When you source natural flagstone slabs from a flagstone yard in Arizona, you’re making decisions that affect project durability, aesthetic continuity, and long-term maintenance requirements. Arizona’s extreme climate conditions—temperatures exceeding 120°F in summer, intense UV exposure year-round, and dramatic day-night thermal cycling—impose specific performance requirements that generic flagstone selections often fail to meet. You need to understand how material composition, thickness tolerances, and surface finish variations interact with regional installation challenges before you commit to material procurement.

The flagstone yard in Arizona selection process differs fundamentally from standard stone procurement because desert climate exposure accelerates material degradation patterns that remain dormant in moderate environments. You’ll encounter thermal expansion coefficients that mandate modified joint spacing protocols, porosity ranges that determine stain resistance under monsoon conditions, and slip resistance variations that change drastically between dry and wet states. Your specification decisions must account for how 180+ days of direct solar exposure annually affects surface temperature, color stability, and structural integrity over 20-year performance cycles.

Material Composition Requirements for Desert Performance

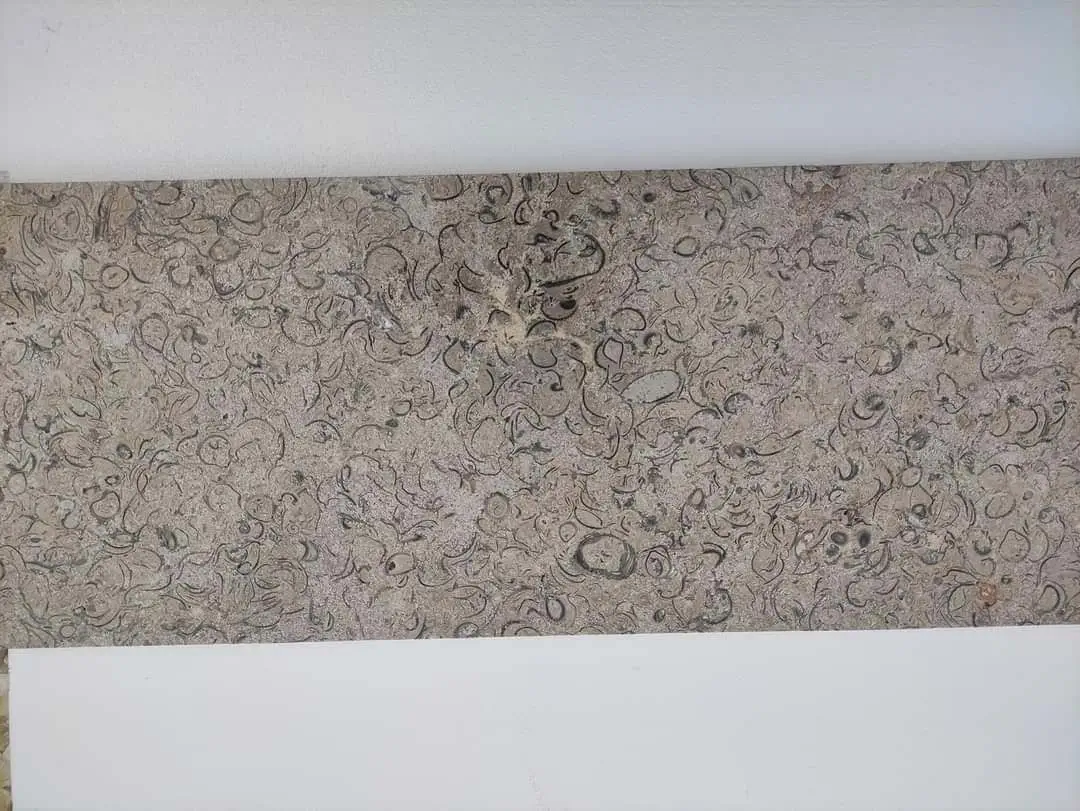

Your flagstone yard in Arizona selection begins with understanding mineralogical composition and how it determines thermal stability. Sedimentary flagstones—sandstone, limestone, and certain quartzites—exhibit different expansion coefficients that directly impact joint spacing requirements and long-term flatness retention. When you specify flagstone for Arizona installations, you’re selecting materials that must withstand daily thermal cycling of 40-60°F surface temperature variation, which creates cumulative stress patterns over thousands of heating-cooling cycles.

Sandstone flagstone typically contains 85-95% quartz with minor feldspar and mica content, resulting in thermal expansion coefficients around 6.2 × 10⁻⁶ per °F. You need this specific data because it determines your expansion joint spacing—for Arizona applications, you should specify joints every 12-15 feet rather than the 20-foot standard used in moderate climates. The slab yard Arizona flagstone options you evaluate must include verified composition analysis, not just visual classification, because mineral content variations of 10-15% create measurable performance differences in high-heat environments.

- You should verify quartz content exceeds 80% for optimal thermal stability in direct sun exposure

- Your specification must address iron oxide content, which affects both color stability and surface temperature absorption

- You’ll find that calcareous sandstones with 15-20% carbonate content show accelerated weathering in areas with pH-variant irrigation water

- Mica content above 8% correlates with surface spalling after 8-12 years in high-traffic applications

Limestone flagstone presents different performance characteristics that you need to evaluate against project-specific exposure conditions. The material’s calcite composition creates surface temperatures 8-12°F lower than sandstone under identical solar exposure, making it preferable for barefoot contact areas around pools. However, you must account for acid sensitivity—monsoon rainwater with pH below 5.8 etches polished limestone surfaces at rates of 0.3-0.5mm per decade, which becomes visually apparent after 15-18 years in uncovered applications.

Thickness Specifications and Structural Considerations

When you evaluate local slab yard Arizona flagstone types, thickness consistency determines installation efficiency and long-term performance reliability. Industry-standard thickness tolerances of ±¼ inch become problematic in large-format flagstone installations where you’re working with pieces ranging from 18-36 inches in dimension. Your base preparation must accommodate these variations, but excessive tolerance stacking creates installation challenges that affect both labor costs and final flatness.

Professional flagstone yard in Arizona installations typically specify 1¼-inch to 2-inch nominal thickness for pedestrian applications, with actual delivered thickness ranging ±3/16 inch on quality-controlled material. You should understand that thinner flagstones (under 1¼ inches) require significantly more precise base preparation—flatness tolerances tighten from ±⅜ inch over 10 feet to ±¼ inch over 10 feet to prevent differential settlement and resulting lippage. This precision requirement increases base preparation labor by 25-30% compared to thicker material installations.

For vehicular applications and commercial high-traffic areas, you need to specify minimum 2-inch thickness with reinforced base assemblies. The granite yard flagstone Arizona suppliers stock often includes 2½-inch material specifically for these applications, though you’ll pay 40-50% premiums over standard residential thickness. Your structural calculations should account for point loading—a 6,000-pound vehicle on a single 2-inch flagstone creates approximately 180 PSI bearing stress, which requires minimum 8,500 PSI compressive strength in the stone and properly densified base aggregate.

Surface Finish Impact on Thermal Properties and Slip Resistance

The slab yard Arizona flagstone sizes you select carry different surface finish options that dramatically affect both thermal performance and safety characteristics. Natural cleft surfaces—the split faces that result from quarrying along bedding planes—provide inherent slip resistance with DCOF values ranging from 0.52 to 0.68 in dry conditions. However, you need to verify wet DCOF performance, which typically drops to 0.38-0.48, potentially falling below the 0.42 minimum threshold specified in ANSI A137.1 for wet pedestrian areas.

When you specify thermal finishing (flame texturing) for granite flagstone, you’re creating micro-roughened surfaces that maintain slip resistance in wet conditions while reducing surface temperature by 6-9°F compared to polished finishes. This temperature reduction comes from increased surface area and altered thermal emissivity—flamed granite reflects approximately 35% of incident solar radiation versus 18-22% for polished surfaces. For pool deck and outdoor shower applications, you should prioritize thermally finished material despite 15-20% cost premiums over natural cleft options.

Honed and polished finishes present aesthetic advantages but create functional complications in Arizona exterior applications. You’ll encounter warehouse inventory at most flagstone yard in Arizona locations that includes these finishes, but you need to understand their limitations. Polished limestone maintains its appearance longer than natural cleft in covered applications, but direct sun exposure causes surface checking after 6-8 years as thermal stress exceeds the tensile strength of the polished skin layer. Your maintenance protocols must include periodic repolishing every 8-10 years for covered applications or acceptance of progressive surface dulling in exposed conditions.

Color Selection and Long-Term Thermal Absorption Patterns

Your flagstone yard in Arizona color selections directly determine surface operating temperatures, which affect both user comfort and material longevity. Light-colored flagstones—creams, tans, and light grays—reflect 55-65% of solar radiation and typically reach peak surface temperatures of 115-135°F during July-August afternoon conditions. Dark flagstones—charcoals, browns, and black granites—reflect only 20-30% of incident radiation and commonly exceed 155°F surface temperature, making them unsuitable for barefoot contact areas.

You should understand that color stability over 15-20 year lifecycles varies significantly by material type and mineral composition. Iron-rich sandstones in red and rust colorways maintain color consistency well in Arizona’s UV-intense environment, while certain gray sandstones with iron sulfide inclusions develop progressive rust staining as weathering oxidizes the sulfide minerals. This staining becomes noticeable after 3-5 years and intensifies over time—a characteristic you need to explain to clients during material selection.

When you review stone slab yard in Arizona inventory, you’ll find that quarry location affects color consistency within material lots. Sandstone from different bedding plane depths shows color variation ranging from subtle (±5% lightness variation) to dramatic (±20% variation with distinct banding). You need to specify either tight color matching with 5-8% material waste to achieve consistency, or embrace natural variation as a design feature with appropriate client expectation management. The Citadel Stone supply store in Tucson maintains full-slab viewing areas where you can evaluate color range across entire material lots before committing to orders.

Porosity and Moisture Management in Monsoon Conditions

Arizona’s monsoon season—typically July through September—creates moisture exposure conditions that require you to evaluate flagstone porosity characteristics carefully. Natural flagstone exhibits porosity ranging from 2% to 12% by volume depending on material type, and this porosity determines water absorption rates, staining susceptibility, and freeze-thaw durability for high-elevation installations above 5,000 feet.

When you specify sandstone flagstone, you’re typically working with 6-9% porosity material that absorbs water at rates of 3-5% by weight during saturation testing per ASTM C97. This absorption rate means that a 20-square-foot flagstone patio can absorb 15-20 gallons of water during heavy monsoon storms, and your base design must provide drainage capacity to evacuate this moisture within 24-48 hours to prevent efflorescence and organic staining. You should specify minimum 2% cross-slope for flagstone surfaces and open-graded base aggregate with permeability coefficients exceeding 1,000 inches per hour.

Limestone flagstone presents lower porosity—typically 2-5%—but its calcareous composition makes it more susceptible to dissolution and etching from acidic water contact. You need to account for how monsoon rainwater in urban areas often carries pH values of 5.2-5.8 due to atmospheric carbon dioxide and pollutant interaction. Over 15-20 year exposure periods, this creates measurable surface recession of 0.4-0.7mm on unprotected limestone, which appears as progressive surface dulling and increased micro-roughness.

Sealing Protocols and Long-Term Maintenance Requirements

Your flagstone yard in Arizona material selections require comprehensive sealing strategies that balance stain protection against vapor transmission requirements. Penetrating sealers—siloxane and silane formulations—provide water repellency while maintaining vapor permeability, allowing subsurface moisture to escape without trapping it beneath the stone surface. You should specify these for most Arizona applications where substrate moisture is properly managed and primary concern is surface staining from organic matter, pool chemicals, or irrigation water minerals.

Film-forming sealers—acrylics and urethanes—create surface barriers that enhance color depth and provide superior stain resistance but require careful evaluation of substrate conditions. When you apply film-forming sealers over insufficiently cured mortar beds or inadequately dried bases, you trap residual moisture that manifests as whitish hazing or delamination after 6-18 months. You need to verify substrate moisture content below 4% using calcium chloride testing before film-forming sealer application, and you must educate clients about 3-5 year reapplication requirements as Arizona’s UV exposure degrades surface films.

- You should specify initial sealer application 30-60 days post-installation to allow efflorescence salts to migrate and be removed

- Your maintenance protocols must include annual cleaning with pH-neutral cleaners to prevent sealer-degrading alkali buildup

- You’ll need to plan for sealer reapplication every 3-5 years for film-forming products, 5-7 years for penetrating sealers

- You must account for how pool deck applications require sealer products specifically rated for continuous chlorinated water exposure

Base Preparation Specifications for Thermal Stability

The structural performance of flagstone yard in Arizona installations depends fundamentally on base assembly design that accommodates both bearing loads and thermal movement. You need to understand that Arizona’s expansive clay soils—present in approximately 60% of the Phoenix and Tucson metro areas—create subsurface movement conditions that standard aggregate base assemblies cannot adequately address. Your geotechnical investigation should include plasticity index testing, with PI values above 20 indicating soils that require modified base designs or soil stabilization protocols.

Standard flagstone base assemblies for Arizona applications consist of 4-6 inches of compacted Class 2 aggregate base (¾-inch minus) over native soil or engineered fill, with geotextile fabric separation layers. You should specify minimum 95% relative compaction per ASTM D1557 (Modified Proctor), verified through nuclear density gauge testing at 50-foot intervals. This compaction level provides adequate bearing capacity for residential pedestrian loads while maintaining sufficient permeability for drainage—properly compacted Class 2 base achieves permeability of 800-1,200 inches per hour.

For installations over expansive soils, you need to implement one of three modified approaches based on site-specific conditions and budget parameters. Soil stabilization using lime treatment (3-5% hydrated lime by weight, mixed to 8-inch depth) reduces plasticity index and swell potential by 40-60%. Alternatively, you can specify thickened aggregate base sections—8-10 inches instead of standard 4-6 inches—to bridge over moderate soil movement. The third approach involves moisture maintenance systems using subsurface drip irrigation around perimeter zones to minimize soil moisture variation and resulting volume change.

Joint Spacing and Installation Details for Thermal Movement

When you lay out flagstone yard in Arizona material, joint spacing protocols must accommodate thermal expansion that exceeds movement ranges in moderate climates by 40-50%. A 20-foot flagstone expanse in direct Arizona sun can experience surface temperature swings from 60°F (pre-dawn winter) to 145°F (mid-afternoon summer), creating linear expansion of approximately 0.18 inches with typical sandstone expansion coefficients. Your joint spacing must absorb this movement without creating compression stress that causes edge spalling or vertical displacement.

Professional installations typically specify ⅜-inch to ½-inch joint widths for flagstone applications, filled with either polymeric sand or mortar depending on installation method. You should understand that polymeric sand systems—modified with polymer binders that activate with water—provide some flexibility to accommodate thermal movement while restricting sand loss and weed growth. However, you’ll find these systems work best with consistent joint widths; variation exceeding ±⅛ inch reduces polymer activation effectiveness and allows premature sand loss within 18-24 months.

Mortar-set flagstone installations over concrete slabs require isolation joints every 12-15 feet aligned with control joints in the concrete substrate. You need to detail these joints as true movement joints, not simply mortar-filled expansion spaces. Your specification should call for backer rod installation to proper depth (typically joint width plus ¼ inch) with polyurethane or silicone sealant finish that maintains elasticity through Arizona’s temperature extremes. Failure to provide adequate movement joints results in transmitted stress that cracks flagstones along their weakest planes within 2-4 years.

Edge Details and Transition Conditions

Your flagstone yard in Arizona projects require careful edge detail design where paving meets structures, planting areas, or grade changes. Unsupported flagstone edges—cantilevered beyond the base aggregate by more than 1 inch—become vulnerable to breakage from foot traffic concentration along perimeter zones. You should specify either concrete edge restraints or steel edging systems that provide continuous support while remaining visually discrete.

Concrete edge restraints for flagstone installations typically consist of 4-inch wide by 8-inch deep continuous footings placed at finish grade elevation. You need to ensure these restraints are isolated from building foundations with ½-inch expansion joint material to prevent differential movement transmission. The flagstone overhangs this concrete edge by ½ to ¾ inch, creating a clean visual termination while maintaining full structural support. Your detailing must address how these edge restraints transition at radius conditions—curved edges require either formed concrete or segmented straight sections with maximum 2-foot chord lengths.

Steel edging systems—typically 1/8-inch by 4-inch steel strips secured with 12-inch stakes at 3-foot intervals—provide flexible edge restraint that accommodates curved layouts more readily than concrete. However, you need to specify corrosion-resistant steel or aluminum options for Arizona’s high-heat conditions where metal oxidation accelerates. Standard mild steel edging shows visible rust staining on adjacent flagstone within 18-24 months; powder-coated or stainless steel options eliminate this issue at 60-80% cost premiums.

Common Specification Mistakes in Arizona Flagstone Projects

Professional experience across hundreds of Arizona flagstone installations reveals recurring specification errors that compromise project performance and create costly remediation requirements. You can avoid these mistakes by understanding their root causes and implementing proven preventive protocols during design and procurement phases.

- You often encounter flagstone specifications that reference inappropriate industry standards developed for moderate climates without Arizona-specific modifications

- Your joint spacing details must exceed minimum standards—the common mistake is applying 20-foot expansion joint spacing when Arizona conditions require 12-15 foot maximum intervals

- You’ll find that generic sealer specifications fail to address Arizona UV exposure intensity and required reapplication frequencies specific to high-desert conditions

- You should verify base preparation specifications account for expansive soil conditions present across 60% of metro Phoenix and Tucson areas

- Your thickness specifications need to address actual delivered tolerance ranges, not nominal dimensions that create installation complications

Inadequate attention to color variation within material lots creates client dissatisfaction in 15-20% of projects. When you specify “natural variation” without defining acceptable ranges, you create subjective quality disputes. Professional specifications include either tight color matching protocols with associated waste factors, or defined variation parameters using standardized color measurement systems. You should establish visual mockups showing maximum acceptable variation before material procurement to align client expectations with natural stone characteristics.

Drainage design inadequacies account for approximately 30% of flagstone performance problems in Arizona installations. You need to recognize that monsoon storm intensities reach 2-3 inches per hour, creating surface runoff that exceeds the infiltration capacity of most flagstone joint systems. Your specifications must include positive surface drainage at minimum 2% slope combined with subsurface drainage systems—perforated pipe in aggregate trenches at low points—to evacuate water that penetrates through joints and accumulates at the base level.

Truck Delivery and Project Logistics

When you coordinate flagstone yard in Arizona material deliveries, you need to account for truck access constraints and material handling requirements that affect project scheduling and site logistics. Flagstone typically ships on flatbed trucks or specialized stone delivery vehicles that require adequate turning radius, overhead clearance, and stable surface conditions for safe unloading. You should verify that your site access accommodates 40-foot overall vehicle length with minimum 14-foot inside turning radius before scheduling deliveries.

Material offloading procedures significantly impact both installation efficiency and breakage rates. Truck-mounted forklifts or boom cranes provide controlled offloading that minimizes breakage compared to manual handling of individual pieces. You need to coordinate offloading location based on installation sequencing—flagstone placed too far from final position requires double handling that increases labor costs by 25-35% and raises breakage risk. Your site logistics plan should position material storage within 50 feet of installation areas while maintaining clear access paths for installation crews.

Lead times from warehouse to project site typically range from 3-7 business days for locally stocked materials, extending to 3-4 weeks for special-order colors or sizes requiring direct quarry shipment. You should build these lead times into project schedules with appropriate buffers—2-week minimums for standard materials, 6-week minimums for special orders. Summer heat conditions in Arizona often restrict delivery windows to morning hours before temperatures exceed 105°F, effectively reducing daily delivery capacity during June through August and requiring you to extend overall project timelines by 15-20% during peak heat periods.

Citadel Stone’s stone slab yard in Arizona — Premium Flagstone Specification Guidance for Arizona Cities

When you evaluate Citadel Stone’s stone slab yard in Arizona for your project, you’re accessing premium flagstone materials specifically selected for extreme desert climate performance. At Citadel Stone, we provide detailed technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat extremes to high-elevation freeze-thaw conditions. This section outlines how you would approach specification decisions for six representative cities, demonstrating the climate-specific considerations that professional flagstone installations require.

Your material selection process would begin by analyzing specific environmental stressors in each location—daily temperature ranges, annual precipitation patterns, elevation-related freeze-thaw cycles, and UV exposure intensity. You’d then match these conditions to flagstone characteristics including thermal expansion coefficients, porosity ranges, compressive strength ratings, and surface finish options. At Citadel Stone, we maintain comprehensive technical data for all stocked materials, enabling you to make evidence-based specification decisions rather than relying on generic product descriptions or aesthetic preferences alone.

Phoenix Applications

In Phoenix installations, you’d prioritize light-colored sandstone or limestone flagstone that maintains surface temperatures within acceptable ranges for barefoot contact around pools and outdoor living areas. You would specify material with thermal expansion coefficients around 5.8-6.2 × 10⁻⁶ per °F combined with expansion joint spacing at 12-foot maximum intervals to accommodate the 80-90°F daily temperature swings common during summer months. Your base preparation would address expansive clay soils present across much of the metro area, potentially incorporating lime stabilization for PI values exceeding 20. At Citadel Stone, our technical team would recommend specific sealing protocols for pool deck applications where continuous chlorinated water exposure requires specialized sealer formulations rated for chemical resistance.

Tucson Considerations

Your Tucson projects would address similar heat challenges as Phoenix but with greater monsoon moisture exposure requiring enhanced drainage design. You’d specify flagstone with 6-8% porosity ratings that balance water absorption for drainage purposes against staining susceptibility from organic matter and mineral deposits. The specification would include positive surface drainage at 2.5% minimum slope combined with open-graded base aggregate providing minimum 1,000 inches per hour permeability. You would detail subsurface drainage systems using perforated pipe in aggregate-filled trenches at paving low points to evacuate water accumulation during intense monsoon storms reaching 2-3 inches per hour intensity.

Scottsdale Standards

In Scottsdale’s resort and high-end residential applications, you would emphasize aesthetic consistency alongside performance requirements. Your material selection would specify tight color variation tolerances—typically ±5% lightness variation measured using standardized colorimetry—requiring 8-10% material waste during installation to achieve visual consistency. You’d recommend premium thermally finished granite flagstone for pool decks and spa surrounds, accepting 18-22% cost premiums over standard sandstone options in exchange for superior slip resistance (wet DCOF 0.48-0.54) and minimal maintenance requirements over 20+ year lifecycles. The specification would include initial penetrating sealer application followed by color-enhancing sealer topcoats to achieve the saturated appearance typical of luxury installations.

Flagstaff Requirements

Your Flagstaff installations at 7,000-foot elevation would prioritize freeze-thaw durability as the primary performance criterion. You’d specify flagstone with maximum 5% porosity and verified freeze-thaw resistance per ASTM C1026, requiring minimum 300-cycle survival without structural degradation. Material thickness would increase to 1½-inch minimum for pedestrian areas, 2½-inch for vehicular applications to provide adequate mass for thermal stability during winter temperature cycling. You would detail base assemblies with 6-8 inch aggregate depth placed over frost-protected footings extending below 18-inch frost depth. At Citadel Stone, we would recommend specific granite varieties with proven performance in freeze-thaw environments, avoiding sedimentary stones that show progressive spalling in high-elevation applications.

Sedona Aesthetics

In Sedona’s distinctive red rock landscape, you would select flagstone colors that complement rather than compete with the natural environment. Your specification would favor warm sandstone tones—rusts, tans, and buff colorways—that harmonize with surrounding geology while providing the thermal performance required for 6,500-foot elevation. You’d address moderate freeze-thaw exposure (60-80 annual cycles) with flagstone porosity specifications limited to 6% maximum and base preparation including frost protection measures at building interfaces where heat loss creates localized freezing conditions. The project would balance aesthetic integration with functional performance requirements including slip resistance for steep-slope applications common in Sedona’s topographically varied residential sites.

Mesa Installations

Your Mesa projects would optimize value engineering while maintaining professional performance standards appropriate for residential and light commercial applications. You’d specify regionally available sandstone flagstone in standard thicknesses (1¼-inch to 1½-inch) with natural cleft surfaces providing cost-effective slip resistance without premium thermal finishing. The specification would address Mesa’s predominantly stable soil conditions with standard 4-6 inch aggregate base assemblies, increasing to 8-inch depths in identified areas with expansive clay presence. You would recommend cost-effective polymeric sand joint systems for moderate-traffic residential applications, reserving mortar-set installations for commercial projects or high-traffic residential areas requiring maximum joint stability and longevity.

Professional Procurement and Quality Verification

Your flagstone yard in Arizona procurement process should include comprehensive quality verification protocols that extend beyond visual inspection to include measurable performance testing. Professional specifications reference ASTM standards for critical performance characteristics—C170 for compressive strength, C97 for absorption and bulk specific gravity, C1028 for slip resistance, and C1026 for freeze-thaw durability in elevation applications. You need to request certified test data from suppliers documenting that delivered material meets specification requirements, not simply generic product literature citing typical values.

When you evaluate material at the yard, visual inspection should assess color consistency within the lot, thickness variation across multiple pieces, and surface finish uniformity. You should pull random samples from different pallet locations—material quality can vary significantly between pallets supposedly containing identical material. Your inspection protocol needs to identify and reject pieces with structural defects including through-cracks, delamination planes, or excessive iron sulfide inclusions that will cause rust staining. Professional practice allocates 5-8% material overage for selection waste, acknowledging that natural stone inevitably includes pieces that fail to meet aesthetic or structural standards.

Material storage at the project site requires attention to prevent damage and weathering before installation. You should specify elevated storage on timber blocking rather than direct ground contact, which prevents bottom-layer pieces from absorbing ground moisture and developing staining. Flagstone pallets need weather protection using breathable tarps that prevent water accumulation while allowing vapor transmission—impermeable plastic sheeting traps moisture and accelerates efflorescence development. Your site logistics plan must position stored material to prevent forklift or vehicle damage while maintaining efficient access for installation crews.

Final Considerations

Your professional approach to flagstone yard in Arizona material selection integrates aesthetic objectives with rigorous performance requirements specific to desert climate exposure. Successful specifications balance thermal stability, moisture management, structural adequacy, and long-term maintenance considerations while working within project budget parameters and scheduling constraints. You need to recognize that natural stone’s inherent variability requires flexible specification approaches that define acceptable performance ranges rather than absolute values, establishing clear quality standards without eliminating the natural characteristics that make flagstone aesthetically distinctive.

The economic analysis of flagstone installations should extend beyond initial material and installation costs to include lifecycle maintenance requirements and expected service life. You’ll find that premium materials with 15-20% higher initial costs often deliver superior long-term value through reduced maintenance frequency, longer resealing intervals, and extended functional lifespan reaching 25-30 years versus 15-18 years for economy-grade materials. Your client communications need to present these lifecycle economics clearly, demonstrating how specification decisions affect total cost of ownership rather than simply first cost.

Professional practice in Arizona flagstone specification continues to evolve as material options expand, installation techniques improve, and long-term performance data accumulates from completed projects. You should maintain ongoing education regarding new material options, modified installation protocols for challenging conditions, and emerging best practices addressing climate-specific challenges. For comprehensive guidance on related premium materials and installation methods, review Premium marble slab inventory available at Arizona stone yards before finalizing your project specifications. Citadel Stone’s stone slab yard in Arizona viewing process includes lighting simulation and digital visualization tools.