When you need to create curved edges and circular patterns in Arizona flagstone installations, you’re dealing with one of the most challenging yet rewarding aspects of hardscape construction. Flagstone radius cutting Arizona requires specialized techniques that account for material brittleness, varying stone thickness, and the extreme thermal conditions unique to the Southwest. You’ll find that successful curved cutting depends on understanding both the mechanical properties of flagstone and the tools that can handle irregular natural stone geometry.

The process differs significantly from cutting straight lines. You’re working with sedimentary stone that has natural cleavage planes, inconsistent density, and thickness variations that can range from 3/4 inch to 2-1/2 inches within a single piece. Your cutting strategy needs to accommodate these variables while maintaining smooth curves that meet design specifications. Professional installations in Arizona’s climate zones require you to consider how thermal expansion affects curved joints — radius cuts create varying joint widths that respond differently to temperature fluctuations than straight installations.

Understanding Flagstone Properties for Curved Cutting

Before you attempt any flagstone curved cutting, you need to understand the material’s structural characteristics. Flagstone splits along sedimentary layers, which means your cutting approach must account for grain direction. When you cut against the grain on a tight radius, you’ll encounter significantly more edge chipping than cuts that follow natural stratification patterns. This becomes critical in Arizona installations where exposed edges face intense UV exposure and thermal cycling that can propagate micro-fractures from poor cuts.

The porosity of flagstone affects your cutting technique as well. Material with 5-8% porosity absorbs water during wet-cutting operations, which temporarily increases brittleness. You should plan your flagstone circular shaping work during morning hours when ambient temperatures stay below 85°F — this gives you a wider working window before evaporation accelerates and changes the stone’s cutting characteristics. For projects requiring trade flagstone paving supply, you’ll want to verify material consistency across pallets, as porosity variations affect how cleanly radius cuts finish.

- You should test cut scrap pieces to identify grain direction before marking your primary cuts

- Your material selection needs to account for thickness consistency — variations beyond 1/4 inch complicate curved installations

- You’ll achieve better results with flagstone that has compressive strength above 9,000 PSI for tight radius work

- Thermal expansion coefficients of 5.1 × 10⁻⁶ per °F require you to adjust joint spacing on curves

Tool Selection for Radius Cutting

Your tool selection determines cutting quality and project efficiency. Angle grinders with 4-1/2 or 7-inch diamond blades handle most flagstone arc creation work, but blade selection matters more than grinder size. You need continuous-rim diamond blades rated for natural stone — segmented blades designed for concrete create excessive chipping on flagstone edges. The rim height affects curve smoothness; you’ll get better results with blades that have 10mm rim height compared to standard 7mm variants.

For tight radius cuts below 18 inches, you should use wet-cutting techniques with a grinder-mounted water feed system. Dust suppression is secondary — the primary benefit is cooling the blade to prevent thermal stress micro-fractures in the stone. Dry cutting works for gentle curves above 36-inch radius, but you’ll need to make multiple shallow passes rather than attempting full-depth cuts. Arizona’s low humidity accelerates blade wear during dry cutting; expect 30-40% shorter blade life compared to humid climates.

Tile saws with sliding tables handle straight cuts efficiently but struggle with curves. You can use them for initial roughing cuts on large-radius work, then finish with grinders. The key is maintaining consistent blade speed — variable-speed tools let you adjust for stone density variations within the same piece. When you encounter harder sections, dropping from 10,000 to 7,500 RPM reduces chipping and extends blade life.

Layout and Marking Techniques

Accurate layout determines whether your finished curves meet design intent. You’ll need to transfer radius dimensions from plans to actual stone pieces, accounting for the irregular shapes inherent in flagstone. String-and-pivot methods work for large-radius curves, but you must account for the string’s tendency to bow under tension — use braided mason’s line rather than twisted cord to minimize this effect.

For flagstone curve techniques involving multiple pieces that form a continuous arc, you should dry-lay the entire section before marking any cuts. This reveals how natural stone edges interact and lets you optimize cut locations to minimize waste. Mark your cut lines with lumber crayons rather than chalk — chalk disappears when wet-cutting begins, while crayon marks remain visible through water spray. You’ll want to mark both the top surface and edges to maintain visual reference as you cut from multiple angles.

Template creation from 1/4-inch hardboard speeds repetitive curve work. When you need six curved step treads with identical 42-inch radius, cutting one template lets you transfer that curve to each stone piece with consistent accuracy. The template also helps you estimate material requirements — you can overlay it on pallet stones to identify which pieces will yield the cuts you need without excessive waste.

- You should add 1/8 inch to your cut lines to account for grinding and smoothing operations after initial cuts

- Your marking needs to indicate grain direction with arrows so you remember optimal cutting approach

- You’ll reduce errors by numbering each piece in complex curved patterns before cutting begins

- Allow 1/4-inch joint spacing on curves, increasing to 3/8 inch for radius below 24 inches

Cutting Technique Fundamentals

The actual cutting process for flagstone radius cutting Arizona requires steady hand control and proper body positioning. You need to support the stone on a stable surface with the cut line extending 2-3 inches beyond the support edge — this prevents vibration that causes chipping. For curved cuts, you’ll rotate the stone as you progress along the arc rather than trying to pivot the grinder through complex angles. This keeps the blade perpendicular to the cut line and maintains consistent depth.

Start your cuts 1/8 inch outside your marked line and make the first pass at half the stone’s thickness. This initial pass establishes the curve geometry without committing to full-depth cutting that’s difficult to correct. After completing the first pass around the entire curve, you can make a second pass to full depth. This two-pass approach reduces stress on the stone and gives you better control over edge quality.

Blade entry and exit points require special attention. When you begin a curved cut, enter the stone at a slight angle rather than plunging straight down — this reduces impact stress that can fracture thin flagstone. As you approach the end of your cut, slow your feed rate and let the blade do the work without forcing it. Forcing the blade through the last inch creates the majority of edge chips you’ll need to repair later.

Managing Thermal Stress During Cutting

Arizona’s extreme temperatures create cutting challenges you won’t find in moderate climates. When you’re working in 105°F ambient conditions, flagstone surface temperatures can reach 140-160°F in direct sun. Starting cuts on thermally expanded stone leads to micro-fractures that appear 6-12 months later as the installation cycles through seasonal temperature ranges. You should shade your work area and allow stone to cool to ambient temperature before cutting — this typically requires 45-60 minutes of shade time for 1-1/2 inch thick material.

Wet cutting provides some thermal management, but water temperature matters. If you’re using water that’s been sitting in truck-mounted tanks under desert sun, you’re applying 110°F water that provides minimal cooling benefit. You’ll get better results with fresh water from shaded sources that stays below 75°F. The temperature differential between blade and stone affects cutting efficiency and edge quality measurably.

Watch for thermal stress indicators during cutting. If you see small chips appearing 1/4 to 1/2 inch behind your blade path, the stone is experiencing thermal shock from rapid temperature changes. This happens most often when you switch from dry to wet cutting mid-project — the sudden cooling creates stress that exceeds the stone’s tensile strength in areas where cutting has already reduced structural integrity.

Creating Compound Curves and Circular Patterns

When your design requires flagstone circular shaping for features like fire pit surrounds or curved steps with varying tread depths, you’re dealing with compound curves that change radius along their length. These require progressive marking techniques where you establish multiple reference points rather than relying on a single-radius template. You’ll need to mark every 6-8 inches along the curve and connect those points with a flexible curve guide — thin metal strapping or a length of PEX tubing works well for this purpose.

Circular patterns for medallions or compass rose designs demand precision that pushes flagstone’s natural irregularity to its limits. You should select premium-grade material with consistent thickness for these applications — variations beyond 3/16 inch become visually obvious in geometric patterns. The cutting sequence matters; start with the center stone and work outward so each subsequent piece references already-installed material. This approach accommodates the small dimensional variations inherent in natural stone without letting errors compound.

For circular fire pit surrounds, you’re typically working with a consistent outer radius but varying inner radius as you account for stone width differences. Your cuts need to maintain parallel sides for each piece, which means you’re creating two different radius curves per stone. Template work becomes essential here — you’ll waste significant material if you attempt these cuts without careful planning. Professional practice involves creating full-scale layout drawings on plywood that show actual stone positions before cutting begins.

Edge Finishing and Smoothing

After cutting, your flagstone arc creation work is only 70% complete. The exposed edges require finishing to remove sharp corners, smooth out minor irregularities, and create edges that match the stone’s natural weathered appearance. You’ll use the same angle grinder with diamond grinding wheels — not cutting blades — to reshape edges. Start with 50-grit wheels for aggressive stock removal, then progress through 120-grit and 220-grit for final smoothing.

Edge profile affects both aesthetics and safety. Sharp 90-degree edges look unnatural on flagstone and create trip hazards on step treads. You should create a 1/8-inch chamfer on all exposed edges, which breaks the sharp corner without making the edge obviously worked. For pool decks and high-traffic areas, round the edge to a 3/16-inch radius — this provides better slip resistance than sharp edges and reduces injury risk from impacts.

The grinding process generates significant dust even with wet-cutting techniques. You’ll need dust collection or water spray to maintain visibility and protect surrounding surfaces. In Arizona’s low humidity, dust clouds linger for extended periods and create problems with adjacent properties. Professional installations use grinder-mounted dust shrouds connected to HEPA-filtered vacuums, which capture 95-98% of dust at the source. This is particularly important in residential areas where dust complaints can delay projects.

- You should complete all edge finishing before installation to avoid damaging adjacent stones

- Your grinding technique needs to maintain consistent pressure — excessive force creates flat spots on curved edges

- You’ll achieve better color matching by wetting edges after grinding to preview their finished appearance

- Allow edges to dry completely before sealing, typically 48-72 hours in Arizona’s low humidity

Joint Spacing Considerations for Curves

Joint spacing on curved flagstone installations differs from straight-line work. The geometry of radius cuts creates varying joint widths — the inside radius of a curve naturally produces narrower joints than the outside radius. You need to account for this during layout and cutting. For a 36-inch radius curve using 12-inch wide stones, the inside joint might measure 1/4 inch while the outside joint reaches 1/2 inch. This variation is acceptable if it’s consistent along the entire curve.

Thermal expansion affects curved joints differently than straight installations. As flagstone expands in Arizona’s heat, the stones try to grow along their length. In straight installations, this growth is uniform across all joints. In curved patterns, expansion creates differential stress — inside radius joints compress more than outside radius joints. You should increase minimum joint width on curves by 1/16 inch compared to straight work to accommodate this differential movement.

Joint fill material selection impacts curve performance. Polymeric sand works well for straight joints but can fail in tight-radius curves where joint width varies significantly. The polymer activation requires consistent joint width for proper hardening. You’ll get more reliable results with standard joint sand on curves, accepting that you’ll need to replenish it more frequently. For high-end installations requiring superior joint stability, you should specify flexomeric jointing compounds that accommodate width variations without failure.

Common Mistakes in Curved Flagstone Cutting

The most frequent error in flagstone curved cutting involves attempting cuts without adequate stone support. You need stable support within 3 inches of the cut line on both sides of the blade. Unsupported stone vibrates during cutting, which creates chatter marks and edge chips that require extensive grinding to correct. Professional setups use adjustable sawhorses with padded crossbars that can be positioned precisely for each cut.

Blade depth mistakes cause problems you’ll discover only after installation. Cutting completely through the stone seems logical, but it creates bottom-edge chipping as the blade exits. You should cut to within 1/8 inch of breakthrough, then snap the final connection by supporting both sides and applying controlled pressure. This technique produces clean bottom edges that require minimal finishing. The snapping process follows natural cleavage planes, so you’re working with the stone’s structure rather than against it.

Speed-related errors compromise cut quality and waste material. New operators tend to force the blade through stone too quickly, which overheats the blade and creates rough cuts requiring extensive rework. You should maintain steady feed rates that let the diamond abrasive do its work — forcing doubles cutting time once you factor in edge repair. For 1-1/2 inch flagstone, appropriate feed rate is approximately 3-4 linear inches per minute on curved cuts, slower than the 6-8 inches per minute achievable on straight cuts.

- You should never start cutting without verifying blade guard position and proper PPE including eye protection and dust masks

- Your blade depth needs checking before each cut since grinder bases can shift during transport and handling

- You’ll avoid costly mistakes by cutting test pieces before starting on finish material

- Attempting to cut curves freehand without guide marks produces irregular results requiring replacement stones

Installation Considerations for Curved Cuts

Once you’ve completed your flagstone radius cutting Arizona work, installation presents unique challenges. Base preparation for curved patterns requires more attention than straight installations. You need consistent base depth that follows the curve precisely — variations in base depth translate directly to finished surface irregularities that become obvious on curved work. Use screeding guides that match your curve radius, typically constructed from thin plywood or composite material that can be bent to match design radius.

Setting curved flagstone requires different techniques than straight work. You can’t use string lines for elevation control on curves — they don’t conform to radius geometry. Instead, you’ll use a rigid template cut to match your design radius, checking elevation at multiple points along each stone. Professional installations use laser levels with rotating heads that can project a level plane across the entire curved area, providing continuous elevation reference.

Your base material affects how well curved installations perform. Crusher fines compact well for straight work but can shift under the differential loading that curves create. You’ll get better long-term stability using well-graded aggregate base with angular particles that interlock mechanically. This is particularly important in Arizona where thermal cycling creates daily expansion and contraction that can destabilize poorly constructed bases over time.

Working With Varying Stone Thickness

Natural flagstone thickness varies significantly within single pieces and across pallets. When you’re creating curved patterns, these variations complicate installation more than in straight work. You have two approaches: select premium material with tight thickness tolerances, or adjust your base depth for each piece. Premium selection is more expensive initially but saves labor during installation. Base adjustment requires more time but lets you use more affordable material grades.

Thickness variations affect how you mark cut lines. If your stone varies from 1-1/4 inches on one side to 1-3/4 inches on the other, your curve needs to reference the thick edge as the finished face. Attempting to use the thin edge as the primary face creates problems during installation because you’ll need excessive base material on one side to level the piece. You should always orient stones so the thick portion faces areas with maximum visibility and traffic.

When you’re mixing stones of different thickness in curved patterns, you need to account for how this affects visual flow. Radical thickness changes create shadow lines that look like installation errors even when everything is properly leveled. You should group similar-thickness stones together and create intentional coursing breaks where thickness transitions occur. This makes the variation look deliberate rather than accidental.

Safety Protocols for Radius Cutting Work

Flagstone radius cutting generates more kickback risk than straight cutting. The curved blade path creates varying load on the blade, and any binding produces rotational force that can twist the grinder in your hands. You need firm two-handed grip on all grinders, with your body positioned to the side of the cutting plane rather than behind it. This positioning keeps you out of the kickback path if the blade binds and the grinder suddenly rotates.

Respiratory protection is non-negotiable for dry cutting operations. Flagstone dust contains crystalline silica, which causes irreversible lung damage with chronic exposure. You should use NIOSH-approved respirators rated for silica dust — standard dust masks don’t provide adequate protection. For extended cutting sessions, powered air-purifying respirators provide better protection and are more comfortable in Arizona’s heat since they don’t restrict breathing as much as passive respirators.

Eye protection requires full-seal safety glasses rather than standard side-shield glasses. Curved cutting creates debris that travels in unpredictable directions, and side-shield glasses don’t protect against particles approaching from below or above. You’ll also need hearing protection rated for at least 25 dB noise reduction — angle grinders produce 95-105 dB at operator position, well above the 85 dB threshold for hearing damage.

Citadel Stone flagstone for sale Arizona — Specifications for Curved Applications

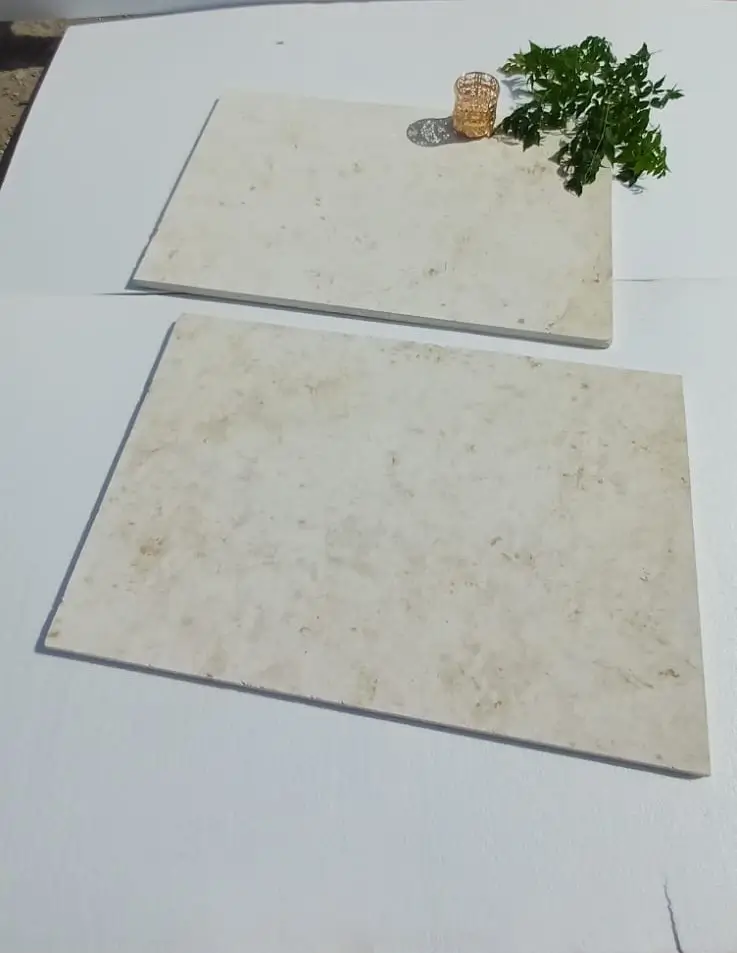

When you evaluate Citadel Stone’s flagstone for sale for Arizona curved cutting projects, you’re looking at material specifically selected for its workability and structural consistency. At Citadel Stone, we maintain warehouse inventory of flagstone with thickness tolerances within 1/4 inch, which simplifies curved installations compared to material with 1/2-inch or greater variation. This section outlines how you would approach specification decisions for three representative Arizona cities based on their distinct climate conditions and typical project requirements.

The hypothetical guidance provided here addresses technical considerations you should evaluate when planning curved flagstone installations across Arizona’s diverse regions. Your material selection needs to account for local temperature extremes, freeze-thaw exposure in high-elevation areas, and the intense UV radiation common throughout the state. Each city presents unique challenges that affect how you would specify material grade, thickness, and finishing requirements.

Flagstaff Elevation Considerations

In Flagstaff’s 7,000-foot elevation environment, you would need to specify flagstone with porosity below 6% to handle 100+ annual freeze-thaw cycles. Your curved cutting work would benefit from material with compressive strength above 10,000 PSI since freeze-thaw stress compounds with the structural reduction that radius cuts create at edges. You’d want to increase joint spacing to 3/8 inch minimum on curves to accommodate freeze expansion without generating stress fractures. Typical installations in similar mountain climates demonstrate that sealed edges on curved cuts extend service life by 30-40% compared to unsealed work. When you design curved steps or radius walls in Flagstaff conditions, you should specify material thickness of at least 1-1/2 inches to provide adequate thermal mass for freeze protection.

Sedona Aesthetic Standards

Sedona projects typically emphasize aesthetic integration with the region’s distinctive red rock landscape. You would select flagstone with warm earth tones and specify cutting techniques that preserve natural edge character where possible. Your flagstone arc creation work would focus on gentle radius curves above 48 inches rather than tight geometric patterns, matching the organic forms common in high-end Sedona landscape design. Color consistency becomes critical in curved installations since radius cuts expose fresh stone that may not match weathered surfaces. You’d need to plan for edge treatment that accelerates weathering appearance or specify sealer that minimizes color difference between cut and natural edges. Professional specifications for similar applications recommend dry-laid installation methods that allow seasonal movement without visible joint deterioration, particularly important in Sedona’s high-visibility resort and residential projects.

Peoria Heat Management

In Peoria’s extreme desert heat environment, you would specify flagstone radius cutting Arizona material with reflective properties that reduce surface temperature. Light-colored flagstone can run 20-30°F cooler than darker variants, which matters significantly for curved pool decks and patio areas where users contact surfaces barefoot. Your cutting specifications would emphasize smooth edge finishing to eliminate sharp corners that concentrate heat and create burn risks. You’d want to coordinate curved flagstone installations with shade structure design so that critical walking surfaces receive afternoon shade during peak summer months. Warehouse delivery timing becomes important in Peoria heat — you should schedule material arrival to allow 48-hour acclimatization before cutting begins, preventing thermal shock during the cutting process. For curved installations near pool areas, you would specify non-slip edge treatments that maintain effectiveness when wet, typically requiring 3/16-inch radius edge profiles rather than simple chamfers.

Specialized Applications

Fire pit surrounds represent one of the most common curved flagstone applications in Arizona. You’re creating circular patterns typically ranging from 6 to 12 feet in diameter, with the flagstone forming a heat-resistant border around the fire feature. Your cutting needs to produce consistent radius on both inner and outer edges of each stone, which requires precise template work. The inner edge receives direct radiant heat, so you should specify material that’s been tested to 400°F without spalling or color change. Professional installations maintain 18-inch minimum distance between flame and flagstone, but heat transfer through air still affects the stone.

Curved step treads combine the challenges of radius cutting with the structural requirements of load-bearing applications. You need material thickness of at least 2 inches for treads that span more than 24 inches, increasing to 2-1/2 inches for spans above 36 inches. Your curves typically feature gentler radius on treads compared to decorative elements — 60-inch radius is common for safety and manufacturing practicality. The nosing detail requires special attention; you should create a 1/4-inch bullnose on the leading edge rather than leaving a sharp corner that becomes a trip hazard and chips easily under traffic.

Curved garden borders and planting bed edges use thinner material, typically 3/4 to 1 inch thickness. These applications let you work with tighter radius cuts since structural loading is minimal. You can create serpentine patterns with radius down to 12 inches using thin material and progressive cutting techniques. The challenge shifts to installation rather than cutting — thin flagstone on tight curves requires more substantial edge support to prevent shifting and settling over time.

Final Considerations

Your success with flagstone radius cutting Arizona depends on matching technique to material characteristics and project requirements. The curved work demands more time and generates more waste than straight installations, typically 20-30% longer fabrication time and 15-20% higher material requirements due to cutting scrap. You should factor these realities into project scheduling and budgeting from the beginning rather than discovering them mid-project. Quality curved flagstone work separates premium installations from standard work, commanding appropriate pricing that reflects the specialized skills involved.

The relationship between cutting precision and installation quality becomes more obvious in curved work than straight installations. Small cutting errors that might be acceptable in straight joints become visually obvious in radius patterns where the eye naturally follows the curve. You’ll find that investing time in careful layout and precise cutting saves substantially more time during installation and produces results that justify premium pricing. For additional insights on managing water flow in flagstone installations, review Professional techniques for cutting flagstone drainage channels in Arizona before you finalize your project approach. Drainage solutions available in Citadel Stone’s engineered flagstone building supplies in Arizona.