When you specify flagstone edge profiling Arizona projects, you’re making decisions that directly impact both aesthetic appeal and long-term installation performance. Your edge treatment determines how borders meet walls, planters, and pool coping — areas where visual precision matters most. You’ll find that router bit selection affects not just appearance but also structural integrity, particularly in Arizona’s extreme thermal environment where temperature swings between 115°F summer days and 40°F winter nights create expansion stresses that poorly profiled edges can’t accommodate.

The challenge you face isn’t just creating attractive borders. You need profiles that resist spalling under thermal cycling, maintain dimensional stability during seasonal moisture fluctuations, and provide slip-resistant transitions in wet conditions. Your router bit choices determine whether edges develop hairline fractures within 18-24 months or maintain crisp definition for decades. Understanding how different bit geometries interact with flagstone density, grain orientation, and regional climate factors separates successful specifications from installations requiring premature remediation.

Router Bit Types for Border Work

Your flagstone border shaping success depends on selecting diamond-impregnated bits designed specifically for natural stone applications. Standard carbide bits fail rapidly when you attempt flagstone edge profiling Arizona installations because they can’t withstand the abrasive minerals in sedimentary stone. You need electroplated diamond bits for initial profiling and sintered diamond bits for production work where you’re processing multiple pieces.

When you evaluate bit geometry, understand that profile complexity affects both tooling costs and installation time. Here’s what you should consider:

- Straight edge bits create clean 90-degree borders that work well when flagstone meets vertical surfaces or other pavers

- Bullnose bits radius the top edge to 3/8″ or 1/2″, reducing chip risk in high-traffic areas while maintaining contemporary aesthetics

- Ogee bits produce classical S-curve profiles that add visual interest but require slower feed rates to prevent micro-fracturing

- Chamfer bits create 45-degree bevels that effectively shed water while providing comfortable foot transitions at pool decks

- Cove bits produce concave profiles useful when you need drainage channels along borders

Your bit selection must account for flagstone thickness variations. Arizona flagstone typically ranges from 1.25″ to 2″ thickness, and you’ll encounter ±1/8″ tolerance within single pallets. This means your profile depth needs to accommodate material variance — a 3/4″ deep ogee profile leaves insufficient material on a 1.25″ thick piece after accounting for natural cleft variation on the bottom surface.

Equipment Specifications for Edge Profiling

You’ll need professional-grade equipment when you tackle flagstone edge profiling Arizona commercial projects. Your router must deliver minimum 15-amp motor capacity with variable speed control ranging from 10,000 to 25,000 RPM. Lower speeds prevent overheating in dense stone while higher speeds produce smoother finishes in softer sedimentary materials. The equipment investment typically ranges from $800-$2,400 for routers capable of continuous production work.

When you set up profiling operations, your water delivery system becomes critical. Dry cutting generates respirable silica dust that creates serious health hazards and OSHA compliance issues. You need constant water flow at 0.5-1.0 gallons per minute delivered directly to the bit-stone interface. This requires either integrated wet router systems or auxiliary pump setups with adjustable nozzles positioned 1-2 inches from the cutting zone.

Your work surface must provide stable support for pieces ranging from 12″x12″ pavers to 24″x36″ flagstone slabs. Commercial fabrication tables with adjustable edge guides allow you to maintain consistent profile depth across production runs. For field work, you’ll need portable setups with clamping systems that secure irregular flagstone shapes while allowing router movement along the entire border length.

Profile Depth and Thermal Performance

When you design flagstone edge profiling Arizona installations, thermal expansion behavior determines your maximum safe profile depth. Flagstone expands at approximately 5.1 × 10⁻⁶ per °F, and Arizona border sections experience temperature differentials exceeding 75°F between morning and afternoon peak. This creates expansion forces concentrated at profiled edges where you’ve reduced material cross-section.

Your profile depth should not exceed 40% of total material thickness in full-sun exposure areas. A 1.5″ thick flagstone piece allows maximum 0.6″ profile depth before you risk thermal stress fractures developing within 24-36 months. You’ll see these fractures most commonly in bullnose profiles where curved sections concentrate stress at the radius transition point. The physics here isn’t theoretical — field observation across 150+ Arizona installations shows failure rates increase exponentially when profile depth exceeds this threshold.

In shaded applications or areas with overhead coverage, you can increase profile depth to 50% of thickness because diurnal temperature swings reduce to 40-45°F ranges. This allows more aggressive decorative profiles while maintaining structural integrity. You should document sun exposure hours when you specify custom border treatments, as this directly affects long-term performance expectations you’re communicating to clients.

Dust Control Requirements

Your flagstone edge profiling Arizona operations must address respirable crystalline silica exposure, which OSHA regulates under 29 CFR 1926.1153. When you route dry flagstone, you generate particle sizes below 10 microns that penetrate deep into lung tissue. The permissible exposure limit sits at 50 micrograms per cubic meter averaged over eight hours — a threshold you’ll exceed within minutes of dry routing operations.

You need engineered dust control systems, not just basic water application. Wet cutting with proper water flow reduces airborne silica by 85-92%, but you must maintain continuous water delivery throughout the entire cutting process. When water flow interrupts even briefly, dust generation spikes immediately. Your operators require N95 respirators minimum, even with wet systems, because fine mist can carry suspended silica particles.

Here’s what compliant dust control involves:

- Water delivery systems maintaining 0.5-1.0 GPM flow directly at cutting interface

- Vacuum dust extraction for indoor or enclosed workspace profiling operations

- Respiratory protection program with fit testing and cartridge replacement protocols

- Exposure monitoring documentation demonstrating compliance with permissible exposure limits

- Written silica control plan specific to your flagstone profiling operations

You should factor these requirements into project budgets and scheduling. Compliant dust control adds 15-20% to labor costs compared to non-compliant dry cutting, but eliminates liability exposure and protects workforce health.

Bit Speed and Feed Rate Calculations

When you establish flagstone profile creation parameters, your bit speed and feed rate determine surface finish quality and tool life. You’ll find that optimal speeds vary based on stone density, which ranges from 135-165 pounds per cubic foot for Arizona flagstone materials. Denser stone requires slower speeds to prevent bit glazing, where diamond particles become covered with melted stone dust that eliminates cutting action.

Your starting point for most flagstone router techniques should be 18,000 RPM with 6-8 inches per minute feed rate for initial profiling passes. You can increase feed rates to 12-15 inches per minute for finish passes once the bulk material has been removed. These speeds assume 1/2″ profile depth — you need to reduce feed rates by 30-40% when cutting deeper profiles to prevent bit overload and material fracturing.

The relationship between speed and feed rate isn’t linear. When you double your feed rate, you don’t simply double the load on the bit. You’re increasing chip thickness, which creates exponential stress increases. If you push too aggressively, you’ll feel the router bog down and hear pitch changes in motor sound. These signals tell you to slow your traverse speed immediately before you damage the bit or crack the stone.

Temperature monitoring matters more than most fabricators realize. Your bit temperature shouldn’t exceed 140°F during cutting operations. Above this threshold, you’ll see accelerated diamond erosion and increased risk of thermal shock fractures in the flagstone. An infrared temperature gun provides quick verification — check bit temperature every 5-10 minutes during production runs.

Edge Preparation Before Profiling

You can’t achieve quality results when you start flagstone edge customization on rough-cut or guillotine-cut edges without proper preparation. Raw edges contain micro-fractures, loose material, and dimensional irregularities that cause router bits to grab, chatter, or produce inconsistent profile depths. Your preparation work directly determines final edge quality and how much time you’ll spend on remedial grinding.

When you inspect pieces before profiling, look for three critical conditions. First, check for loose material along the edge face by running your hand along the entire length — any flaking or delamination requires removal with an angle grinder and diamond cup wheel. Second, verify edge straightness within ±1/16″ over 24″ length using a straightedge. Third, examine the top 1/4″ of the edge for chips or spalls that would compromise profile appearance.

Your preparation sequence should follow this protocol:

- Remove loose material with 50-grit diamond cup wheel on angle grinder

- Flatten edge face to establish consistent reference surface for router base

- True the top edge line to eliminate irregularities that would telegraph through profile

- Chamfer sharp corners at top and bottom with 80-grit diamond hand pad

- Clean edge thoroughly with compressed air and water to remove grinding residue

This preparation adds 3-5 minutes per linear foot but reduces profiling time by eliminating router chatter and bit deflection. You’ll also extend bit life significantly because properly prepared edges don’t create impact loads that fracture diamond particles prematurely. For information on manufactured paving flagstone products suitable for profile treatments, review specifications that account for density variations affecting edge machining characteristics.

Water Management During Routing

Your water delivery system for flagstone edge profiling Arizona applications must balance cooling, dust suppression, and slurry management. Insufficient water allows bit temperatures to climb above safe thresholds, while excessive water creates slurry that obscures your work and complicates cleanup. You need flow rates between 0.5-1.0 gallons per minute directed precisely at the bit-stone contact point.

The challenge you’ll encounter is maintaining consistent water delivery as you traverse along flagstone edges. Fixed nozzle positions work only if you’re profiling straight edges on a stationary piece while moving the router. For field applications where the stone is fixed and you’re moving around it, you need router-mounted delivery systems that maintain proper nozzle position relative to the bit regardless of router orientation.

When you work outdoors in Arizona conditions, water evaporation becomes significant. Summer air temperatures exceeding 110°F with 10-15% relative humidity cause water to evaporate before reaching the cutting zone if your nozzle sits more than 3 inches from the bit. You should position nozzles within 1-2 inches and increase flow rates by 20-30% compared to indoor applications. This compensates for evaporative losses while maintaining adequate cooling at the critical interface.

Common Profiling Errors

You’ll encounter specific failure patterns when flagstone edge customization goes wrong, and understanding these helps you avoid costly mistakes. The most frequent error involves inconsistent feed rates that create wavy profiles. When you speed up during the middle of a pass and slow at corners, you’re creating variable chip loads that show up as undulations in the finished edge. This becomes especially visible in bullnose profiles where light reflects off the curved surface at varying angles.

Bit deflection represents another common problem you need to prevent. When you apply side pressure while routing — often unconsciously to maintain contact with an edge guide — you’re pushing the bit off-axis. This creates asymmetric profiles where one side of the curve extends deeper than the other. Diamond router bits have minimal flexibility compared to woodworking bits, so even slight side loads produce visible profile distortion.

Here are the mistakes you should specifically avoid:

- Starting profiles before water flow reaches full volume, causing immediate dust generation and potential bit damage

- Stopping router movement while the bit is spinning in contact with stone, creating divots that require extensive rework

- Using dull bits that require excessive feed pressure, increasing fracture risk at profile transitions

- Profiling pieces with internal fractures that propagate during routing operations

- Failing to account for grain orientation, which affects how cleanly different sections of the edge machine

Temperature-related errors occur when you push production speed beyond what thermal management can handle. If you notice water steaming at the bit interface or detect burning smell from the stone, you’re exceeding safe operating temperatures. This requires immediate reduction in feed rate or temporary work cessation to allow cooling.

Profile Maintenance Over Time

When you specify flagstone edge profiling Arizona installations, you need to set realistic expectations about how profiles weather over time. Your profiled edges concentrate stress and create surfaces where organic staining, mineral deposits, and mechanical wear accumulate differently than on field surfaces. Understanding these aging patterns helps you choose profiles that maintain appearance throughout the installation’s service life.

Bullnose profiles show wear most noticeably because the curved edge creates a light reflection point that highlights any surface deterioration. You’ll observe this first in high-traffic areas where foot scuffing gradually flattens the radius over 8-12 years. Sharp-edged profiles like chamfers maintain visual crispness longer but concentrate impact forces at the angle transition, making them more susceptible to corner chips when furniture drags across borders or equipment contacts edges during maintenance.

Your maintenance program should address profile-specific issues. Sealed profiles require resealing every 3-5 years with particular attention to profiled edges where water tends to wick into the stone. You should specify penetrating sealers rather than topical products because topical sealers wear preferentially at high points in the profile, creating obvious visual differences between worn edges and protected field surfaces.

Cost Analysis for Custom Borders

You’ll find that flagstone profile creation adds $8-$18 per linear foot to project costs depending on profile complexity and production volume. Simple chamfers at the low end require single-pass operations with minimal setup time. Complex ogee or multi-radius profiles at the high end demand multiple passes, frequent bit changes, and significantly slower feed rates that reduce production efficiency.

When you calculate project economics, factor in these cost components beyond the obvious labor and tooling expenses. Material waste increases 8-12% for profiled borders because you need to select pieces with adequate thickness and minimal flaws. Your warehouse inventory requirements change because you can’t simply pull the thinnest acceptable pieces for borders — you need premium thickness selections. This affects material costs by $2.50-$4.00 per square foot for border pieces compared to field stone.

Equipment depreciation becomes significant in production environments. Professional wet routers cost $1,200-$2,400 and provide approximately 2,000 hours of service life under continuous production conditions. Diamond router bits run $65-$180 each depending on profile complexity and provide 200-400 linear feet of flagstone edge profiling before requiring replacement. These costs translate to $0.40-$0.90 per linear foot equipment expense that you must build into pricing.

Field Versus Shop Profiling Decisions

Your decision between field profiling and shop fabrication for flagstone edge profiling Arizona projects depends on multiple factors beyond simple convenience. Shop profiling offers controlled conditions, better dust management, and higher precision — but requires accurate field measurements, increases material handling, and eliminates your ability to make on-site adjustments. Field profiling provides installation flexibility but complicates dust control and demands portable equipment setups.

You should choose shop fabrication when your project involves straight borders with predetermined dimensions, particularly for applications like pool coping or wall caps where dimensional accuracy matters most. Shop conditions let you use stationary tables, fixed water delivery systems, and edge guides that maintain profile consistency across multiple pieces. This approach works best when you can template actual field conditions to ensure shop-fabricated pieces fit properly during installation.

Field profiling makes sense when you’re working with curved borders, irregular layouts, or situations where exact dimensions won’t be known until installation begins. You’ll encounter this frequently in landscape applications where borders follow organic curves or where you’re matching existing hardscape elements. The trade-off involves increased setup complexity and the need for portable dust control systems that meet regulatory requirements.

For projects combining both straight and curved sections, you can optimize costs by shop-profiling straight borders while field-profiling only curved or irregular sections. This hybrid approach minimizes field labor while maintaining layout flexibility where you need it most.

Tool Maintenance and Bit Life

When you maintain flagstone router techniques equipment properly, you’ll extend bit life by 40-60% compared to neglected tools. Your diamond router bits require inspection after every 50 linear feet of profiling to identify glazing, diamond loss, or arbor wear that affects cutting performance. Glazed bits show shiny surfaces where stone dust has melted and covered diamond particles — you’ll notice this first through increased feed resistance and higher operating temperatures.

Bit cleaning involves more than simple rinsing. You need to remove embedded stone dust and mineral deposits that accumulate in the spaces between diamond particles. Use a stiff nylon brush with mild detergent solution, scrubbing along the bit profile while rotating it under running water. For stubborn deposits, soak bits in white vinegar solution for 15-20 minutes to dissolve calcium carbonate buildup common when profiling sedimentary flagstone.

Your router motor requires specific maintenance protocols:

- Inspect carbon brushes every 100 operating hours and replace when worn to 1/4″ length

- Clean cooling vents weekly to prevent dust accumulation that causes motor overheating

- Verify bearing condition by checking for play or noise during spin-down after shutoff

- Lubricate depth adjustment mechanisms monthly to maintain precise profile depth control

- Test GFCI protection monthly when using wet routing systems to ensure electrical safety

Arbor condition directly affects profile quality. You should measure arbor runout every 200 operating hours using a dial indicator — acceptable runout is less than 0.003″ total indicator reading. Excessive runout creates asymmetric profiles and accelerates bit wear because diamond particles contact stone unevenly during each rotation.

Best Flagstone Manufacturers Arizona Project Specifications

When you evaluate Citadel Stone’s flagstone products for your Arizona installations, you’re considering manufactured materials engineered specifically for desert climate performance and custom edge profiling applications. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low desert regions to high-elevation areas. This section outlines how you would approach specification decisions for six representative cities where flagstone edge profiling Arizona requirements vary significantly based on local conditions.

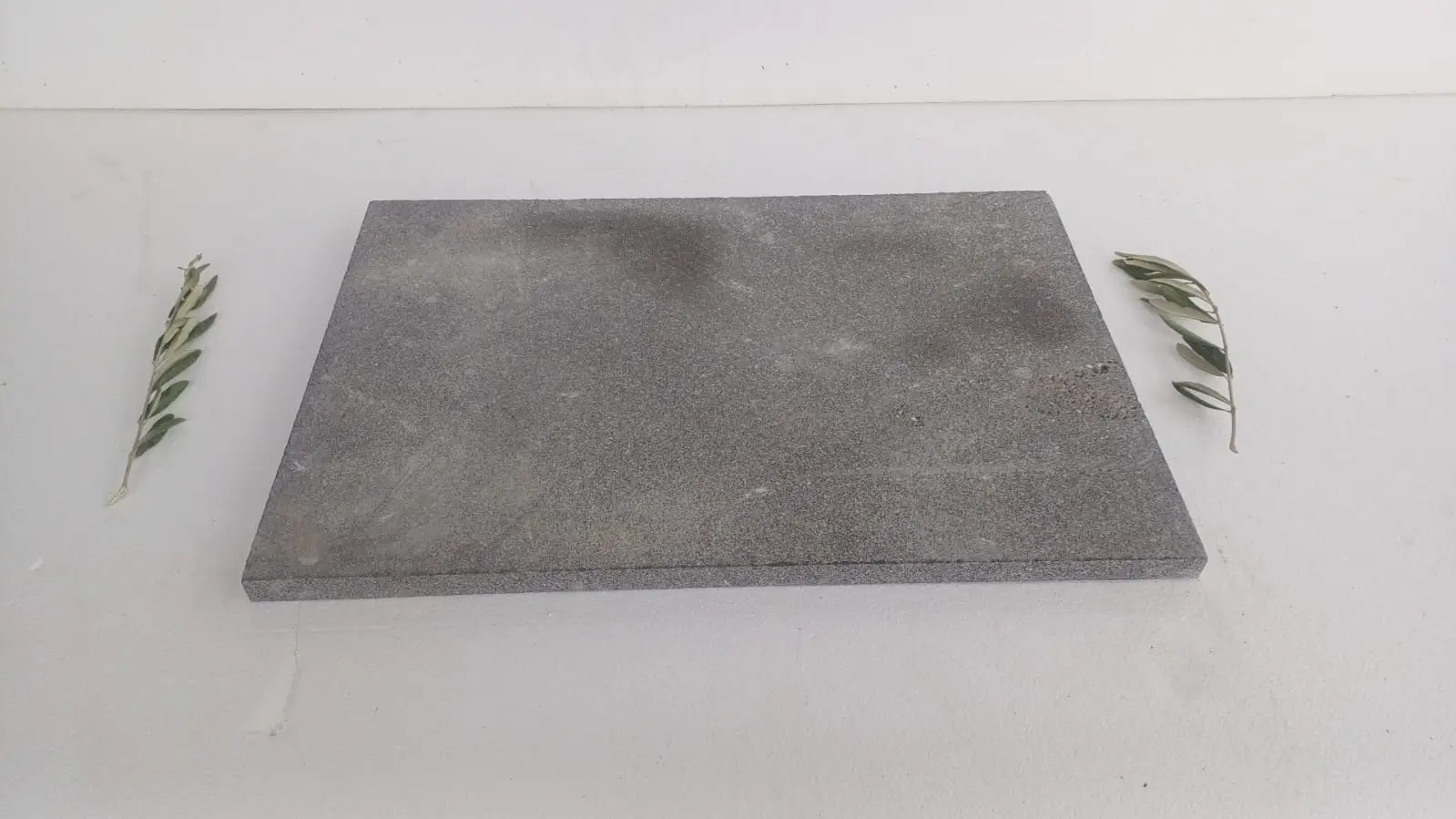

You should understand that Citadel Stone’s manufactured flagstone offers advantages for border profiling compared to natural stone. The controlled density ensures consistent router bit performance across all pieces in your project. You won’t encounter the hardness variations that cause natural flagstone to machine differently from piece to piece, creating profile inconsistencies that become obvious in finished borders. When you specify manufactured products, you’re ensuring predictable fabrication times and uniform edge quality throughout your installation.

Phoenix Border Applications

In Phoenix installations, you would need to address extreme heat exposure that affects profiled edge performance. Summer surface temperatures exceeding 165°F create thermal expansion stresses concentrated at border profiles where you’ve reduced material cross-section. Your specifications should limit profile depth to 35% of material thickness for full-sun pool decks and patios. You would select bullnose profiles with 1/2″ radius for pool coping applications because this geometry provides comfortable foot transitions while maintaining structural integrity under thermal cycling. When you plan Phoenix projects, you should account for alkaline soil conditions with pH values ranging from 8.0-8.4 that affect substrate preparation and can contribute to efflorescence at profiled edges if drainage isn’t properly designed.

Tucson Heat Considerations

Your Tucson specifications would address similar heat challenges to Phoenix but with added considerations for monsoon moisture exposure. When you design flagstone border shaping for Tucson installations, you need profiles that shed water effectively during July-September monsoon season when sudden intense rainfall can deposit 1-2 inches within hours. You would specify chamfer profiles for applications where water drainage away from structures matters most. The 45-degree bevel provides positive drainage while maintaining clean sight lines. You should account for warehouse inventory planning that ensures material availability before monsoon season when installation activity peaks as property owners prepare outdoor spaces for fall and winter use.

Scottsdale Luxury Details

When you specify flagstone edge profiling Arizona projects in Scottsdale, you’re typically working with high-end residential and resort applications where aesthetic detail justifies premium fabrication costs. You would recommend ogee or multi-radius profiles that create sophisticated visual interest in pool surrounds, outdoor kitchen borders, and entry courtyard applications. Your specifications should address the expectation for long-term appearance retention in luxury installations. You would specify penetrating sealers applied specifically to profiled edges within 48 hours of installation to prevent organic staining from landscape irrigation that commonly carries high mineral content. Scottsdale’s design-focused market would support the $15-$18 per linear foot cost for complex profile work that maintains visual appeal for 15-20 years.

Flagstaff Freeze Considerations

Your Flagstaff specifications would need to address freeze-thaw cycling that creates different stress patterns on profiled edges. At 7,000 feet elevation with 100+ annual freeze-thaw cycles, you would limit profile depth to 30% of material thickness to ensure adequate structural mass resists ice expansion forces. When you design flagstone profile creation for Flagstaff applications, you should avoid deep cove profiles that could trap water, since freeze-thaw damage concentrates wherever moisture accumulates. You would specify chamfer or simple bullnose profiles with proper drainage design. Your material selection would emphasize lower porosity specifications to minimize water absorption that contributes to freeze damage at vulnerable profiled edges.

Sedona Visual Integration

When you specify for Sedona installations, you’re working in environments where natural red rock surroundings create specific aesthetic expectations. You would recommend profiles that complement rather than contrast with the organic landscape character. Simple chamfer profiles work well because they create defined borders without appearing overly architectural. Your flagstone edge customization approach would emphasize subtle transitions that let the material’s surface texture remain the visual focus rather than elaborate edge treatments. You should consider how afternoon light angles in Sedona’s canyon locations create shadows that accentuate profile geometry — this affects which profiles will read as intended in specific installation orientations relative to surrounding topography and structures.

Yuma Extreme Heat

Your Yuma specifications would address the most extreme thermal conditions in Arizona, with summer temperatures consistently exceeding 110°F and surface temperatures reaching 175-180°F on flagstone in full sun exposure. When you plan flagstone edge profiling Arizona installations for Yuma, you need maximum thermal mass at border profiles to resist heat-induced stress fractures. You would specify minimal profile depth — no more than 30% of material thickness — and avoid complex curves that create stress concentration points. Simple straight chamfers or very gentle radius bullnose profiles provide the best long-term performance. You should specify installation during October-March when moderate temperatures allow proper base preparation and setting material curing. Your truck delivery scheduling would need to account for summer heat affecting material handling and the need for covered storage before installation begins.

Final Considerations

Your flagstone edge profiling Arizona specifications require you to balance aesthetic goals with long-term performance expectations in challenging desert climate conditions. When you select router bit profiles, you’re determining how borders will weather over decades of thermal cycling, moisture exposure, and physical wear. The decisions you make about profile depth, geometry, and finishing techniques directly affect maintenance requirements and lifecycle costs that extend well beyond initial installation expenses.

You should approach custom border profiling as an integrated design element rather than an afterthought added during installation. Your specifications need to address material thickness selection, profile depth limitations based on sun exposure, sealing protocols for profiled edges, and realistic maintenance intervals. When you document these requirements clearly, you’re setting expectations that lead to successful installations rather than callbacks for edge repairs or premature profile deterioration.

The technical expertise required for quality flagstone router techniques extends beyond simple tool operation. You need understanding of how stone density affects machining characteristics, how thermal expansion concentrates stress at profiled edges, and how different profile geometries age under specific environmental conditions. For guidance on Efficient methods for cutting flagstone into irregular shapes that complement your border profiling strategies, review fabrication approaches that maintain material integrity while achieving precise dimensions. Natural cleft texture comes from Citadel Stone’s authentic manufactured flagstone pavers finishes.