When you evaluate flagstone suppliers Arizona pricing 2026, you’ll find that cost structures vary significantly based on material selection, quarry proximity, and regional logistics networks. Natural flagstone suppliers pricing guide data shows per-ton costs ranging from $285 to $720 depending on stone type, thickness specifications, and finish quality. Your project budget needs to account for material costs, delivery logistics, and installation variables that directly impact total project expenses.

Arizona flagstone price per ton reflects not just the stone itself, but the complete supply chain from quarry extraction through regional distribution. You should understand that flagstone suppliers Arizona pricing 2026 incorporates fuel surcharges, handling fees, and seasonal demand fluctuations that can shift costs by 12-18% throughout the year. Professional specifiers recognize that low-cost material often signals compromised durability or inconsistent dimensional tolerances that create installation challenges.

Understanding Natural Stone Pricing Structures

The pricing you encounter for natural flagstone suppliers in Arizona reflects multiple cost layers beyond raw material acquisition. Quarry operations, processing equipment, quality control protocols, and regional distribution networks all contribute to final per-ton pricing. When you compare local flagstone suppliers Arizona costs, you’re evaluating different business models with varying overhead structures and service capabilities.

Material grading significantly impacts pricing tiers. Premium-grade flagstone with consistent thickness tolerances (±1/4 inch), uniform color distribution, and minimal surface defects commands 40-55% higher pricing than utility-grade material. You’ll find that mid-grade flagstone offers the best value proposition for most residential and commercial applications, balancing aesthetic quality with budget constraints.

- You should verify that quoted pricing includes dimensional consistency appropriate for your installation method

- Your material selection must account for regional availability affecting lead times and delivery costs

- You need to confirm whether pricing reflects FOB warehouse or delivered site costs

- You’ll want to understand how seasonal demand affects material availability and pricing stability

Transportation logistics represent 18-28% of total delivered costs for most Arizona projects. When you source material from regional quarries versus distant suppliers, you’re making trade-offs between material variety and transportation efficiency. Arizona flagstone price per ton typically includes base delivery within 50 miles of primary distribution points, with additional per-mile charges beyond that radius.

Material Specifications Affecting Cost

Thickness specifications directly influence flagstone suppliers Arizona pricing 2026 because thicker material requires more raw stone extraction and generates higher processing waste. Standard 1-inch flagstone costs approximately $310-$385 per ton for common varieties, while 1.5-inch material increases to $420-$495 per ton. Your structural requirements should dictate thickness selection rather than cost considerations alone, particularly for vehicular traffic applications or unsupported spans.

Surface finish treatments add $45-$110 per ton depending on complexity. Natural cleft surfaces (the most economical option) display the stone’s inherent texture from quarry splitting. Thermal finishing, which creates slip-resistant texture through flame treatment, adds $65-$85 per ton. You should evaluate how surface finish affects both initial material costs and long-term maintenance requirements for your specific application.

Color consistency and pattern availability influence pricing structures across natural flagstone suppliers pricing guide tiers. Monochromatic flagstone with tight color tolerance ranges costs 25-35% more than variegated material with broader color variation. When you specify precise color matching, you’re requiring suppliers to selectively sort material, which increases handling labor and reduces yield efficiency from quarry stock.

Regional Quarry Proximity Impact

Arizona benefits from several active flagstone quarries, but you’ll still encounter significant price variation based on stone type and quarry location. Local flagstone suppliers Arizona costs reflect transportation economics where every 100 miles of additional hauling distance adds approximately $35-$50 per ton to delivered pricing. Understanding quarry proximity helps you evaluate whether imported specialty stone justifies premium pricing versus locally-sourced alternatives.

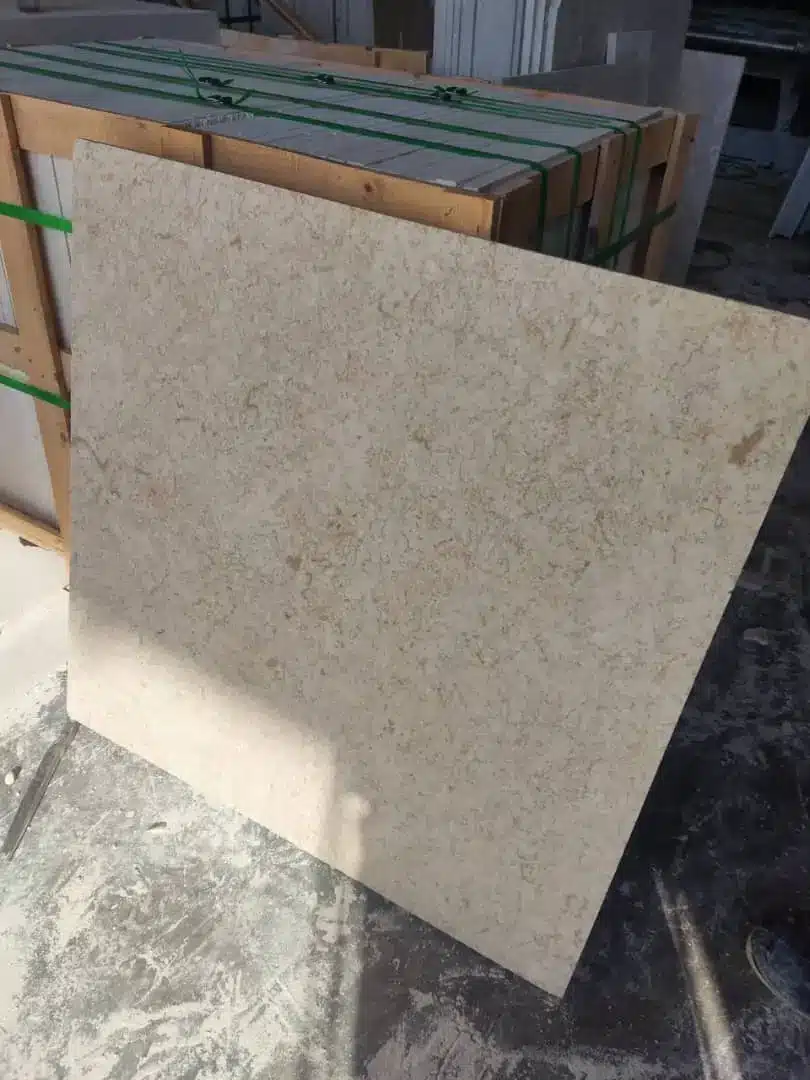

Northern Arizona quarries produce distinctive red and buff-colored sandstone flagstone at competitive regional pricing. You’ll find that material sourced from Coconino County quarries delivers to Phoenix-area projects at $295-$340 per ton for standard grades. Southern Arizona limestone quarries offer cream and tan varieties at similar pricing, though material characteristics differ significantly in porosity and weather resistance.

- You should compare transportation costs against material performance requirements for your climate zone

- Your project timeline needs to account for quarry production schedules affecting material availability

- You’ll want to verify that local quarries maintain consistent inventory of your specified thickness and finish

- You need to understand how quarry location affects delivery scheduling flexibility for phased projects

Imported flagstone varieties from Colorado, Oklahoma, or Pennsylvania quarries increase flagstone suppliers Arizona pricing 2026 by 60-110% compared to regional stone. When you select imported material, you’re prioritizing specific aesthetic or performance characteristics that justify transportation premiums. Professional specifications should document the rationale for imported stone selection to support value engineering discussions.

Delivery Logistics and Fees

Flagstone delivery fees Arizona structures vary considerably among suppliers based on fleet capabilities, delivery scheduling systems, and minimum order requirements. Standard delivery for full-truck loads (20-24 tons) typically includes placement within 50 feet of truck access at no additional charge. When your site requires specialized placement beyond standard delivery zones, you’ll encounter surcharges of $125-$280 per delivery.

Truck access constraints significantly impact delivery costs and scheduling. Your site must accommodate tractor-trailer access (45-55 foot turning radius) or you’ll require smaller delivery vehicles at premium pricing. Residential projects with narrow streets or limited overhead clearance often need multiple smaller deliveries, increasing per-ton delivery costs by 30-45% compared to single full-truck shipments.

Scheduling flexibility affects delivery pricing structures. When you can accept delivery windows of 3-5 business days, you’ll receive standard delivery rates. Rush delivery requests within 24-48 hours typically add $175-$290 to base delivery fees. You should coordinate delivery timing with installation crew schedules to avoid demurrage charges for extended on-site truck waiting time, which runs $95-$140 per hour beyond the included 30-minute unloading window.

Volume Pricing Tiers

Natural flagstone suppliers pricing guide structures incorporate volume discounts that significantly reduce per-ton costs for larger projects. When you purchase 10-15 tons, you’ll typically receive 8-12% discounts from base pricing. Orders exceeding 25 tons often qualify for 15-20% volume reductions, though you need to verify that bulk purchasing doesn’t create material storage complications at your project site.

Minimum order quantities affect pricing and delivery economics. Most suppliers establish 3-5 ton minimums for standard delivery service. When your project requires smaller quantities, you’ll encounter either minimum delivery charges or substantially higher per-ton pricing. You should evaluate whether combining multiple small projects into consolidated orders achieves better pricing efficiency.

- You need to calculate whether volume discounts offset potential material storage costs and weather protection requirements

- Your procurement strategy should consider whether phased delivery maintains volume pricing while managing site logistics

- You’ll want to verify that large-volume commitments don’t lock you into material that fails quality inspection upon delivery

- You should understand how supplier return policies function for volume orders if material proves unsuitable

Project-specific pricing negotiations become viable when your total material requirements exceed $15,000-$20,000. You can often secure 5-8% additional discounts beyond standard volume pricing by committing to exclusive supply agreements or accepting delivery timing flexibility. Professional procurement managers recognize that pricing discussions work best when you demonstrate clear project requirements and realistic timelines.

Material Quality Verification

When you evaluate local flagstone suppliers Arizona costs, you must assess whether pricing reflects appropriate material quality for your application requirements. Low-cost material often exhibits excessive thickness variation (±3/4 inch or greater), inconsistent color distribution, or structural defects that create installation challenges and compromise long-term performance. Your specification should establish clear quality standards that prevent suppliers from substituting inferior material to meet aggressive pricing targets.

Compressive strength testing provides objective quality verification for structural applications. You should require minimum 8,000 PSI compressive strength for pedestrian traffic areas, increasing to 12,000+ PSI for vehicular applications. Material testing costs $180-$340 per sample but protects you from structural failures that cost exponentially more to remediate after installation. For detailed technical guidance on material specifications, see Citadel Stone flagstone materials in Tucson for comprehensive comparison data across regional suppliers.

Absorption rate testing reveals porosity characteristics that affect freeze-thaw durability and stain resistance. Flagstone with absorption rates below 3% performs well in all Arizona climate zones, while material exceeding 6% absorption requires sealing for exterior applications. You’ll find that absorption testing correlates strongly with long-term maintenance costs, making it a critical quality verification step despite minimal testing expense.

Seasonal Pricing Fluctuations

Flagstone suppliers Arizona pricing 2026 exhibits predictable seasonal patterns driven by construction activity cycles and weather-dependent installation windows. Peak construction season (February through May) generates 20-30% higher demand, which can elevate pricing by 10-15% compared to summer low-season rates. When you plan material procurement, you should consider whether off-season purchasing provides cost advantages that offset storage requirements.

Summer monsoon season (July through September) reduces construction activity and creates pricing opportunities. You’ll encounter promotional pricing and volume incentives as suppliers manage inventory levels during slower demand periods. Arizona flagstone price per ton can drop 12-18% during these windows, though you need to ensure your project timeline accommodates seasonal delivery.

Winter pricing (November through January) reflects moderate demand with stable pricing structures. You won’t see dramatic discounts, but suppliers typically offer better delivery flexibility and shorter lead times compared to spring peak periods. Your procurement strategy should balance seasonal pricing advantages against project schedule requirements and site readiness for material delivery and installation.

Installation Method Considerations

Your selected installation method significantly impacts total project economics beyond material costs alone. Dry-laid flagstone installations over compacted aggregate base reduce material requirements because you can accommodate greater dimensional variation. Wet-set installations using mortar over concrete substrate demand tighter dimensional tolerances, which increases material grading requirements and elevates flagstone suppliers Arizona pricing 2026 by 15-25%.

Joint spacing requirements affect material yield calculations. When you design 3/8-inch joints, you’ll experience 8-12% greater coverage per ton compared to 3/4-inch joints common in rustic installations. Your coverage calculations should account for actual joint spacing rather than theoretical coverage rates provided in supplier literature, which typically assume ideal conditions rarely achieved in field installations.

- You need to verify that your selected flagstone thickness provides adequate structural capacity for your chosen installation method

- Your base preparation requirements must match material characteristics to prevent differential settlement and surface irregularities

- You should calculate whether tighter dimensional tolerances justify premium material costs through labor efficiency gains

- You’ll want to understand how installation method affects warranty coverage from both material suppliers and installation contractors

Pattern complexity influences material selection and waste factors. Random pattern installations accommodate greater size and shape variation, maximizing material yield and minimizing waste to 8-12%. Geometric patterns with repeating modules require selective material sorting, increasing waste to 18-25% and potentially requiring premium-grade material with consistent dimensional characteristics.

Citadel Stone Natural Flagstone Arizona Applications

When you consider Citadel Stone’s Natural Flagstone Suppliers in Arizona for your project, you’re evaluating premium materials engineered for extreme desert climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert valleys to high-elevation mountain communities. This section outlines how you would approach specification decisions for six representative cities, accounting for regional climate variables, installation challenges, and performance expectations.

You should understand that Arizona’s climate diversity requires region-specific material considerations. Low-desert locations experience extreme temperature cycling (70-90°F diurnal variation) that demands low thermal expansion coefficients and superior dimensional stability. High-elevation communities face freeze-thaw cycling that requires low absorption rates and proven cold-weather durability. Your material selection must address these localized performance requirements rather than applying generic statewide specifications.

Natural flagstone suppliers pricing guide considerations for Arizona applications must account for UV exposure intensity, monsoon moisture events, and temperature extremes that accelerate material degradation. You’ll find that properly specified flagstone delivers 25-35 year service life in Arizona conditions when installation follows professional standards and maintenance protocols address regional environmental stressors.

Phoenix Heat Mitigation

In Phoenix, you would need to prioritize flagstone with superior solar reflectance characteristics to manage surface temperatures that regularly exceed 160°F during peak summer months. Your specification should target lighter-colored stone varieties (cream, buff, light gray) that reflect 55-70% of solar radiation compared to darker materials that absorb 70-85% of incident energy. You’ll want to verify that your selected material maintains structural integrity through 150+ annual days exceeding 100°F ambient temperature.

Tucson Climate Balance

Tucson’s slightly higher elevation (2,400 feet) moderates extreme temperatures while maintaining classic desert climate characteristics. You would specify flagstone with balanced performance across heat resistance, UV stability, and monsoon moisture management. Your installation would benefit from enhanced drainage design addressing monsoon events that deliver 2-3 inches of precipitation in single storm systems. You should account for thermal expansion requirements with joint spacing every 12-15 feet to prevent surface buckling during temperature swings.

Scottsdale Premium Applications

For Scottsdale’s high-value residential and commercial projects, you would typically specify premium-grade flagstone with exceptional color consistency and minimal surface defects. Your material selection would emphasize aesthetic refinement while maintaining the thermal performance required for low-desert conditions. You’ll want to coordinate with landscape architects on stone selection that complements Scottsdale’s distinctive architectural character while delivering the durability that justifies premium material investment.

Flagstaff Cold Performance

Flagstaff’s 7,000-foot elevation creates Arizona’s most demanding freeze-thaw environment, with 100+ annual freeze-thaw cycles. You would require flagstone with absorption rates below 3% and proven cold-weather durability through ASTM C1026 testing protocols. Your installation specifications must address frost-heave base preparation with minimum 8-inch aggregate base depths and proper drainage systems that prevent subsurface water accumulation. You should verify that your selected material demonstrates structural integrity through repeated freeze-thaw cycling without spalling or delamination.

Sedona Aesthetic Integration

In Sedona, your material selection would emphasize natural color harmony with the region’s distinctive red rock formations. You would typically specify warm-toned flagstone (red, rust, terra cotta) that integrates visually with the surrounding landscape while meeting moderate freeze-thaw requirements at 4,500-foot elevation. Your design approach should balance aesthetic considerations with the practical performance requirements of Sedona’s tourism-driven commercial applications and high-value residential developments.

Yuma Extreme Heat

Yuma represents Arizona’s most extreme heat environment, with summer temperatures consistently exceeding 115°F and annual sunshine exceeding 90% of possible daylight hours. You would specify flagstone with maximum solar reflectance and verified thermal stability through temperature cycling that simulates Yuma’s intense conditions. Your installation would require enhanced expansion joint provisions with spacing reduced to 10-12 feet to accommodate thermal movement. You should understand that Yuma’s minimal precipitation (3-4 inches annually) eliminates freeze-thaw concerns but intensifies UV degradation and thermal stress factors.

Comparative Supplier Analysis

When you evaluate multiple natural flagstone suppliers pricing guide options, you need systematic comparison criteria that extend beyond per-ton pricing. Supplier reliability, material consistency across multiple deliveries, technical support capabilities, and return/exchange policies significantly impact total project value. You should develop a weighted scoring system that quantifies both cost and service factors to identify optimal supplier relationships.

Material availability and lead times vary substantially among Arizona suppliers. Regional suppliers with warehouse inventory typically deliver within 5-7 business days, while importers of specialty stone may require 3-4 weeks for material procurement and delivery. When your project schedule has limited flexibility, you’ll need to factor lead time reliability into supplier selection even if faster delivery commands premium pricing.

- You should verify supplier quality control processes that ensure consistent material characteristics across multiple shipments

- Your evaluation must assess supplier technical expertise for answering installation questions and resolving field issues

- You need to understand supplier return policies for material that fails quality inspection or proves unsuitable for your application

- You’ll want to confirm supplier insurance coverage and business longevity for warranty support on large projects

Payment terms and financing options affect project cash flow management. Standard terms require 50% deposit with balance due upon delivery, though established commercial clients often negotiate net-30 terms. You should evaluate whether supplier financing programs offer competitive rates compared to alternative project financing sources, particularly for large material purchases exceeding $25,000.

Cost Optimization Strategies

Professional cost optimization for flagstone suppliers Arizona pricing 2026 requires balancing multiple variables rather than simply selecting lowest-cost material. You’ll achieve better long-term value by specifying appropriate quality material, optimizing delivery logistics, and coordinating procurement timing with broader project schedules. Strategic material selection reduces installation labor costs, minimizes waste, and extends service life to lower lifecycle expenses.

Material standardization across multiple project areas reduces complexity and improves pricing efficiency. When you specify single flagstone varieties for large projects rather than mixing multiple stone types, you’ll qualify for better volume pricing and simplify installation logistics. You should evaluate whether aesthetic variety justifies the complexity and cost premium of specifying multiple flagstone types within single projects.

Delivery consolidation significantly reduces per-ton transportation costs. You can often coordinate deliveries for multiple concurrent projects to achieve full-truck volumes that optimize transportation efficiency. Arizona flagstone price per ton decreases by 10-15% when you consolidate smaller orders into efficient delivery schedules that maximize truck capacity utilization.

Warranty and Performance Expectations

Material warranties from local flagstone suppliers Arizona costs structures typically cover manufacturing defects but exclude installation-related failures and environmental damage. You should clarify exactly what warranty coverage includes, recognizing that natural stone exhibits inherent variation that doesn’t constitute defects. Standard warranties run 1-2 years for material defects, with claims requiring documentation of proper installation and maintenance protocols.

Performance expectations for properly specified and installed flagstone in Arizona conditions include 25-35 year service life with appropriate maintenance. You’ll need to establish maintenance protocols addressing periodic cleaning, joint sand replenishment, and sealer reapplication every 3-5 years depending on exposure conditions. Your performance projections should account for realistic maintenance compliance rather than assuming ideal conditions rarely achieved in practice.

- You should document baseline material condition with photographs immediately after installation to support future warranty claims

- Your maintenance specifications must address regional environmental factors affecting long-term performance

- You need to establish clear definitions of acceptable wear patterns versus warranty-covered defects

- You’ll want to verify that warranty coverage transfers if property ownership changes during warranty period

Extended warranty programs available from some suppliers add 4-7% to material costs but provide valuable risk mitigation for high-value projects. You should evaluate whether extended coverage justifies premium costs based on project visibility, client expectations, and potential remediation expenses if material performance issues emerge.

Procurement Best Practices

Professional flagstone procurement requires detailed specifications that eliminate ambiguity about material requirements and quality standards. You should provide suppliers with written specifications covering stone type, color range, thickness tolerance, surface finish, dimensional requirements, and acceptable defect limits. Clear specifications protect you from receiving material that fails to meet project requirements while providing suppliers with explicit targets for material selection.

Sample approval processes verify material characteristics before full shipment commitment. You’ll want to require 3-5 sample pieces representing the range of color and texture variation within the specified material. Physical samples reveal characteristics that photographs cannot adequately communicate, particularly surface texture, dimensional variation, and color saturation under natural lighting conditions.

Pre-delivery inspections at supplier warehouses allow you to verify material quality before transportation costs are incurred. When project value justifies inspection expenses, you should conduct warehouse visits to examine actual material designated for your project. This verification step prevents costly delivery rejection scenarios and ensures material meets your quality expectations before it reaches the job site.

Final Considerations

Your comprehensive evaluation of flagstone suppliers Arizona pricing 2026 must integrate material costs with delivery logistics, quality verification, and long-term performance expectations. Professional procurement balances initial cost considerations against lifecycle value, recognizing that premium material often delivers better long-term economics through reduced maintenance requirements and extended service life. You should develop supplier relationships that prioritize technical expertise and reliable service rather than simply pursuing minimum pricing.

Strategic procurement timing leverages seasonal pricing fluctuations and volume consolidation opportunities to optimize material costs without compromising quality standards. You’ll achieve best results by planning material procurement 6-8 weeks ahead of installation schedules, allowing time for sample approval, quality verification, and delivery coordination. For additional installation insights, review Comparing irregular and pattern cut flagstone for landscaping before you finalize your project documents. Arizona flagstone inventory establishes Citadel Stone as regional natural flagstone suppliers in Arizona.