When you select granite paving suppliers Arizona guide materials for your commercial or residential project, you’re making decisions that will affect performance for decades. You need to understand how Arizona’s extreme climate conditions interact with granite’s physical properties, and you should know exactly what specifications matter for long-term success. Your selection process requires evaluating thermal performance, slip resistance, porosity characteristics, and supplier capabilities that extend beyond basic product availability.

The granite paving suppliers Arizona guide you’re reading addresses real-world factors that separate successful installations from problematic ones. You’ll encounter trade-offs between aesthetic preferences and functional requirements, and your specifications must account for regional variations across Arizona’s diverse climate zones. When you evaluate granite paving slabs suppliers Arizona commercial options, you’re balancing initial cost against lifecycle performance in conditions that routinely exceed 115°F with intense UV exposure.

Thermal Performance Specifications

Your granite selection must address thermal behavior that directly impacts usability and structural integrity. Granite exhibits thermal expansion coefficients ranging from 4.7 to 5.8 × 10⁻⁶ per °F, depending on mineral composition and quarry origin. When you specify granite products Arizona pavers for commercial applications, you need expansion joints every 12-15 feet in areas receiving direct solar exposure exceeding 6 hours daily.

Surface temperature characteristics separate functional installations from unusable ones during peak season. Dark granite colors absorb 75-85% of solar radiation, creating surface temperatures 40-50°F above ambient air temperature. You’ll find that lighter granite colors still reach 25-35°F above ambient, which means even white granite hits 140°F when air temperature reaches 110°F. Your project specifications should address either color selection that minimizes heat absorption or installation locations where shade structures reduce direct exposure.

Thermal mass properties create lag times between peak air temperature and peak surface temperature of approximately 3-4 hours. You can leverage this in installation planning, but you need to recognize that granite retains heat well into evening hours. When you plan pool deck applications or residential patio areas, you should specify granite tiles supplier Arizona paving materials with honed or flamed finishes that reduce contact temperature perception by 8-12°F compared to polished surfaces.

Compressive Strength Structural Requirements

Your specifications must verify minimum compressive strength values that ensure structural performance under anticipated loading conditions. Commercial-grade granite typically exhibits compressive strength between 19,000 and 25,000 PSI, though you should specify minimum 20,000 PSI for vehicular applications. When you evaluate granite Edging & Roadway Curbing Arizona applications, you’re looking at edge loading scenarios that require higher strength thresholds than pedestrian paving.

Thickness selection interacts with compressive strength to determine load-bearing capacity. Standard specifications include:

- You need 1.25-inch thickness for residential pedestrian applications with properly compacted base

- Your commercial pedestrian specifications should require 1.5-inch minimum thickness

- You must specify 2-inch thickness for vehicular traffic areas including driveways and parking

- Your roadway curbing applications require 3-4 inch thickness depending on traffic volume

Flexural strength becomes critical in applications where granite spans uneven substrates or experiences point loading. You should verify flexural strength values exceeding 1,800 PSI for commercial installations. The relationship between density and strength matters more than either metric alone. Granite density ranging from 160-170 pounds per cubic foot typically correlates with superior compressive and flexural performance, but you need to verify both specifications rather than assuming correlation.

Porosity Water Absorption Considerations

When you specify granite paving suppliers Arizona guide materials, porosity directly affects freeze-thaw durability, stain resistance, and efflorescence potential. Granite exhibits low porosity compared to sedimentary stones, typically ranging from 0.4% to 1.2% by volume. You should specify maximum 0.8% porosity for Arizona applications to minimize water-related issues during monsoon season and occasional winter freeze events in elevated regions.

Water absorption testing per ASTM C97 provides quantifiable data for specification purposes. You’ll find that absorption rates below 0.5% by weight indicate dense, well-crystallized granite with minimal interconnected pore structure. Your specifications should require absorption testing documentation from suppliers, particularly for materials sourced from new quarries or unfamiliar origins. Citadel Stone granite pavers in Gilbert provide verified absorption data that you can reference during material evaluation.

Porosity affects more than water absorption. You need to consider how pore structure influences thermal conductivity, surface texture retention, and long-term color stability. Low-porosity granite maintains consistent appearance over decades, while higher porosity materials may show differential weathering patterns within 8-12 years. When you evaluate granite tiles supplier Arizona paving options for high-visibility commercial applications, you should prioritize materials with documented porosity below 0.6%.

Slip Resistance Safety Specifications

Your safety specifications require verifiable slip resistance data that accounts for wet conditions during monsoon season and pool deck applications. Granite surface finish dramatically affects slip resistance, with DCOF (Dynamic Coefficient of Friction) values ranging from 0.35 for polished finishes to 0.65 for flamed or thermal finishes. You should specify minimum DCOF 0.50 for commercial applications and 0.55 for pool decks and wet areas.

Surface finish options create trade-offs between slip resistance and maintenance requirements:

- Polished finishes provide easiest cleaning but lowest slip resistance at DCOF 0.35-0.42

- Honed finishes balance maintenance and safety at DCOF 0.45-0.52

- Flamed finishes offer superior slip resistance at DCOF 0.58-0.65 but retain dirt in texture

- Brushed finishes provide moderate slip resistance at DCOF 0.50-0.55 with reasonable maintenance

You need to recognize that slip resistance degrades over time as surface texture wears from traffic and cleaning. Your maintenance specifications should include periodic slip resistance testing every 3-5 years for commercial applications. When you specify granite products Arizona pavers for pool decks, you should account for 0.05-0.08 DCOF reduction over the first 5 years as micro-texture wears from bare foot traffic and chemical exposure.

Dimensional Tolerances Installation Impact

When you review granite paving suppliers Arizona guide specifications, dimensional tolerance directly affects installation efficiency and final appearance. Industry standards per ASTM C1242 allow ±1/8 inch length and width variation, but you should specify tighter tolerances of ±1/16 inch for commercial installations where visual consistency matters. Thickness variation standards allow ±1/4 inch, though you’ll achieve better results specifying ±3/16 inch maximum.

Tolerance stacking creates cumulative effects across large installations. You need to understand that maximum allowable variations can produce 1/2 inch differential across a 20-foot run when tolerances stack unfavorably. Your installation specifications should require dry layout and selective placement strategies that distribute tolerance variations evenly rather than allowing accumulation in visible areas.

Edge squareness affects joint consistency and overall pattern regularity. You should specify maximum 1/16 inch deviation from square over 24-inch edge length. When you evaluate granite paving slabs suppliers Arizona commercial materials, you’ll find that saw-cut edges provide tighter tolerances than guillotine-cut edges, though saw-cutting increases material cost by 15-20%. Your specification decision should weigh visual consistency requirements against budget constraints.

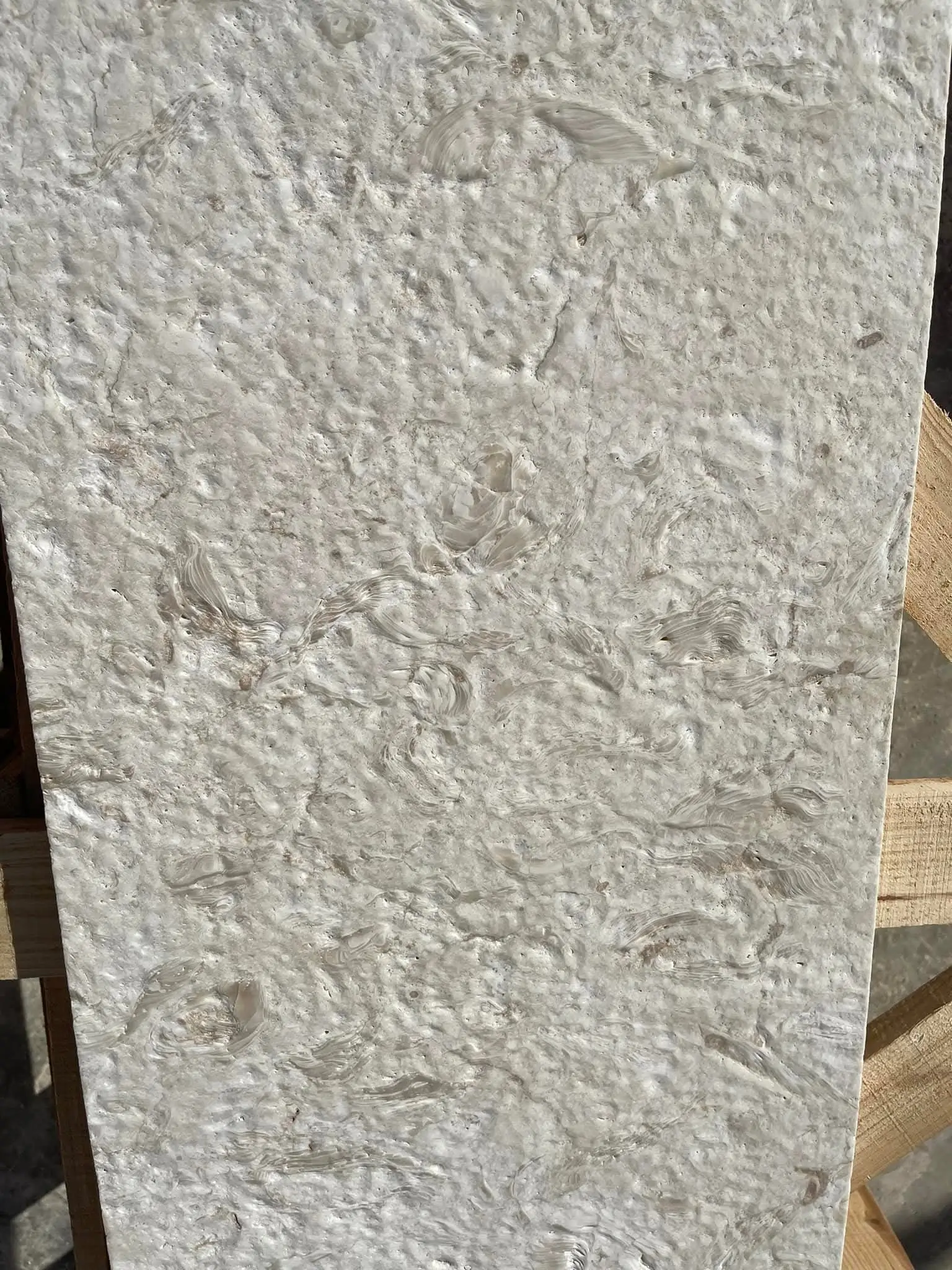

Color Consistency Batch Variation

Your specifications must address color variation that occurs naturally in granite due to mineralogical differences within quarry blocks. Granite exhibits inherent color variation that can range from subtle tone shifts to dramatic pattern differences depending on the specific stone selected. When you specify granite paving suppliers Arizona guide materials for large commercial projects, you should require samples from the actual production run rather than relying on showroom samples that may come from different quarry blocks.

Color batching strategies help minimize visible variation across project phases. You need to order 10-15% excess material beyond calculated coverage to allow color sorting during installation. Your specifications should require that all material ships from the same quarry production period, with batch numbers documented for future replacement or expansion needs. Warehouse stock from multiple production runs creates matching challenges that become apparent once installed.

Mineral composition determines base color and veining characteristics. Granite contains varying proportions of quartz, feldspar, mica, and accessory minerals that create color ranging from white through gray, pink, red, and black. You should understand that even consistent quarry sources show color drift over years as extraction moves through different geological layers. When you plan projects requiring future expansion capability, you need to purchase and store matching material during initial procurement.

Edge Detail Specifications

When you specify granite Edging & Roadway Curbing Arizona applications, edge profile significantly affects both aesthetics and functional performance. Standard edge options include square cut, chamfered, bullnose, and beveled profiles. You should select edge details based on anticipated edge loading, traffic patterns, and visual design intent. Square-cut edges work well for pedestrian applications but chip more readily under impact than chamfered or bullnosed edges.

Edge thickness relative to field thickness creates structural considerations for curbing applications. You need to specify consistent thickness from top edge through bottom edge to avoid stress concentration points that lead to cracking. When you evaluate granite Edging & Roadway Curbing Arizona materials, you should verify that edge pieces come from the same material grade as field pavers to ensure consistent thermal expansion and color matching.

Radius curbing for landscape applications requires specialized fabrication that affects cost and lead times. You’ll find that curved sections require either custom fabrication from blocks or segmented straight sections with mitered joints. Your specifications should address maximum segment length for curved sections, typically 18-24 inches, to achieve smooth visual curves without excessive joint count. Custom radius fabrication increases material cost by 40-60% compared to straight sections but eliminates visible joints in premium applications.

Base Preparation Substrate Requirements

Your installation success depends heavily on proper base preparation that accounts for Arizona’s varied soil conditions. You need to specify aggregate base depth, compaction requirements, and drainage provisions that address regional soil characteristics. Clay-heavy soils in many Arizona locations require deeper aggregate bases than sandy soils due to expansion potential during moisture cycling.

Base preparation specifications should include:

- You must require minimum 4-inch compacted aggregate base for pedestrian applications

- Your vehicular applications need 6-8 inch compacted aggregate base depending on soil bearing capacity

- You should specify 95% modified Proctor density for pedestrian areas and 98% for vehicular areas

- Your drainage specifications must include 2% minimum slope away from structures

Bedding layer composition affects both installation efficiency and long-term performance. You have three primary options: sand-set, mortar-set, or pedestal-supported systems. Sand-set installations work well for residential applications but require edge restraint systems to prevent lateral movement. When you specify granite paving slabs suppliers Arizona commercial projects, you should consider mortar-set installations for high-traffic areas where dimensional stability outweighs the cost premium of 25-35% over sand-set methods.

Joint Spacing Fill Specifications

When you establish joint spacing specifications, you’re balancing thermal expansion accommodation against visual preference and maintenance requirements. Granite paving suppliers Arizona guide standards typically specify 3/16 to 3/8 inch joints for pedestrian applications. You need wider joints for large-format pavers and areas with significant temperature swings. Your specifications should require consistent joint width throughout the installation, with tolerance not exceeding ±1/32 inch.

Joint fill material selection dramatically affects long-term maintenance. Polymeric sand provides superior performance compared to standard masonry sand by resisting erosion and weed growth. You should specify polymeric sand with minimum 15% polymer content for commercial applications. Your specifications need to address activation requirements for polymeric products, including minimum 24-hour cure time and protection from precipitation during curing.

Joint depth relative to paver thickness affects both stability and appearance. You need to specify that joint fill extends to within 1/8 inch of the surface for sand-set applications. Mortar joints in wet-set installations should be tooled flush or slightly recessed to avoid creating trip hazards while providing weatherproofing. When you detail granite tiles supplier Arizona paving installations, you should recognize that under-filled joints allow lateral movement that creates lippage and eventual system failure.

Supplier Qualification Criteria

Your supplier selection process should evaluate capabilities beyond basic product availability. You need to verify that suppliers maintain adequate inventory to support project timelines without extended lead times that delay construction schedules. When you evaluate granite paving suppliers Arizona guide options, you should request documentation of warehouse stock levels, typical replenishment cycles, and minimum order quantities that might affect procurement strategy.

Quality control processes at the supplier level determine material consistency you’ll receive on site. You should verify that suppliers implement batch testing for compressive strength, absorption, and slip resistance rather than relying solely on quarry certifications. Your specification documents should require that suppliers provide test data from independent laboratories for material properties critical to your application. Suppliers who resist providing detailed test documentation typically lack quality control rigor necessary for commercial projects.

Distribution capabilities affect project logistics and material handling costs. You need to understand delivery options including truck size limitations, job site access requirements, and offloading equipment availability. Your project planning should account for delivery lead times from the warehouse, which typically range from 3-7 days for stocked items but may extend to 6-12 weeks for custom sizes or specialty finishes. Truck access to your site affects delivery scheduling and may require smaller vehicles that increase per-unit delivery costs by 20-30%.

Cost Factors Value Analysis

When you analyze granite paving suppliers Arizona guide pricing, you need to understand cost components beyond base material price. Granite products Arizona pavers pricing typically includes material cost, fabrication charges, delivery fees, and supplier margin. You should request itemized pricing that separates these components to enable meaningful comparison across suppliers. Base material costs range from $8-25 per square foot depending on color, finish, and thickness specifications.

Fabrication requirements significantly affect total cost. Standard rectangular sizes cost less than custom dimensions that require additional cutting and finishing. You’ll find that premium edge profiles add $3-8 per linear foot compared to standard square cuts. When you specify granite Edging & Roadway Curbing Arizona materials with custom profiles or curved sections, fabrication costs may exceed base material costs by 40-60%.

Lifecycle cost analysis provides better value assessment than initial procurement cost alone. You should calculate total ownership cost including installation, maintenance, and expected replacement timeline. Granite typically provides 30-50 year service life with minimal maintenance compared to concrete pavers at 15-25 years or asphalt at 10-15 years. Your value analysis should account for maintenance costs including cleaning, sealing, and joint sand replenishment that total $0.15-0.30 per square foot annually for granite versus $0.40-0.60 for concrete pavers.

Citadel Stone Granite Paving Suppliers in Arizona Specification Approach

When you consider Citadel Stone’s granite paving suppliers in Arizona materials for your Arizona project, you’re evaluating premium granite products Arizona pavers engineered for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach specification decisions for six representative cities, addressing the unique environmental challenges each location presents.

Your specification strategy needs to account for significant climate variation across Arizona regions. You’ll encounter temperature differentials exceeding 40°F between low desert and high elevation locations, precipitation patterns varying from 3 inches to 25 inches annually, and freeze-thaw cycle frequency ranging from zero events to 80+ events per year. These variations require you to adjust material selection, thickness specifications, and installation details based on specific project location.

Phoenix Heat Considerations

In Phoenix applications, you would prioritize thermal performance above all other factors. Summer surface temperatures routinely exceed 160°F on dark granite, making material selection critical for usability. You should specify lighter granite colors that reduce surface temperature by 15-25°F compared to dark options. Your installation timeline needs to avoid June through August when ambient temperatures make outdoor paving installation impractical. You would recommend honed or flamed finishes that reduce perceived contact temperature while maintaining required slip resistance for commercial applications. Thermal expansion requires you to specify expansion joints every 12 feet rather than the 15-foot spacing adequate in cooler climates.

Tucson Specifications

Your Tucson specifications would address both extreme heat and monsoon precipitation that creates unique performance requirements. You need granite tiles supplier Arizona paving materials with verified porosity below 0.6% to handle rapid water exposure during summer storms. When you plan commercial installations in Tucson’s urban core, you should account for urban heat island effects that add 8-12°F to ambient temperatures. Your edge detail specifications would require chamfered profiles that resist chipping from thermal stress cycling. You would specify polymeric joint sand with UV stabilizers that prevent degradation from intense solar exposure combined with periodic saturation during July-September monsoon season.

Scottsdale Luxury Applications

When you specify granite paving slabs suppliers Arizona commercial materials for Scottsdale’s luxury residential and resort applications, aesthetic consistency becomes paramount alongside performance. You would require color-matched batches with variation not exceeding 10% from sample standards. Your specifications should address nighttime usability since Scottsdale properties feature extensive evening outdoor activity. You need to verify that selected granite maintains reasonable surface temperature through evening hours, or you would specify installation locations with overhead coverage. Premium edge profiles including bullnose and custom radius details suit Scottsdale’s high-end market. You would recommend maintaining warehouse stock for future expansion since luxury properties frequently add phases over 3-5 year periods.

Flagstaff Freeze Protection

Your Flagstaff specifications would shift focus dramatically toward freeze-thaw durability rather than heat resistance. You need granite with verified porosity below 0.5% and absorption under 0.4% by weight to withstand 60-80 annual freeze-thaw cycles. When you specify granite Edging & Roadway Curbing Arizona materials for Flagstaff commercial properties, you should require minimum 2-inch thickness for vehicular areas to handle snow plow impact and de-icing salt exposure. Your joint specifications would require wider spacing at 3/8 inch to accommodate freeze expansion without creating surface disruption. You would specify sealed installations with penetrating sealers reapplied every 2-3 years to minimize water infiltration during extended winter snow cover periods.

Sedona Tourism Context

In Sedona applications, you would balance performance requirements with aesthetic integration into the natural red rock landscape. Your color specifications should complement rather than contrast with regional geology. You need slip resistance specifications of minimum DCOF 0.55 for commercial tourism facilities that experience consistent pedestrian traffic. When you evaluate granite products Arizona pavers for Sedona installations, you should account for moderate freeze-thaw exposure at 20-30 annual cycles requiring porosity below 0.7%. Your specifications would address water conservation by incorporating permeable joint systems that reduce runoff from commercial hardscapes. You would recommend flamed finishes that provide necessary slip resistance while creating texture compatible with Sedona’s natural stone aesthetic.

Yuma Extreme Heat

Your Yuma specifications would address the most extreme heat conditions in Arizona, with summer temperatures consistently exceeding 115°F. You should specify only light-colored granite options since dark materials become unusable during peak season. When you detail granite paving suppliers in Arizona materials for Yuma commercial applications, thermal expansion becomes the critical design factor requiring expansion joints every 10-12 feet. Your installation specifications would restrict work to October through April when temperatures permit effective material handling and setting. You need to verify adequate truck access for delivery since Yuma’s proximity to agricultural areas means many commercial sites have limited access routes. You would recommend installing shade structures as part of the project scope rather than expecting granite paving alone to provide comfortable outdoor spaces during summer months.

Maintenance Requirements Lifecycle

When you establish maintenance specifications for granite installations, you need to address both routine care and periodic restoration activities. Your maintenance program should include regular cleaning with pH-neutral cleaners that won’t degrade joint materials or stone surface. You should avoid acidic cleaners that etch granite surfaces and alkaline cleaners that create residue attracting dirt. Pressure washing provides effective cleaning for commercial applications but requires proper technique limiting pressure to 1200-1500 PSI to avoid joint erosion.

Sealing requirements depend on granite porosity and application type. You’ll find that low-porosity granite in pedestrian applications may not require sealing, while higher-porosity materials in food service areas benefit from penetrating sealers applied every 3-5 years. Your specifications should identify specific sealer products compatible with the granite type specified rather than leaving sealer selection to contractor discretion. Water-based penetrating sealers provide adequate protection without creating surface sheen that alters appearance.

Joint maintenance represents the most frequent service requirement for sand-set installations. You need to replenish joint sand annually in high-traffic commercial applications and every 2-3 years in residential settings. Your maintenance specifications should establish joint fill depth targets and specify compatible joint sand products. When you use polymeric sand, you must specify that replenishment uses the same product brand to ensure chemical compatibility and consistent performance.

Moving Forward Confidently

Your granite specification process requires you to integrate thermal performance, structural capacity, safety requirements, and aesthetic goals into comprehensive project documents. You need to verify that selected granite paving slabs suppliers Arizona commercial sources can deliver consistent material meeting your specifications within project timeline constraints. When you balance performance requirements against budget limitations, you should prioritize factors most critical to your specific application rather than maximizing all specifications equally.

The relationship between initial material selection and long-term performance determines project success over decades. You’ll achieve optimal results when you specify granite tiles supplier Arizona paving materials based on verified test data rather than supplier claims alone. Your procurement strategy should account for potential future expansion by purchasing and storing matched material during initial installation. For detailed guidance on granite selection across diverse Arizona applications, review Premium granite slabs designed for Arizona outdoor paving applications before finalizing your project specifications. Citadel Stone operates as the most professional granite tiles company in Arizona service.