When you evaluate Flagstone Suppliers Arizona guide options for your outdoor living spaces, you’re making decisions that affect performance for decades. You need to understand how regional climate extremes interact with material properties — surface temperatures in Phoenix reach 160°F on summer afternoons, creating thermal stress that eliminates poorly selected stone within five years. Your specification process requires balancing aesthetic preferences with technical performance data that most suppliers don’t discuss until problems emerge post-installation.

You’ll discover that local flagstone suppliers Arizona selection involves more than comparing price sheets. The porosity variations between quarry sources affect freeze-thaw durability in Flagstaff differently than heat retention in Yuma. When you specify natural flagstone suppliers Arizona types for commercial projects, you’re committing to performance characteristics that determine maintenance costs and replacement timelines. Your success depends on understanding these material behaviors before you finalize purchase orders.

Material Selection Criteria for Desert Climates

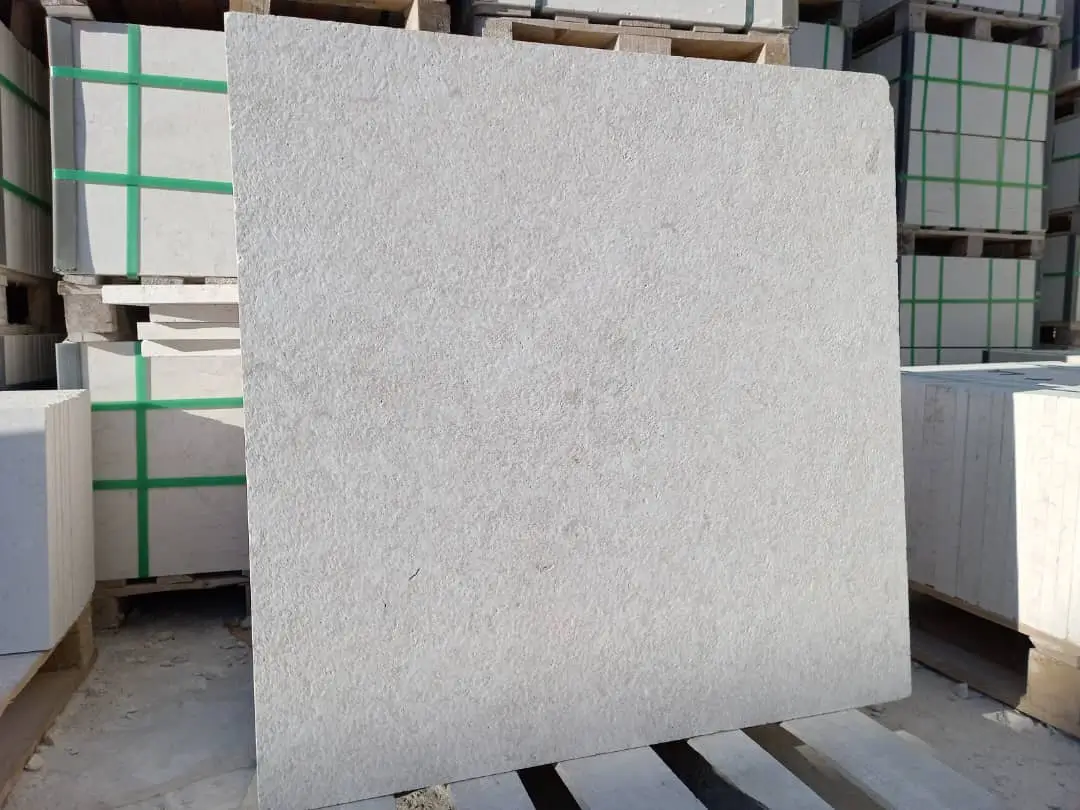

Your primary concern with Arizona flagstone colors grades centers on thermal mass behavior and surface temperature management. You need to recognize that color selection isn’t purely aesthetic — lighter tones reflect 60-70% of solar radiation while darker materials absorb heat and maintain elevated temperatures three hours after sunset. This affects usability patterns for residential patios and commercial hardscapes where barefoot traffic occurs.

When you evaluate natural flagstone suppliers Arizona types, you should verify quarry source documentation. Sedimentary flagstones from different geological formations exhibit porosity ranges from 2% to 12%, directly impacting water absorption and freeze-thaw resistance. You’ll find that materials with interconnected pore structures below 5% provide optimal performance in high-desert applications where diurnal temperature swings exceed 40°F.

- You need to confirm compressive strength exceeds 8,000 PSI for vehicular applications and 6,500 PSI minimum for pedestrian zones

- Your slip resistance specifications should target DCOF ratings between 0.50 and 0.65 for pool decks and water features

- You must account for thermal expansion coefficients averaging 5.8 × 10⁻⁶ per °F in Arizona installations

- Thickness tolerances of ±3/16 inch require you to plan base preparation that accommodates irregular profiles

The relationship between density and thermal conductivity determines how quickly surfaces heat and cool. You should specify materials with density ranges between 145-165 pounds per cubic foot for optimal thermal mass performance. Lower density flagstones heat rapidly but cool faster, while denser materials maintain temperature longer — this trade-off affects your project’s functional hours during extreme weather periods.

Surface Finish Performance Factors

You’ll encounter four primary surface treatments when you review local flagstone suppliers Arizona selection options: natural cleft, thermal, honed, and textured. Each finish creates distinct performance characteristics that you need to match with application requirements. Natural cleft surfaces provide inherent slip resistance with DCOF values typically ranging 0.55-0.68, but the irregular texture complicates furniture placement and creates trip hazards in commercial settings.

Your specification decisions regarding surface finish directly impact maintenance requirements over the installation’s service life. Honed finishes show traffic patterns and etching from acidic substances within 18-24 months in high-use areas. You need to educate clients that the smooth appearance requires annual resealing and accepts visible wear as patina rather than damage.

When you evaluate Arizona flagstone colors grades with different finishes, you should conduct wet slip resistance testing. Dry DCOF ratings drop 0.12-0.18 points when surfaces become wet — a critical safety factor for pool decks and covered patios where monsoon rains create standing water. You’ll find that textured finishes maintain more consistent slip resistance across wet and dry conditions, though they accumulate organic debris in texture valleys.

Thickness Specifications and Structural Requirements

You need to understand that flagstone thickness directly correlates with spanning capability and structural integrity. Industry standards establish minimum thickness requirements, but you should specify based on actual substrate conditions and loading scenarios. For pedestrian applications over compacted aggregate base, you’ll typically specify 1.5 to 2 inch thickness. Vehicular traffic requires 2.5 to 3 inch minimum thickness to prevent fracture under concentrated wheel loads.

Your base preparation specifications matter more than thickness alone. You should require 4-6 inches of compacted Class 2 aggregate base with 95% compaction for pedestrian areas, increasing to 8-10 inches at 98% compaction for driveways. The base must provide uniform support — voids under flagstones create point loading that causes fractures regardless of material thickness. When you coordinate with our flagstone specialists, you’ll receive substrate recommendations specific to your soil conditions and loading requirements.

- You should specify bedding layer composition using coarse sand or stone dust at 1-1.5 inch depth

- Your installation details must address edge restraint systems preventing lateral movement

- You need to plan expansion joints every 12-15 feet based on thermal expansion calculations

- Slope requirements of 2% minimum ensure positive drainage away from structures

The interaction between thickness and material density affects installation labor costs and equipment requirements. Thicker flagstones weighing 18-25 pounds per square foot require mechanical handling equipment, impacting your project budget and site access requirements. You’ll need to verify that your installation crews have proper equipment before specifying premium thickness materials.

Color Stability and UV Resistance Considerations

When you specify Arizona flagstone colors grades for exposed applications, you must account for UV degradation and mineral oxidation that alter appearance over time. Iron-rich flagstones develop rust-colored surface staining when moisture penetrates the material and oxidizes ferrous minerals. You’ll observe this most prominently in buff and tan colorways where iron content ranges from 3-7% by composition.

Your long-term appearance expectations need to align with material behavior. Natural flagstone suppliers Arizona types include sedimentary formations that weather differently than igneous alternatives. Sandstone-based flagstones exhibit more pronounced color shifts during the first 24-36 months of exposure compared to denser metamorphic options. You should provide clients with weathered samples showing expected patina development rather than fresh-cut material that misrepresents installed appearance.

The relationship between porosity and color retention affects your sealer specifications. You need to apply penetrating sealers that don’t create surface films prone to delamination under thermal cycling. Water-based silane/siloxane blends provide UV-stable protection without altering surface appearance significantly. When you maintain resealing schedules every 18-24 months, you’ll extend color stability and reduce moisture-related staining.

Joint Spacing and Polymeric Sand Requirements

You’ll find that joint spacing specifications for Flagstone Suppliers Arizona guide applications require balancing aesthetic preferences with structural necessity. Tight joints below 1/4 inch create visual continuity but complicate sand retention and drainage function. You should specify joint widths between 3/8 and 5/8 inch for optimal polymeric sand performance and long-term stability.

Your polymeric sand selection impacts joint durability and weed suppression effectiveness. Premium formulations contain higher polymer content that creates stronger interlock when activated, but they’re more sensitive to installation moisture conditions. You need to ensure substrate moisture content stays below 6% during installation — higher moisture prevents proper polymer activation and leads to joint failure within the first year.

- You must verify that your installation timing avoids temperatures above 95°F during polymer activation

- Your compaction process should achieve 92-95% joint fill capacity without overfilling

- You need to plan for 15-20% joint sand replenishment during first season settling

- Surface cleaning before activation prevents polymer haze on flagstone faces

The thermal expansion behavior of polymeric sand differs from flagstone materials, creating stress at interfaces during temperature cycling. You’ll observe joint sand degradation most rapidly in areas with direct solar exposure exceeding seven hours daily. Your maintenance specifications should include annual joint inspection and selective replenishment to maintain structural integrity and prevent edge spalling.

Drainage and Base Design Integration

When you design drainage systems for flagstone installations, you need to account for the material’s porosity and joint permeability working together. You can’t rely solely on surface drainage — subsurface water management prevents base saturation that leads to settling and frost heave. Your base layer specifications should include geotextile fabric separation between subgrade and aggregate to prevent fines migration that clogs drainage pathways.

You’ll achieve optimal performance when your base permeability exceeds surface permeability by factor of 4-5. This gradient ensures water moves through joints into the base layer and away from the installation rather than pooling at the substrate interface. You should specify open-graded aggregate in the lower base courses to create drainage channels, transitioning to denser material in upper courses for flagstone support.

Your edge detail specifications must accommodate drainage discharge without creating erosion problems. You need to design collection systems at installation perimeters that capture subsurface flow and direct it to appropriate disposal points. When you ignore this detail, you’ll observe undermining at edges where concentrated flow exits the base layer, causing settlement and joint deterioration.

Regional Soil Interactions and Expansion Management

You face specific challenges with local flagstone suppliers Arizona selection when expansive clay soils dominate your project site. These soils exhibit volumetric changes of 3-8% between wet and dry states, creating vertical movement that flagstone installations can’t accommodate without proper isolation. You need to verify soil classifications through geotechnical testing rather than relying on visual assessment.

When you encounter clay content above 35% with plasticity index exceeding 20, you should specify over-excavation and replacement with engineered fill. The alternative involves chemical stabilization using lime or cement treatment to reduce expansion potential. Your base design must include sufficient depth to isolate flagstone from soil movement — typically 14-18 inches of properly compacted aggregate provides adequate buffer.

The relationship between soil moisture maintenance and installation stability requires you to consider irrigation system design. Drip systems that maintain consistent soil moisture prevent the wet-dry cycling that drives expansion. You’ll observe fewer maintenance issues when landscape irrigation maintains moisture content within 10% of optimum rather than allowing seasonal extremes that create movement patterns.

Sealant Selection and Application Protocols

Your sealant specifications for natural flagstone suppliers Arizona types must address both stain protection and surface enhancement expectations. You need to distinguish between film-forming topical sealers that alter appearance significantly and penetrating treatments that protect without visible surface change. Topical sealers create 2-4 mil surface films prone to wear and delamination under thermal stress, requiring removal and reapplication every 2-3 years.

You should specify penetrating silane/siloxane blends that chemically bond within the flagstone pore structure rather than coating the surface. These treatments provide water and oil repellency while allowing vapor transmission that prevents subsurface moisture accumulation. When you apply penetrating sealers at manufacturer-specified coverage rates, you’ll achieve 5-7 year performance before reapplication becomes necessary.

- You must verify substrate moisture content below 4% before sealer application to ensure proper penetration

- Your application timing should avoid surface temperatures above 90°F that accelerate solvent evaporation

- You need to apply two coats wet-on-wet within specified time windows for optimal penetration depth

- Test applications on sample pieces verify appearance and performance before full installation treatment

The interaction between sealers and polymeric sand systems requires careful coordination. You need to complete flagstone sealing before polymeric sand installation — reverse sequence causes sealer to coat sand particles and prevent proper polymer activation. When you maintain proper sequencing, you’ll avoid joint failure and sealer performance issues that create costly remediation requirements.

Premium Flagstone Suppliers in Arizona: Citadel Stone Specification Guidance for Arizona Regions

When you evaluate Citadel Stone’s Flagstone Suppliers in Arizona for your regional projects, you’re considering premium materials engineered for extreme climate performance across diverse applications. At Citadel Stone, we provide technical guidance for hypothetical installations across Arizona’s varied climate zones, from low-desert heat to high-elevation freeze-thaw exposure. This section outlines how you would approach material selection and specification decisions for six representative cities, demonstrating the climate-specific considerations that drive professional flagstone specifications.

Phoenix Heat Performance

In Phoenix, you’ll encounter extreme thermal stress conditions where summer surface temperatures routinely exceed 155°F. Your material selection would prioritize lighter Arizona flagstone colors grades that reflect solar radiation and maintain lower surface temperatures. You would specify flagstone dealers Arizona inventory with verified thermal properties including reflectance values above 0.65 and thermal conductivity below 1.8 BTU/hr·ft·°F. The urban heat island effect amplifies thermal cycling, requiring you to increase expansion joint frequency to every 12 feet rather than standard 15-foot spacing. You’d recommend installation scheduling during October through March when ambient temperatures allow proper polymeric sand activation and sealer curing without thermal interference.

Flagstaff Freeze-Thaw Requirements

Your Flagstaff specifications would address freeze-thaw cycling that averages 110 events annually at 7,000-foot elevation. You would require flagstone dealers Arizona inventory documentation showing water absorption below 3% by weight and verified frost resistance through ASTM C1026 testing. The material selection would emphasize denser flagstones with minimal interconnected porosity that resists ice crystallization damage. You’d specify 3-inch minimum thickness for vehicular applications and require base depth of 10-12 inches with open-graded lower courses providing subsurface drainage. Your sealer specifications would mandate penetrating treatments that don’t trap moisture within the material structure, preventing spalling damage during freeze events.

Scottsdale Luxury Applications

When you specify for Scottsdale’s luxury residential market, you would balance aesthetic requirements with technical performance in high-heat conditions. Your material selection would feature premium natural flagstone suppliers Arizona types with consistent color distribution and minimal mineral inclusions that create staining. You’d recommend honed surface finishes for formal applications where smooth texture suits furniture placement, combined with aggressive sealing protocols to manage etching from pool chemistry and outdoor kitchen activities. The specifications would address truck access constraints common in gated communities and coordinate warehouse delivery timing with project schedules. You would specify installation details that accommodate landscape lighting integration and drainage systems serving elaborate water features.

Tucson Desert Integration

Your Tucson approach would integrate flagstone installations with native desert landscaping and xeriscaping principles. You’d specify local flagstone suppliers Arizona selection that complements regional color palettes featuring warm earth tones matching surrounding geology. The material selection would emphasize porosity ranges of 4-6% that allow limited water absorption without compromising structural integrity during monsoon events. You would design drainage systems handling 2-inch rainfall intensities during summer thunderstorms, incorporating permeable joint systems that reduce runoff. Your specifications would address UV exposure approaching 90% of theoretical maximum, requiring sealers with proven resistance to photochemical degradation through accelerated weathering protocols.

Sedona Red Rock Coordination

In Sedona, you would specify Arizona flagstone colors grades that coordinate with iconic red rock formations while meeting municipal design guidelines. Your material palette would feature warm buff, tan, and rust tones that blend with the natural landscape rather than creating visual contrast. You’d address elevation-specific considerations at 4,500 feet where temperature extremes range from 15°F winter lows to 105°F summer peaks. The specifications would account for high tourist traffic in commercial applications, requiring enhanced slip resistance and accelerated wear resistance. You would coordinate flagstone dealers Arizona inventory availability with seasonal construction windows that avoid summer heat and winter freeze conditions limiting installation quality.

Yuma Extreme Heat Protocols

Your Yuma specifications would address the most extreme heat conditions in Arizona, where temperatures exceed 110°F for extended periods. You’d specify the lightest available Arizona flagstone colors grades to minimize heat absorption and maintain surface temperatures below barefoot-safe thresholds. The material selection would prioritize low thermal mass that allows rapid cooling after sunset. You would require installation methods using wider joint spacing at 5/8 inch to accommodate thermal expansion exceeding standard calculations. Your base specifications would include reflective aggregate materials in upper courses to reduce heat transfer from substrate. You’d mandate installation timing strictly between November and February when ambient conditions allow proper material handling and setting without heat-related complications.

Maintenance Specifications for Long-Term Performance

You need to develop maintenance protocols that address specific deterioration mechanisms affecting Flagstone Suppliers Arizona guide installations in desert climates. Your maintenance schedule should include annual joint inspection and selective polymeric sand replenishment addressing areas where UV degradation and thermal cycling cause polymer breakdown. You’ll find that joints receiving direct solar exposure require attention every 18-24 months, while shaded areas maintain integrity for 3-4 years.

Your sealer reapplication timing depends on exposure conditions and traffic intensity. You should conduct annual water droplet testing to verify hydrophobic performance — when water absorption occurs within 5-10 seconds rather than beading on the surface, resealing becomes necessary. High-traffic areas typically require treatment every 18-24 months, while protected locations extend to 4-5 years between applications.

- You must remove organic debris from joints quarterly to prevent root penetration that displaces polymeric sand

- Your cleaning protocols should avoid pressure washing above 1,200 PSI that erodes joint material

- You need to address efflorescence deposits using pH-neutral cleaners rather than acidic solutions that etch flagstone surfaces

- Edge restraint systems require annual inspection to verify integrity and prevent lateral movement

The relationship between maintenance investment and service life follows predictable patterns. You’ll observe that installations receiving proper maintenance achieve 25-30 year performance without major intervention. Neglected installations show structural problems within 10-12 years requiring complete reconstruction rather than repair. Your maintenance specifications should communicate these lifecycle implications to property owners during project planning.

Procurement Logistics and Lead Time Planning

When you coordinate material procurement for projects requiring specific natural flagstone suppliers Arizona types, you need to account for quarry production schedules and inventory cycles. Premium materials with consistent color and thickness tolerances often require 6-8 week lead times from order placement to truck delivery. You should verify warehouse stock availability for your required quantities before you commit to project timelines with clients.

Your procurement strategy should include material overages accounting for field cutting waste and breakage during installation. You’ll typically specify 8-12% overage for random pattern installations and 5-7% for modular layouts with standardized dimensions. When you order insufficient material, obtaining matching lots from the same quarry run becomes difficult, creating visible color variations that compromise installation appearance.

The logistics of material delivery require coordination with site access constraints and storage capabilities. You need to verify that truck access accommodates tractor-trailer deliveries for full pallet quantities, or arrange smaller vehicle deliveries at premium freight costs. Your storage planning should protect materials from ground moisture and provide adequate space for sorting and staging during installation. When you neglect these logistics details, project delays and material damage create cost overruns that eliminate profit margins.

Budget Optimization Without Performance Compromise

You face constant pressure to reduce material costs while maintaining performance standards, requiring strategic approaches to value engineering. Your budget optimization should focus on specification adjustments that don’t compromise structural integrity or longevity. You can achieve cost savings by relaxing thickness tolerances from ±1/8 inch to ±3/16 inch, accepting greater dimensional variation that installation technique can accommodate through base adjustments.

When you evaluate cost differentials between flagstone dealers Arizona inventory options, you need to perform lifecycle cost analysis rather than comparing unit prices alone. Premium materials costing 20-30% more initially may deliver 40-50% longer service life, reducing annualized costs significantly. You should calculate total ownership costs including maintenance requirements and replacement timing to identify genuine value propositions.

- You can reduce material costs by accepting natural cleft surfaces rather than specifying honed finishes that require additional processing

- Your specifications might allow mixed thickness lots that provide cost savings while meeting minimum structural requirements

- You should consider regional quarry sources that reduce freight costs without compromising material performance

- Timing purchases during off-peak seasons may yield 10-15% discounts when quarries manage inventory levels

The relationship between specification precision and cost requires you to identify which parameters truly affect performance versus those serving aesthetic preferences. You’ll find that relaxing color consistency tolerances provides significant savings when you educate clients that natural variation enhances rather than detracts from flagstone character. Your value engineering discussions should distinguish between requirements and preferences, allowing informed decisions that optimize budget allocation.

Common Specification Errors and Prevention Strategies

You’ll encounter recurring mistakes in Flagstone Suppliers Arizona guide specifications that create performance problems and disputes. The most common error involves failing to address thermal expansion adequately, using generic joint spacing recommendations that don’t account for Arizona’s extreme temperature ranges. You need to calculate expansion requirements based on actual temperature differentials rather than applying standard details developed for moderate climates.

Your specifications often omit critical substrate preparation details, assuming contractors will provide adequate base systems without explicit requirements. This creates situations where insufficient compaction and inadequate depth lead to settlement and structural failure. You should provide complete base specifications including material gradation, lift thickness, compaction percentages, and testing protocols that verify compliance.

The failure to specify sealer types explicitly causes problems when contractors apply inappropriate products. You’ll observe installations where high-solids topical sealers create glossy surface films that clients reject, or where inadequate coverage rates provide insufficient protection. Your specifications must identify specific product types, manufacturer requirements, coverage rates, and application methods that achieve intended performance.

Project Delivery Coordination and Installation Oversight

When you manage flagstone project delivery, you need to coordinate multiple trades and material deliveries in proper sequence. Your installation timing must account for base preparation completion, material delivery, and weather windows that allow proper installation. You should develop detailed schedules that identify dependencies and critical path activities, communicating expectations clearly to all stakeholders.

Your field oversight responsibilities include verifying that installation practices match specifications rather than defaulting to contractor standard methods. You need to conduct base inspections before flagstone placement, confirming compaction levels and surface preparation meet requirements. During installation, you should monitor joint spacing consistency, bedding layer thickness, and drainage slope compliance that affect long-term performance.

The relationship between installation quality and weather conditions requires you to enforce work restrictions during extreme temperatures. You must stop installation when ambient temperatures exceed 95°F or fall below 40°F, as these conditions prevent proper setting material curing and polymeric sand activation. Your project schedules should build in weather contingencies that account for Arizona’s seasonal patterns rather than assuming continuous work progression.

Final Considerations

Your professional specification process for flagstone installations requires you to integrate material science, climate analysis, and construction methodology into cohesive project documents. You’ve seen how Arizona’s extreme conditions demand attention to thermal behavior, moisture management, and structural design that exceeds generic industry standards. When you apply these principles, you’ll deliver installations that meet performance expectations throughout 20-30 year service lives rather than failing prematurely due to specification inadequacies. For detailed guidance on coordinating material procurement with project timelines, review Inventory management systems for tracking natural stone slabs to optimize your supply chain efficiency. Citadel Stone imports premium materials as international Flagstone Suppliers in Arizona for luxury projects.