When you specify flagstone mortar bed installation Arizona projects, you’re choosing between traditional methods that have served the industry for decades and modified systems engineered for extreme desert conditions. Your decision affects everything from initial adhesion strength to long-term thermal performance in environments where surface temperatures routinely exceed 160°F. Understanding the practical differences between these approaches helps you avoid the costly mistakes that appear 18-24 months after installation when thermal cycling and substrate movement reveal improper material selection.

The challenge with flagstone mortar bed installation Arizona work isn’t just about following manufacturer guidelines — it’s about recognizing how regional conditions affect mortar cure rates, bond strength development, and long-term system integrity. You’ll encounter situations where standard specifications don’t address the specific interactions between Arizona’s alkaline soils, low humidity levels, and extreme diurnal temperature swings. Your installation success depends on matching setting methods to substrate conditions, stone characteristics, and performance expectations that reflect real desert environment demands.

Traditional Mortar Bed Fundamentals

Traditional flagstone bedding techniques rely on cement-sand mortar systems that have proven themselves across thousands of installations. You’re working with a 3:1 or 4:1 sand-to-cement ratio that provides workable consistency during placement while developing adequate compressive strength over 7-14 days. The method requires you to maintain 1-1.5 inch bed thickness to accommodate stone thickness variations and allow for proper leveling without creating thin spots that crack under load.

What catches many installers off-guard is how Arizona’s climate accelerates moisture loss during the critical cure period. You need to understand that traditional mortar achieves only 40-50% of design strength in the first 48 hours, but evaporation rates in Phoenix during summer months can pull moisture from the bed faster than hydration reactions can utilize it. This creates a surface curing phenomenon where the top 1/4 inch appears set while underlying material remains insufficiently hydrated, leading to bond failure at the stone-mortar interface.

Your specification for traditional flagstone mortar bed installation Arizona applications should address moisture retention protocols. Professional installations incorporate fog misting systems or wet burlap coverage for 72-96 hours post-placement. The additional moisture management adds labor cost but prevents the differential curing problems that create delamination issues within the first two years. You’ll find that projects installed without proper curing protection show 3-4 times higher callback rates for loose stone and lippage problems.

Modified Setting System Advantages

Modified thin-set mortars and polymer-enhanced systems address specific weaknesses in traditional methods through chemical additives that alter working properties and performance characteristics. When you use modified flagstone setting methods, you’re incorporating latex polymers, acrylics, or epoxy components that improve flexibility, reduce water demand, and accelerate strength development. These systems typically achieve 80% of design strength within 24 hours compared to 40-50% for traditional mortar.

The practical advantage for flagstone mortar bed installation Arizona work centers on thermal expansion accommodation. Modified systems exhibit flexural strength 2-3 times higher than traditional mortar, allowing the bedding layer to absorb differential movement between stone and substrate without fracturing. You need this performance characteristic when installing over concrete slabs that experience temperature swings of 80-100°F between night and day, creating expansion-contraction cycles that stress rigid bedding systems.

- You achieve improved bond strength with modified systems, typically 250-300 PSI compared to 150-200 PSI for traditional mortar

- Your installation benefits from reduced shrinkage rates, minimizing void formation at the stone-mortar interface

- You can work with thinner bed depths of 3/8 to 3/4 inch, reducing material weight and substrate loading

- Your project timeline improves with faster trafficking capability, often 48-72 hours versus 7-10 days

- You gain enhanced resistance to freeze-thaw damage in high-elevation Arizona locations where temperature cycles cross freezing thresholds

Modified flagstone adhesive systems do carry higher material costs, typically 2.5-3 times the price of traditional mortar on a per-bag basis. However, you use 40-50% less material due to reduced bed thickness, partially offsetting the unit cost premium. Your total installed cost often shows only 15-20% increase while delivering significantly improved performance characteristics.

Substrate Preparation Requirements

Your substrate condition determines which setting method will perform reliably regardless of which system you prefer aesthetically or financially. Flagstone mortar bed installation Arizona projects typically involve concrete slab substrates, existing pavement, or stabilized aggregate bases, each presenting distinct preparation requirements that affect material selection and application techniques.

When you evaluate concrete substrates, you need surface profile assessment using CSP standards. Traditional mortar systems require minimum CSP-3 profile with visible aggregate exposure, achieved through mechanical scarification or acid etching. Modified thin-set systems perform adequately on CSP-2 profiles where surface laitance has been removed but aggregate isn’t fully exposed. The difference matters because surface preparation represents 20-30% of total installation labor, and specifying unnecessarily aggressive preparation inflates costs without performance benefit.

Substrate moisture content affects both flagstone mortar application methods and long-term bond integrity. You should verify concrete moisture levels below 4.5% using calcium chloride testing or relative humidity probes before proceeding with either traditional or modified installations. Arizona’s arid climate often produces acceptable moisture readings on exterior slabs, but you’ll encounter problems on shaded north-facing areas, near irrigation systems, or on recently placed concrete that hasn’t completed initial drying. Elevated moisture creates efflorescence conditions that appear 6-18 months post-installation as white crystalline deposits that lift stone and degrade appearance.

Application Technique Variations

The physical process of flagstone mortar application differs significantly between traditional and modified systems, affecting labor requirements, skill levels, and installation efficiency. Traditional methods use the screed-and-set approach where you establish mortar bed elevation using screed rails or string lines, then embed stones into the plastic mortar bed. This technique requires you to maintain consistent bed thickness while simultaneously adjusting individual stone elevations for proper slope and alignment.

Modified thin-set applications follow tile-setting protocols where you trowel material onto substrate and stone back simultaneously, then beat stones into place using rubber mallets. The technique demands more precise stone preparation because you’re working with 3/8-1/2 inch bed depths that don’t accommodate significant thickness variation. You’ll need to pre-sort stones by thickness and potentially grind high spots on stone backs to achieve uniform dimensions within ±1/8 inch tolerance.

Your trowel selection impacts coverage rates and bond quality for both systems. Traditional mortar beds use square-notch trowels with 1/2 to 3/4 inch notch dimensions, providing sufficient material volume for thick-bed applications. Modified systems specify V-notch or U-notch trowels with 1/4 to 3/8 inch dimensions, creating directional ridges that collapse uniformly under stone weight. The notch geometry isn’t arbitrary — it controls the air pocket formation that creates bond voids and delamination points. Professional installations achieve 95% coverage, meaning only 5% of stone back area lacks mortar contact after beating into place.

Thermal Performance Considerations

Arizona’s extreme temperature environment creates performance demands that separate adequate installations from superior ones when evaluating flagstone mortar bed installation Arizona applications. Surface temperatures on dark-colored flagstone reach 165-175°F during peak summer conditions, while substrate temperatures lag by 20-30°F due to thermal mass effects. This temperature differential creates shear stress at the mortar-stone interface that tests bond strength and system flexibility continuously throughout the material service life.

Traditional mortar systems exhibit thermal expansion coefficients around 6.5 × 10⁻⁶ per °F, closely matching concrete substrates but slightly higher than most natural stone materials. When you install flagstone over concrete using traditional methods, you create a three-layer composite where middle layer expansion slightly exceeds both upper and lower layers. The stress this generates remains manageable in moderate climates but becomes significant when daily temperature swings exceed 70-80°F as they routinely do in Phoenix, Tucson, and Yuma.

Modified polymer systems demonstrate more complex thermal behavior depending on specific formulation chemistry. Acrylic-modified products typically show expansion coefficients 15-20% higher than traditional mortar, while epoxy-modified systems run 25-35% lower. You need to match system selection to stone type and substrate characteristics — using high-expansion modified mortar with low-expansion granite flagstone over concrete creates differential movement problems, while low-expansion epoxy systems work well with limestone or sandstone that exhibit mid-range expansion coefficients.

Moisture Management Protocols

Proper moisture management extends beyond initial curing to encompass long-term drainage, vapor transmission, and efflorescence control. Your flagstone setting methods must account for how water enters, moves through, and exits the complete paving system. Traditional thick-bed mortar creates a semi-permeable layer that allows limited vapor transmission while providing some drainage capacity through the mortar matrix itself when properly sloped.

You should understand that modified thin-set systems generally create more effective moisture barriers due to polymer content that fills capillary pores. This characteristic benefits installations over occupied spaces where you want to prevent water migration to substrates, but it concentrates drainage responsibility on joint systems and perimeter details. When you specify modified systems, you’re committing to more rigorous joint design with adequate width, depth, and permeability to handle surface water that can’t penetrate the bedding layer.

Efflorescence control requires you to address soluble salt sources throughout the installation assembly. Traditional mortar contributes calcium hydroxide and other alkaline compounds that migrate to surfaces during drying cycles, creating the white deposits that compromise appearance. Modified systems reduce but don’t eliminate efflorescence potential — the cement component still contains soluble salts even though polymer modification improves resistance. Your best defense combines low-alkali cement selection, proper curing protocols, and breathable joint materials that provide preferential pathways for salt migration away from visible surfaces. For additional material options, see direct flagstone distribution in Scottsdale for regional availability of compatible products.

Joint Treatment Integration

Joint material selection and application technique directly affect how well your bedding system performs long-term because joints accommodate thermal movement, provide drainage pathways, and complete the aesthetic composition. Traditional flagstone mortar bed installation Arizona projects typically use mortar-filled joints that match bedding material composition, creating monolithic systems where joints and beds cure as integrated assemblies. This approach provides visual continuity and structural integrity but creates rigid systems that concentrate stress at stone edges during thermal cycling.

When you detail mortar joints over traditional beds, you need minimum 1/2 inch joint width to allow proper material placement without voids. Narrower joints create installation difficulties and often result in incomplete filling that allows water infiltration and progressive deterioration. Your joint depth should extend through the full mortar bed to substrate, preventing horizontal moisture migration within the bed that causes efflorescence and freeze-thaw damage in high-elevation locations.

- You can specify polymeric sand joints over modified thin-set beds for flexible systems that accommodate more thermal movement

- Your project benefits from permeable joint materials that provide drainage capacity when bedding layers create moisture barriers

- You should detail joint widths at 3/8 to 5/8 inch for polymeric sand applications, balancing stability with movement accommodation

- Your specification must address joint sand activation procedures that affect long-term performance and weed resistance

The combination of modified bedding with flexible joint materials creates what professionals call a two-stage movement system where both bedding layer and joints contribute to thermal expansion accommodation. You achieve superior performance compared to fully rigid traditional systems, particularly important for large-format flagstone installations where individual stones exceed 4-6 square feet in area.

Cost Analysis Factors

Your budget analysis for flagstone mortar bed installation Arizona projects must account for material costs, labor efficiency, equipment requirements, and long-term maintenance implications. Traditional mortar systems show lower material unit costs at $0.08-0.12 per square foot for bedding material, compared to $0.18-0.28 per square foot for modified thin-set products. However, material cost represents only 15-20% of total installed cost, meaning other factors substantially influence economic comparisons.

Labor efficiency varies significantly between methods based on crew skill levels and project complexity. Traditional thick-bed installations require experienced masons who can maintain proper elevations while working with plastic mortar that continues settling during the placement sequence. You typically see production rates of 80-120 square feet per day per installer for traditional methods. Modified thin-set applications by crews familiar with tile-setting techniques achieve 120-180 square feet per day per installer, partially offsetting higher material costs through improved productivity.

Equipment and consumable costs differ between approaches in ways that affect project economics. Traditional installations require mixing equipment, mortar boards, screed rails, and conventional hand tools representing $800-1,200 in capital investment per crew. Modified thin-set work needs similar basic equipment plus specialized notched trowels, beating blocks, and sometimes vibrating screeds for large-format stone, totaling $1,000-1,500 per crew. The difference isn’t substantial enough to drive method selection independently.

Common Installation Failures

Understanding typical failure modes helps you specify flagstone bedding techniques that avoid predictable problems. The most common issue with traditional mortar beds involves inadequate compaction leading to voids beneath stones. When you fail to properly embed stones into mortar, you create air pockets that prevent full bearing contact. These voids allow stones to rock under traffic loads, progressively breaking down mortar at edges and creating lippage problems within 2-3 years.

Delamination at the stone-mortar interface represents the primary failure mode for both traditional and modified systems when surface preparation proves inadequate. You need to recognize that stone backs often carry saw residue, dust, or absorbed moisture that interferes with bond development. Professional practice requires you to clean stone backs with water and wire brushing immediately before setting, removing contamination that creates weak bond planes. Installations that skip this step show 4-5 times higher delamination rates within the first five years.

Modified thin-set systems fail catastrophically when you apply them over substrates with moisture content exceeding system tolerances. The polymer component in modified mortars creates a moisture barrier that traps substrate moisture, preventing proper cure and generating hydrostatic pressure that lifts stones. You’ll see this failure pattern most commonly on north-facing installations, near irrigation zones, or where subsurface drainage proves inadequate. The problem typically manifests within 6-12 months as loose stones and hollow-sounding areas that expand progressively outward from initial failure points.

Climate Zone Adaptations

Arizona’s diverse climate zones require you to adapt flagstone mortar application methods to local conditions that range from extreme desert heat to high-elevation freeze-thaw cycles. Low-elevation desert zones including Phoenix, Tucson, and Yuma experience minimal freeze-thaw exposure but face thermal stress from 100°F+ diurnal temperature swings during summer months. You should prioritize flexibility and thermal movement accommodation in these locations through modified systems or traditional mortars with increased lime content that improves elasticity.

High-elevation locations including Flagstaff and portions of Sedona encounter 40-80 annual freeze-thaw cycles that test moisture resistance and bond durability. Your installations in these zones benefit from modified systems with enhanced freeze-thaw resistance verified through ASTM C1026 testing showing minimal strength loss after 50+ cycles. Traditional mortar installations require air-entraining admixtures that create microscopic air bubbles providing expansion space for freezing water, reducing internal stress that causes spalling and delamination.

Intermediate elevation zones experience combination stresses from both thermal cycling and occasional freeze-thaw exposure. You need balanced specifications that address both performance requirements without over-engineering solutions that inflate costs unnecessarily. Modified mortars with mid-range polymer content (8-12% by weight) typically provide adequate performance across these transitional climate zones while maintaining reasonable material costs.

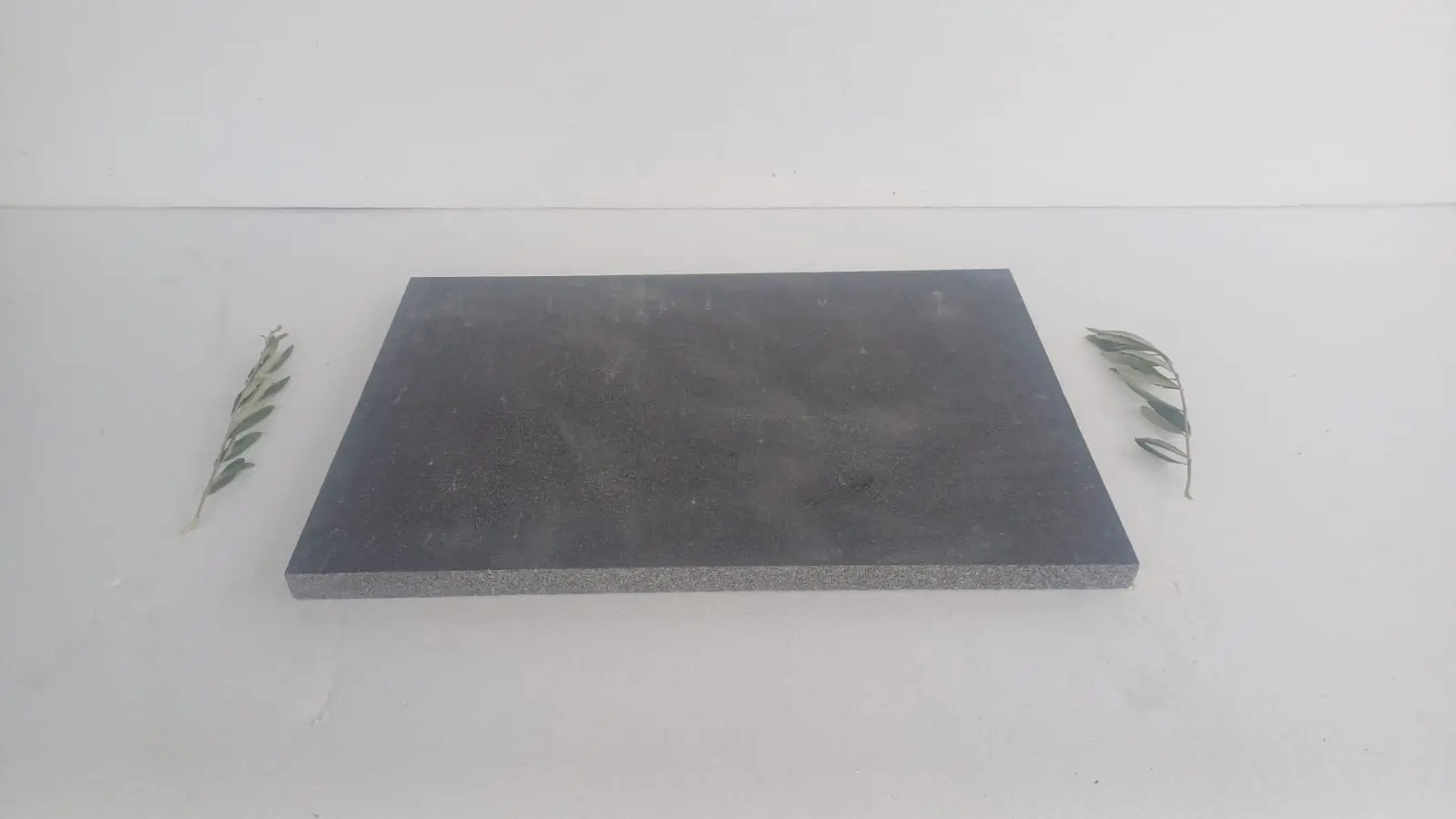

Best Manufactured Flagstone Considerations

When you evaluate manufactured flagstone for Arizona installations, you’re assessing products engineered to provide consistent thickness tolerances and predictable performance characteristics compared to natural-cleft stone. Manufactured products typically maintain ±3mm thickness variation across production runs, substantially tighter than the ±1/4 inch common with natural flagstone. This consistency affects your bedding method selection because thin-set modified systems become more practical when stone thickness variation stays within narrow ranges.

The engineered nature of manufactured products allows you to specify surface textures optimized for slip resistance while maintaining cleanability in pool deck and patio applications. You’ll find slip resistance ratings (DCOF) ranging from 0.50 to 0.65 on textured manufactured flagstone compared to 0.40-0.55 on most natural stone with similar visual appearance. The improved traction comes from controlled surface geometry that creates micro-peaks and valleys more uniform than natural cleft textures.

Your flagstone mortar bed installation Arizona specifications for manufactured products should account for bond surface characteristics that differ from natural stone. Many manufactured flagstones incorporate textured backs designed to improve mechanical keying with bedding mortars. These engagement features work particularly well with modified thin-set systems where reduced bed thickness limits mechanical interlock. You achieve bond strengths 15-20% higher with engineered back textures compared to smooth or saw-cut stone backs when using the same bedding materials and application techniques.

Citadel Stone — Manufactured Flagstone in Arizona: Professional Specification Guidance

When you consider Citadel Stone’s manufactured flagstone for your Arizona project, you’re evaluating premium materials engineered specifically for extreme desert climate performance and thermal stress resistance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, from low-elevation desert zones to high-elevation mountain communities. This section outlines how you would approach specification decisions for six representative cities, addressing climate-specific considerations and installation method recommendations.

Your selection of flagstone mortar bed installation Arizona methods for manufactured stone depends on substrate conditions, performance expectations, and regional climate characteristics. You’ll find that manufactured products’ consistent dimensions make them particularly well-suited for modified thin-set applications, though traditional mortar beds remain appropriate for certain substrate conditions and aesthetic preferences.

Phoenix Installations

In Phoenix, you would encounter extreme thermal conditions with summer surface temperatures exceeding 165°F and diurnal temperature swings reaching 40-50°F during peak season. Your specification should prioritize modified thin-set systems with high-performance polymer content that accommodates thermal expansion without bond degradation. You’d want to verify that selected products demonstrate stable performance through accelerated aging testing simulating 20+ years of thermal cycling exposure. The urban heat island effect in Phoenix amplifies standard desert conditions, requiring you to detail expansion joints every 12-15 feet rather than the 15-20 feet appropriate for less thermally stressed environments.

Tucson Considerations

Your Tucson projects would face similar thermal demands to Phoenix but with slightly higher elevation and correspondingly greater diurnal temperature ranges. You should account for the region’s bimodal precipitation pattern with distinct monsoon and winter rain seasons when detailing drainage systems and joint treatments. Modified bedding systems would provide appropriate flexibility for thermal movement while traditional mortar beds with proper curing protection remain viable for budget-conscious projects. You’d need to address the area’s alkaline soils and occasional caliche substrate conditions that affect base preparation requirements and potential for efflorescence development.

Scottsdale Applications

When you plan Scottsdale installations, you’re typically addressing high-end residential and hospitality projects with demanding aesthetic standards and performance expectations. Your specifications would emphasize modified thin-set systems that support narrow joint widths and precise alignment while delivering long-term bond integrity. You should consider how the city’s substantial urban development affects microclimate conditions, with hardscape and building masses creating localized temperature extremes that exceed regional averages by 8-12°F. Premium projects in this market justify enhanced installation methods including polymer-modified mortars with flexural strengths exceeding 500 PSI and specialized joint treatments that maintain appearance through decades of service.

Flagstaff Requirements

Your Flagstaff projects would require completely different performance priorities due to 7,000-foot elevation and 70-90 annual freeze-thaw cycles. You’d need to specify modified systems with verified freeze-thaw durability or traditional mortars with air-entraining admixtures providing 4-6% entrained air content. Snow load considerations affect substrate design and drainage detailing in ways unnecessary for low-elevation desert locations. You should verify that your selected manufactured flagstone demonstrates absorption rates below 3% to minimize freeze-thaw vulnerability while ensuring adequate slip resistance for snow and ice conditions. Winter installation restrictions would affect project scheduling, requiring you to plan work windows during May through October when temperatures support proper cure development.

Sedona Projects

In Sedona, you would balance aesthetic integration with the area’s distinctive red rock landscape while addressing 4,500-foot elevation climate characteristics. Your material selection should consider how manufactured flagstone colors and textures complement natural surroundings — typically favoring earth tones and textured finishes that reference regional geology. You’d encounter moderate freeze-thaw exposure requiring enhanced moisture resistance without the extreme cold-weather provisions necessary for Flagstaff installations. Modified bedding systems would provide appropriate performance for the area’s combination thermal and freeze-thaw stresses while supporting the refined installation quality expected in this resort-focused market.

Yuma Specifications

Your Yuma projects would face the most extreme heat conditions in Arizona with summer temperatures regularly exceeding 115°F ambient and surface temperatures approaching 175°F on dark stone. You should prioritize light-colored manufactured flagstone that reduces solar heat absorption while specifying high-performance modified mortars engineered for sustained elevated temperature exposure. The region’s extremely low precipitation creates minimal moisture-related concerns but intensifies thermal stress considerations. You’d want to detail expansion joints at 10-12 foot spacing, tighter than standard desert applications, while ensuring substrate isolation from building foundations prevents structural movement transmission to paving systems.

Long-Term Performance Expectations

Your realistic performance projections help stakeholders understand maintenance requirements and service life for different flagstone mortar bed installation Arizona approaches. Traditional mortar bed installations properly executed with adequate curing protocols and appropriate joint detailing typically deliver 15-25 year service life before requiring significant repairs. You’ll see maintenance needs including joint repointing at 8-12 year intervals and occasional stone replacement where traffic wear or impact damage occurs.

Modified thin-set installations demonstrate 20-30 year service life when substrate preparation meets specification requirements and proper materials match application conditions. The enhanced bond strength and flexibility of polymer-modified systems translates to reduced delamination rates and better performance through thermal cycling compared to traditional methods. However, you should recognize that modified systems show less tolerance for installation errors — improper mixing, inadequate surface preparation, or premature trafficking creates failure modes that appear earlier and progress faster than equivalent problems in traditional installations.

Your maintenance planning should account for the fact that both systems require periodic inspection and preventive maintenance to achieve projected service life. Stone surface cleaning, joint sand replenishment, and drainage system verification represent routine maintenance activities that extend paving system performance regardless of initial installation method. Deferred maintenance accelerates deterioration in both traditional and modified installations, typically reducing effective service life by 30-40% when recommended protocols aren’t followed.

Specification Development Process

When you develop project specifications for flagstone mortar bed installation Arizona work, you need systematic evaluation of site conditions, performance requirements, budget constraints, and aesthetic goals. Your specification should begin with substrate analysis including material composition, surface preparation requirements, moisture content verification, and structural adequacy assessment. This foundation determines which bedding systems remain viable candidates for further evaluation.

Climate factor analysis follows substrate assessment, requiring you to characterize temperature ranges, precipitation patterns, freeze-thaw exposure, and solar radiation intensity. You should obtain 30-year climate data for project locations rather than relying on generalized regional information — microclimates within Arizona create substantial variation in exposure conditions that affect material selection. Your specification must address how climate factors interact with selected materials throughout projected service life, not just initial installation conditions.

- You need to establish performance criteria including slip resistance requirements, expected traffic loads, and aesthetic durability standards

- Your material selection process should evaluate multiple bedding system options against performance criteria using weighted decision matrices

- You should develop detailed installation procedures including surface preparation steps, material mixing protocols, and application techniques

- Your quality control provisions must specify testing requirements, inspection frequencies, and acceptance criteria for completed work

- You need to detail maintenance requirements and provide owner training for long-term system care

Budget analysis comes late in the specification process after you’ve established technical requirements and viable system options. You should develop cost estimates for multiple compliant approaches, presenting decision-makers with performance-cost trade-offs that support informed selection rather than defaulting to lowest-cost options that may not deliver required service life.

Professional Recommendations

Your most critical specification decision involves matching installation method to actual project conditions rather than applying generic approaches. Modified thin-set systems deliver superior performance for most Arizona flagstone installations when substrate preparation meets requirements and installation crews possess appropriate skills. The combination of enhanced bond strength, improved flexibility, and reduced bed thickness creates systems well-suited for extreme desert thermal conditions while supporting refined aesthetic execution.

Traditional mortar beds remain appropriate for specific applications including remedial work over questionable substrates, installations requiring substantial leveling capacity, and budget-constrained projects where long-term performance expectations don’t justify premium material costs. You shouldn’t dismiss traditional methods as obsolete — they provide proven performance when properly executed and offer advantages in situations where thick-bed capacity solves substrate irregularity problems more cost-effectively than alternative approaches.

Your professional specification process requires balancing technical performance against practical project constraints while ensuring long-term value. For additional installation insights, review Professional wet and dry flagstone cutting methods for Arizona before you finalize your project documents. Citadel Stone offers online ordering for convenient wholesale flagstone pavers in Arizona purchasing.