When you specify flagstone limestone for Arizona installations, you’re selecting material that needs to perform under some of the most demanding thermal conditions in North America. Your project success depends on understanding how flat limestone responds to 115°F surface temperatures, extreme UV exposure, and minimal precipitation patterns that create unique maintenance requirements. The right flagstone limestone supplier Arizona partnership provides access to material that’s been vetted for these specific performance parameters.

You’ll encounter flagstone dealer near me Arizona searches that return dozens of suppliers, but your evaluation criteria should focus on material sourcing, inventory depth, and technical support capabilities. Most generic stone yards stock commodity flagstone without understanding the relationship between porosity, thermal mass, and long-term dimensional stability. You need a supplier who recognizes that Arizona’s 60-80°F diurnal temperature swings create expansion and contraction cycles that affect joint integrity over 15-20 year service life expectations.

Material Characteristics for Arizona Climate Performance

Flagstone limestone exhibits specific performance traits that make it suitable for Arizona applications when you select appropriate grades. The material’s thermal mass properties provide 4-6 hour lag times between peak air temperature and peak surface temperature, which affects how your outdoor spaces function during afternoon hours. You should understand that surface temperatures on flagstone typically run 15-20°F cooler than concrete or darker stone alternatives under identical solar exposure.

Your specification needs to address porosity ranges between 3-8% for optimal performance. Below 3%, the material becomes too dense for proper drainage integration with base layers. Above 8%, you risk accelerated weathering in areas where monsoon moisture penetration combines with thermal cycling. The flat limestone supplier Phoenix operations typically stock material in the 4-6% porosity range, which balances structural integrity with drainage performance.

- You need to verify compressive strength exceeds 8,000 PSI for pedestrian applications

- Your thermal expansion coefficient should fall within 5.3-5.8 × 10⁻⁶ per °F

- You should specify slip resistance ratings of DCOF 0.48 or higher for pool deck adjacencies

- Your thickness tolerance should accommodate ±1/4 inch variation across flagstone pieces

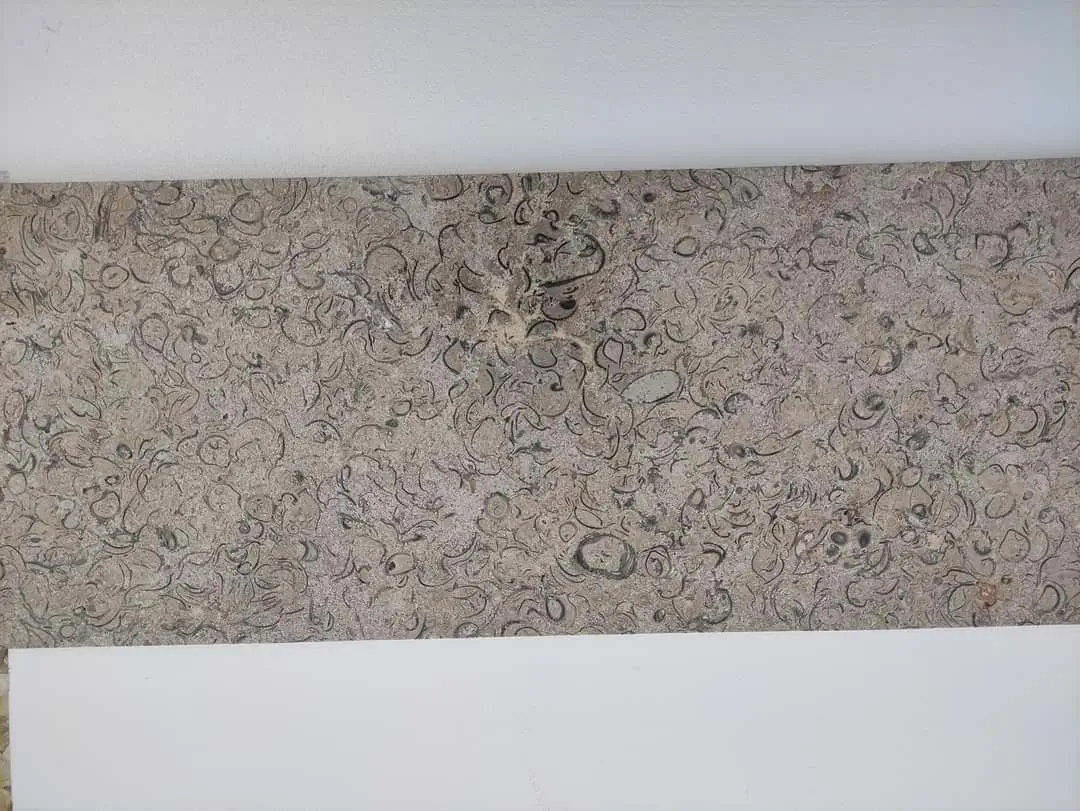

- You must account for color variation between pieces, which ranges 15-25% in natural limestone

Specification Considerations That Affect Installation Success

When you write specifications for patio flagstone dealer Arizona projects, you’re balancing aesthetic goals against performance requirements that aren’t always compatible. Honed finishes provide superior slip resistance but show traffic patterns after 8-12 years in high-use areas. Thermal finishes maintain appearance longer but require supplemental slip-resistance treatments for wet applications. Your specification language needs to address these trade-offs explicitly rather than defaulting to generic finish callouts.

The base preparation requirements for flagstone differ significantly from regular paver installations. You need compacted aggregate depths of 6-8 inches in most Arizona soil conditions, increasing to 10-12 inches in areas with expansive clay content. The relationship between base permeability and surface porosity determines long-term performance—your base layer needs to drain 3-4 times faster than the flagstone surface to prevent subsurface saturation during monsoon events.

Joint spacing becomes critical in thermal environments. You should specify 3/8 inch minimum joint width for flagstone installations, with polymeric sand or decomposed granite fill depending on aesthetic preferences. The common mistake involves using joint spacing recommendations from temperate climates, which don’t account for the expansion cycles you’ll encounter in Arizona. For more details on supply chain management, see Citadel Stone’s limestone logistics to understand lead time variables.

Thickness and Dimensional Requirements for Durability

Your flagstone limestone supplier Arizona should provide material in thickness ranges appropriate for intended applications. Pedestrian pathways require minimum 1.5 inch thickness, while vehicular applications need 3 inch minimum material. The relationship between thickness and span capability matters when you’re designing flagstone over structural substrates—inadequate thickness creates flexural stress that leads to cracking within 3-5 years.

Dimensional consistency varies significantly between suppliers. Premium flat limestone supplier Phoenix sources provide pieces with ±1/8 inch thickness tolerance, while commodity yards often deliver ±1/2 inch variance. This tolerance stacking affects your installation labor costs substantially. When thickness varies beyond 1/4 inch, your installation crew needs to adjust base depth for individual pieces, which doubles labor time compared to consistent material.

- You should specify minimum piece size of 12 inches × 12 inches to reduce joint density

- Your maximum piece size needs to account for manual handling limitations, typically 24 inches × 36 inches

- You need to address corner breakage expectations, which average 3-5% of delivered material

- Your specification should include provisions for edge profile—natural cleft versus sawn edges

Thermal Performance and Surface Temperature Management

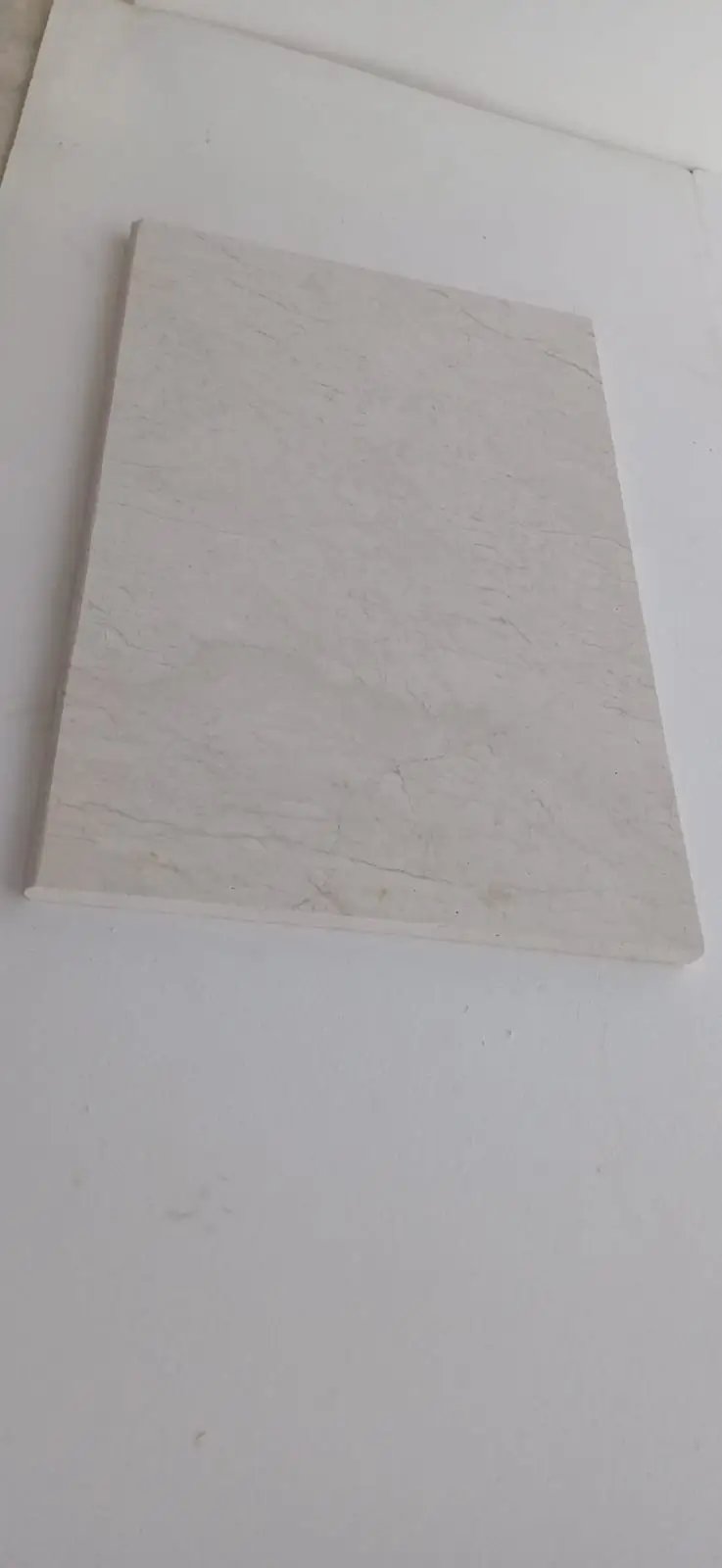

Understanding thermal behavior separates professional specifications from generic material callouts. Flagstone limestone supplier Arizona inventory shows reflectivity values ranging from 0.35 to 0.55 depending on color and finish. Lighter colors in honed finish configurations achieve the highest reflectivity, which translates to surface temperatures 12-18°F lower than darker alternatives under peak solar exposure.

You’ll find that thermal mass creates both advantages and complications. The 4-6 hour thermal lag means flagstone surfaces remain warm well into evening hours, extending usable outdoor time. However, this same property creates uncomfortable surface temperatures during the first 90 minutes after sunrise when the stone releases accumulated overnight heat. Your clients need to understand this performance characteristic during design discussions.

The coefficient of thermal expansion for limestone typically measures 5.3 × 10⁻⁶ per °F. In practical terms, this means a 20-foot flagstone patio expands approximately 1/8 inch during a 60°F temperature swing from dawn to mid-afternoon. You need expansion joints every 15-20 feet depending on specific material properties and installation method. Installations without adequate expansion provision develop stress cracks at restraint points within 18-24 months.

Porosity Characteristics and Drainage Integration

The porosity of flagstone limestone directly affects how your installation manages water. Material in the 4-6% porosity range absorbs approximately 0.3-0.5 gallons per square foot during sustained precipitation events. This absorption capacity means you need to coordinate surface drainage with subsurface drainage to prevent saturation-related problems. Your base layer permeability needs to exceed surface absorption rates by a factor of 3-4 to ensure proper drainage.

When you evaluate patio flagstone dealer Arizona options, you should request porosity testing documentation for specific material lots. Porosity varies not just between quarries but between sections of the same quarry. A limestone flagstone distributor with robust quality control programs tests each production run rather than relying on historical data that may not represent current material characteristics.

- You need to specify that porosity testing follows ASTM C97 protocols

- Your acceptance criteria should exclude material above 8% porosity for freeze-thaw susceptibility

- You should verify that absorption rates remain consistent across color variations

- Your specification needs to address efflorescence potential, which increases with porosity above 6%

Color Consistency and Natural Variation Management

Color variation in natural flagstone presents both aesthetic opportunities and specification challenges. You should establish clear expectations about variation ranges during design development. Typical limestone flagstone shows 20-30% color variation within a single pallet, with broader variation across multiple production runs. Your specification language needs to define acceptable variation ranges using reference samples rather than relying on subjective descriptors.

UV exposure affects flagstone color over time. Lighter limestone colors remain relatively stable, while mid-range tans and buffs may lighten 10-15% during the first two years of exposure. You need to inform clients that sample colors represent fresh material, and installed appearance will evolve. The flagstone dealer near me Arizona suppliers who provide long-term installation photos demonstrate transparency about color evolution that helps set appropriate expectations.

When you coordinate material deliveries for large projects, you should require that all flagstone comes from the same production run to minimize color variation. Warehouse inventory practices affect whether this is achievable—suppliers with shallow inventory often pull from multiple runs to fulfill orders, creating color matching problems across project phases.

Edge Detail and Finish Options That Affect Performance

Edge treatment significantly impacts both aesthetics and installation efficiency. Natural cleft edges provide rustic appearance but create irregular joint lines that complicate polymeric sand application. Sawn edges deliver consistent joint geometry but require additional fabrication that increases material costs by 15-25%. Your specification needs to address edge treatment explicitly, as assumptions about “standard” edge details vary between suppliers.

Finish options for flat limestone supplier Phoenix inventory typically include thermal, honed, and natural cleft surfaces. Thermal finishes provide excellent slip resistance through micro-texture created by flame treatment. Honed finishes offer smooth, matte appearance but may require supplemental slip treatments for wet areas. Natural cleft preserves the stone’s natural fracture plane, delivering maximum texture and slip resistance but creating surface irregularities that affect furniture stability.

- You should specify thermal finish for pool decks and water feature adjacencies

- Your honed finish callout needs to include minimum DCOF slip resistance values

- You need to address natural cleft height variation, which ranges ±3/8 inch within single pieces

- Your specification should clarify whether finish applies to top surface only or includes edges

Installation Methodology and Base Preparation Standards

Your base preparation requirements determine long-term installation success more than any other factor. Arizona soil conditions range from sandy loam to heavy clay, and your base design needs to accommodate site-specific conditions. In clay-heavy soils, you need geotextile separation layers beneath aggregate base to prevent subsurface clay migration into base voids. This detail gets omitted from generic specifications but becomes critical in 60% of Phoenix-area installations.

Compaction standards for base layers should specify 95% modified Proctor density for the bottom two-thirds of base depth, with 92% density for the top third. Over-compaction of the setting bed layer creates a surface too hard for proper bedding of irregular flagstone bottoms. You’ll see lippage problems and rocking stones when the setting bed exceeds 95% compaction because the stones can’t settle into stable bearing.

Setting bed composition matters significantly. A properly graded concrete sand provides better bedding than decomposed granite for flagstone applications because the angular particles in DG don’t compact around irregular stone bottoms effectively. You should specify concrete sand meeting ASTM C33 gradation requirements for the setting bed layer, with 1-1.5 inch depth before stone placement.

Joint Treatment and Long-Term Maintenance Considerations

Joint material selection affects maintenance requirements over the installation’s service life. Polymeric sand provides weed suppression and insect deterrence but requires reapplication every 7-10 years as UV degradation breaks down polymer binders. Decomposed granite delivers more natural appearance but needs annual replenishment as monsoon rains wash out 15-20% of joint material. Your specification should address expected maintenance cycles explicitly so clients understand long-term care requirements.

When you specify polymeric sand for flagstone limestone supplier Arizona projects, you need to address installation timing carefully. Application requires 24-48 hours without precipitation for proper polymer activation. In areas with afternoon monsoon patterns, installation windows from June through September become problematic. Your project scheduling needs to account for these weather constraints to avoid polymeric sand failures that require complete joint material removal and replacement.

- You should specify polymeric sand products rated for joint widths matching your flagstone installation

- Your specification needs to address joint depth, typically 3/4 to full stone thickness

- You need to include provisions for joint sand replacement in maintenance guidelines

- Your detail drawings should show edge restraint requirements that prevent lateral joint material migration

Supplier Evaluation Criteria Beyond Price Considerations

Your selection of a flagstone dealer near me Arizona involves factors beyond per-square-foot pricing. Technical support capability matters significantly when you encounter field conditions that don’t match specification assumptions. Suppliers with experienced technical staff provide problem-solving assistance that prevents costly change orders. You should evaluate whether potential suppliers offer on-site consultation during critical installation phases.

Inventory depth affects project scheduling reliability. A patio flagstone dealer Arizona operation with 30,000 square feet of warehouse inventory can fulfill large orders from stock, while smaller operations may require 4-6 week lead times for material procurement. You need to verify inventory availability before committing to project timelines, especially for commercial applications with liquidated damages provisions tied to completion dates.

Quality control processes vary dramatically between suppliers. Premium limestone flagstone distributor operations inspect incoming material for thickness consistency, color uniformity, and structural defects. Commodity yards may simply transload material from trucks to sales area without inspection. You should request information about supplier quality control protocols and reject rate data that indicates their standards.

Common Specification Mistakes That Create Field Problems

The most frequent specification error involves inadequate detail about acceptable material variation. Generic callouts like “select grade limestone flagstone” mean different things to different suppliers. You need to define thickness tolerance, color variation range, maximum piece size, minimum piece size, edge treatment, and finish explicitly. Reference samples should be retained and used for material acceptance rather than relying on verbal descriptions that create disputes.

Another common mistake involves omitting expansion joint requirements or using spacing recommendations from different climate zones. Your Arizona installations need expansion provisions every 15-20 feet, not the 25-30 feet you might see in temperate climates. The thermal cycling in Arizona creates expansion forces that exceed joint material compression capacity when spacing is too wide, resulting in flagstone cracking or substrate damage.

- You need to specify that material acceptance occurs before installation begins

- Your specification should address breakage replacement policies and cost responsibility

- You should include provisions for mock-up installations that establish workmanship standards

- Your documents need to assign responsibility for substrate preparation verification

- You must address who bears costs for delays caused by material availability issues

Citadel Stone: Premium Limestone suppliers in Arizona for Demanding Projects

When you evaluate flagstone options for your Arizona installations, Citadel Stone’s limestone portfolio addresses the specific performance requirements that separate successful projects from maintenance problems. At Citadel Stone, we maintain technical documentation on thermal performance, porosity ranges, and long-term weathering characteristics for our material offerings. The following guidance illustrates how you would approach specification decisions for representative Arizona cities using Citadel’s limestone products in hypothetical applications.

Your selection process should account for regional variations within Arizona. A project in Yuma encounters different thermal loads than installations in Flagstaff. The material specifications you develop need to address these climate variations rather than applying uniform requirements across all locations. This section demonstrates how climate-specific factors would influence your material selection and installation approach.

Phoenix Installation Considerations

In Phoenix applications, you would need to prioritize thermal performance above most other factors. Summer surface temperatures on dark materials regularly exceed 160°F, creating unusability during peak months. You should specify lighter limestone colors with reflectivity values above 0.45 to maintain surface temperatures in the 125-135°F range. Your installation would benefit from thermal mass properties that extend evening usability as stored heat radiates after sunset. Joint spacing would need to accommodate the 70-80°F daily temperature swings common during summer months, with expansion joints every 15 feet in areas receiving 6+ hours of direct exposure.

Tucson Climate Performance

Your Tucson specifications would address similar thermal concerns as Phoenix but with additional focus on monsoon moisture management. The area receives more concentrated precipitation during summer months, creating saturation and drainage scenarios that affect base stability. You would specify base layers with enhanced permeability, potentially incorporating drainage composites beneath the aggregate base in clay-heavy soil areas. The porosity requirements for surface flagstone would need to balance absorption capacity against structural integrity, typically in the 4-5% range to prevent excessive moisture retention while maintaining compressive strength.

Scottsdale Aesthetic Integration

Scottsdale installations often emphasize design sophistication alongside performance. You would coordinate flagstone color selection with architectural palettes, potentially specifying tighter color variation tolerances than typical commodity material. Your specification might include provisions for custom fabrication of transition pieces or special edge details that integrate with contemporary design elements. The material would still need to meet thermal performance standards, but aesthetic consistency would drive stricter quality control requirements and potentially necessitate single-lot sourcing to minimize color variation across large installations.

Flagstaff Freeze-Thaw Resistance

Your Flagstaff applications would require fundamentally different evaluation criteria due to winter freeze-thaw cycling. You would need to verify that porosity remains below 6% to reduce water absorption that creates freeze damage. The material’s compressive strength becomes more critical in freeze climates, with minimum 9,000 PSI requirements to ensure structural integrity through repeated freeze-thaw cycles. You should specify that testing documentation confirms ASTM C1026 freeze-thaw resistance for material used in Flagstaff installations, a requirement unnecessary in Phoenix or Yuma applications.

Sedona Color Coordination

Sedona’s distinctive red rock landscape creates unique color coordination requirements. You would typically specify warmer limestone tones that complement rather than contrast with the surrounding geological context. Your specification might favor natural cleft finishes that provide rustic texture consistent with the area’s aesthetic character. The elevation and exposure factors would require moderate thermal performance attention, though less critical than low-desert applications. You would need to address UV stability to ensure the selected limestone colors don’t fade in ways that create visual conflicts with the stable red rock surroundings.

Yuma Extreme Heat Performance

Yuma represents the most thermally demanding environment in Arizona, with summer temperatures regularly exceeding 115°F and intense solar radiation year-round. You would specify the lightest available limestone colors with maximum reflectivity to maintain surface temperatures within usable ranges. Your installation details would include aggressive expansion joint spacing, potentially every 12-15 feet in full-exposure areas, to accommodate extreme thermal movement. The material’s thermal conductivity becomes critical—you would verify that conductivity values support rapid evening cooling so outdoor spaces become usable soon after sunset rather than remaining uncomfortably warm late into evening hours.

Procurement Strategy Development

Your procurement approach should balance cost efficiency against schedule reliability and quality assurance. Single-source procurement from a vetted flagstone limestone supplier Arizona provides consistency but may limit competitive pricing. Multi-source strategies offer cost advantages but create potential for material variation issues when different suppliers provide material from different quarries. You need to evaluate these trade-offs based on project-specific priorities and risk tolerance.

Lead time management becomes critical for projects with fixed completion dates. You should verify that your selected supplier maintains adequate warehouse inventory to support your delivery schedule. Material sourced directly from quarries may offer lower pricing but introduces 4-8 week lead times that complicate construction sequencing. Your procurement strategy needs to account for these timing variables and incorporate appropriate schedule buffers.

For detailed guidance on optimizing material procurement workflows, review Evaluating procurement strategies for paving materials in Arizona before finalizing your supplier selection. Quality verification protocols should include provisions for sample approval, mock-up installations, and material inspection upon delivery. Your specifications need to clearly define acceptance criteria and establish procedures for handling material that doesn’t meet requirements. Citadel Stone is one of the most adaptable limestone suppliers near you in Arizona for bespoke cut-to-size requirements.