in Arizona conditions before requiring major restoration or replacement. You should clarify that appearance evolution is normal—natural stone develops patina over time as weathering affects surface characteristics. This aging process is generally considered desirable in natural materials, but clients accustomed to manufactured products may not understand these expectations unless you explicitly address them during specification review. Your documentation should include photographs of installations at 5, 10, and 15 years to illustrate typical appearance evolution.

Procurement Logistics and Project Timeline Coordination

Material procurement timing affects project schedules more significantly than most clients recognize. When you coordinate with landscape stone suppliers Arizona hardscaping distributors, you need to account for lead times that vary seasonally and with material selection. Standard stocked materials from regional distribution centers typically ship within 5-7 business days, while special-order materials sourced from specific quarries may require 6-8 weeks. Your project schedule must incorporate these lead times plus additional contingency for potential delays during peak construction seasons.

Truck access and delivery logistics require advance planning that considers site constraints and neighborhood restrictions. Flatbed deliveries for palletized stone materials require overhead clearance of 14-16 feet and turning radius sufficient for 48-foot articulated vehicles. You need to verify site access during preconstruction planning—discovering delivery limitations after materials are ordered creates expensive transloading requirements and schedule delays. When you coordinate deliveries, confirm that forklifts or other material handling equipment will be available on site. Pallets weighing 2,000-3,000 pounds cannot be manually offloaded and require mechanical equipment that should be arranged before delivery appointment.

Material staging and storage affect quality preservation between delivery and installation. You should specify on-site storage requirements that protect materials from contamination, staining, and damage. Natural stone should be stored on level ground with pallets elevated on blocking to prevent ground moisture wicking into bottom layers. Your storage specifications need to address covering requirements—materials should be protected from rain that can cause efflorescence but must have air circulation to prevent condensation accumulation. When storage duration exceeds 30 days, inspection protocols should verify that materials remain in acceptable condition before installation begins. For additional project planning resources, review Wholesale pricing structures for bulk landscape stone purchases before you finalize your material orders and project scheduling. Trade accounts benefit from Citadel Stone’s landscape stone dealers in Arizona wholesale programs.