The quick answer — what grooved pavers solve

Grooved pavers address three critical challenges in modern hardscape design: inadequate surface drainage, pedestrian slip hazards, and limited aesthetic options for high-performance applications.

Traditional flat pavers rely entirely on joint spacing and sub-surface drainage to manage water flow. This approach often proves insufficient during intense rainfall events, creating standing water that compromises both safety and structural performance. Grooved pavers introduce controlled surface channels that direct water flow while maintaining the structural benefits of modular paving systems.

The precision-cut channels also enhance slip resistance by providing directional traction and reducing water film thickness on walking surfaces. This dual functionality makes grooved pavers particularly valuable for high-traffic areas, sloped surfaces, and exterior applications where safety standards are paramount.

Understanding grooved pavers — terminology and types

What “grooved” / “kerfed” means

The terms “grooved” and “kerfed” refer to precision-cut channels machined into paver surfaces after initial fabrication. These channels, typically ranging from 3mm to 12mm in width and 2mm to 8mm in depth, create controlled drainage pathways while maintaining the structural integrity of the base material.

Kerf grooved pavers specifically refer to cuts made with diamond saw blades, producing clean, consistent channel profiles. Directional grooves run parallel in a single direction, while cross-grooved patterns create intersecting channels for enhanced drainage capacity. Linear groove patterns align channels with anticipated water flow directions, while grid patterns provide multidirectional drainage capability.

Common materials and grooving characteristics

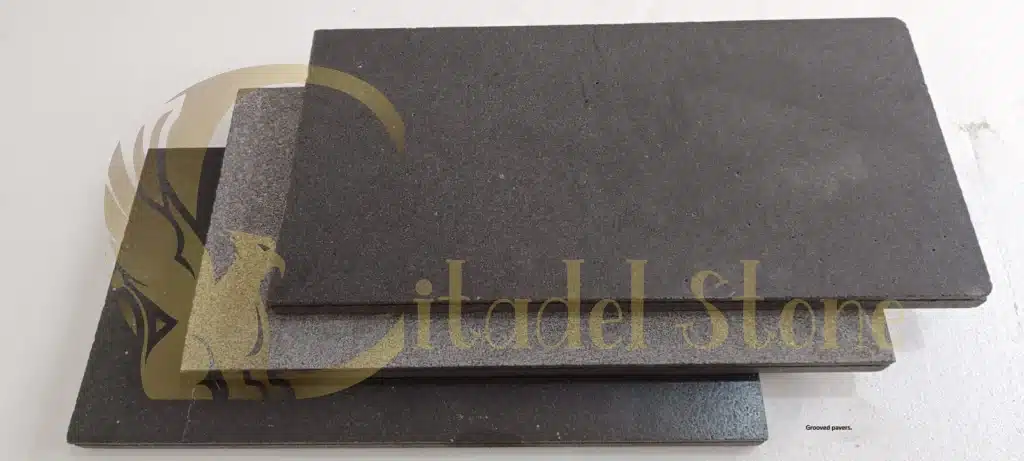

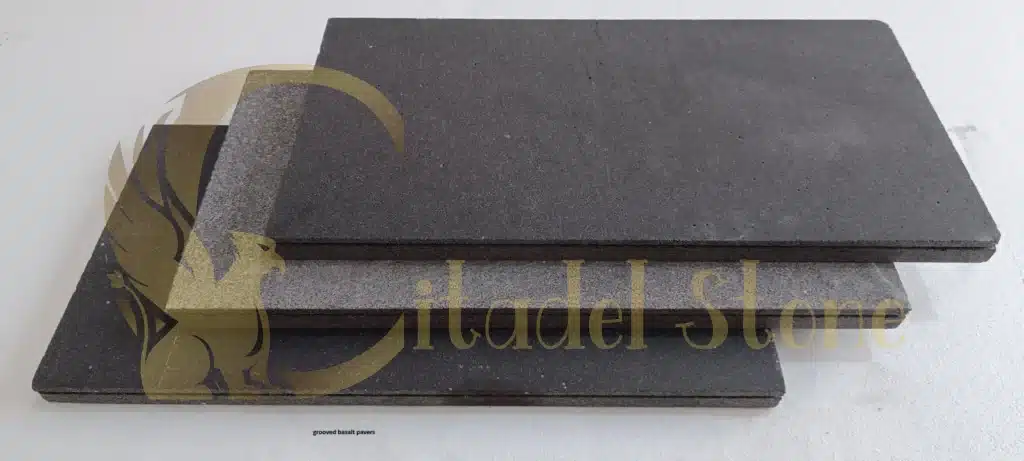

Grooved basalt pavers offer exceptional durability and consistent kerf quality due to basalt’s fine grain structure. The material’s natural hardness allows for precise channel cutting while maintaining edge stability under thermal cycling.

Granite grooved pavers provide similar performance characteristics with broader color and texture options. The material’s crystalline structure supports clean kerf cuts, though natural veining may require specialized cutting techniques to prevent chipping.

Concrete grooved pavers accommodate wider groove dimensions and custom channel profiles. The material’s moldable nature allows for integral groove formation during casting, though post-production kerfing provides superior dimensional precision.

Porcelain pavers accept extremely precise grooves with minimal material displacement. The controlled density of manufactured porcelain supports consistent kerf quality across large installations.

Drainage fundamentals — how grooves manage stormwater & runoff

Surface drainage vs sub-surface drainage strategies

Linear drainage pavers function as the primary surface water management system, channeling runoff directly to collection points or permeable zones. This surface-based approach reduces reliance on sub-surface infrastructure while providing visible water management performance.

Grooved pavers integrate with conventional sub-surface drainage through strategic channel placement. Groove orientation directs surface flow toward linear drains, catch basins, or permeable edges where water transitions to subsurface systems. This hybrid approach maximizes drainage efficiency while maintaining design flexibility.

Permeable grooved paving extends drainage functionality by incorporating permeable bedding materials beneath grooved surfaces. Water flows through surface channels while excess volume infiltrates through joint spacing into aggregate base layers.

Design parameters: groove pitch, depth, spacing, and slope

Channel capacity depends on groove cross-sectional area and surface slope. Typical groove dimensions range from 4mm to 10mm width with depths of 3mm to 6mm for pedestrian applications. Commercial vehicle areas may require groove dimensions up to 15mm width and 10mm depth.

Groove spacing typically ranges from 50mm to 200mm center-to-center, balancing drainage capacity with structural integrity. Closer spacing increases surface drainage area but may compromise load-bearing performance in vehicular applications.

Surface slope requirements vary with expected rainfall intensity and groove capacity. Typical minimum slopes range from 1% to 2% for grooved surfaces, compared to 2% to 4% for conventional flat pavers.

Design checks for engineers:

- Verify surface slope exceeds 1% minimum for positive drainage

- Calculate groove capacity based on anticipated rainfall intensity (typical range: 25mm to 100mm per hour for design storms)

- Confirm groove depth provides adequate flow area without creating tripping hazards

- Validate thermal movement accommodation in groove-to-groove joint spacing

- Check compatibility with specified pedestal or clip retention systems

Safety & accessibility — slip resistance, COF, and ADA considerations

COF targets for pedestrian safety

Slip-resistant grooved pavers achieve enhanced traction through both surface texture and groove-induced water displacement. Typical wet COF values for grooved natural stone range from 0.50 to 0.70, exceeding standard requirements for pedestrian surfaces.

COF performance varies with groove orientation, depth, and surface finish. Deep grooves with textured channel floors provide maximum slip resistance but may create maintenance challenges in debris-prone environments.

Current ADA-compliant surfaces require verification against updated accessibility standards. Groove dimensions must balance drainage effectiveness with mobility device compatibility. Typical maximum groove width limitations range from 6mm to 12mm to prevent wheel entrapment.

Groove orientation & slip behavior

Directional groove patterns provide maximum traction when aligned perpendicular to expected foot traffic direction. This orientation engages groove edges during heel strike and toe-off phases of walking motion.

Parallel groove orientation may reduce slip resistance in the groove-parallel direction while maintaining cross-directional traction. Cross-hatched groove patterns provide multidirectional slip resistance at the expense of reduced individual groove effectiveness.

Balancing groove depth for drainage vs tripping risk

Groove depth selection requires balancing drainage capacity with pedestrian safety considerations. Typical depth ranges from 3mm to 8mm provide effective water channeling while maintaining smooth surface transitions.

Maximum depth limitations typically range from 6mm to 10mm to prevent heel catch or mobility device interference. Surface edge treatments, including chamfered or radiused groove edges, reduce sharp transitions that could create tripping hazards.

Structural & wind/thermal performance

Integration with clip/pedestal systems

Clip-retained grooved pavers accommodate thermal movement while maintaining precise groove alignment across installations. Specialized clip systems allow individual paver adjustment without compromising overall surface continuity.

Pedestal-mounted grooved pavers require careful attention to thermal expansion joints. Groove patterns must align with expected movement directions to prevent binding or surface distortion during temperature cycling.

Wind uplift considerations become critical in rooftop applications. Grooved surfaces may experience different uplift pressures due to air flow interaction with channel geometry.

Movement joints and thermal expansion

Thermal movement accommodation requires coordination between groove spacing and expansion joint placement. Linear grooves parallel to anticipated movement directions provide maximum flexibility during thermal cycling.

Freeze-thaw durability depends on groove profile and material selection. Sharp groove corners may concentrate thermal stress, while radiused profiles distribute expansion forces more effectively.

Mechanical retention systems must accommodate differential movement between grooved pavers and supporting structures. Flexible clip systems or controlled sliding connections prevent thermal stress concentration.

Materials & finishes — matching groove patterns to aesthetics and performance

Surface finish trade-offs

Honed groove surfaces provide consistent, low-reflectance channels with predictable drainage characteristics. The smooth finish minimizes debris retention while maintaining adequate slip resistance through groove geometry.

Sawn groove surfaces offer maximum cost-effectiveness with acceptable performance for most applications. The slightly textured surface from diamond blade cutting provides additional slip resistance within groove channels.

Textured groove finishes maximize slip resistance and debris retention capacity. Bush-hammered or sandblasted groove surfaces provide enhanced traction but require more intensive maintenance protocols.

Color and patterning integration

Urban plaza design benefits from groove patterns that complement architectural elements while maintaining drainage functionality. Linear grooves can emphasize directional movement or create visual rhythm within larger paving areas.

Joint patterning coordination ensures groove terminations align with paver edges rather than creating incomplete channels. This attention to detail maintains both visual consistency and drainage effectiveness.

Color selection affects both aesthetic integration and thermal performance. Lighter colors reduce surface temperature while darker colors may enhance groove definition and shadow effects.

Installation & maintenance best practices

Installation procedures by system type

On-grade installations require establishing positive drainage slope before paver placement. Groove alignment verification ensures continuous channel flow from installation start to drainage collection points.

Pedestal-mounted installations demand precise leveling to maintain groove continuity across elevation changes. Individual paver adjustment capability allows fine-tuning of channel slope and alignment.

Mortar-set applications require careful mortar placement to avoid groove contamination. Protective tape or temporary channel blocking prevents mortar intrusion during installation.

Maintenance protocols

Linear drainage pavers require systematic debris removal to maintain channel capacity. Compressed air cleaning removes loose material while preserving groove profile integrity.

Caution: High-pressure washing may damage groove edges or drive debris deeper into channels. Medium-pressure techniques with specialized groove-cleaning attachments provide effective cleaning without surface damage.

Seasonal inspection protocols should include:

- Quarterly: Visual inspection for debris accumulation and surface damage

- Bi-annually: Groove capacity verification and channel cleaning

- Annually: COF testing and groove depth measurement

- As needed: Resealing applications based on material type and exposure conditions.

Drainage engineering examples & worked checks

Groove capacity estimation uses hydraulic principles adapted for shallow channel flow. Illustrative capacity calculations assume Manning’s roughness coefficients between 0.012 and 0.020 for machined stone channels.

A typical groove cross-section of 6mm width by 4mm depth on a 2% slope provides approximately 0.15 liters per meter per minute flow capacity under design conditions. These illustrative examples require engineering verification for specific project conditions.

Hydraulic modeling inputs for engineering verification:

- Groove cross-sectional dimensions and spacing

- Surface slope and anticipated flow path length

- Expected rainfall intensity and duration for design storm events

- Downstream drainage capacity and elevation constraints

- Material roughness coefficients and channel edge conditions

Design inspiration — modern projects that benefit from grooved pavers

Urban plazas utilize grooved pavers to manage runoff from surrounding hardscapes while providing slip-resistant pedestrian surfaces. Linear groove patterns can emphasize circulation routes or create visual interest through shadow and texture variation.

Rooftop terraces benefit from the enhanced drainage capacity of grooved systems, particularly in intensive green roof applications where traditional drainage may prove inadequate. The reduced weight compared to thicker conventional systems provides additional structural advantages.

Transit platforms require robust slip resistance and drainage performance under high-traffic conditions. Grooved basalt pavers provide durability and maintenance simplicity essential for transportation infrastructure.

Commercial courtyards integrate grooved pavers with landscape elements and architectural features. Groove orientation can direct drainage toward planted areas or collection systems while maintaining design continuity.

Pool deck applications leverage both drainage and slip resistance benefits. Groove patterns complement pool geometry while channeling water away from pedestrian areas.

Citadel Stone’s showroom facilities offer full-scale mockups for groove pattern evaluation and slip-resistance testing. These installations allow designers to experience different groove configurations before specifying final systems.

Comparison: Grooved pavers vs alternative drainage strategies

| Criteria | Grooved Pavers | Permeable Pavers | Slotted Drains | Conventional Slope |

|---|---|---|---|---|

| Drainage Performance | Excellent surface flow control | Good infiltration capacity | Concentrated collection | Relies on gravity flow |

| Pedestrian Safety | Enhanced slip resistance | Variable with surface type | Grating compatibility issues | Standard COF only |

| Maintenance Needs | Periodic groove cleaning | Vacuum cleaning required | Frequent grate service | Minimal ongoing care |

| Installation Complexity | Moderate alignment needs | Base preparation critical | Precise grading required | Standard techniques |

| Lifecycle Cost | Typical range: Medium | Typical range: Medium-High | Typical range: High | Typical range: Low |

| Aesthetic Flexibility | High pattern variety | Limited by porosity needs | Industrial appearance | Standard paver options |

Specification checklist — what to ask your supplier & installer

- Groove dimension specifications including width, depth, and profile tolerances

- COF test reports for both dry and wet conditions with test method documentation

- Clip or pedestal system compatibility verification and load capacity data

- Wind uplift testing results for rooftop applications with safety factor confirmation

- Installation drawings showing groove alignment and thermal expansion details

- Warranty terms covering groove integrity, slip resistance performance, and material defects

- Quality control procedures for groove cutting precision and consistency

- Thermal cycling test data demonstrating freeze-thaw durability

- Sample availability for mockup construction and field verification testing

- Technical support availability during design development and installation phases

- Maintenance protocol documentation with recommended cleaning procedures and frequencies

- Replacement part availability for clip systems and damaged pavers

Quick buyer’s checklist — specifying grooved pavers for your project

- Confirm drainage requirements and calculate groove capacity needs for design storm events

- Verify slip resistance requirements and specify appropriate COF targets for application

- Determine thermal movement requirements and select compatible retention systems

- Specify groove orientation based on primary drainage direction and foot traffic patterns

- Select material type based on durability requirements, aesthetic goals, and budget constraints

- Confirm installation system compatibility with structural loading and wind exposure conditions

- Specify quality control requirements for groove cutting precision and surface finish

- Plan maintenance access and specify cleaning equipment compatibility with groove dimensions

- Verify warranty coverage for both material performance and installation workmanship

- Coordinate with landscape architect for integration with planted areas and site drainage systems

- Confirm availability of replacement pavers for future repairs or modifications

- Specify mockup requirements for groove pattern verification before full installation

Conclusion

Grooved pavers represent a sophisticated approach to balancing drainage performance, pedestrian safety, and design flexibility in contemporary hardscape projects. The precision engineering required for effective groove systems demands careful specification and expert installation to achieve optimal performance.

Citadel Stone’s experience with grooved paver systems across diverse applications provides the technical expertise necessary for successful project implementation. From initial concept development through installation support, our team ensures groove specifications align with both performance requirements and aesthetic goals.

The investment in properly designed grooved paver systems delivers long-term value through reduced maintenance requirements, enhanced safety performance, and design versatility that adapts to evolving site conditions.

Contact Citadel Stone to request grooved paver mockup samples, technical cut sheets, and design consultation services tailored to your specific project requirements.