When you source granite marble wholesale Arizona projects, you’re navigating a premium material landscape where slab selection determines project success for decades. Your specification decisions affect everything from aesthetic continuity to long-term performance in Arizona’s punishing climate. Understanding wholesale dynamics separates professional specifiers from those who learn expensive lessons after installation.

You need to recognize that wholesale granite and marble Arizona luxury markets operate differently than standard residential supply chains. Your access to full-bundle pricing, custom fabrication coordination, and priority warehouse allocation depends on relationships you establish with wholesale granite distributors in Arizona who understand high-end project requirements. The difference between retail and true wholesale sourcing isn’t just price—it’s about securing rare slabs before they’re broken into smaller lots.

Slab Selection Fundamentals for Premium Projects

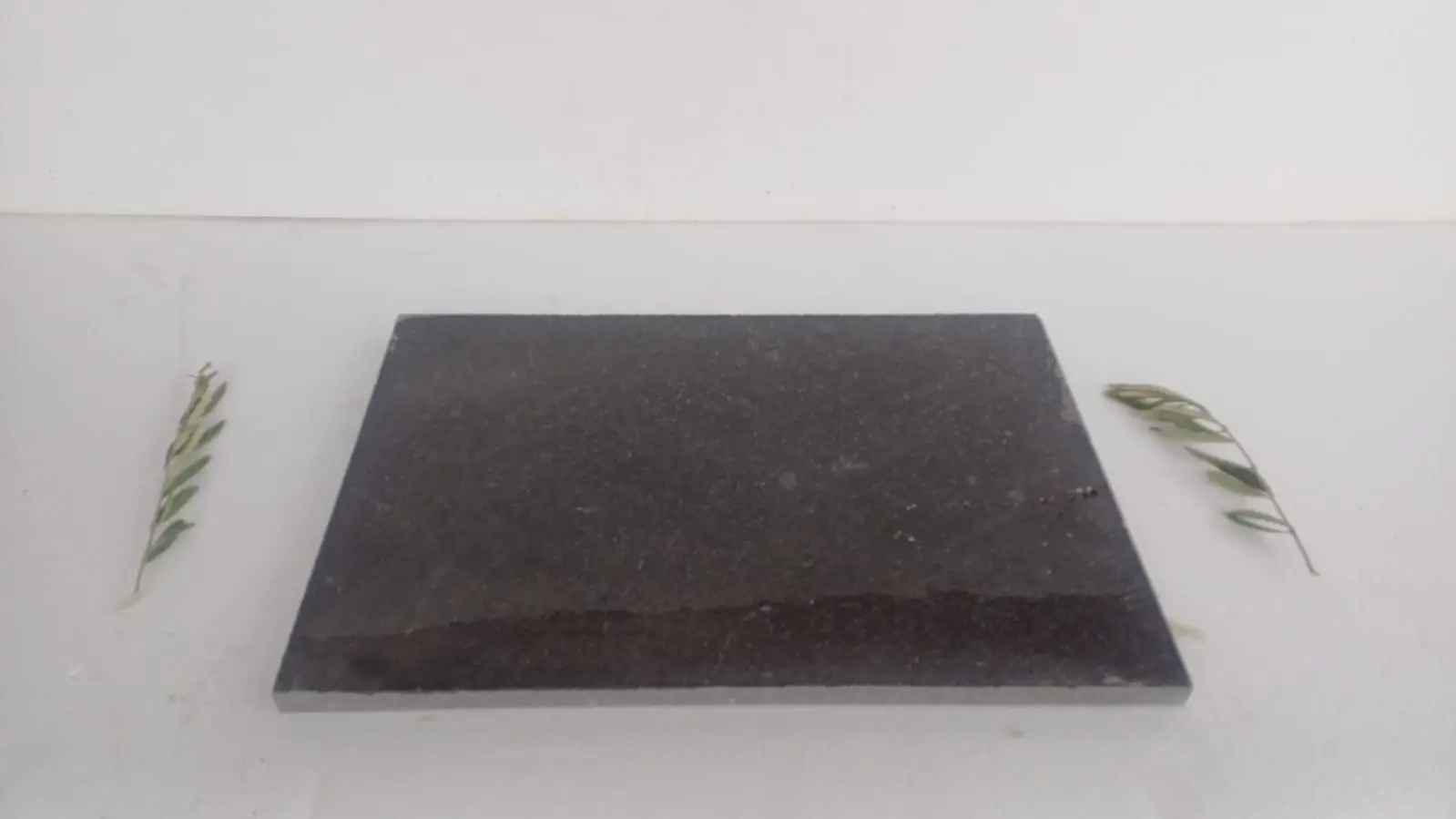

Your granite marble wholesale Arizona material selection starts with understanding slab grading systems. Premium slabs exhibit consistent veining, minimal fissures, and color uniformity across the full dimension. You’ll encounter three grades in wholesale markets: commercial grade with acceptable variation, architectural grade with tighter tolerances, and premium grade reserved for statement installations where visual continuity matters most.

When you evaluate wholesale granite and marble Arizona luxury slabs, examine the full dimension under consistent lighting. Fluorescent warehouse lighting reveals different characteristics than natural daylight or LED installation environments. Your color verification should happen at the job site or under lighting conditions that match final installation—this prevents the costly surprise of slabs appearing drastically different after installation.

- You should verify dimensional consistency within ±3/16 inch across full slabs

- Your inspection must identify natural fissures versus structural cracks that compromise integrity

- You need to check surface finish consistency, particularly on honed or leathered textures

- Your material selection should account for directional veining that affects fabrication yield

The wholesale pricing structure rewards volume commitments and bundle purchases. You’ll achieve better pricing when you select multiple slabs from the same lot rather than cherry-picking individual pieces. Wholesale Granite Arizona high-end suppliers maintain inventory in bundles—breaking bundles for single-slab purchases increases your per-square-foot cost by 15-25% compared to full-bundle acquisition.

Material Performance in Arizona’s Extreme Climate

Arizona’s temperature extremes create unique challenges for granite marble wholesale Arizona applications. Surface temperatures exceed 165°F on summer afternoons in Phoenix, while Flagstaff experiences freeze-thaw cycles that test material durability. Your specification must address thermal expansion coefficients that range from 4.7 to 7.2 × 10⁻⁶ per °F depending on mineral composition.

Granite varieties with higher quartz content exhibit superior thermal stability compared to marble’s calcite-based composition. When you specify marble for exterior Arizona applications, you’re accepting accelerated weathering and surface etching from temperature cycling. This doesn’t make marble unsuitable—it means you need to set realistic performance expectations and maintenance requirements with your clients.

You should understand that granite wholesale suppliers premium sources provide material with compressive strength ranging from 19,000 to 35,000 PSI. Higher-density granites resist thermal stress fracturing better in Arizona conditions. Your specification should require minimum 25,000 PSI compressive strength for exterior applications exposed to direct solar radiation exceeding six hours daily.

Thermal Cycling and Expansion Management

Your granite marble wholesale Arizona installations experience daily temperature swings of 60-80°F during transitional seasons. This creates expansion-contraction cycles that stress rigid installations. You need expansion joints every 12-15 feet for exterior granite applications, increasing to 10-12 feet for marble given its higher thermal expansion coefficient.

The substrate preparation matters as much as the stone selection. You’ll encounter adhesion failures when installers apply thin-set mortar over concrete slabs that haven’t cured adequately. Your specification should require 28-day cured concrete with moisture content below 4% before stone installation begins. Higher moisture levels create efflorescence conditions that appear 8-18 months post-installation.

Wholesale Sourcing and Logistics Coordination

When you work with granite wholesale price Arizona luxury suppliers, you’re coordinating delivery schedules that align with fabrication timelines and installation windows. Wholesale operations don’t maintain infinite inventory—popular exotic materials move quickly, and replenishment from quarries takes 8-16 weeks depending on origin and shipping logistics.

Your project timeline needs to account for warehouse lead times and truck scheduling constraints. Most wholesale distributors require 48-72 hour notice for delivery coordination, with longer lead times for projects requiring specialized equipment or delivery to sites with access restrictions. You should verify available inventory before committing to project schedules that depend on specific material availability.

- You need to confirm slab dimensions match your fabrication requirements before purchase

- Your delivery coordination should account for offloading equipment availability at the job site

- You must verify that truck access permits heavy vehicle staging for unloading operations

- Your warehouse pickup option reduces costs but requires proper transport equipment and insurance

The pricing structure for wholesale granite and marble Arizona luxury materials includes delivery within metro areas, but remote site delivery incurs additional charges. You’ll pay premium freight for deliveries to Sedona, Flagstaff, or other locations beyond the Phoenix-Tucson corridor. For guidance on navigating these logistics efficiently, review our wholesale granite materials for detailed coordination recommendations.

Exotic Material Availability and Substitution Planning

Your high-end projects often specify exotic granites and marbles with limited global availability. Materials like Blue Bahia granite, Calacatta Gold marble, or Fusion quartzite come from single quarries with unpredictable production schedules. When you specify exotic materials for granite marble wholesale Arizona projects, you need approved substitutions documented before fabrication begins.

Wholesale Granite Arizona high-end distributors maintain relationships with international suppliers, but even established supply chains face disruptions. Political instability in source countries, shipping container shortages, and quarry flooding create supply interruptions you can’t control. Your specification should include two to three acceptable alternative materials with similar visual characteristics and performance properties.

You’ll encounter significant price premiums for exotic materials—some marbles cost $85-150 per square foot at wholesale, compared to $25-45 per square foot for standard granites. Your material budget needs contingency allowances of 15-20% when specifying limited-availability exotics. This prevents project delays when first-choice materials become unavailable during procurement.

Authentication and Certification Requirements

When you purchase premium materials through granite wholesale suppliers premium channels, you should require quarry certification and material testing documentation. Reputable wholesalers provide technical data sheets showing absorption rates, compressive strength, and flexural strength based on ASTM testing protocols.

Your due diligence should verify material authenticity, particularly for high-value marbles where misrepresentation occurs. True Calacatta marble originates from specific Italian quarries—you’ll find numerous imitations marketed as Calacatta that are actually Chinese white marbles with similar veining. The performance characteristics differ substantially, affecting long-term durability and weathering patterns.

Fabrication Coordination and Quality Control

Your granite marble wholesale Arizona material procurement separates slab acquisition from fabrication services. This gives you flexibility to select specialized fabricators based on project complexity, but it requires careful coordination between wholesale suppliers, fabrication shops, and installation crews.

You need to establish clear custody chains and damage liability. When slabs transfer from warehouse to fabricator, document existing fissures and surface imperfections with photographs. Your purchase agreement should specify who bears financial responsibility for damage during handling, fabrication, and installation phases.

- You should coordinate fabrication drawings with wholesale slab dimensions to optimize yield

- Your edge detail specifications affect fabrication complexity and labor costs significantly

- You need to approve digital templating before fabrication begins to prevent dimensional errors

- Your quality control inspection should occur at the fabrication shop before delivery

The fabrication timeline for granite wholesale price Arizona luxury projects typically requires 2-3 weeks after template approval. Complex edge details, specialty cutouts, or bookmatched installations extend fabrication time to 3-4 weeks. You should build these timelines into project schedules and communicate clearly with all stakeholders about realistic delivery expectations.

Installation Specifications and Site Conditions

When you specify granite marble wholesale Arizona installations, your site conditions directly affect installation methodology and long-term performance. Concrete substrate preparation, climate conditions during installation, and curing protocols determine whether your premium materials perform as intended.

You’ll encounter installation failures when crews rush the process during unfavorable weather conditions. Summer afternoon temperatures above 105°F cause thin-set mortars to cure too rapidly, compromising bond strength. Your installation specifications should restrict work to morning hours during June through September, when ambient temperatures remain below 95°F.

The substrate flatness requirements for large-format slabs exceed standard tile installation tolerances. You need substrates flat within 1/8 inch over 10 feet for slabs larger than 24 inches in any dimension. Greater substrate variation creates lippage that’s unacceptable in wholesale granite and marble Arizona luxury installations where visual perfection matters.

Adhesive Selection for Arizona Climate

Your adhesive specification must address Arizona’s extreme temperature conditions and low humidity. Standard thin-set mortars designed for moderate climates don’t provide adequate working time when ambient temperatures exceed 100°F and relative humidity drops below 15%. You should specify polymer-modified thin-sets rated for extended open time in hot, dry conditions.

The adhesive coverage requirements increase for large-format slabs to prevent hollow spots that concentrate stress. You’ll need 95% coverage minimums for slabs exceeding 900 square inches, achieved through back-buttering and substrate troweling. Lesser coverage creates point loading that leads to thermal stress cracking during Arizona’s daily temperature cycles.

Cost Analysis and Value Engineering Strategies

Your budget development for granite marble wholesale Arizona projects requires understanding the complete cost structure beyond material acquisition. Wholesale pricing represents 35-45% of total installed cost—fabrication, delivery, installation labor, and substrate preparation constitute the remaining investment.

You can achieve significant cost optimization through strategic material selection that maintains aesthetic intent while improving fabrication efficiency. Slabs with minimal veining complexity and consistent color reduce fabrication waste and labor time. Your value engineering efforts should focus on slab dimensions that align with fabrication equipment capabilities and minimize offcut waste.

- You should evaluate standard slab dimensions versus custom sizes to reduce premium charges

- Your edge detail selections dramatically affect fabrication labor costs and timelines

- You need to balance exotic material aesthetics against availability and price premiums

- Your installation methodology choices affect labor costs by 20-30% depending on complexity

The Wholesale Granite Arizona high-end market offers volume discounts for projects requiring multiple material types or large square footage commitments. You’ll negotiate better pricing when you consolidate purchases with single suppliers rather than sourcing different materials from multiple vendors. This also simplifies logistics coordination and reduces administrative complexity.

Maintenance Requirements and Longevity Planning

When you specify granite wholesale suppliers premium materials for Arizona projects, you’re committing clients to maintenance protocols that preserve appearance and performance. Granite requires less maintenance than marble, but both materials benefit from periodic sealing and proper cleaning procedures.

Your maintenance specifications should establish realistic service intervals based on material porosity and environmental exposure. Low-porosity granites with absorption rates below 0.4% require sealing every 3-5 years in covered applications. Higher-porosity materials and all exterior applications need sealing every 1-2 years to prevent moisture infiltration and staining.

You should educate clients that marble’s calcite composition makes it vulnerable to acid etching from common cleaning products and environmental exposure. Arizona’s alkaline soils and occasional acid rain create surface etching that dulls polished finishes over time. Your maintenance recommendations need to include pH-neutral cleaning products and prompt spill cleanup to minimize etching damage.

Sealer Selection and Application Protocols

Your sealer specification affects both performance and maintenance intervals. Penetrating sealers provide longest-lasting protection for granite marble wholesale Arizona applications, migrating into the stone structure rather than forming surface films. You should specify solvent-based penetrating sealers for maximum durability, though water-based versions offer environmental advantages with slightly shorter service life.

The application timing matters significantly—new installations require 48-72 hours of cure time before sealer application. Your installation specifications should clarify whether the fabricator, installer, or maintenance contractor bears responsibility for initial sealing. Clear responsibility assignment prevents the common situation where everyone assumes someone else handled sealing.

Wholesale granite distributors in Arizona: Citadel Stone’s Technical Approach

When you evaluate Citadel Stone’s wholesale granite distributors in Arizona services for your premium projects, you’re accessing technical guidance designed for Arizona’s specific environmental challenges. At Citadel Stone, we provide hypothetical specification frameworks for diverse regional applications across the state. This section outlines how you would approach material selection and installation planning for six representative Arizona cities, demonstrating the climate-specific considerations that affect granite marble wholesale Arizona project success.

Phoenix Metro Applications

In Phoenix applications, you would prioritize low-absorption granites with thermal expansion coefficients below 6.0 × 10⁻⁶ per °F. Your specification would address surface temperatures exceeding 165°F during summer months, requiring materials with proven thermal stability. You’d need expansion joints every 12 feet for exterior installations and substrate preparation that accounts for concrete thermal movement. When you plan warehouse deliveries to Phoenix project sites, you should schedule during cooler months when material handling and installation conditions optimize adhesive curing. Your material selection would favor darker granites that mask the inevitable dust accumulation from desert conditions while maintaining heat resistance properties.

Scottsdale Luxury Specifications

For Scottsdale luxury projects, you would specify exotic granite wholesale price Arizona luxury materials that deliver visual impact while withstanding extreme heat. Your selections would include bookmatched slabs for feature walls and continuous veining across large surfaces. You’d coordinate with wholesale granite and marble Arizona luxury suppliers to secure premium-grade materials with minimal fissuring and consistent color. Your installation specifications would require climate-controlled staging areas and morning-only installation windows during summer months. You should account for Scottsdale’s high-end aesthetic expectations while ensuring material performance matches the investment level.

Tucson Desert Performance

In Tucson environments, you would address slightly cooler temperatures than Phoenix but similar low-humidity conditions affecting installation. Your granite marble wholesale Arizona material specifications would prioritize UV resistance and thermal cycling tolerance. You’d need to account for Tucson’s monsoon season moisture exposure that creates temporary high-humidity conditions affecting unsealed stone. Your specification would require penetrating sealers applied within 72 hours of installation completion. When you coordinate truck deliveries to Tucson sites, you should verify access routes can accommodate full-size delivery vehicles, particularly for hillside properties common in the area.

Flagstaff Freeze-Thaw Considerations

For Flagstaff projects, you would shift focus to freeze-thaw durability rather than extreme heat resistance. Your specifications would require granite with absorption rates below 0.3% and proven resistance to 50+ annual freeze-thaw cycles. You’d need to account for snow load on horizontal surfaces and ice formation that can spall improperly selected materials. Your installation methodology would include cold-weather thin-set mortars rated for application in temperatures down to 35°F. You should specify that wholesale granite distributors in Arizona provide materials tested according to ASTM C1026 freeze-thaw resistance protocols for Flagstaff applications.

Sedona Aesthetic Integration

In Sedona installations, you would balance material performance with aesthetic harmony to surrounding red rock landscapes. Your wholesale Granite Arizona high-end selections would favor warm-toned granites that complement rather than contrast with natural surroundings. You’d coordinate with Wholesale granite and marble Arizona luxury suppliers to source materials with earthy color palettes while maintaining required performance characteristics. Your specifications would address the logistical challenges of Sedona’s limited truck access and remote site conditions that increase delivery costs and complicate material staging. You should plan for extended lead times and coordinate closely with local building departments regarding material approvals.

Mesa Commercial Applications

For Mesa commercial projects, you would prioritize durability and cost efficiency while maintaining professional aesthetics. Your granite marble wholesale Arizona specifications would favor consistent-grade materials available in volume for large-format commercial installations. You’d need materials that withstand high foot traffic and commercial cleaning protocols without showing premature wear. Your installation specifications would address substrate requirements for commercial loading conditions and coordination with building systems. When you evaluate granite wholesale suppliers premium options for Mesa projects, you should verify warehouse stock levels support your square footage requirements and installation timeline without material shortages causing delays.

Quality Verification and Project Acceptance Criteria

Your quality control process for granite marble wholesale Arizona installations should include multiple inspection points before final acceptance. You need to verify material authenticity, fabrication accuracy, and installation quality against project specifications and industry standards.

When you conduct pre-installation inspections, examine slabs for manufacturing defects, finish consistency, and dimensional accuracy. Your acceptance criteria should define tolerance ranges for thickness variation (typically ±1/16 inch), edge straightness (±1/32 inch per linear foot), and surface flatness (1/16 inch over 10 feet). Materials falling outside these tolerances create installation challenges and visual imperfections.

- You should verify color consistency across all slabs before fabrication begins

- Your edge detail inspection must confirm profiles match approved shop drawings

- You need to check that cutouts and penetrations align with fixture locations accurately

- Your final installation review should assess lippage, joint consistency, and overall workmanship

The Wholesale Granite Arizona high-end market maintains quality standards that exceed residential-grade materials, but verification remains your responsibility. You can’t assume premium pricing guarantees perfect execution—systematic inspection at each project phase protects your professional reputation and client satisfaction.

Building Strategic Supplier Relationships

When you develop long-term relationships with granite wholesale price Arizona luxury distributors, you gain access to benefits beyond competitive pricing. Established relationships provide priority allocation of limited-availability materials, flexible payment terms, and advance notice of incoming exotic slabs before general market release.

Your supplier selection should prioritize reliability and technical expertise over lowest initial pricing. You need distributors who understand project-grade material requirements and provide accurate lead time projections. Suppliers who overpromise and underdeliver create project delays that damage your client relationships and professional reputation.

You should establish clear communication protocols regarding material availability, pricing validity periods, and delivery scheduling. Wholesale markets experience price volatility based on shipping costs, currency fluctuations, and quarry production changes. Your supplier agreements need mechanisms for handling price adjustments between quotation and purchase order placement.

Risk Mitigation and Contingency Planning

Your granite marble wholesale Arizona project planning should include contingency strategies for common supply chain disruptions. Material damage during transport, fabrication errors, and installation failures occur despite careful planning—your response protocols determine whether these become minor inconveniences or project catastrophes.

You should maintain relationships with multiple wholesale granite distributors in Arizona to provide sourcing alternatives when primary suppliers face inventory shortages. This redundancy creates competitive pricing pressure while ensuring material availability doesn’t single-source your projects into vulnerable positions.

- You need approved material substitutions documented before procurement begins

- Your contracts should specify damage liability and replacement material timelines

- You should maintain contingency budgets of 10-15% for unforeseen material costs

- Your project schedules must include buffer time for material delays and corrections

The insurance and liability considerations for high-value materials require specific attention. You need to verify that materials are insured during warehouse storage, transport, fabrication, and installation. Your contracts should clearly assign financial responsibility for damage at each custody transfer point.

Final Considerations

Your success with granite marble wholesale Arizona projects depends on comprehensive planning that addresses material selection, supplier coordination, fabrication management, and installation execution. You need to balance aesthetic requirements with performance demands while managing budgets and timelines across complex supply chains.

When you approach high-end stone projects professionally, you’re coordinating multiple specialized trades and suppliers toward unified project goals. Your attention to technical details, quality verification, and proactive problem-solving separates successful luxury installations from those that disappoint despite premium material investments. For comprehensive technical resources and project planning guidance, review Commercial-grade granite and marble wholesale distribution in Arizona before finalizing your material specifications. Membership programs distinguish Citadel Stone’s granite wholesale dealers in Arizona loyalty benefits.