When you specify flagstone for Arizona installations, thickness selection directly determines whether your project performs as expected or fails within the first five years. You’ll encounter thickness options ranging from 1 inch to 3 inches, and each increment carries specific load-bearing implications that affect everything from pedestrian pathways to vehicular applications. The relationship between thickness, weight capacity, and substrate preparation creates a specification challenge that requires you to balance structural performance against budget constraints.

Your flagstone thickness selection guide Arizona begins with understanding that load-bearing capacity isn’t just about the stone itself. You need to account for how base preparation, joint spacing, and regional soil conditions interact with material thickness to create a complete structural system. The decision you make during specification affects installation costs, long-term maintenance requirements, and whether your client faces premature failure or enjoys decades of reliable performance.

Thickness Fundamentals and Structural Performance

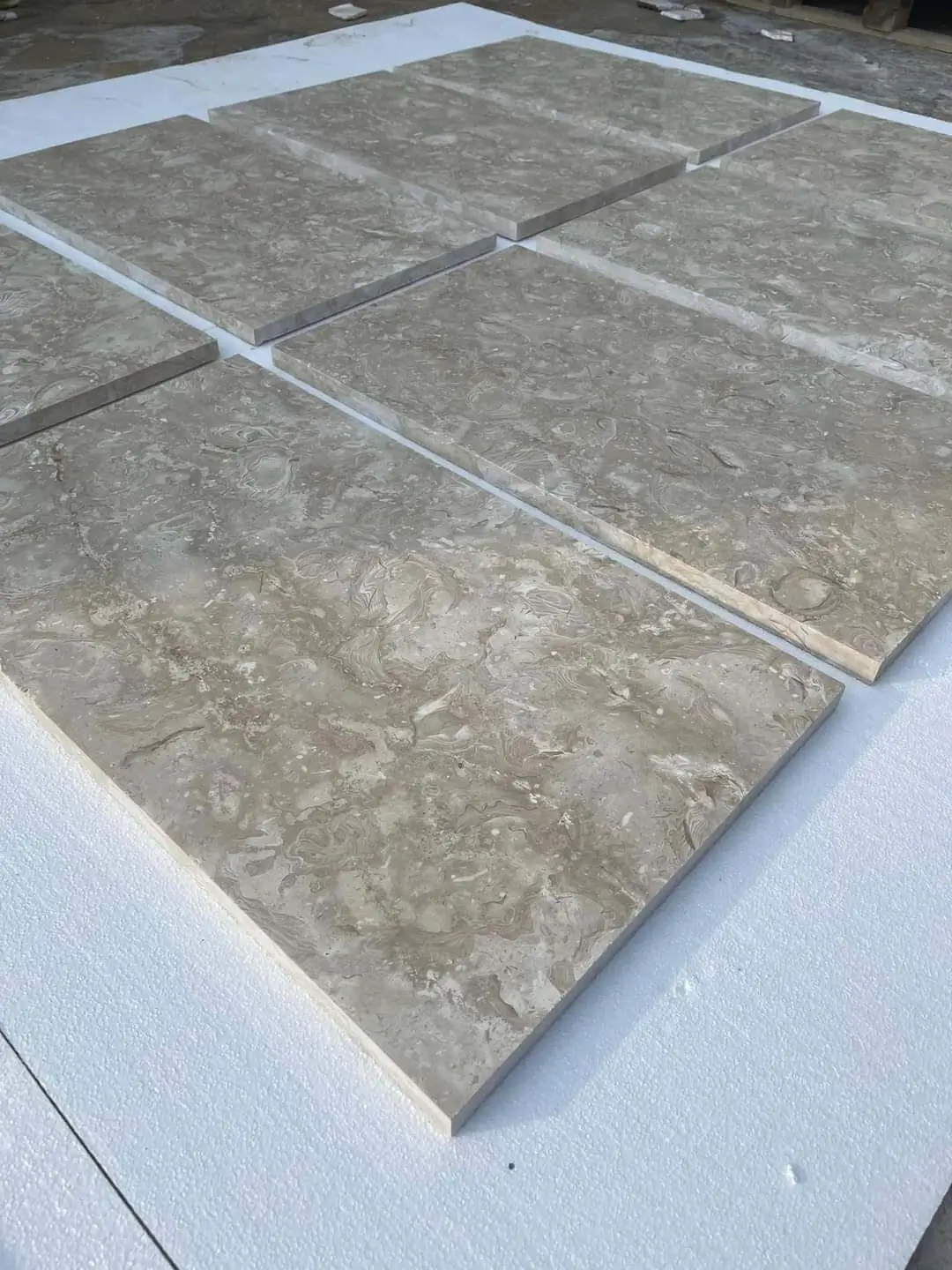

You should understand that flagstone thickness directly correlates with flexural strength, which determines how the material responds to point loads and deflection stress. When you work with 1-inch thick material, you’re limited to pedestrian traffic applications with properly prepared bases. Your specification needs to increase to 1.5-inch thickness for commercial foot traffic areas, and 2-inch or greater thickness for any application involving vehicular loads or equipment access.

The structural performance of flagstone thickness selection guide Arizona applications depends on three interconnected factors you must evaluate simultaneously. First, the material’s inherent compressive strength typically ranges from 12,000 to 18,000 PSI for quality Arizona flagstone. Second, your base preparation quality determines how loads transfer from the surface through the stone into the substrate. Third, the span between support points affects maximum safe loading regardless of material strength.

- You need minimum 1-inch thickness for residential walkways with foot traffic only

- Your commercial plaza specifications require 1.5-inch minimum thickness for concentrated pedestrian loads

- You must specify 2-inch thickness for driveway applications with passenger vehicle access

- Your heavy equipment areas demand 2.5 to 3-inch thickness with reinforced base systems

When you evaluate Flagstone Suppliers in Arizona thickness options, you’ll find that each 0.5-inch increment adds approximately 6-7 pounds per square foot to the installed weight. This weight increase affects not just structural capacity but also installation labor costs and substrate bearing requirements. You should calculate total system weight including base materials to verify your substrate can support the complete assembly without settlement issues.

Load-Bearing Capacity and Application-Specific Requirements

Your load-bearing calculations must account for both static loads and dynamic impact forces that occur during normal use. When you specify flagstone for pedestrian applications, you’re dealing with point loads ranging from 150 to 250 pounds concentrated on areas as small as 1-2 square inches. For vehicular applications, your calculations need to accommodate loads exceeding 3,000 pounds per tire contact patch, with impact factors increasing loads by 30-40% during normal driving conditions.

The relationship between thickness and span becomes critical when you work with unsupported spans between base contact points. You’ll find that 1-inch material safely spans 6-8 inches between rigid support points, while 1.5-inch thickness extends safe spans to 10-12 inches. Your 2-inch material specifications allow spans up to 14-16 inches, which accommodates less precisely compacted base preparations common in residential installations.

For flagstone thickness selection guide Arizona projects, you need to consider how thermal cycling affects structural performance over time. The material experiences temperature differentials exceeding 140°F between summer midday surface temperatures and winter nighttime lows. These thermal cycles create expansion and contraction movements that stress the material at support points, effectively reducing safe load capacity by 8-12% compared to laboratory testing conditions.

Pedestrian Pathway Specifications and Design Criteria

When you design pedestrian pathways using flagstone thickness selection guide Arizona guidelines, you’re balancing aesthetics against long-term durability requirements. You should specify minimum 1-inch thickness for residential applications where foot traffic remains light and infrequent. Your base preparation becomes the critical performance factor at this thickness, requiring you to maintain 4-6 inches of compacted aggregate base with 95% compaction density to prevent deflection under load.

Your commercial pathway specifications demand increased thickness to accommodate higher traffic volumes and prevent accelerated wear. You’ll find that 1.5-inch thickness provides the durability margin needed for shopping centers, office complexes, and public spaces where daily traffic counts exceed 500 pedestrians. The additional thickness reduces stress concentrations at support points by approximately 35% compared to 1-inch material, which translates to service life extensions from 15-20 years to 25-30 years in properly maintained installations.

- You need compacted aggregate base depth equal to 4-6 times the flagstone thickness

- Your joint spacing should not exceed 0.5 inches for optimal load distribution

- You must verify base materials provide permeability exceeding 10 inches per hour

- Your edge restraint systems require anchoring every 24-30 inches for thickness under 1.5 inches

The interaction between local flagstone suppliers in Arizona load bearing specifications and pathway width affects your thickness selection decisions. When you design pathways wider than 48 inches, you create longer unsupported spans that increase deflection risk. You should increase thickness by 0.25 inches for each additional 12 inches of pathway width beyond 48 inches, or add intermediate support through modified base preparation techniques.

Vehicular Application Requirements and Heavy Load Specifications

You face significantly different specification requirements when your flagstone installation must support vehicular traffic. Your minimum thickness jumps to 2 inches for passenger vehicle applications, and you need to verify that selected material demonstrates minimum 14,000 PSI compressive strength. The base preparation requirements intensify dramatically, with you needing to provide 8-12 inches of compacted aggregate base at 98% density to prevent rutting and settlement under repeated loading.

When you specify flagstone for areas with commercial vehicle access or equipment traffic, your thickness requirements increase to 2.5-3 inches depending on gross vehicle weight ratings. You should understand that natural flagstone suppliers in Arizona weight capacity specifications assume single-piece installation without through-cracks or lamination defects. Any material showing internal planes of weakness requires rejection regardless of nominal thickness, as these defects concentrate stress and lead to catastrophic failure under vehicular loads.

Your driveway applications create unique challenges because turning movements generate lateral shear forces exceeding straight-line traffic by 200-300%. You need to address these forces through enhanced edge restraint systems and modified joint patterns that prevent horizontal displacement. The flagstone thickness selection guide Arizona protocols require you to increase thickness by 0.5 inches in areas where vehicles regularly execute turning maneuvers compared to straight approach sections.

- You must specify minimum 2-inch thickness for driveways serving passenger vehicles

- Your commercial vehicle areas require 2.5-inch thickness with reinforced base preparation

- You need to increase thickness to 3 inches where gross vehicle weights exceed 15,000 pounds

- Your turning radius areas demand thickness increases of 0.5 inches above adjacent sections

Base Preparation Integration with Thickness Selection

The relationship between your flagstone thickness and required base preparation depth follows established ratios that you must respect for reliable performance. You should provide base depth equal to minimum 4 times the flagstone thickness for pedestrian applications, increasing to 6 times thickness for vehicular loads. This ratio ensures adequate load distribution into the substrate while preventing punch-through failures where concentrated loads exceed base bearing capacity.

Your base material selection interacts with thickness specifications to create the complete structural system. You’ll achieve optimal performance when you use crushed angular aggregate in the 0.75-inch minus gradation, which compacts to 96-98% density and provides interlock that resists horizontal displacement. When you work with Flagstone Suppliers in Arizona thickness specifications, you need to verify that warehouse stock includes consistent thickness tolerances within ±0.25 inches to prevent rocking and settlement issues during installation.

The compaction requirements for your base preparation increase with flagstone thickness because heavier materials generate higher impact forces during installation. You should achieve minimum 95% compaction for 1-inch material applications, increasing to 98% compaction for 2-inch and thicker installations. Your compaction verification needs to occur in 2-inch lifts using nuclear density gauge testing or comparable methods that document compliance before flagstone placement begins.

Thermal Performance and Climate-Specific Factors

When you specify flagstone thickness selection guide Arizona installations, thermal performance becomes a critical consideration that affects both structural integrity and user comfort. You need to understand that material thickness directly influences thermal mass properties and surface temperature behavior. Your 1-inch material reaches peak surface temperatures within 2-3 hours of solar exposure, while 2-inch thickness extends this thermal lag to 4-5 hours, which can reduce peak temperatures by 12-18°F through increased thermal mass effects.

The thermal expansion coefficient for quality flagstone typically ranges from 4.8 to 5.6 × 10⁻⁶ per °F, which you must account for in joint spacing calculations. When you work with 2-inch thick material in Arizona installations experiencing 140°F temperature swings, you’ll see dimensional changes of approximately 0.08 inches per 10 linear feet. Your joint spacing needs to accommodate this movement while maintaining structural interlock, typically requiring 0.375 to 0.5-inch joints for optimal performance.

- You should expect surface temperatures 15-25°F above ambient air temperature during peak solar exposure

- Your thermal mass calculations show 2-inch material stores 40% more heat than 1-inch thickness

- You need joint spacing that accommodates 0.08 inches expansion per 10 feet of material

- Your light-colored material selections reduce peak surface temperatures by 10-15°F compared to dark stone

The interaction between thickness and thermal cycling affects long-term durability through repeated stress at support points. You’ll find that thicker material better resists thermal stress cracking because the increased mass dampens temperature fluctuations at the stone-base interface. When you evaluate local flagstone suppliers in Arizona load bearing performance over time, you should account for 5-8% strength reduction after 10 years of thermal cycling in properly specified installations.

Porosity, Drainage, and Moisture Management

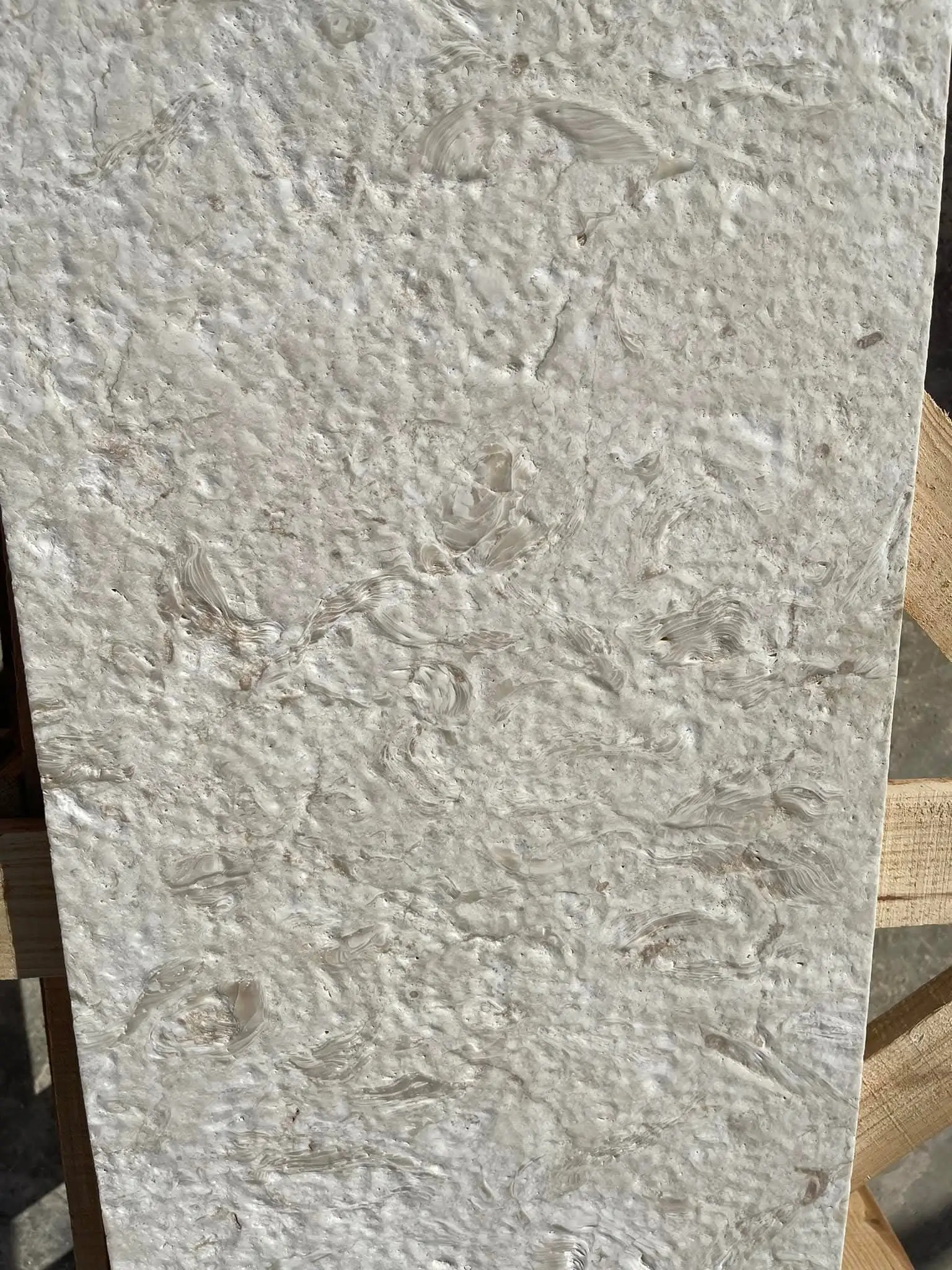

Your thickness selection decisions affect drainage performance through the relationship between material volume and pore structure connectivity. When you specify flagstone with porosity ranging from 3-7%, you need to understand that thicker material provides greater total pore volume that can temporarily store moisture during precipitation events. This storage capacity affects how quickly water transfers through the material into the base layer, with 2-inch thickness providing approximately 60% more temporary storage than 1-inch material.

The drainage requirements for your installation depend on whether you’re working with pedestrian or vehicular applications. You need to provide base materials with permeability exceeding flagstone permeability by minimum 3-4 times to prevent subsurface water accumulation. When you encounter situations where natural flagstone suppliers in Arizona weight capacity specifications include high-porosity material, you should increase base permeability proportionally to maintain proper drainage gradients.

Your flagstone thickness selection guide Arizona protocols must address freeze-thaw durability in northern regions where Flagstaff and surrounding areas experience 100+ annual freeze-thaw cycles. You need to specify material with porosity below 5% and verify that pore structure shows minimal interconnection that could allow water penetration and ice formation. The thickness becomes critical because freeze damage typically initiates at the bottom surface where moisture accumulates, making thinner material more vulnerable to spalling and delamination failures.

Installation Methodology and Thickness-Specific Techniques

When you plan installation procedures, material thickness dictates handling requirements and placement techniques that affect labor costs and schedule. You’ll find that 1-inch material allows single-person handling for pieces up to 18-24 inches in dimension, while 2-inch thickness requires two-person crews for pieces exceeding 12 inches. Your labor productivity typically decreases by 25-30% when you move from 1-inch to 2-inch material due to increased handling difficulty and placement precision requirements.

Your setting bed preparation changes with material thickness because you need to accommodate increased weight and maintain consistent support across the entire bottom surface. You should use 1-inch sand setting beds for 1-inch flagstone, increasing to 1.5-inch beds for 2-inch material to allow adequate adjustment during placement. When you work with Flagstone Suppliers Arizona application specs for thick material, you need to verify that setting bed materials remain consistent in gradation and moisture content to prevent differential settlement after installation.

- You need single-person handling capability for 1-inch material under 20 inches dimension

- Your 2-inch material requires two-person crews for efficient installation productivity

- You should provide setting bed depth equal to flagstone thickness for optimal adjustment

- Your joint filling procedures must address 30-40% greater joint volume in 2-inch installations

The vibration and compaction requirements during installation increase with material thickness. You’ll achieve proper seating when you use plate compactors generating 3,000-4,000 pounds force for 1-inch material, increasing to 5,000-6,000 pounds force for 2-inch thickness. Your compaction passes need to occur after joint filling reaches 50-60% depth to provide lateral restraint that prevents edge chipping during the compaction process.

Cost Analysis and Value Engineering Thickness Decisions

Your material costs increase proportionally with thickness, but you need to understand that the relationship isn’t linear when you account for complete installed costs. When you specify 2-inch material instead of 1-inch thickness, your material costs typically increase by 85-95% rather than doubling because quarrying efficiency improves with thicker production runs. The installation labor costs increase by only 25-35% despite the material weight doubling, because handling techniques and crew efficiency adapt to accommodate heavier pieces.

The value engineering equation changes when you factor long-term performance and replacement costs into your analysis. You’ll find that flagstone thickness selection guide Arizona installations using 1.5-inch material in commercial applications cost approximately 40% more initially than 1-inch specifications, but service life extends from 15-20 years to 25-30 years. Your lifecycle cost analysis shows the thicker material provides 15-20% lower annualized costs when you account for replacement expenses and business interruption during reconstruction.

When you evaluate proposals from local flagstone suppliers in Arizona load bearing specialists, you should request pricing for multiple thickness options simultaneously. You’ll often discover volume pricing advantages that reduce incremental costs for thicker material by 10-15% compared to ordering different thicknesses separately. For comprehensive material options and technical guidance, see our natural flagstone resources which provide detailed specification support. Your truck delivery scheduling becomes more efficient when you standardize on single thickness specifications across project phases, reducing warehouse coordination complexity and potential material shortages.

Edge Details and Restraint System Requirements

Your edge restraint specifications must scale with material thickness to prevent horizontal displacement and maintain geometric alignment over time. When you work with 1-inch flagstone, you can typically specify plastic or aluminum edge restraints anchored every 24 inches into compacted base materials. Your 2-inch thickness applications require more robust restraint systems, with you needing to specify steel or reinforced composite materials anchored every 18 inches to accommodate the increased lateral forces generated by heavier material.

The relationship between thickness and edge restraint becomes critical in areas subject to vehicular traffic or equipment loads. You need to understand that lateral forces at edges increase disproportionately with material weight because thicker pieces generate higher momentum during any horizontal displacement events. Your restraint system anchoring depth should equal minimum 1.5 times the flagstone thickness, with anchor spacing decreasing as thickness increases to maintain consistent restraint capacity per linear foot.

- You should specify plastic edge restraints for 1-inch pedestrian applications with 24-inch anchor spacing

- Your 1.5-inch commercial applications require aluminum or steel restraints anchored every 20 inches

- You need heavy-duty steel restraints for 2-inch vehicular applications with 18-inch anchor spacing

- Your restraint system anchoring depth must equal minimum 1.5 times flagstone thickness

Common Specification Errors and Performance Failures

You’ll encounter recurring specification errors that lead to premature failure regardless of material quality when thickness selection doesn’t match application requirements. The most common mistake involves specifying 1-inch material for commercial applications where traffic volumes and load concentrations exceed residential parameters. You should understand that this under-specification leads to corner breakage, surface spalling, and complete fracture failures typically appearing within 3-5 years rather than expected 20-25 year service life.

Your specifications fail when you don’t account for the complete load path from surface through flagstone into base and substrate materials. When you specify adequate thickness but pair it with inadequate base preparation, you create a weak link that concentrates stress and causes premature failure. The natural flagstone suppliers in Arizona weight capacity ratings assume proper base support, and you’ll see published capacity reductions of 40-60% when base compaction falls below 95% density or depth decreases below minimum requirements.

The interaction between joint spacing and thickness creates failure modes you need to avoid through proper specification integration. You’ll generate problems when you specify wide joints exceeding 0.75 inches with thin material under 1.5 inches, because the unsupported edges become vulnerable to impact damage and corner breakage. Your joint spacing should decrease as material thickness decreases, maintaining edge support that prevents cantilever stress concentrations during normal loading conditions.

Citadel Stone Approach: hardscape stone suppliers in Arizona Technical Guidance Across Arizona Regions

When you consider Citadel Stone’s hardscape stone suppliers in Arizona materials for your projects, you’re evaluating premium flagstone products engineered for Arizona’s extreme climate conditions. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse geographic regions, from low desert installations to high elevation mountain settings. This section outlines how you would approach thickness selection decisions and load-bearing specifications for six representative Arizona cities, demonstrating application-specific considerations you should evaluate during project planning.

Your thickness selection process would need to account for regional climate variations, soil conditions, and typical application requirements that differ substantially across Arizona’s elevation and temperature zones. You should recognize that warehouse delivery logistics and material availability affect your project scheduling in ways that require early coordination with suppliers. The following city-specific scenarios demonstrate how you would integrate thickness specifications with local conditions to achieve optimal performance outcomes.

Phoenix Heat Specifications

In Phoenix applications, you would specify minimum 1.5-inch thickness for commercial pedestrian areas to address extreme thermal cycling that creates material stress exceeding typical desert environments. Your load-bearing calculations would need to account for thermal expansion generating 0.09 inches movement per 10 feet during summer temperature swings from 75°F nighttime lows to 115°F afternoon peaks. You should recommend 2-inch thickness for vehicular applications where surface temperatures regularly exceed 160°F, creating thermal stress that reduces effective load capacity by 10-12% compared to moderate climate installations. Your base preparation would require 8-10 inches compacted depth at 97% density to prevent settlement in Phoenix’s caliche-laden soils that soften during monsoon moisture infiltration events.

Tucson Load Requirements

Your Tucson specifications would emphasize 1.5 to 2-inch thickness ranges for mixed-use applications combining pedestrian and occasional vehicular access common in residential courtyard designs. You would need to address the city’s 12-inch annual rainfall concentration during monsoon season, requiring enhanced drainage specifications with base permeability exceeding 15 inches per hour. The flagstone thickness selection guide Arizona recommendations for Tucson would include provisions for thermal mass utilization in outdoor living spaces, where 2-inch material provides temperature moderation benefits during evening hours. Your edge restraint systems would need reinforcement in areas subject to monsoon runoff erosion, with anchor spacing reduced to 16 inches in vulnerable perimeter locations.

Scottsdale Luxury Applications

When you plan high-end Scottsdale installations, you would typically specify 2-inch thickness as the minimum standard for luxury residential and resort applications where visual mass and premium aesthetics drive material selection. Your specifications would address the integration of flagstone with water features and pool decks, requiring slip resistance verification through ASTM C1028 testing showing wet dynamic coefficient exceeding 0.50. You should account for vehicle access requirements in resort porte-cochère areas where 2.5-inch thickness becomes necessary to support shuttle buses and service vehicles. Your material selections would emphasize warm earth tones that complement desert landscaping while maintaining surface temperatures within acceptable ranges for barefoot traffic around pool areas, requiring you to specify lighter colored materials that reflect 55-65% of incident solar radiation.

Flagstaff Freeze-Thaw Durability

Your Flagstaff specifications would require enhanced scrutiny of material porosity and pore structure because freeze-thaw cycling exceeds 100 annual events at 7,000-foot elevation. You would specify minimum 1.5-inch thickness even for residential pedestrian applications to provide adequate mass that resists thermal shock during rapid temperature transitions common in mountain climates. The load-bearing requirements would address snow load accumulation that adds 15-25 pounds per square foot during winter months, requiring you to verify that combined dead load and live load calculations remain within material capacity limits. Your drainage specifications would need to prevent subsurface ice lens formation through enhanced base permeability and proper slope gradients that maintain 2% minimum fall away from structures, with you needing to increase thickness to 2 inches in areas where drainage complications create moisture retention concerns.

Sedona Aesthetic Integration

In Sedona projects, you would balance thickness specifications against aesthetic requirements for material that complements iconic red rock formations surrounding the city. Your typical specifications would recommend 1.5-inch thickness for residential pathways and patios, increasing to 2-inch thickness for commercial installations serving tourism and hospitality facilities. You should address the city’s strict design review requirements that favor natural stone materials matching regional geology, requiring you to source flagstone with warm red, tan, and rust color ranges that integrate visually with the landscape. Your installation methodology would need to accommodate sloped terrain common in hillside developments, requiring modified base preparation techniques that prevent downslope material creep while maintaining proper drainage characteristics through rocky substrate conditions typical of Sedona’s geological setting.

Yuma Extreme Heat Performance

When you specify for Yuma installations, you would need to address the combination of extreme heat and high solar intensity that creates the most demanding thermal conditions in Arizona. Your thickness recommendations would emphasize 2-inch minimum specifications for any application receiving direct solar exposure, as surface temperatures regularly exceed 170°F during summer months. You should account for the city’s minimal 3-inch annual rainfall that reduces moisture-related concerns but intensifies dust infiltration into joints, requiring you to specify modified joint filling materials that resist wind erosion. Your load-bearing calculations would need to address agricultural and commercial vehicle traffic common in Yuma’s economy, with you specifying 2.5 to 3-inch thickness for areas serving farm equipment and heavy trucks. The thermal expansion provisions would require increased joint spacing reaching 0.625 inches to accommodate movement ranges exceeding Phoenix by 15-20% due to Yuma’s more extreme temperature differentials between winter lows and summer peaks.

Selection Criteria and Professional Implementation

Your final thickness selection decision should integrate all performance factors into a comprehensive specification that addresses structural requirements, climate conditions, and budget parameters. You need to verify that chosen thickness provides adequate safety factors above minimum requirements, typically specifying material 15-20% thicker than calculated minimums to accommodate real-world condition variations and unexpected loading events. The professional specification process requires you to document all assumptions regarding traffic patterns, load distributions, and environmental exposure factors that influenced your thickness decision.

When you finalize specifications, you should prepare detailed installation instructions that communicate thickness-specific requirements to contractors and installation crews. Your documentation needs to address base preparation depths, compaction requirements, edge restraint specifications, and joint spacing parameters that correspond to selected material thickness. You’ll achieve optimal outcomes when you conduct pre-installation meetings that verify all parties understand the relationships between thickness, base preparation, and expected performance, reducing field errors that compromise carefully engineered specifications.

Your specification process should include contingency planning for situations where preferred thickness becomes unavailable due to warehouse inventory limitations or production scheduling constraints. You need to establish acceptable alternatives that maintain performance requirements through modified installation techniques or enhanced base preparation, ensuring project continuity when material procurement challenges arise. For additional considerations on material selection supporting environmental objectives, review Native Arizona landscape stone supporting desert wildlife habitats before you finalize your project documents. Citadel Stone’s bulk pricing benefits volume local flagstone suppliers in Arizona buyers.