When you’re planning architectural installations across Arizona’s desert landscape, you’ll encounter a critical challenge: how to achieve the aesthetic impact of full-thickness flagstone while managing weight restrictions, structural limitations, and budget constraints. Flagstone veneer cutting Arizona techniques transform standard-thickness slabs into lightweight profiles that maintain visual authenticity while solving practical installation problems. You need to understand the precise cutting methodologies, equipment requirements, and performance trade-offs that determine whether your veneer application will deliver 20-year durability or require costly remediation within five years.

The decision to specify flagstone thin cutting versus full-thickness installation affects everything from structural loading calculations to long-term maintenance protocols. Your project’s success depends on matching cutting technique to application type, substrate condition, and environmental exposure. What most specifiers miss is how profile reduction alters the material’s thermal performance, moisture behavior, and mechanical strength in ways that standard product literature doesn’t address.

Profile Reduction Fundamentals

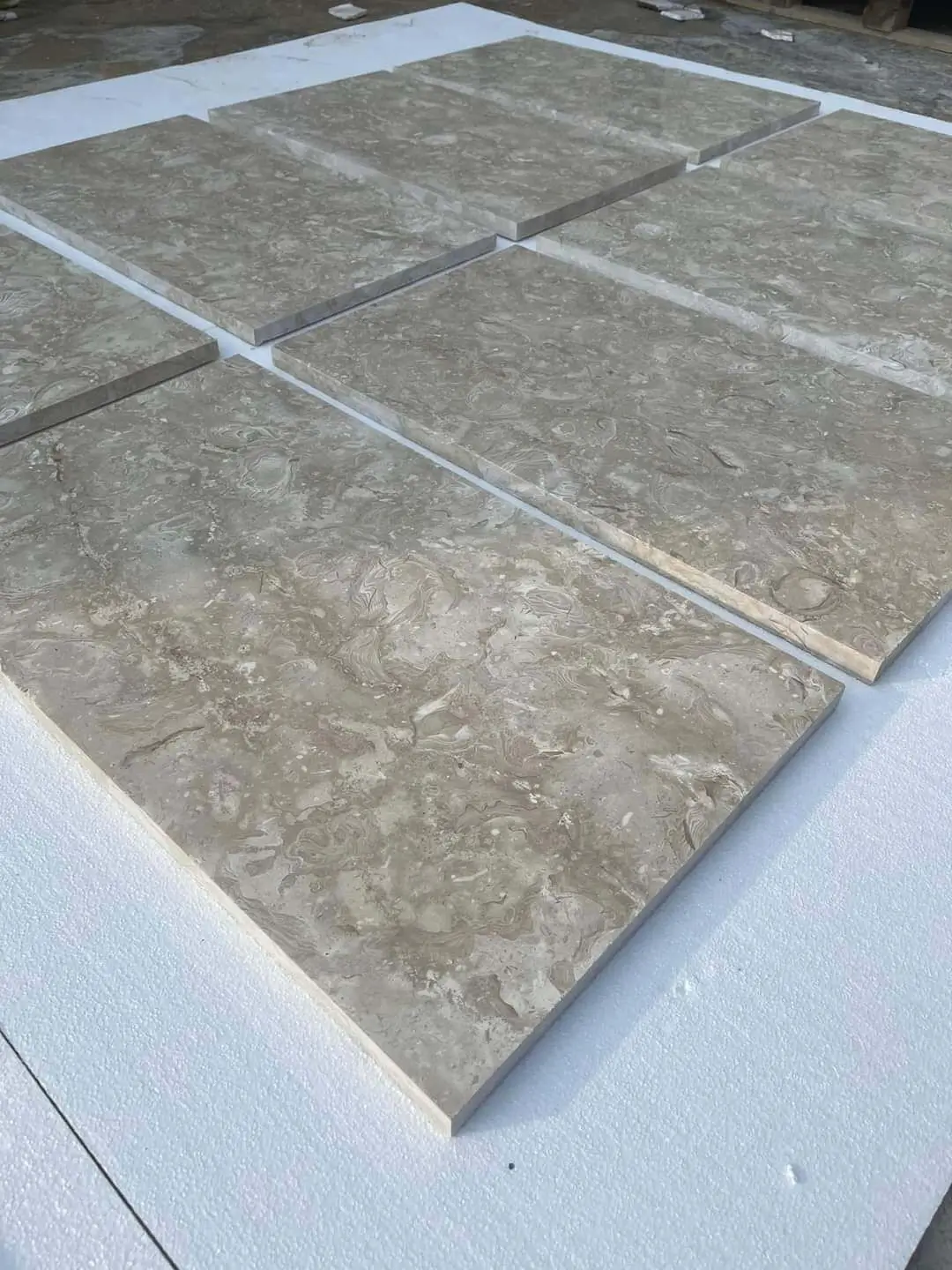

Flagstone veneer creation begins with understanding the relationship between original slab thickness and final application requirements. You’re typically working with source material ranging from 1.5 to 3 inches thick, reducing it to veneer profiles between 0.5 and 1.25 inches depending on installation method and structural demands. The cutting process isn’t simply about removing material—you’re fundamentally changing how the stone responds to thermal cycling, moisture infiltration, and mechanical stress.

When you specify flagstone profile reduction for Arizona applications, you need to account for the state’s extreme diurnal temperature swings that can exceed 40°F between day and night during shoulder seasons. Thinner profiles respond more quickly to temperature changes, which affects both thermal expansion behavior and surface temperature extremes. You’ll see peak surface temperatures on 0.75-inch veneer that are 8-12°F higher than equivalent full-thickness slabs during mid-afternoon exposure, creating conditions that impact both user comfort and long-term material stability.

The mechanical properties of cut flagstone require careful evaluation beyond simple compressive strength ratings. Your specification must address how cutting operations affect edge integrity, surface planarity, and internal stress distribution. Professional flagstone veneer cutting Arizona operations use diamond-blade wet saws with blade diameters matched to slab dimensions—typically 24 to 36-inch blades for production cutting. The wet-cutting process serves dual purposes: cooling the blade to prevent thermal damage to the stone matrix and suppressing silica dust that creates both health hazards and visibility problems in production environments.

Cutting Equipment Specifications

You’ll encounter three primary equipment categories for flagstone thin cutting operations, each with distinct capabilities and limitations that affect cut quality, production rates, and cost efficiency. Bridge saws provide the highest precision for dimensional cutting, with programmable positioning systems that deliver repeatability within ±0.5mm across production runs. These systems work best when you’re processing uniform slabs into consistent veneer dimensions for large-scale commercial installations.

For irregular flagstone shapes that require custom profiling, table saws with adjustable fences offer greater flexibility at lower capital cost. You sacrifice some precision—typical variance runs ±2mm on manual operations—but gain the ability to adapt cutting paths to natural stone edges and cleavage patterns. When you’re working with flagstone lightweight options for residential applications where perfect dimensional consistency matters less than character preservation, table saw operations provide the optimal balance.

- You should verify blade specifications match stone hardness and silica content

- Your water delivery system must maintain consistent flow at 4-6 gallons per minute

- You need adequate runoff management to handle slurry volumes exceeding 50 gallons per hour

- Your electrical service must support motor loads between 5-15 HP depending on blade diameter

Portable cutting systems serve specialized applications where you need to perform flagstone veneer cutting Arizona operations on-site rather than in controlled shop environments. These units compromise precision and production rate for mobility, but they solve critical problems when you’re retrofitting existing installations or working with fragile material that won’t survive transportation to off-site cutting facilities. Expect dimensional variance approaching ±3-4mm and production rates 60% lower than stationary equipment.

Dimensional Tolerance Management

When you establish thickness specifications for flagstone profile reduction projects, you’re balancing competing demands: structural requirements, aesthetic expectations, installation methodology, and cost constraints. The industry standard tolerance for veneer cutting is ±3mm for mechanized operations and ±5mm for hand-guided cuts, but your actual specification needs to account for how tolerance stacking affects installation outcomes.

Consider a typical scenario where you’re specifying 0.75-inch veneer with ±3mm tolerance. You’ll see actual delivered thickness ranging from 16mm to 22mm across a production lot. When you factor in substrate variation of ±2mm and setting bed thickness variance of ±3mm, your finished surface can exhibit elevation changes approaching 8mm between adjacent units. That’s enough variation to create perceptible lips at joints that become trip hazards and create visual irregularities that clients notice immediately.

Your specification approach should separate structural minimum thickness from aesthetic surface tolerance. You need to maintain minimum thickness for mechanical strength while controlling the exposed face planarity that determines visual quality. Professional flagstone veneer cutting Arizona operations achieve this through two-stage processing: initial rough cutting establishes thickness minimums with standard tolerance, followed by face grinding or honing that brings exposed surfaces into tighter planarity specs of ±1mm.

Moisture Behavior Modifications

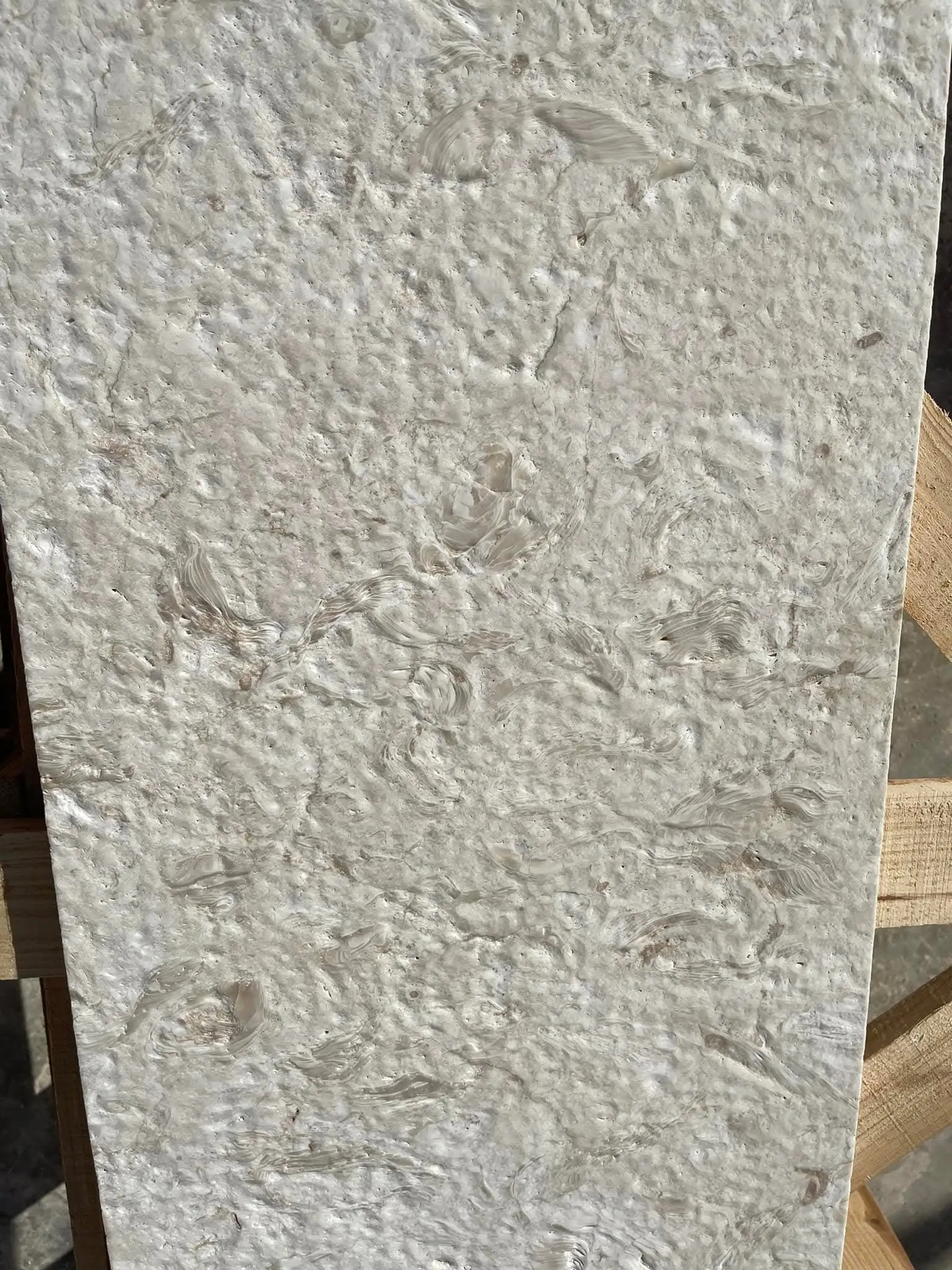

The transformation from full-thickness flagstone to thin veneer profiles fundamentally alters how the material interacts with moisture, affecting everything from efflorescence patterns to freeze-thaw durability. You need to understand that cutting operations expose interior stone surfaces that haven’t undergone the natural weathering and mineral migration processes that condition exterior faces during quarrying and initial processing.

Freshly cut surfaces exhibit porosity characteristics 15-25% higher than weathered faces, creating preferential pathways for moisture infiltration when used as the bedding surface in veneer applications. When you install cut-face-down in mortar or adhesive setting beds, you’re creating conditions where moisture can penetrate more readily than with natural-face bedding. This becomes critical in Arizona applications where you’re managing moisture from irrigation systems, monsoon exposure, and occasional freeze events in elevation zones above 3,500 feet.

For applications requiring flagstone lightweight options in moisture-exposed environments, consider specifying sealed cut faces before installation. Professional-grade penetrating sealers applied to cut surfaces reduce moisture absorption by 40-60% without creating impermeable barriers that trap subsurface moisture. You should verify compatibility between sealer chemistry and your planned setting materials—some sealers interfere with mortar bond development when applied to bedding faces.

Thermal Performance Considerations

Flagstone veneer cutting Arizona operations create thermal performance characteristics distinctly different from full-thickness installations, with implications for both user comfort and long-term material stability. The reduced thermal mass in thin profiles means faster temperature response to environmental conditions—a property that creates both advantages and challenges depending on application context and exposure conditions.

You’ll observe that 0.75-inch veneer reaches peak surface temperature approximately 90 minutes earlier in the daily cycle compared to 2-inch full-thickness slabs under identical solar exposure. This affects shaded cooling patterns in outdoor living spaces and influences the timing of peak discomfort for barefoot contact on pool decks and patio surfaces. When you’re designing spaces for afternoon use during Arizona’s extended summer season, this temporal shift in peak temperature can determine whether the installation meets functional requirements.

- Veneer profiles between 0.5-0.75 inches exhibit surface temperatures 10-15°F higher than full-thickness equivalents

- Thermal cycling amplitude increases by 25-30% in thin profiles versus thick slabs

- Thermal expansion coefficients remain constant but total dimensional change decreases proportionally with thickness

- Radiant cooling after sunset occurs 40-50% faster in veneer installations

The reduced thermal mass also affects freeze-thaw performance in Arizona’s higher elevation zones where you’ll encounter 20-40 annual freeze cycles. Thinner profiles cycle through the freeze-thaw threshold more frequently during marginal temperature conditions, increasing cumulative stress exposure. Your specification should account for this by requiring lower porosity ratings—below 4% absorption—for veneer applications in freeze-prone zones compared to 6% tolerances acceptable for full-thickness installations in the same environments.

Structural Attachment Methods

When you transition from full-thickness flagstone installation to flagstone veneer creation, your structural attachment methodology changes fundamentally. Full-thickness units rely primarily on bearing capacity and compressive strength transmitted through sand-set or mortar beds. Veneer installations shift load transfer to tensile bond strength between stone and substrate, creating failure modes you must address through proper material selection and surface preparation.

You’re working with bond strengths typically ranging from 50-150 PSI depending on substrate condition, setting material chemistry, and surface preparation quality. That’s adequate for vertical applications and protected horizontal surfaces, but you need to recognize the limitations for high-traffic areas and mechanically stressed installations. Professional flagstone thin cutting specifications for demanding applications often incorporate mechanical anchoring systems—stainless steel pins or tabs—that supplement adhesive bonds with positive mechanical connection.

For guidance on alternative approaches to achieving similar aesthetic outcomes, see natural Arizona flagstone available in Lake Havasu for comprehensive material options. Your attachment system selection depends on substrate type, with concrete providing optimal bond surfaces and wood or metal substrates requiring specialized primers and flexible adhesives that accommodate differential movement between materials with varying expansion coefficients.

Edge Treatment Specifications

The edges created during flagstone profile reduction require specific attention because they represent the most vulnerable zones for moisture infiltration, mechanical damage, and aesthetic defects. You’ll need to decide between three primary edge treatment approaches: natural breakage edges, saw-cut edges, and finished edges with secondary processing.

Natural breakage edges preserve the irregular character that defines flagstone aesthetics but create dimensional unpredictability that complicates layout and installation. When you’re working with flagstone veneer cutting Arizona projects that prioritize authentic appearance over dimensional precision, you can guide cutting operations to intersect natural cleavage planes, allowing controlled breakage that mimics natural edges while maintaining thickness control. This technique requires skilled operators who understand the stone’s internal structure and can read cleavage indicators during cutting operations.

Saw-cut edges provide maximum dimensional control but create geometric precision that may conflict with rustic design intent. You can mitigate this through secondary edge processing—tumbling, flaming, or hand-chiseling—that softens the mechanical appearance while maintaining the dimensional advantages. Professional operations typically add $2-4 per linear foot for secondary edge finishing, but you gain installation efficiency through improved unit-to-unit fit that reduces field adjustment time.

Application-Specific Thickness Recommendations

Your thickness specification for flagstone lightweight options must match application demands with material capabilities, recognizing that insufficient thickness creates premature failure while excess thickness wastes material and increases unnecessary cost. Vertical veneer applications on interior or protected exterior walls function reliably at 0.5-0.625 inch thickness when properly adhered to sound substrates. You’re relying entirely on adhesive bond strength with minimal mechanical stress beyond the stone’s own weight.

Horizontal applications introduce significantly higher demands. Protected patio surfaces with pedestrian traffic only require minimum 0.75-inch thickness to provide adequate flexural strength across typical joint spacing of 8-12 inches. When you increase loading to vehicular traffic or reduce support spacing beyond 12 inches, you need to step up to 1.0-1.25 inch profiles to prevent flexural failure under concentrated loads.

- You should specify 0.5-0.625 inches for interior wall veneer applications

- Your exterior wall specifications require 0.625-0.75 inches to handle thermal cycling

- You need 0.75-1.0 inches for pedestrian paving on well-supported bases

- Your vehicular applications demand 1.25-1.5 inches minimum for durability

Pool coping and raised edge conditions create special challenges because the stone cantilevers beyond its support, creating bending moments that demand higher thickness. You’ll achieve 15-20 year service life with 1.25-inch minimum thickness for coping applications with 2-3 inch overhang, increasing to 1.5 inches for 4-inch overhangs common in contemporary pool designs.

Cost Efficiency Analysis

The economic case for flagstone veneer cutting Arizona operations versus full-thickness installation depends on multiple factors beyond simple material cost per square foot. You need to account for reduced structural requirements, simplified installation, decreased transportation costs, and potential performance trade-offs that affect lifecycle costs.

Material yield represents the first economic consideration. When you process full-thickness slabs into veneer, you’re typically achieving 2.0-2.5 square feet of veneer surface per square foot of source material, depending on waste factors and thickness reduction ratio. A 2-inch source slab cut into 0.75-inch veneer theoretically yields 2.67 times the coverage area, but practical yield averages 2.2-2.4 after accounting for kerf loss, breakage, and dimension optimization.

Transportation economics favor veneer significantly in Arizona’s dispersed geography where project sites may be 100-300 miles from material sources or warehouse locations. You’ll reduce shipping weight by 60-70% compared to full-thickness equivalent coverage, translating to freight cost reductions of 45-55% when shipping by dedicated truck. For smaller orders using LTL carriers, the savings become even more pronounced because you’re reducing dimensional weight calculations that often control LTL pricing.

Quality Control Protocols

Professional flagstone thin cutting operations implement systematic quality control that addresses dimensional accuracy, surface integrity, and structural soundness. You should require verification protocols at three stages: incoming material inspection, post-cutting verification, and pre-shipment final inspection. Each stage catches specific defect categories that, if undetected, create field installation problems or performance failures.

Incoming material inspection focuses on structural flaws that cutting operations might expose or exacerbate. You’re looking for internal fractures, clay seams, iron concentrations, and fossil voids that compromise structural integrity or create aesthetic defects in finished veneer. Professional operations reject 8-15% of incoming material during this stage, with rejection rates climbing to 20-25% for lower-grade source material.

Post-cutting verification measures dimensional compliance and identifies cutting defects including blade wander, surface scoring, and edge chipping. You should establish acceptance criteria based on application requirements—±2mm tolerance for precision installations versus ±5mm for rustic applications. Statistical process control monitoring tracks dimensional trends across production runs, identifying equipment calibration drift before it produces out-of-spec material.

Manufactured Flagstone Pavers Arizona: Citadel Stone Project Planning

When you evaluate Citadel Stone’s manufactured flagstone pavers for your Arizona projects, you’re considering engineered products designed specifically for the state’s extreme climate demands. At Citadel Stone, we provide technical guidance for both full-thickness and veneer applications across Arizona’s diverse environments. This section outlines how you would approach specification decisions for representative cities, demonstrating the analysis process you should follow when planning your installations.

Arizona’s climate zones span from low desert valleys with minimal freeze exposure to high-elevation communities experiencing 60+ annual freeze-thaw cycles. Your material selection and thickness specification must account for these variations while maintaining design consistency across multi-site developments. Flagstone veneer cutting Arizona techniques allow you to optimize material use by matching thickness to site-specific demands rather than applying uniform specifications across varying conditions.

Chandler Applications

In Chandler’s low-desert environment, you would address extreme heat exposure with minimal freeze concerns. Your specifications would focus on thermal performance and UV stability for installations experiencing 175+ days annually above 95°F. You’d typically specify 0.75-1.0 inch veneer for protected patio applications, stepping up to 1.25 inches for unshaded pool deck areas where thermal cycling amplitude exceeds 80°F daily during peak season. When you verify warehouse availability, you should confirm lead times accommodate summer installation constraints that limit working hours to early morning periods. Local soil conditions in Chandler’s clay-heavy substrates would require you to address base preparation that prevents differential settlement affecting veneer integrity over time.

Tempe Considerations

Tempe applications would demand similar heat management but with added complexity from urban heat island effects that elevate nighttime temperatures 8-12°F above surrounding areas. You would need to account for reduced thermal cycling amplitude in your expansion joint specifications, potentially allowing 18-foot spacing versus 15-foot standards in less urbanized areas. Your flagstone lightweight options would provide advantages for rooftop and elevated deck installations common in Tempe’s mixed-use developments where structural loading constraints limit full-thickness applications. When you coordinate truck deliveries to dense urban sites, you’d need to address access restrictions and staging limitations that affect material handling logistics and installation sequencing.

Surprise Specifications

In Surprise’s rapidly developing northwestern valley location, you would encounter newer construction with engineered substrates providing optimal veneer installation conditions. Your specifications could take advantage of consistent base preparation to minimize thickness requirements—0.75 inches would suffice for most pedestrian applications when you’re working over properly compacted aggregate bases meeting 95% modified Proctor density. The area’s master-planned communities would allow you to establish consistent material specifications across multiple phases, optimizing warehouse inventory management and achieving economies of scale through consolidated ordering. You’d want to verify that your cutting operations could maintain production continuity for multi-year development timelines requiring consistent material appearance across sequential installations.

Mesa Parameters

Mesa’s elevation range from 1,200 to 1,800 feet creates microclimates requiring adjusted specifications. You would address occasional light freeze events in northern Mesa neighborhoods by specifying lower porosity ratings—below 4% absorption—for flagstone veneer creation serving exposed horizontal applications. Your thickness specifications would increase to 1.0-1.25 inches for these freeze-prone areas to provide additional thermal mass buffering that reduces freeze-thaw cycling frequency during marginal temperature conditions. When you plan material staging, Mesa’s extensive geography would require you to consider multiple delivery points to minimize on-site transportation distances across large-scale residential developments.

Scottsdale Requirements

Scottsdale applications would typically emphasize premium aesthetics requiring tighter dimensional tolerances and refined edge treatments. You’d specify ±2mm thickness tolerance versus ±3-4mm standards for less demanding applications, requiring more sophisticated flagstone thin cutting equipment and skilled operators. Your edge treatment specifications would likely incorporate secondary processing—light tumbling or hand-finishing—to achieve the refined-yet-natural appearance characteristic of high-end Scottsdale installations. When you coordinate with architects and designers on these projects, you’d need to provide larger sample selections allowing precise color and texture matching across multiple material lots to maintain visual consistency in prominent installations.

Glendale Planning

In Glendale’s mixed residential and commercial environment, you would balance performance requirements with budget constraints affecting municipal and commercial projects. Your flagstone profile reduction specifications would optimize material usage by varying thickness across single projects—0.75 inches for low-traffic areas and 1.0-1.25 inches for high-traffic zones. This graduated approach would reduce overall material costs while maintaining adequate performance where demands justify thicker profiles. You’d want to verify that cutting operations could efficiently process mixed-thickness orders without excessive setup time that negates material savings. When you estimate installation labor, Glendale’s competitive market would require you to provide detailed layout drawings that minimize field cutting and adjustment time affecting labor productivity.

Common Specification Errors

When you develop specifications for flagstone veneer cutting Arizona projects, certain recurring errors compromise performance, increase costs, or create installation difficulties. The most common mistake involves specifying uniform thickness across applications with varying structural demands. You waste material and budget when you apply 1.25-inch thickness to protected wall applications that would perform adequately at 0.625 inches, while you create failure risk by specifying 0.75 inches for vehicular applications requiring 1.5 inches minimum.

Inadequate tolerance specification represents another frequent problem. When you specify thickness without addressing planarity and edge straightness tolerances, you leave critical quality parameters undefined. Your installer receives material meeting thickness specs but exhibiting surface warping or edge irregularity that creates installation problems and aesthetic defects. Professional specifications separate three distinct tolerances: thickness (typically ±3mm), planarity (±2mm across any 12-inch span), and edge straightness (±3mm deviation across full edge length).

- You should avoid specifying thickness alone without planarity and edge tolerance

- Your specifications must address both structural minimum and aesthetic surface requirements

- You need to verify cut surface treatment requirements for moisture-exposed applications

- Your edge treatment specs should match design intent while maintaining installation efficiency

Failure to address moisture management in cut surfaces creates delayed problems that don’t manifest until months or years post-installation. When you don’t specify sealer application to cut faces in moisture-exposed applications, you’re accepting 40-60% higher moisture absorption rates through bedding surfaces compared to natural-face installations. This accelerates efflorescence development, freeze-thaw damage in susceptible climates, and staining from substrate moisture carrying soluble salts into the stone.

Installation Coordination

Successful flagstone lightweight options installation requires coordination between cutting operations, material delivery, substrate preparation, and field installation sequencing. You need to recognize that veneer installation proceeds differently than full-thickness work, with tighter timing requirements because adhesive working times and environmental conditions create narrower installation windows.

Your project schedule should account for substrate preparation completion before material delivery. Unlike sand-set full-thickness installations where you can stockpile material on-site during base preparation, adhesive-set veneer requires clean, protected storage and immediate installation capability upon delivery. You’ll minimize material handling damage and weather exposure by scheduling delivery in quantities matching 2-3 days’ installation capacity rather than full-project quantities delivered at once.

Weather restrictions for veneer installation exceed those for conventional flagstone work. You need to avoid installation when substrate temperatures fall below 40°F or exceed 90°F, when precipitation threatens within 24 hours, or when wind speeds exceed 15 mph creating dust contamination of adhesive surfaces. These constraints significantly limit installation windows during Arizona’s summer months and occasional winter weather events, requiring you to build schedule flexibility that accounts for weather delays.

Performance Expectations

When you set performance expectations for flagstone veneer cutting Arizona installations, you should base projections on realistic assessment of material properties, installation quality, environmental exposure, and maintenance commitment. Well-executed veneer installations in appropriate applications deliver 20-30 year service life matching full-thickness equivalents, but you need to recognize the conditions that make this outcome achievable.

Vertical applications in protected locations represent the lowest-risk veneer use, with minimal mechanical stress and reduced environmental exposure. You can expect these installations to maintain structural integrity and aesthetic appearance for 25-35 years with minimal maintenance beyond periodic cleaning. Horizontal applications introduce higher demands through traffic wear, thermal cycling, and moisture exposure that require more aggressive maintenance protocols to achieve comparable service life.

For additional surface protection strategies, review Protective resin coatings that enhance and seal flagstone surfaces before you finalize your project specifications. Your maintenance program should include biennial resealing for horizontal applications in moisture-exposed locations, annual joint inspection and repair, and periodic cleaning using pH-neutral products that don’t degrade sealers or accelerate surface weathering. Professional maintenance extends veneer service life by 40-60% compared to unmaintained installations experiencing accelerated degradation from moisture infiltration and surface contamination. Citadel Stone’s fleet ensures reliable wholesale flagstone pavers in Arizona delivery.