When you specify granite rock landscape supplies Arizona for your next project, you’re making decisions that affect performance for decades. The state’s extreme temperature swings—from 115°F summer days in Phoenix to freezing nights in Flagstaff—demand materials that won’t just survive but maintain structural integrity and aesthetic appeal. You need to understand how granite’s crystalline structure responds to thermal cycling, UV exposure, and minimal precipitation before you commit to specifications.

Arizona’s landscape architecture relies heavily on granite rock landscape supplies Arizona because the material’s thermal mass properties align with desert climate requirements. You’ll find that granite absorbs heat during peak sun exposure and releases it gradually, creating microclimates that benefit surrounding plantings. Your material selection should account for granite’s 5.3 × 10⁻⁶ per °F thermal expansion coefficient—this isn’t just a specification detail, it’s what determines whether your boulder placements shift over time or remain stable through 50-degree daily temperature variations.

Granite Varieties and Performance Characteristics

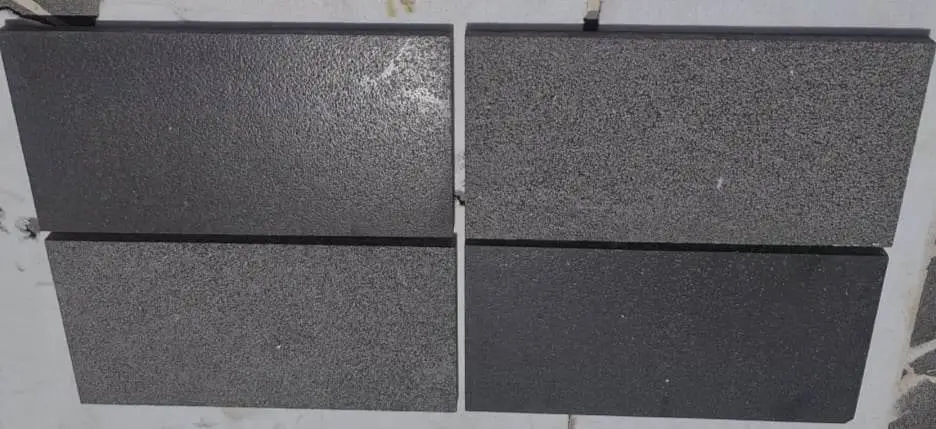

The granite formations available through landscape granite Arizona materials sources vary significantly in composition and field performance. You’re primarily selecting between three granite types: biotite granite (black and silver flecking), muscovite granite (lighter tones with mica), and hornblende granite (darker, denser formations). Each type responds differently to Arizona’s climate stressors.

When you evaluate granite landscape stone suppliers selection, you should prioritize compressive strength exceeding 25,000 PSI—substantially higher than the 8,000 PSI minimum for paving applications. Landscape boulders experience different stress loads than horizontal surfaces. Your specification needs to address point-load resistance, particularly for installations where boulders rest on limited contact areas or support vertical elements.

- You’ll achieve optimal performance with granite porosity between 0.4% and 1.2% for Arizona applications

- Your material should demonstrate absorption rates below 0.5% by weight to resist efflorescence

- Granite’s Mohs hardness of 6-7 provides superior abrasion resistance compared to sedimentary alternatives

- You need to verify feldspathic content, as higher feldspar percentages correlate with better UV stability

The crystalline structure of granite rock landscape supplies Arizona determines long-term color stability. You should understand that biotite-rich granites may show minor oxidation after 8-12 years in full sun exposure, transitioning from deep black to charcoal tones. This isn’t material failure—it’s predictable weathering that many landscape architects intentionally specify for evolving aesthetic character.

Boulder Sizing and Placement Specifications

Your boulder specifications must address both aesthetic composition and structural stability. The relationship between boulder mass, contact surface area, and soil bearing capacity determines whether your installations remain stable or settle unevenly over time. For Direct-from-Quarry Stone AZ sourcing, you’re typically selecting from five size classifications that affect everything from crane requirements to long-term performance.

When you specify large granite rocks landscaping variety for focal elements, you need to calculate soil bearing pressure using actual contact area, not overall boulder dimensions. A 4,000-pound boulder with 2.5 square feet of ground contact creates approximately 1,600 PSF pressure—well within native caliche bearing capacity but potentially problematic in disturbed or amended soils. You should always verify subsurface conditions before finalizing boulder sizes.

- Accent boulders: 150-400 lbs, suitable for planting bed integration and border definition

- Feature boulders: 400-1,200 lbs, appropriate for entry statements and sight line anchors

- Statement boulders: 1,200-3,500 lbs, designed for primary focal points and architectural integration

- Monumental boulders: 3,500-8,000 lbs, specified for landmark installations and large-scale compositions

- Signature elements: 8,000+ lbs, reserved for civic projects and destination landscapes

The placement depth for granite rock landscape supplies Arizona directly affects stability and visual proportion. You’ll want to bury 20-30% of boulder height to create the appearance of natural geological emergence rather than surface-placed rocks. This burial depth also provides lateral stability against equipment contact, vandalism, and seismic movement. Your excavation specifications should include compacted base material extending 6-8 inches beyond boulder perimeter to distribute loads and prevent settling.

Thermal Performance and Heat Island Mitigation

You need to understand granite’s thermal behavior because it fundamentally affects landscape comfort and plant performance. Granite’s specific heat capacity of 0.79 kJ/kg·K means the material requires substantial energy input to change temperature, creating thermal lag that moderates extreme surface temperatures. When you’re working with landscape granite Arizona materials in urban settings, this thermal mass becomes a strategic asset for heat island mitigation.

Your darker granite selections will reach surface temperatures of 165-180°F during peak summer exposure in Phoenix or Tucson. Lighter granite tones—silver, white, and buff varieties—stabilize at 135-150°F under identical conditions. This 30-degree differential affects surrounding plant stress, irrigation requirements, and pedestrian comfort zones. You should map sun exposure patterns and specify granite tones accordingly, reserving darker materials for shaded positions or areas without foot traffic.

The thermal mass properties of granite rock landscape supplies Arizona create microclimate benefits that extend beyond the installation footprint. When you position substantial boulder masses strategically, you’re creating thermal buffers that moderate temperature swings for adjacent plantings. For guidance on complementary materials with different thermal characteristics, see our grey marble products for alternatives in high-visibility applications. You’ll find that combining materials with varying specific heat capacities creates more complex and beneficial microclimate gradients than monolithic material selections.

Base Preparation and Structural Requirements

The longevity of your granite installations depends more on base preparation than material quality. You’re building on desert soils that present unique challenges—expansive clays in basin areas, caliche layers that seem stable until disturbed, and sandy profiles with minimal cohesion. Your base specification must address site-specific subsurface conditions rather than applying generic recommendations.

When you encounter caliche layers (and you will in 70% of Arizona sites), you need to determine whether you’re working with true hardpan or partially cemented soil. True caliche provides excellent bearing capacity—often exceeding 4,000 PSF—but creates drainage complications. Your specification should include caliche profiling to identify layer thickness and continuity. Installations on intact caliche require perimeter drainage details to prevent water ponding and soil saturation at the caliche interface.

- You should specify minimum 6-inch compacted aggregate base for boulders under 1,500 lbs

- Your installations exceeding 3,000 lbs require 12-inch base depth with engineered fill specifications

- Base materials must achieve 95% Standard Proctor density in 4-inch lifts

- You need to verify subgrade bearing capacity reaches 1,500 PSF minimum before base placement

For projects involving granite landscape stone suppliers selection across multiple site conditions, you’ll want to develop zoned base specifications rather than single-detail approaches. Areas with native undisturbed soil may require minimal base preparation, while zones with imported fill or previous disturbance need comprehensive structural base systems. Your specifications should include field verification protocols that allow base depth adjustments based on actual encountered conditions rather than assumed profiles.

Cobble, Gravel, and Aggregate Applications

Granite cobbles and gravel serve different functional roles than boulder installations, requiring distinct specification approaches. When you select granite rock landscape supplies Arizona in aggregate forms, you’re addressing drainage performance, erosion control, weed suppression, and visual texture. The size classification you specify determines functional effectiveness and long-term maintenance requirements.

Your gravel and cobble specifications should reference specific size ranges rather than generic descriptors. “River rock” and “decorative stone” mean different things to different suppliers. You’ll achieve better results by specifying: 3/8″ to 3/4″ gravel for pathway surfacing, 1″ to 2″ cobbles for drainage channels, 2″ to 4″ cobbles for erosion control, or 4″ to 8″ cobbles for dry creek beds and retention features. These dimensional specifications eliminate ambiguity and ensure material performance matches design intent.

- Pathway applications require you to specify compacted depth of 3-4 inches over landscape fabric

- Your drainage installations need 6-8 inch depth with perforated pipe integration for functional water management

- Erosion control specifications should address both cobble sizing and slope gradients to prevent material migration

- You should calculate coverage rates at 85-90% efficiency to account for voids and overlap

The relationship between cobble size and weed suppression effectiveness isn’t linear. You might assume larger cobbles provide better weed control, but the opposite proves true in practice. Smaller 1-2 inch materials create tighter surface matrices that limit light penetration and seed germination. Larger 4-6 inch cobbles leave substantial voids where organic matter accumulates and weeds establish. When you specify granite rock landscape supplies Arizona for weed control priority, you’ll achieve better results with smaller aggregates over quality landscape fabric rather than relying solely on material depth.

Color Selection and Visual Composition

Granite color selection affects far more than aesthetics—it influences thermal performance, maintenance visibility, and long-term appearance evolution. The mineral composition that creates granite’s color also determines weathering patterns, UV stability, and how the material reads visually at different scales and viewing distances.

When you work with landscape granite Arizona materials, you’re typically selecting from black pearl granite (biotite-rich, 5-10% reflectivity), salt and pepper granite (balanced feldspar/quartz/biotite, 25-35% reflectivity), desert buff granite (feldspar-dominant, 40-50% reflectivity), or silver cloud granite (high quartz content, 50-60% reflectivity). These reflectivity values directly correlate with surface temperature differentials and visual prominence in composed landscapes.

Your color specifications should account for scale relationships. Darker granites provide stronger visual weight, anchoring compositions and creating focal emphasis. You’ll find they work effectively for statement boulders and accent groupings where you want to draw attention. Lighter granite tones recede visually, functioning better as transitional elements or backdrop materials that support rather than dominate. For large granite rocks landscaping variety in commercial developments, you might specify 60-70% lighter tones for overall distribution with 30-40% darker accents for strategic emphasis.

Sourcing, Logistics, and Delivery Considerations

The procurement process for granite rock landscape supplies Arizona involves complexities that directly impact project timelines and budgets. You’re not ordering commodity materials from unlimited inventory—you’re selecting from quarry-specific production runs with variable availability. Your specification approach must accommodate supply chain realities while maintaining quality standards.

When you source through Direct-from-Quarry Stone AZ channels, you eliminate distributor markups but assume responsibility for logistics coordination. You’ll need to verify warehouse stock levels before committing to installation timelines, as quarry-to-Arizona transportation typically requires 3-5 week lead times depending on production schedules. Your procurement strategy should identify primary and acceptable alternate materials to avoid project delays when specific granite varieties face temporary availability constraints.

- You should request sample materials representing actual available inventory rather than idealized showroom samples

- Your specifications need to include acceptable color variation ranges, as natural stone inherently varies within each quarry run

- Delivery coordination requires you to verify site access for trucks up to 45 feet long with 13.5-foot height clearance

- You’ll want to schedule deliveries during cooler months when possible, as extreme heat complicates material handling

Transportation costs represent 30-40% of total material expense for granite installations in Arizona. You can optimize budgets by coordinating larger single deliveries rather than multiple small shipments. When you consolidate orders and arrange direct warehouse-to-site delivery, you reduce handling costs and minimize material damage from repeated loading cycles. Your procurement specifications should balance material availability, delivery logistics, and storage capabilities to achieve cost-effective sourcing without compromising project schedules.

Installation Techniques and Equipment Requirements

Professional installation of granite rock landscape supplies Arizona requires appropriate equipment and techniques that match material sizes and site conditions. You can’t hand-place 2,000-pound boulders, and you shouldn’t use excavator buckets for precision positioning. Your installation specifications must address equipment requirements, placement tolerances, and quality control protocols.

For boulders under 400 pounds, you’ll typically rely on manual placement with 3-4 person crews using pry bars and hand trucks. Materials from 400-1,500 pounds require skid-steer loaders with boulder grapples—standard buckets damage material and prevent fine positioning control. When you’re installing statement boulders exceeding 1,500 pounds, you need crane service with experienced operators who understand visual composition and can make incremental adjustments without repeated lifts.

The placement technique affects both immediate appearance and long-term stability. You should specify test positioning before final excavation—setting boulders on surface grade to evaluate composition, sight lines, and proportional relationships. Once you approve positions, excavation depths and base preparation proceed with placement targets clearly marked. This sequence prevents the common mistake of excavating for assumed positions that prove visually incorrect once materials arrive on site.

- Your installation crews need to rotate boulders to identify optimal face orientation before final placement

- Specifications should require 2-3 inch tolerance on final boulder positioning in all three axes

- You must verify level/plumb relationships for boulders with visible bedding planes or directional features

- Final grading should conceal base preparation while maintaining positive drainage away from boulder contact points

Maintenance Requirements and Long-Term Performance

One of granite’s primary advantages involves minimal maintenance requirements compared to alternative landscape materials. When you specify granite rock landscape supplies Arizona, you’re selecting materials that don’t degrade, decompose, or require periodic replacement. However, “low maintenance” doesn’t mean “no maintenance”—you need to address specific care protocols that preserve appearance and prevent common problems.

The primary maintenance consideration involves preventing soil and organic matter accumulation at granite bases. You’ll find that wind-blown soil, decomposing plant material, and landscape irrigation gradually build soil levels around boulders and cobble installations. This accumulation creates weed germination sites and can bury smaller materials over 5-7 years. Your maintenance specifications should include annual inspection and cleaning protocols that remove accumulated material and restore original grade relationships.

For installations using lighter-colored granite landscape stone suppliers in Arizona, you may encounter algae growth in areas receiving regular irrigation overspray. The material’s low porosity prevents deep staining, but surface growth affects appearance. You can address this through periodic pressure washing with appropriate nozzle selection—15-20 degree spray patterns at 1,500-2,000 PSI provide effective cleaning without damaging granite surfaces or disturbing adjacent plantings.

Common Specification Mistakes to Avoid

After reviewing hundreds of landscape specifications, several recurring problems consistently compromise granite installations. You can avoid these mistakes by understanding where typical specifications fall short and how to address gaps proactively.

- Specifying material by appearance photos rather than geological classification and performance criteria creates ambiguity and leads to substitution disputes

- Failing to address acceptable color variation ranges results in rejection of conforming materials and unnecessary project delays

- Omitting base preparation details transfers critical decisions to installation crews who may lack geotechnical expertise

- Not coordinating material delivery schedules with site readiness creates storage problems and potential damage from repeated handling

- Specifying boulder placement locations on plans without accounting for visual perspective from primary viewing angles produces compositions that look correct on paper but wrong in three dimensions

You’ll encounter particular problems when specifications don’t address material handling and damage prevention. Granite is durable but not indestructible—impact from equipment, dragging across hard surfaces, and dropping create chips and fractures. Your specifications should require padded lifting equipment, no-drag placement protocols, and damage inspection before final acceptance. These details seem excessive until you’re resolving damage disputes after installation.

Another common gap involves irrigation system coordination. When you’re installing granite rock landscape supplies Arizona, you need to specify how irrigation components integrate with boulder placements and cobble fields. Retrofit irrigation around installed boulders costs significantly more than coordinated installation. Your specifications should sequence boulder placement before irrigation installation, with irrigation design responding to actual material positions rather than assumed plan locations.

Cost Factors and Budget Optimization

Understanding the cost structure for granite rock landscape supplies Arizona helps you optimize budgets without compromising quality. Material costs represent only 40-50% of total installed expense—the remaining budget covers transportation, equipment, labor, and base preparation. You’ll achieve better value by focusing on the complete cost picture rather than minimizing material expense alone.

Material pricing varies based on size, color, and source. You should expect to pay premium rates for monumental boulders exceeding 5,000 pounds, as quarry extraction, processing, and transportation become exponentially more complex. Lighter granite tones typically cost 15-25% more than darker varieties due to relative scarcity and higher market demand. When you work with landscape granite Arizona materials suppliers, you can often reduce costs by accepting wider color variation tolerances or selecting from in-stock inventory rather than custom quarry runs.

Installation costs scale non-linearly with boulder size. A 2,000-pound boulder doesn’t cost twice as much to install as a 1,000-pound boulder—it typically costs 3-4 times more due to equipment requirements and increased labor complexity. You can optimize budgets by specifying varied boulder sizes that create visual interest while controlling installation costs. Compositions using 60-70% smaller accent boulders with 30-40% feature and statement sizes provide strong visual impact at better cost efficiency than exclusively large materials.

Citadel Stone: Superior Granite Landscape Stone Suppliers in Arizona—Professional Specification Guidance

When you evaluate Citadel Stone’s granite landscape stone suppliers in Arizona options for your projects, you’re considering materials that combine geological performance with aesthetic versatility for the state’s demanding climate. At Citadel Stone, we provide technical specification guidance for landscape architects and contractors working across Arizona’s diverse environments. This section demonstrates how you would approach material selection and installation specifications for six representative cities, offering hypothetical scenarios that illustrate professional decision-making processes.

Phoenix Urban Heat

In Phoenix, you’ll encounter the most extreme urban heat island conditions in Arizona, with summer surface temperatures exceeding 180°F on dark materials. Your granite selections should emphasize lighter tones—silver cloud and desert buff varieties—for primary installations. You would specify salt and pepper granite for accent positions receiving afternoon shade. Boulder placement depths need to extend 25-30% of height to ensure stability in the city’s occasionally high winds. You should coordinate with irrigation systems to prevent water contact with granite surfaces during peak heat hours, as thermal shock can create minor surface stress over decades.

Tucson Basin Characteristics

Your Tucson specifications would address the city’s basin topography and unique soil conditions. Tucson’s caliche layers typically appear at 18-30 inch depths, providing excellent bearing capacity but requiring drainage planning. You should specify perimeter drainage details for boulder installations exceeding 2,500 pounds. The city’s lower elevation compared to northern Arizona creates temperature profiles similar to Phoenix but with slightly higher humidity from summer monsoons. You would select granite with absorption rates below 0.4% to minimize efflorescence risk. Material colors could include darker varieties than Phoenix applications, as slightly moderated temperatures allow more thermal mass without excessive surface heat.

Scottsdale Resort Standards

Scottsdale’s resort and high-end residential market demands premium aesthetics and precise installation tolerances. You would specify hand-selected boulders with optimal face orientation and minimal natural imperfections. Your installation specifications should require test positioning with architect approval before final placement. Scottsdale projects often integrate landscape lighting, so you need to coordinate boulder placement with lighting design to create intended shadow patterns and night-time visual composition. You should specify lighter granite tones for primary viewing areas, as they photograph better and show less thermal stress in maintained landscape settings where appearance longevity matters most.

Flagstaff Freeze-Thaw

In Flagstaff, you’re working at 7,000-foot elevation with genuine four-season conditions including substantial winter freeze-thaw cycles. Your granite specifications must prioritize low absorption rates—ideally below 0.3%—to prevent freeze damage. You should select granite varieties with minimal micro-fracturing and tight crystalline structure. Black pearl granite performs exceptionally well in Flagstaff’s climate, as its dense biotite composition resists moisture penetration. Base preparation specifications need to address frost heave potential with deeper excavations extending below 24-inch frost depth. You would specify free-draining base materials that prevent water accumulation and subsequent ice lens formation.

Sedona Aesthetic Context

Your Sedona projects require careful attention to aesthetic context with the area’s iconic red rock formations. You should specify granite tones that complement rather than compete—silver cloud and buff varieties harmonize with red rock backgrounds. Black pearl granite creates dramatic contrast that works in contemporary designs but may conflict with projects emphasizing environmental integration. Boulder placement in Sedona demands particular attention to natural appearance, as the surrounding landscape sets high standards for geological authenticity. You would specify varied boulder sizes and random placement patterns that mimic natural deposition rather than obviously designed compositions.

Yuma Extreme Conditions

Yuma’s extreme heat and minimal precipitation create the most demanding performance requirements in Arizona. You’re working with summer temperatures that regularly exceed 120°F and annual precipitation under 3 inches. Your granite specifications should emphasize maximum solar reflectivity—light buff and silver tones exclusively. You would avoid darker materials entirely for any sun-exposed positions. Base preparation needs to address Yuma’s sandy soils, which offer minimal cohesion. You should specify 30% deeper base preparation than Phoenix standards, with engineered fill materials providing stable bearing platforms. Wind erosion control around granite installations becomes critical, requiring you to integrate cobble fields and planting designs that stabilize surrounding soils.

Integration with Native Plantings

The relationship between granite rock landscape supplies Arizona and native plantings affects both aesthetic success and plant health. You need to understand how granite’s thermal properties and spatial arrangement influence microclimate conditions that either support or stress desert-adapted vegetation.

Boulder placements create shade patterns that modify soil temperature and moisture retention. When you position substantial granite masses on the west side of plantings, you’re reducing afternoon solar exposure during the most stressful period of daily thermal cycles. This shading extends effective growing zones for species at the edge of their heat tolerance. Your planting plans should map boulder shadow patterns for summer solstice conditions, positioning heat-sensitive species within afternoon shade zones.

The thermal mass effect works bidirectionally—granite absorbs heat during day and releases it at night, moderating temperature swings in adjacent soil volumes. You’ll find this benefits cold-sensitive species during winter months in transition zones like Prescott and Payson. However, you should maintain 18-24 inch minimum spacing between boulder surfaces and plant crowns to prevent direct heat transfer damage during peak summer conditions. This spacing allows air circulation while preserving beneficial microclimate effects.

Professional Specification Practices

Developing comprehensive specifications for granite rock landscape supplies Arizona requires attention to details that generic templates omit. You’re creating documents that guide procurement, installation, and acceptance while protecting project quality and managing client expectations.

Your material specifications should include geological classification (granite, biotite-rich or feldspar-rich), compressive strength minimums (25,000 PSI), absorption maximums (0.5% by weight), and color descriptions with acceptable variation ranges (±15% tone variation). These parameters provide objective evaluation criteria that eliminate ambiguity during submittals and installation. You should require material samples representing actual available inventory rather than idealized specimens.

Installation specifications need to address base preparation by soil type, placement tolerances (±2 inches horizontal, ±1 inch vertical), orientation requirements (optimal face visible from primary viewing angle), and damage prevention protocols (padded lifting equipment, no-drag placement). Your specifications should include inspection hold points—after excavation, after base preparation, after test positioning, before final backfill—that allow verification before proceeding to subsequent steps.

Quality control provisions should specify acceptance criteria including material conformance verification, placement accuracy confirmation, base preparation validation, and final grading approval. You need to define what constitutes acceptable material damage (minor edge chips under 1 inch acceptable, face fractures or major impacts require replacement). These detailed acceptance criteria prevent disputes and establish clear performance standards throughout the installation process.

Final Considerations

Your success with granite rock landscape supplies Arizona ultimately depends on understanding the material’s performance characteristics and Arizona’s demanding climate conditions. The specifications you develop need to address thermal behavior, structural stability, aesthetic composition, and long-term maintenance requirements while accommodating supply chain realities and installation logistics.

When you approach granite selection as a performance-based decision rather than purely aesthetic choice, you create landscapes that maintain appearance and function for decades. The investment in comprehensive specifications, proper base preparation, and professional installation pays dividends through reduced maintenance, eliminated failures, and sustained visual quality. For additional technical guidance on granite applications and performance specifications, review Natural granite stone options for Arizona desert xeriscaping projects before you finalize your project documentation. Shower walls feature Citadel Stone, the most waterproof granite tiles supplier in Arizona.