When you’re cutting flagstone for commercial plaza installations or high-end residential projects in Arizona, you’ll quickly discover that standard blade sawing can’t handle slabs exceeding 12 feet in any dimension. Flagstone wire sawing Arizona operations use diamond-embedded wire technology that allows you to process massive format pieces up to 30 feet long while maintaining tolerances within ±1/16 inch. You need to understand how wire saw systems differ fundamentally from circular blade methods — the continuous loop wire system enables you to cut through thickness variations that would bind conventional blades, making it essential for irregular natural stone profiles.

Your specification decisions for large format flagstone depend on understanding wire sawing capabilities and limitations. The process involves threading a diamond-studded wire through the stone block, then running it at speeds between 25-40 meters per second while maintaining precise tension control. You’ll achieve cut depths impossible with blade systems, but you’re trading speed for accuracy — wire sawing processes material at roughly 12-18 square feet per hour compared to 35-50 square feet for standard blade work on smaller pieces.

Wire Saw Mechanics for Flagstone

The wire itself consists of spring steel cable embedded with diamond beads spaced at precise intervals, typically 10-12mm apart for flagstone applications. When you specify fabricated flagstone production in Glendale operations, you’re requesting equipment that maintains consistent wire tension between 800-1200 pounds throughout the cut cycle. Tension fluctuations beyond ±50 pounds create surface wave patterns that become visible after installation, particularly on honed or polished finishes where light reflection amplifies even minor irregularities.

Your wire selection depends on stone hardness and the type of cut you need. Flagstone typically measures 4-6 on the Mohs scale, requiring electroplated diamond wire with bead concentrations between 28-32 beads per meter for optimal performance. You’ll experience faster cutting with higher bead concentrations, but tool life decreases proportionally — expect 40-60 linear feet of cutting from a single wire assembly in typical Arizona flagstone applications.

- You should specify wire diameter between 10.5-11.5mm for flagstone thickness ranging from 1.5 to 4 inches

- Your project requires coolant flow rates of 8-12 gallons per minute to prevent thermal damage during extended cuts

- You need to account for wire stretch during operation, which can affect dimensional accuracy by 0.5-1.2mm over cuts exceeding 15 feet

- Wire speed adjustment becomes critical when you encounter density variations within the same stone block

Dimensional Accuracy Considerations

Flagstone wire sawing Arizona operations achieve tolerances that standard quarry methods can’t match, but you need to understand the factors that affect precision. The wire deflection phenomenon becomes significant on cuts longer than 8 feet — the wire naturally wants to follow the path of least resistance through the stone, which means you’ll see slight bow patterns if density varies across the block. Experienced operators compensate by adjusting feed rates and wire tension, but you should still expect dimensional variance of ±1/8 inch on cuts exceeding 20 feet in length.

Your specification documents need to address how wire kerf width affects final dimensions. Unlike blade sawing where kerf remains constant at the blade thickness, wire sawing creates kerfs between 12-15mm (roughly 1/2 inch) that can widen slightly as diamond beads wear during the cut. You’ll need to add this kerf dimension to your target measurements, plus an additional 1-2mm allowance for surface finishing operations if you’re planning subsequent honing or polishing.

Surface Finish Quality

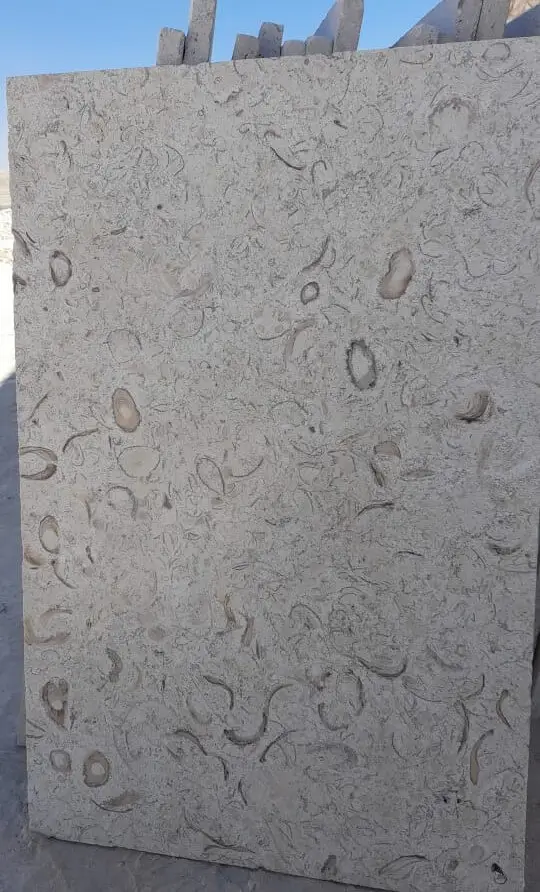

The surface left by flagstone precision cutting using wire methods differs significantly from blade-sawn finishes. Wire sawing produces a distinctive pattern of parallel striations running perpendicular to the cut direction, with striation depth typically measuring 0.3-0.8mm depending on wire speed and bead spacing. You can’t use wire-sawn surfaces as final finishes for most architectural applications — they require subsequent processing through gang saws, honing lines, or flaming operations to achieve specification-grade surfaces.

Large Format Cutting Requirements

When you’re processing flagstone slabs beyond standard paver dimensions, flagstone large format cutting operations require specialized material handling that affects both cost and lead time. The wire saw frame itself needs clear access around the entire stone block, meaning you need minimum clearances of 18-24 inches on all sides plus overhead clearance for the drive wheel assembly. Your project timeline should account for 45-60 minutes of setup time per cut position, which becomes significant when you’re processing multiple slabs from a single block.

Material stability during cutting determines whether you’ll achieve your tolerance targets. Flagstone blocks must be supported on a rigid base with support points spaced no more than 4 feet apart to prevent deflection during the cutting cycle. You’ll see dimensional problems if the stone moves even 1-2mm during the cut — the wire will follow the movement, creating stepped surfaces that require extensive remediation. Your fabricator should verify warehouse storage conditions before processing, as blocks stored directly on soil or inadequate foundations may have developed internal stress fractures that propagate during wire sawing.

- You need to specify maximum slab dimensions based on available truck transport — most flatbed carriers handle up to 14 feet width and 28 feet length

- Your crane access requirements change dramatically for slabs exceeding 3,000 pounds, affecting job site logistics

- You should plan for 2-3 week lead times for custom large format cutting compared to 3-5 days for standard sizes

- Material yield drops significantly on large format cuts due to increased scrap from edge trimming and squared corners

Wire Blade Technique Variables

Understanding flagstone wire blade techniques means recognizing how operator skill dramatically affects outcomes. The feed rate — how fast the wire advances through the stone — requires constant adjustment based on real-time feedback from motor load and wire tension. You’ll see optimal results when feed rates maintain wire temperature between 140-180°F, measurable through infrared monitoring during the cut cycle. Operators push feed rates too aggressively to meet production schedules, but this generates excessive heat that causes micro-cracking in the stone matrix up to 3-4mm below the cut surface.

Wire tracking represents another critical technique variable you need to verify with your fabricator. The wire should maintain perpendicular orientation to the stone face throughout the cut, but thermal expansion in the wire and frame assembly causes drift that accumulates over cutting cycles exceeding 90 minutes. Experienced operators reset wire position every 30-40 minutes during extended cuts, but this adds time to your production schedule. You should inspect finished slabs for tracking errors by measuring thickness at multiple points — variance exceeding 3mm indicates tracking problems that affect installation performance.

Coolant System Management

Your wire sawing operation depends on proper coolant delivery to prevent thermal damage and flush cutting debris from the kerf. The coolant mixture — typically water with 3-5% soluble oil additive — needs pH balance between 8.5-9.2 to prevent corrosion on wire components while maintaining lubrication properties. You’ll encounter problems if coolant flow becomes blocked by stone slurry accumulation, which reduces effective cooling and accelerates wire wear by 40-60%.

Accurate Sawing Process Control

Achieving consistent results with flagstone accurate sawing requires monitoring multiple process parameters simultaneously. Modern wire saw systems incorporate load cells that measure cutting force in real-time, with target ranges between 180-240 pounds force for typical flagstone applications. When you see force readings climb above 280 pounds, it indicates either wire wear requiring replacement or density changes in the stone that need feed rate adjustment. Ignoring these signals leads to wire breakage, which can damage the stone block and require restarting the cut from a new position.

Wire tension monitoring provides equally important process feedback. The tension must remain within your specified range throughout the cut cycle, but several factors cause unwanted variation. Drive wheel wear creates eccentric rotation that produces cyclic tension fluctuations at each revolution. Ambient temperature changes affect wire length through thermal expansion — you’ll measure 2-3mm length change per 10°F temperature swing on wire assemblies spanning 12-15 feet. Your fabricator should conduct cuts during stable temperature periods, typically early morning hours in Arizona operations, to minimize these effects.

- You should require documented process parameters for each cut, including wire speed, feed rate, and tension readings at 15-minute intervals

- Your quality verification needs to include surface temperature measurements immediately post-cut to confirm thermal limits weren’t exceeded

- You’ll want to inspect wire bead condition at the start and completion of each cut to verify uniform wear patterns

- Process documentation helps you identify systematic problems that affect multiple slabs from the same production run

Thickness Variation Management

Natural flagstone presents inherent thickness variation that complicates wire sawing operations. Unlike manufactured materials with consistent cross-sections, flagstone blocks often vary 1-3 inches in thickness across a single slab. When you’re implementing flagstone precision cutting methods, you need strategies to manage these variations. The wire saw can follow the top surface contour while cutting parallel to it, maintaining constant material thickness, or you can cut perfectly flat planes that produce slabs with variable thickness matching the original block irregularity.

Your specification choice between parallel cutting and flat cutting affects both cost and application suitability. Parallel cutting requires continuous wire height adjustment controlled by mechanical followers or laser scanning systems that track the top surface. This adds 15-20% to processing time but produces slabs with consistent thickness that simplify installation. Flat cutting runs faster but creates thickness variation you’ll need to accommodate during installation with variable-depth setting beds or shimming protocols.

Multi-Wire Gang Cutting

For high-volume production, some fabricators employ gang wire systems that run multiple parallel wires simultaneously through the stone block. You can cut a single flagstone block into 4-8 slabs in one operation, dramatically reducing per-unit production time. However, gang cutting introduces new accuracy challenges. Each wire operates independently with its own tension and feed characteristics, meaning you’ll see variation between slabs from the same cut cycle. Thickness tolerance stacking becomes significant — if each wire produces ±2mm variance, your finished slabs might span a 4-6mm range that affects installation consistency.

Gang wire spacing determines your finished slab thickness, but you can’t arbitrarily position wires at any interval. The minimum practical spacing between adjacent wires measures 40-50mm to prevent mechanical interference between guide pulleys and to maintain adequate cooling water flow in each kerf. This means you’ll generate more scrap when cutting thin flagstone pavers under 1.5 inches thick, as the kerf-to-material ratio becomes unfavorable.

Edge Quality and Finishing

Wire-cut edges require different finishing approaches than blade-sawn edges due to the curved wire path and striation patterns. When you specify large format flagstone pieces with exposed edges, you need to account for additional edge treatment operations. The standard options include diamond grinding to remove major irregularities followed by honing to your desired finish level, or flaming for textured natural-appearance edges. Each finishing operation adds 25-40% to the linear foot cost of edge treatment and extends delivery schedules by 3-5 business days.

Edge perpendicularity matters for installation success, particularly on large format pieces where edge-to-edge joints create visual alignment issues. Wire sawing naturally produces edges within 1-2 degrees of perpendicular to the slab face, but achieving the ±0.5 degree tolerance needed for premium installations requires secondary squaring operations. Your fabricator runs finished slabs through bridge saw stations that trim 1/4 to 1/2 inch from each edge, ensuring precise geometry at the expense of final dimensions being slightly smaller than the initial wire-cut size.

Citadel Stone Manufactured Flagstone Excellence in Arizona

When you evaluate Citadel Stone’s manufactured flagstone for your Arizona project, you’re considering engineered materials that combine natural stone aesthetics with precision manufacturing tolerances. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach specification decisions for six representative cities using wire sawing capabilities to produce large format manufactured flagstone pavers.

Phoenix Precision Requirements

In Phoenix installations, you would specify wire-cut manufactured flagstone with thickness tolerance of ±1/8 inch to accommodate extreme thermal cycling between 115°F daytime peaks and 70°F nighttime lows during summer months. Your wire sawing protocols should address how thermal expansion affects joint spacing — you’ll need 3/16 inch joints for pieces exceeding 6 feet in any dimension to prevent edge spalling. The urban heat island effect in Phoenix metro areas amplifies surface temperatures by 8-12°F compared to surrounding desert, requiring you to verify that wire-cut surface finish provides adequate slip resistance when wet. At Citadel Stone, we would recommend verifying DCOF ratings exceed 0.50 for pool deck applications where water contact creates safety concerns.

Tucson Format Considerations

Tucson projects would benefit from large format manufactured flagstone cut to 4×8 foot dimensions that minimize joint count while maintaining handleability during installation. You would need to coordinate truck access for delivering pieces weighing 850-1,100 pounds each, requiring either crane placement or specialized material handling equipment on site. Your wire sawing specifications should address how Tucson’s monsoon season affects outdoor cutting operations — afternoon thunderstorms from July through September create production delays that extend lead times by 15-20%. The elevated UV exposure at Tucson’s 2,600-foot elevation requires you to verify that any sealers applied to wire-cut surfaces maintain clarity without yellowing over 10+ year service life.

Scottsdale Aesthetic Standards

High-end Scottsdale residential projects would require wire-cut manufactured flagstone with surface finishes matching adjacent natural stone elements. You would coordinate wire blade techniques that produce striation patterns fine enough for subsequent honing operations to achieve 200-grit equivalent smoothness. Your specification needs to address color consistency across multiple production runs, as Scottsdale clients expect minimal variation that wire sawing can help achieve by cutting sequential slabs from the same material block. You should plan for warehouse staging areas where you can lay out finished pieces before delivery, allowing you to arrange slabs for optimal color flow across the installation.

Flagstaff Freeze Protection

At Flagstaff’s 7,000-foot elevation, you would specify wire-cut manufactured flagstone with absorption rates below 3% to prevent freeze-thaw damage during winters with 100+ freeze-thaw cycles annually. Your flagstone accurate sawing protocols must produce smooth, sealed edges that don’t provide entry points for water infiltration that expands during freezing. You’ll need to account for how Flagstaff’s extended winter season from November through April limits outdoor installation windows to approximately 180 days annually. The wire cutting process should minimize micro-cracking that could propagate during freeze cycles, requiring slower feed rates that add 20% to production time but ensure long-term durability in this challenging climate.

Sedona Integration Requirements

Sedona architectural projects emphasize integration with red rock landscapes, requiring wire-cut manufactured flagstone in earth tone colors that complement the natural environment. You would specify flagstone large format cutting to produce irregular edge patterns that mimic natural cleft stone while maintaining the dimensional consistency needed for efficient installation. Your wire sawing approach should create pieces ranging from 18×24 inches to 4×6 feet within the same order, allowing pattern variation that appears organic rather than manufactured. At Citadel Stone, we would guide you through color selection processes that account for how Sedona’s intense sunlight affects perceived color — samples viewed under Arizona sun conditions often appear 15-20% lighter than indoor evaluations suggest.

Yuma Heat Performance

Yuma represents one of America’s hottest climate zones, where you would need wire-cut manufactured flagstone with proven thermal performance under sustained temperatures exceeding 120°F. Your specification should address how flagstone wire blade techniques affect surface porosity — tightly controlled wire speeds produce smoother surfaces with 5-8% lower water absorption that reduces evaporative cooling capacity. You’ll want to balance slip resistance requirements against heat retention properties, as rougher surfaces provide better traction but can reach 15-20°F higher temperatures than honed finishes. Yuma’s agricultural economy means high dust loads that affect wire cutting operations, requiring you to specify enclosed fabrication facilities with filtered air systems to prevent contamination during the cutting process that could compromise surface quality.

Production Efficiency Factors

Your project economics depend on understanding what drives wire sawing productivity. Stone hardness affects cutting speed exponentially rather than linearly — moving from a Mohs 4 limestone to a Mohs 6 sandstone doesn’t just slow cutting by 50%, it can triple your processing time. You need to request hardness testing data from your material supplier before committing to wire sawing methods for unfamiliar stone types. The relationship between hardness, abrasiveness, and wire wear determines whether wire sawing remains cost-effective compared to alternative cutting methods.

Block orientation during cutting significantly impacts both speed and finished quality. Cutting parallel to the stone’s natural bedding planes proceeds 30-40% faster than cutting perpendicular to bedding, but perpendicular cuts often produce more desirable surface characteristics with uniform texture. You should evaluate sample cuts in both orientations during the specification phase to determine which approach best serves your project requirements, recognizing the cost implications of slower cutting speeds.

- You’ll maximize efficiency by grouping multiple cuts from the same block rather than processing single slabs from different blocks

- Your production schedule should account for wire change intervals — typically every 45-60 linear feet of cutting in flagstone

- You can reduce setup time by standardizing cut dimensions across your project rather than specifying numerous custom sizes

- Wire sawing becomes economically favorable when you’re processing runs of 15+ pieces with similar dimensions

Quality Verification Protocols

Before accepting wire-cut flagstone deliveries, you need systematic inspection procedures that verify specification compliance. Dimensional verification should measure thickness at nine points across each slab — four corners, four midpoints, and center — to identify systematic variation patterns. You’ll detect wire tracking problems when thickness measurements show progressive change from one edge to the opposite edge rather than random variation. Your acceptance criteria should define maximum allowable thickness range based on slab size and intended application.

Surface quality inspection requires evaluating both the wire-cut face and any edges that received secondary processing. You should examine cut surfaces under raking light at shallow angles that highlight irregularities invisible under perpendicular illumination. Wire speed variations create periodic waviness with spacing matching the wire loop circumference — typically 12-16 feet for standard frame sizes. These waves measure only 0.5-1.0mm in amplitude but become visually obvious after installation when wet or under certain lighting conditions.

Alternative Cutting Methods

While wire sawing excels for specific applications, you should understand competing technologies to make informed specification decisions. Diamond blade gang saws process flagstone more quickly for standard thickness slabs under 10 feet in length, achieving production rates 2-3 times faster than wire methods. However, blade systems limit you to straight cuts and can’t handle the irregular block shapes that wire saws accommodate easily. Your material utilization improves with wire sawing when processing blocks with natural fissures or voids that would cause blade breakage.

Water jet cutting offers another alternative for complex shapes and curved cuts that wire systems can’t execute. You’ll achieve intricate patterns and custom profiles, but processing speeds drop dramatically — water jet operations measure cutting speed in inches per minute rather than feet per hour. The economics favor water jet only for specialty pieces where design complexity justifies the premium cost, typically 4-6 times higher than wire sawing for equivalent surface area.

Project Considerations

Your successful implementation of wire-cut flagstone depends on coordinating multiple project factors beyond the cutting process itself. You need to verify that your structural design accommodates the weight of large format pieces — a 4×8 foot slab at 1.5 inches thick weighs approximately 800 pounds, requiring adequate substrate support and potentially affecting foundation requirements. Building codes in some jurisdictions limit individual paver weight for safety reasons, particularly in elevated plaza applications where falling pieces present hazards.

Installation logistics change significantly with wire-cut large format pieces. You can’t hand-carry slabs exceeding 300-400 pounds, meaning you’ll need mechanical placement equipment throughout the installation process. This affects job site access requirements, labor costs, and installation timeline. Your contractor should plan for 20-30% longer installation duration compared to standard-size pavers, offset partially by reduced joint count that decreases grouting and sealing labor. For additional surface treatment insights, review Mechanical surface roughening methods for natural stone pavers before you finalize your project specifications. Contractor loyalty rewards come from Citadel Stone’s appreciation flagstone wholesale in Arizona programs.