When you specify grey marble for Arizona installations, you’re working with materials that must perform under some of the most demanding thermal conditions in North America. Grey marble supplier Arizona contemporary selections like Silver Shadow and Grey Emperador deliver the aesthetic refinement your commercial and residential projects require while withstanding temperature swings that regularly exceed 50°F between day and night. You need to understand how these materials respond to thermal cycling, UV exposure, and the state’s unique combination of intense solar radiation with minimal humidity — factors that separate successful long-term installations from premature failures.

Your material selection process should account for how grey marble’s crystalline structure interacts with Arizona’s climate. The state’s elevation variations create distinct performance zones — what works in Yuma’s low-desert heat island behaves differently in Flagstaff’s freeze-thaw cycles. Grey marble supplier Arizona contemporary options provide thermal mass benefits that stabilize interior temperatures, but you’ll need to spec appropriate edge details and expansion joints that accommodate the material’s thermal expansion coefficient of 5.1 × 10⁻⁶ per °F. Professional specifications recognize that grey marble installations in Phoenix require different joint spacing than those in Sedona, where diurnal temperature ranges create more aggressive expansion-contraction cycles.

Grey Marble Material Characteristics for Desert Performance

You’re selecting from materials with distinct performance profiles when you evaluate grey marble supplier Arizona contemporary options. Silver Shadow marble exhibits a fine-grained structure with compressive strength ranging from 9,200 to 11,400 PSI, placing it in the upper performance tier for commercial applications. Your specifications need to account for its 0.18-0.22% water absorption rate — low enough for exterior applications in most Arizona locations, but you should verify that sealed surfaces maintain below 0.15% absorption for areas with intensive water exposure like pool decks or fountain surrounds.

Grey Emperador presents different characteristics you’ll want to understand before specification. This material shows more pronounced veining with compressive strengths typically between 8,800 and 10,200 PSI. The vein structures create natural cleavage planes that affect both fabrication approach and long-term performance. When you detail edge profiles for Grey Emperador, you need to orient veining perpendicular to high-stress edges rather than parallel — a specification detail that prevents edge failures at vein intersections. The material’s porosity ranges from 0.24-0.31%, requiring more aggressive sealing protocols for Arizona exterior applications where dust infiltration becomes visible within 18-24 months on unsealed surfaces.

- You should verify that your selected grey marble meets minimum 8,000 PSI compressive strength for commercial floor applications

- Your sealing specification must address Arizona’s alkaline dust conditions that create visible surface deposits on porous stones

- You need to account for thermal expansion when specifying slab dimensions exceeding 4 feet in any direction

- Your edge detail drawings should indicate vein orientation for structural veined materials like Grey Emperador

Thermal Performance in Arizona Installations

Here’s what catches most specifiers when they work with grey marble supplier Arizona contemporary materials — thermal behavior extends beyond simple expansion coefficients. You’re dealing with a material that absorbs solar radiation at 35-42% efficiency depending on surface finish and color depth. That absorbed energy creates surface temperatures 18-25°F above ambient air temperature during peak solar exposure. Your darker grey marbles like Grey Emperador reach higher surface temperatures than lighter Silver Shadow selections, affecting everything from barefoot comfort around pools to thermal stress at mortar bed interfaces.

The thermal mass properties work in your favor for interior applications. When you specify 3/4-inch grey marble flooring in Arizona homes, you’re creating thermal storage that dampens interior temperature swings by 6-9°F compared to ceramic tile installations of equivalent thickness. This thermal lag effect means peak cooling loads shift 3-4 hours later in the day, potentially reducing HVAC equipment sizing by 12-18% in properly designed installations. You’ll want to coordinate with mechanical engineers early in design to capture these benefits in load calculations rather than discovering them after equipment procurement. For more information on complementary stone options, Citadel Stone white marble in Peoria offers additional design flexibility for mixed-material applications.

Your exterior specifications require different thermal considerations. Grey marble patios and walkways experience surface temperature cycling from 70°F at sunrise to 145°F at 2 PM during summer months in Phoenix and Tucson. That 75°F temperature swing occurs in roughly 6 hours, creating thermal stress rates of 12-13°F per hour. You need expansion joints every 12-15 feet in unconditioned exterior applications, decreasing to 10-12 feet for dark grey marbles with higher solar absorption. The joints themselves require sealant materials rated for ±50% movement capability — standard ±25% sealants fail within 18-30 months under Arizona thermal cycling.

Surface Finish Impact on Performance and Safety

When you evaluate grey marble supplier Arizona contemporary finish options, you’re making decisions that affect slip resistance, maintenance requirements, and long-term appearance retention. Polished finishes on Silver Shadow deliver DCOF (Dynamic Coefficient of Friction) values between 0.38-0.42 when dry, dropping to 0.28-0.32 when wet. Those wet values fall below the 0.42 minimum recommended for walking surfaces, requiring you to specify alternative finishes or supplemental slip-resistance treatments for any areas with water exposure.

Honed finishes provide better slip resistance — you’ll see DCOF values ranging from 0.48-0.54 dry and 0.42-0.46 wet for properly executed honed Grey Emperador surfaces. The trade-off appears in maintenance and appearance retention. Honed surfaces show traffic wear patterns after 8-12 years in commercial applications with moderate to high foot traffic. You need to establish realistic maintenance expectations with your clients regarding periodic refinishing requirements. Residential applications typically extend that timeline to 15-20 years before visible wear patterns develop.

- You should specify honed or textured finishes for any grey marble applications with water exposure or exterior placement

- Your maintenance specifications need to address annual resealing for honed finishes in high-traffic areas

- You’ll find that flamed finishes aren’t viable for most grey marbles due to crystalline structure limitations

- Your specification should prohibit acidic cleaning products that etch marble surfaces and reduce slip resistance

Installation Substrate Requirements and Best Practices

Your installation success with grey marble supplier Arizona contemporary materials depends heavily on substrate preparation — this is where field conditions frequently deviate from specification drawings. You need substrate flatness within 1/8 inch over 10 feet for thin-set applications using grey marble tiles or slabs under 18 inches square. Larger format slabs require tighter tolerances of 1/16 inch over 10 feet to prevent lippage and stress concentrations that lead to cracking. Those tolerances become more critical in Arizona’s clay-heavy soils where seasonal moisture fluctuations cause substrate movement even in supposedly stable structures.

When you specify mortar beds for grey marble installations, you’re choosing between modified and unmodified thin-set products based on specific application conditions. Modified thin-sets with polymer additives provide improved flexibility and bond strength, but you need to verify compatibility with your selected grey marble. Some darker Grey Emperador varieties show discoloration when installed with modified thin-sets due to moisture retention at the mortar interface. You should conduct sample mockups using the exact stone and setting materials specified before proceeding with full installations. Granite products Arizona grey marble applications often share similar substrate preparation requirements that ensure long-term performance.

Your substrate moisture management becomes critical for Arizona ground-level installations. Despite the state’s reputation for dry climate, seasonal monsoons deliver concentrated moisture that saturates substrate materials. You need vapor barriers under all ground-level grey marble installations, positioned below the mortar bed or concrete substrate. The barrier should provide minimum 15-perm vapor transmission rating, with all seams overlapped 6 inches and sealed. Without proper vapor management, you’ll see efflorescence emerging at grout joints within 6-18 months as alkaline salts migrate through the substrate and deposit on marble surfaces.

Grout Joint Specification and Long-Term Performance

Here’s what you need to understand about grey marble grout joints in Arizona installations — joint width directly affects long-term performance and maintenance requirements. You should specify minimum 3/16-inch joints for grey marble tiles under 12 inches square, increasing to 1/4-inch joints for tiles between 12-18 inches, and 3/8-inch joints for slabs exceeding 18 inches in any dimension. Those wider joints accommodate both inherent dimensional tolerances in natural stone (typically ±1/16 inch) and thermal expansion that occurs during Arizona’s extreme temperature swings.

Your grout material selection matters more than most specifiers recognize. Standard cement-based grouts absorb water and provide pathways for moisture migration that leads to efflorescence. You should specify epoxy grouts for all wet areas including pool decks, shower applications, and outdoor kitchens. For interior dry areas, cement-based grouts with penetrating sealers provide adequate performance at lower cost. The sealer application requires reapplication every 18-24 months in Arizona conditions where alkaline dust infiltration degrades sealer effectiveness faster than humid climate installations.

- You need expansion joints at perimeter walls, at transitions between materials, and at regular intervals in large floor areas

- Your grout color selection should anticipate that lighter grouts show more visible dirt accumulation in Arizona’s dusty environment

- You should specify non-sanded grout for joints under 1/8 inch to prevent scratching on polished marble surfaces

- Your maintenance specifications must include procedures for grout sealing and periodic grout replacement in high-wear areas

Sealing Protocols for Arizona Conditions

When you specify grey marble supplier Arizona contemporary installations, sealing represents a critical performance factor that requires specific attention to regional conditions. You’re working with materials that need protection from Arizona’s unique combination of intense UV exposure, alkaline dust, and occasional concentrated moisture from monsoon events. Your sealing specification should mandate penetrating sealers rather than topical coatings — topical products fail rapidly under thermal cycling and UV exposure, typically showing visible degradation within 12-18 months.

The sealing process timing affects performance outcomes significantly. You need to specify that grey marble receives initial sealer application after installation and complete grout cure, but before the space becomes occupied or receives furniture placement. That initial application should consist of two coats applied 4-6 hours apart, allowing proper penetration and cure. You’ll want to require test areas that demonstrate adequate water beading and stain resistance before accepting the installation. Clean White Stone Inventory Arizona specifications frequently reference similar sealing protocols that have proven effective in regional conditions.

Your maintenance specifications should address sealer reapplication intervals based on actual use conditions. Residential interior floors typically require resealing every 24-36 months. Commercial applications with moderate traffic need resealing every 12-18 months. Exterior applications and wet areas require annual resealing to maintain adequate protection. You should specify that clients receive written maintenance instructions including specific sealer product recommendations and application procedures — generic guidance leads to improper maintenance that degrades appearance and reduces service life.

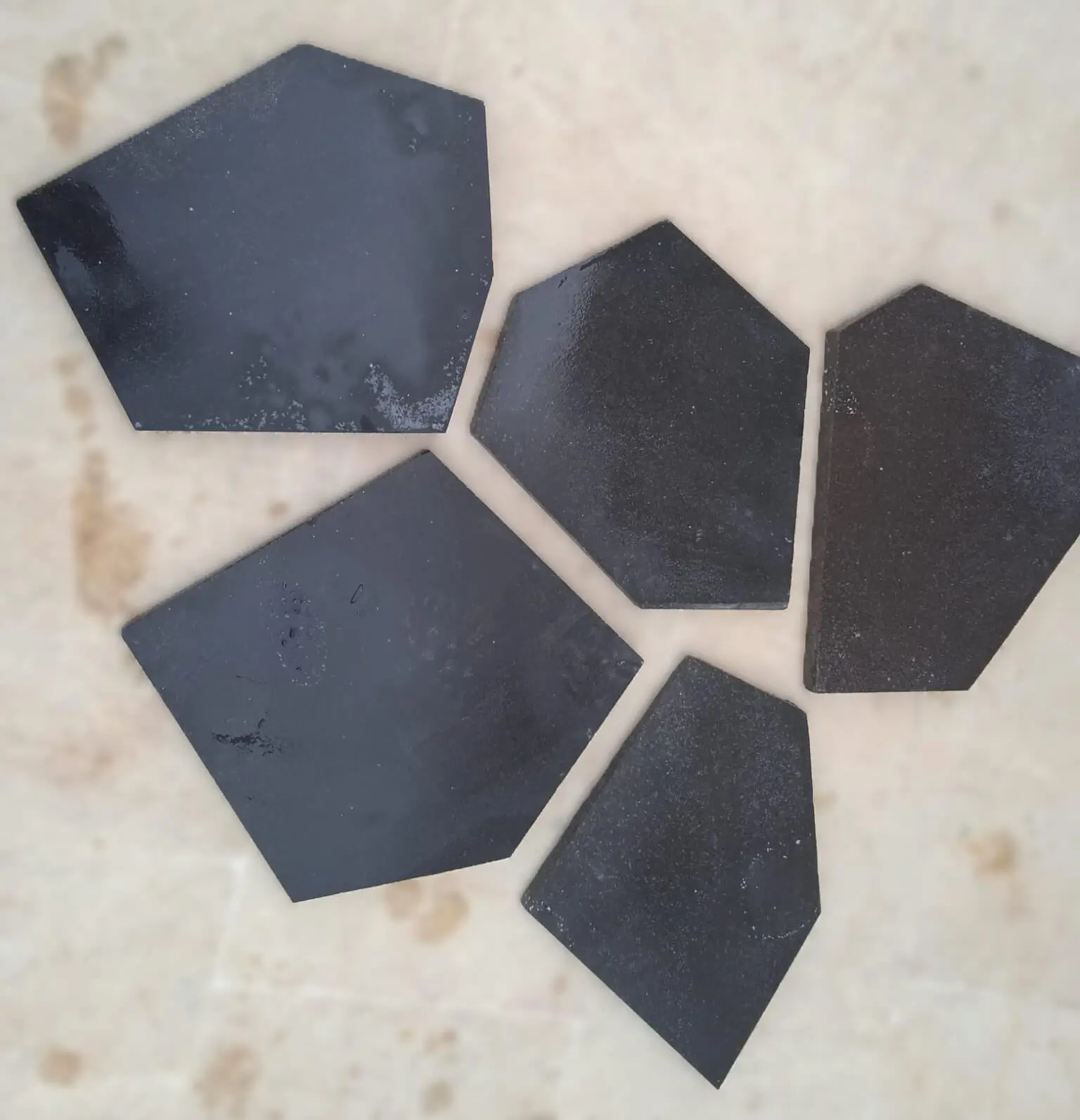

Color Variation Expectations and Quality Standards

You need to establish realistic expectations regarding color variation when you work with grey marble supplier Arizona contemporary materials. Natural stone exhibits inherent variation that distinguishes it from manufactured products — that variation constitutes a defining characteristic rather than a quality defect. Silver Shadow typically shows subtle color shifts from light grey with bluish undertones to medium grey with warmer taupe influences. You should require sample review from the actual material lot designated for the project rather than relying on small showroom samples that may not represent the full range of variation.

Grey Emperador presents more pronounced variation including vein structure density, background color intensity, and the presence of fossil inclusions. Your quality standards should define acceptable variation ranges through approved samples rather than attempting to restrict natural characteristics through written specifications alone. You’ll want to require that the fabricator or installer provide a full-size mockup using actual project materials arranged in proposed installation pattern. That mockup becomes the contractual standard for acceptable variation, preventing disputes during installation.

- You should specify that multiple slabs or tiles be viewed together to assess cumulative visual effect rather than evaluating individual pieces

- Your specifications need to address how materials from different bundles or shipments will be blended to distribute variation evenly

- You’ll find that digital photos rarely represent actual color accurately due to lighting and camera white balance variations

- Your approval process should require in-person review under lighting conditions similar to the final installation environment

Edge Detail and Fabrication Considerations

When you detail edge profiles for grey marble supplier Arizona contemporary applications, you’re making decisions that affect both aesthetics and structural performance. Square edges with minimal easing (1/16-inch radius) provide contemporary clean lines but concentrate stress at corners, making them susceptible to chipping during handling and installation. You should specify minimum 1/8-inch radius easing on all exposed edges for grey marble countertops and vanities. That modest radius reduces edge chipping by approximately 70% during fabrication and installation without significantly altering the desired contemporary aesthetic.

Your specifications for more elaborate edge profiles like ogee or bullnose need to account for how these details affect material strength. Complex profiles reduce effective thickness at critical sections — a 1.5-inch thick slab with elaborate ogee edge may have only 1/2-inch thickness at the thinnest section. You need to verify that your edge profile selection maintains adequate thickness to resist anticipated loads. For grey marbles with pronounced veining like Grey Emperador, you should specify that veins run perpendicular to edge profiles rather than parallel to prevent delamination along vein planes. Colored Natural Stone Inventory AZ options provide additional design possibilities when grey marble characteristics don’t align with specific edge detail requirements.

Fabrication quality directly impacts long-term performance. You should specify that all saw cuts and edge profiles receive proper polishing to remove micro-fissures that propagate into cracks over time. Cut edges that appear acceptable visually may contain surface fractures invisible to the eye but detectable through proper inspection techniques. Your quality assurance specifications should require that fabricators demonstrate proper equipment maintenance and blade sharpness through test cuts before processing project materials.

Thickness Specifications and Structural Considerations

Your thickness selection for grey marble applications depends on span, support conditions, and anticipated loads. Standard 3/4-inch thickness provides adequate strength for residential countertops with maximum 10-inch unsupported overhang and 18-inch spacing between cabinet supports. When you increase unsupported overhang beyond 10 inches, you need either increased thickness (1-1/4 inch minimum) or supplemental support through steel brackets or corbels spaced at 18-inch maximum intervals. Those support requirements become more critical with grey marbles that exhibit lower flexural strength due to vein structures or inherent material characteristics.

Floor applications typically use either 3/8-inch tiles or 3/4-inch slabs depending on format size and installation method. You should specify 3/8-inch thickness for tiles under 12 inches square installed over properly prepared substrates using thin-set application. Larger format tiles between 12-18 inches require 1/2-inch minimum thickness to prevent cracking during installation and under normal floor loads. Slab installations using pieces exceeding 18 inches in any dimension should use 3/4-inch thickness with mortar bed installation to ensure adequate strength and minimize deflection under concentrated loads.

- You need to coordinate grey marble thickness selection with adjacent materials to minimize transitions and lippage conditions

- Your structural specifications should verify that floor framing provides adequate stiffness with maximum L/360 deflection under design loads

- You should specify that large format slabs receive support over their entire area rather than spot support at corners

- Your details must show how thickness transitions occur at material changes including ramps or beveled edges that meet accessibility requirements

Common Specification Mistakes to Avoid

Here’s what trips up even experienced specifiers when they work with grey marble supplier Arizona contemporary materials — assuming that all grey marbles perform identically regardless of origin or specific variety. You can’t simply specify “grey marble” and expect consistent results. Silver Shadow from different quarries exhibits variation in density, porosity, and vein characteristics that affect both appearance and performance. Your specifications need to identify exact material name, quarry source, and finish requirements, then require submission of samples from the actual project material lot for approval before fabrication begins.

Another frequent mistake involves inadequate detailing of expansion joints in large floor areas. You’ll see specifications that require expansion joints at 25-30 foot spacing — intervals that might work for ceramic tile but prove insufficient for natural stone under Arizona thermal conditions. You need expansion joints at maximum 15-foot spacing in both directions for grey marble floor installations, with additional joints at all perimeter conditions, penetrations, and transitions to other materials. Those joints require proper design depth (minimum 1/4 slab thickness) and width (3/8-1/2 inch) to function effectively over the installation’s service life.

Your specifications often fail to address what happens when materials arrive at the site with damage or unacceptable variation. You should include clear acceptance criteria and rejection procedures in your specifications. Define who inspects materials upon delivery, what constitutes acceptable versus rejectable conditions, and how rejected materials get replaced without delaying the project schedule. Without these provisions, you’ll face disputes and delays when inevitable material issues occur. Granite stockists grey varieties typically maintain clear quality standards that help establish appropriate acceptance criteria for your projects.

Maintenance Program Development for Long-Term Performance

When you specify grey marble supplier Arizona contemporary installations, you’re responsible for establishing maintenance programs that preserve appearance and extend service life. Your maintenance specifications should address daily, periodic, and long-term procedures with specific product recommendations rather than generic guidance. Daily maintenance consists of dust mopping or vacuuming to remove abrasive particles, followed by damp mopping using pH-neutral stone cleaner diluted per manufacturer instructions. You need to prohibit vinegar, lemon juice, ammonia-based cleaners, and other acidic or alkaline products that etch marble surfaces and degrade sealers.

Periodic maintenance requirements vary by location and use intensity. You should specify that high-traffic commercial installations receive professional deep cleaning quarterly, including agitation cleaning with approved stone care products followed by thorough rinsing and sealer reapplication. Residential installations typically require professional maintenance annually. Your specifications need to identify qualified maintenance contractors and establish performance standards they must meet. Generic requirements for “periodic maintenance as needed” result in neglected installations that deteriorate prematurely.

Long-term maintenance addresses refinishing requirements that become necessary as surfaces show wear patterns or loss of desired finish. You should establish expectations that honed grey marble floors in commercial applications will require professional refinishing every 8-12 years depending on traffic volume. That refinishing process includes diamond abrasive grinding to remove surface damage, progressive honing to achieve desired finish level, and complete resealing. Your specifications should clarify whether initial project budget includes allowances for long-term maintenance or if building owners need to budget separately for these eventual requirements.

Citadel Stone Grey Marble Supplier Arizona Contemporary Specifications Across Arizona Cities

When you consider grey marble supplier Arizona contemporary options from Citadel Stone for your regional projects, you’re evaluating materials specifically selected for diverse Arizona climate zones. At Citadel Stone, we provide technical guidance for hypothetical applications that demonstrate how you would approach material specification across the state’s varying conditions. This section outlines recommended considerations for six representative Arizona cities, illustrating how climate factors, elevation differences, and local conditions would influence your grey marble selection and installation specifications.

Phoenix Specifications

In Phoenix, you would need to account for extreme heat island effects where summer surface temperatures regularly exceed 145°F on horizontal grey marble installations. Your specifications should address thermal expansion with 3/8-inch expansion joints at 12-foot maximum spacing in both directions. You’d want to specify lighter Silver Shadow grey marble rather than darker Grey Emperador for exterior applications to reduce solar heat gain. The metropolitan area’s alkaline dust conditions would require you to specify annual professional sealing for all exterior grey marble surfaces. Your substrate specifications would need to address expansive clay soils common throughout the Phoenix basin that create seasonal movement affecting ground-level installations. You should require vapor barriers and isolation joints that accommodate substrate movement without transferring stress to finish marble surfaces.

Tucson Considerations

When you specify grey marble for Tucson applications, you’d encounter similar heat challenges as Phoenix but with higher elevation creating marginally more moderate temperatures and increased diurnal temperature ranges. Your expansion joint spacing should remain at 12-foot maximum intervals, but you’d want to specify sealant products rated for ±50% movement capability to accommodate the larger daily temperature swings. Tucson’s caliche soil conditions would require you to address substrate preparation more aggressively than standard specifications. You need to verify that all caliche has been removed and replaced with engineered fill before grey marble installation over ground-level substrates. Your sealing specifications would follow similar annual reapplication schedules as Phoenix, with added attention to monsoon moisture management through proper drainage design and waterproofing details.

Scottsdale Applications

Your Scottsdale specifications would address high-end residential and resort applications where grey marble supplier Arizona contemporary materials meet demanding aesthetic expectations. You’d specify Silver Shadow with tight color sorting to minimize variation in luxury residential installations. For resort pool deck applications, you would require honed finish with minimum 0.42 DCOF wet slip resistance, verified through laboratory testing of actual project materials. Your edge details for Scottsdale countertop and vanity applications would likely incorporate more elaborate profiles than standard projects, requiring you to coordinate carefully with fabricators regarding structural implications of reduced thickness at profile details. You should specify supplemental support through steel brackets for any overhangs exceeding 10 inches, concealed within cabinetry design to maintain clean contemporary aesthetics.

Flagstaff Requirements

In Flagstaff, you’d face entirely different specification requirements due to elevation-driven freeze-thaw cycling that creates conditions more similar to Colorado than southern Arizona. Your grey marble selection would need verification of maximum 0.20% water absorption to prevent freeze-thaw damage. You should specify that all exterior grey marble receives enhanced sealing with penetrating water-repellent sealers applied in two coats, with verification testing confirming proper protection. Your expansion joint spacing could increase slightly to 15-foot intervals due to reduced thermal expansion from lower maximum temperatures, but you’d need to add isolation joints at all interfaces with heated building elements where differential thermal movement occurs. Winter salt exposure from snow removal operations would require you to specify that clients receive explicit guidance prohibiting salt-based deicing products on grey marble surfaces.

Sedona Projects

When you work on Sedona projects, you’d specify grey marble that complements the region’s distinctive red rock aesthetic while meeting performance requirements for the area’s significant diurnal temperature swings. Your finish specifications would likely favor honed surfaces over polished to reduce visual contrast with natural surroundings and provide better slip resistance for outdoor living spaces common in Sedona residential design. You need to account for the area’s tourism-driven commercial applications where foot traffic patterns concentrate in specific zones, requiring you to specify enhanced wear resistance through appropriate thickness selection and maintenance protocols. Your coordination with local design review boards would influence color selection and finish specifications to meet community aesthetic standards that favor materials harmonizing with natural landscape character.

Yuma Specifications

In Yuma, you’d encounter the most extreme heat conditions in Arizona, requiring you to specify grey marble with maximum attention to thermal performance characteristics. Your expansion joint spacing should decrease to 10-12 foot intervals for dark grey marbles in exterior applications. You would need to prohibit polished finishes on any horizontal exterior surfaces due to excessive surface temperatures that create safety concerns. Yuma’s agricultural dust conditions would require you to specify quarterly professional cleaning for commercial installations rather than annual cleaning sufficient in other Arizona locations. Your irrigation coordination would become critical since landscape water overspray onto grey marble surfaces creates persistent staining from Yuma’s high mineral content water. You should require that landscape designers position all irrigation heads to prevent any water contact with marble surfaces and specify minimum 24-inch clear separation between planted areas and grey marble installations.

Final Considerations

Your grey marble supplier Arizona contemporary specifications require comprehensive attention to material selection, climate-appropriate detailing, and realistic maintenance planning. You’ve seen how regional variations across Arizona create distinct specification requirements — what works in Phoenix needs modification for Flagstaff applications, and Yuma conditions demand even more aggressive thermal management strategies. The key to successful grey marble installations lies in your understanding that natural stone performance depends on the complete system including substrate preparation, proper material selection, appropriate detailing, and committed long-term maintenance. You should approach each project by evaluating specific site conditions, use requirements, and client expectations before selecting materials and developing specifications. For complementary material options in your Arizona projects, review Premium Carrara and Calacatta white marble slabs for Arizona projects to explore how different marble varieties can work together in mixed-material applications. Professional installers depend on Citadel Stone’s complete granite tool supply in Arizona.