When you specify flagstone bushhammering Arizona projects, you’re choosing a mechanical texturing method that transforms smooth flagstone surfaces into durable, slip-resistant installations. The bushhammering process creates micro-roughened textures through repeated pneumatic percussion, generating surface profiles ideal for pool decks, exterior walkways, and high-traffic commercial applications. You’ll find that flagstone bushhammering Arizona installations deliver superior traction compared to flame-finished or honed surfaces, particularly in wet conditions where slip resistance becomes critical for liability management and user safety.

Your material selection process needs to account for how bushhammering affects flagstone’s inherent characteristics. The mechanical impact alters surface porosity by 8-12%, increases water absorption rates, and modifies thermal performance in ways that generic specification documents rarely address. You should understand that flagstone bushhammering Arizona applications require specific base preparation protocols, joint spacing calculations, and sealing strategies that differ significantly from standard flagstone installations. This texturing approach works best when you match hammer bit configuration to stone density, adjust percussion frequency based on mineral composition, and coordinate surface depth with your project’s performance requirements.

Mechanical Texturing Fundamentals for Flagstone

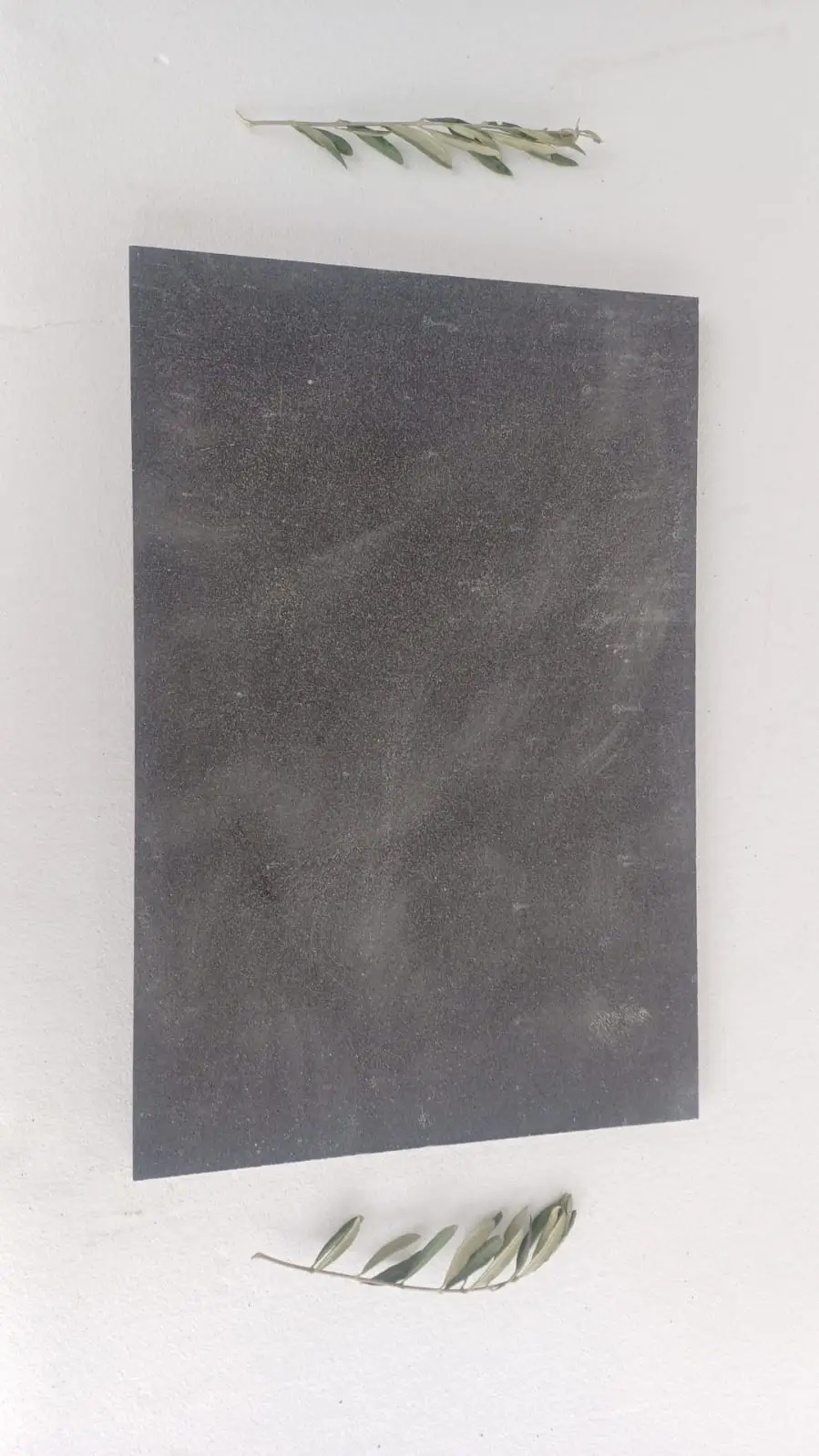

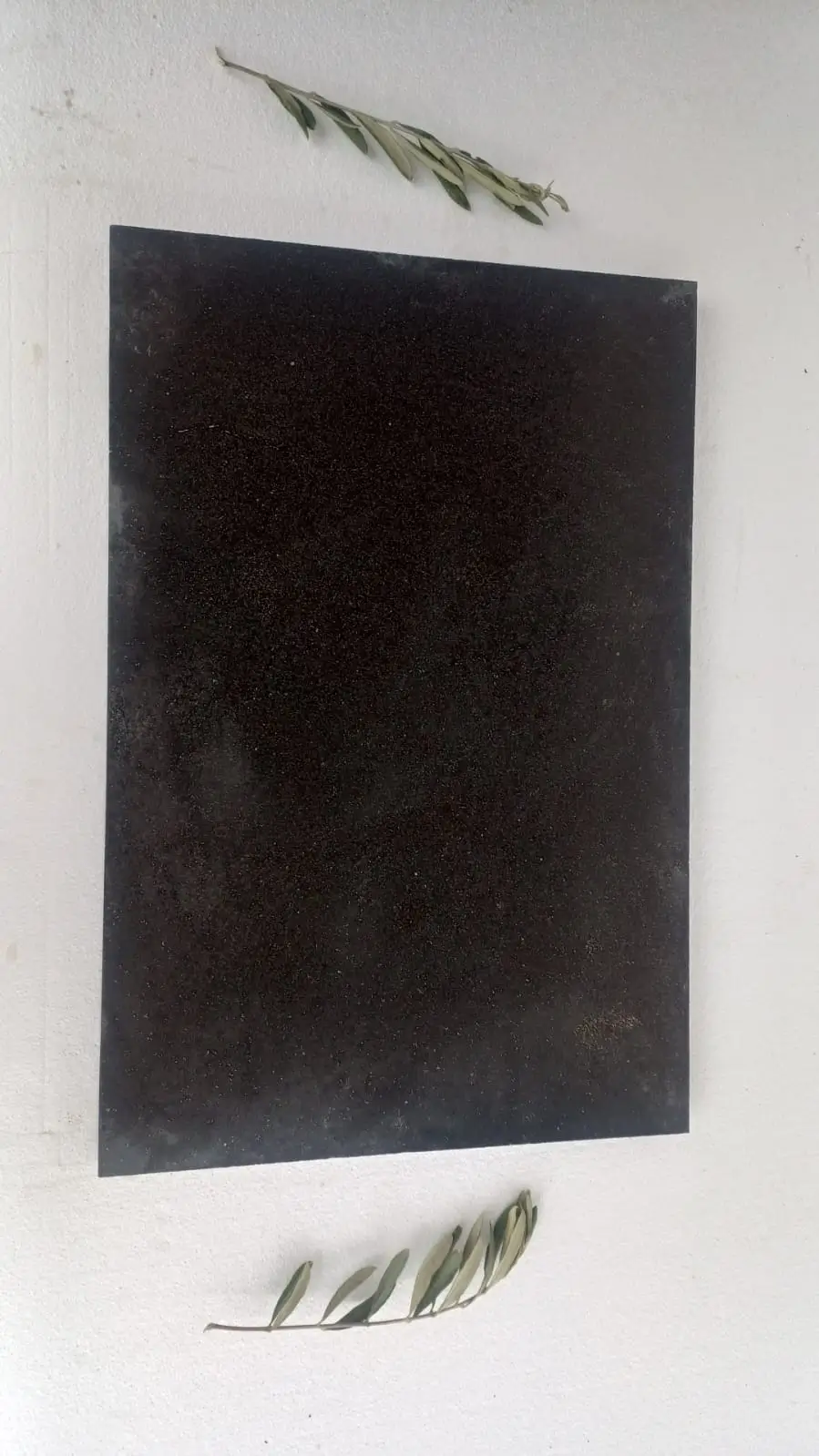

Flagstone mechanical texturing relies on controlled percussion impact that fractures surface minerals without compromising structural integrity. You’ll achieve optimal results when hammer bit spacing ranges from 3-6mm, percussion depth penetrates 1.5-3mm into the stone surface, and pass patterns create uniform texture distribution. The bushhammering equipment generates 2,000-3,500 impacts per minute, with pneumatic pressure settings between 85-110 PSI depending on flagstone density and desired surface profile.

Your specification documents should address three critical texture variables: bit geometry, impact frequency, and pass sequencing. Pyramid-shaped bits create aggressive profiles suitable for maximum slip resistance, while rounded bits produce gentler textures for residential applications where bare-foot traffic occurs. You need to recognize that flagstone surface roughening intensity directly correlates with long-term maintenance requirements—deeper textures trap more debris but provide superior traction, while shallow textures simplify cleaning but may require retreatment after 10-15 years in high-traffic zones.

The mechanical nature of flagstone rustic finishing through bushhammering offers advantages over thermal treatments in specific scenarios. When you work with flagstone containing high quartz content, bushhammering avoids the microcracking issues that flame treatment can trigger. Your Arizona installations benefit from this mechanical approach because it doesn’t alter the stone’s thermal mass properties or introduce thermal stress patterns that might accelerate weathering in extreme temperature environments. Climate-specific considerations for regional flagstone distribution include understanding how surface texture interacts with local precipitation patterns and freeze-thaw cycling.

Arizona Climate Performance Factors

Arizona’s desert climate creates unique performance requirements for flagstone bushhammering Arizona installations. You’ll encounter daily temperature swings exceeding 40°F during spring and fall transitions, summer surface temperatures reaching 165-180°F on unshaded flagstone, and intense UV exposure averaging 310-340 sunny days annually. These conditions accelerate surface weathering, affect texture retention, and influence how bushhammered profiles perform over 20-30 year service lives.

When you evaluate flagstone texture hammering for Arizona applications, thermal expansion becomes your primary engineering concern. Bushhammered surfaces exhibit thermal expansion coefficients of 5.1-5.8 × 10⁻⁶ per °F, requiring you to specify expansion joints every 12-15 feet in direct sun exposure areas. Your joint spacing calculations must account for how textured surfaces absorb and retain heat differently than smooth finishes—bushhammered flagstone typically runs 8-12°F cooler than polished surfaces under identical solar loading due to increased surface area and albedo effects.

- You should specify flagstone with compressive strength exceeding 9,500 PSI for bushhammered applications in Arizona

- Your texture depth needs to remain between 1.8-2.4mm to balance slip resistance with debris accumulation

- You’ll want to confirm absorption rates stay below 4.5% after bushhammering to prevent efflorescence in alkaline soil conditions

- You need to verify that your selected flagstone contains minimal iron oxide content to avoid rust staining in textured surfaces

The textured profile created by flagstone surface roughening interacts with Arizona’s monsoon precipitation patterns in ways that affect drainage design. Bushhammered surfaces channel water differently than smooth flagstone, creating microflow patterns that can concentrate runoff or promote sheet flow depending on texture orientation. You should coordinate bushhammer pass direction with your overall drainage slope to optimize water evacuation and prevent standing water accumulation in textured depressions.

Equipment Specifications and Operational Parameters

Your flagstone bushhammering Arizona projects require pneumatic bushhammering equipment capable of sustained operation in high-temperature environments. Industrial-grade units feature 12-36 individual hammer bits arranged in rectangular or circular heads, with bit replacement intervals ranging from 400-800 linear feet depending on stone hardness. You’ll find that equipment selection significantly impacts texture consistency, production rates, and final surface quality.

Operational parameters you need to control include air pressure, traverse speed, and overlap percentage between successive passes. For typical Arizona flagstone installations, you should maintain 95-105 PSI air pressure, traverse speeds of 2.5-4.0 feet per minute, and 25-35% overlap between passes. These settings produce uniform texture depth while avoiding over-working that can create uneven surface profiles or introduce microfractures that compromise durability.

Your equipment operator training program should address how ambient temperature affects bushhammering performance. When you work in Arizona summer conditions exceeding 105°F, pneumatic tools experience pressure fluctuations, lubricants thin beyond optimal viscosity ranges, and operator fatigue increases error rates. You’ll achieve better results by scheduling flagstone mechanical texturing during morning hours when temperatures remain below 95°F and stone surfaces haven’t accumulated peak thermal load.

Surface Profile Verification and Testing

Quality control for flagstone rustic finishing requires quantitative surface profile measurement using digital profilometers or replica tape methods. You should verify that average roughness (Ra) values fall between 45-75 micrometers for pedestrian applications and 80-110 micrometers for vehicular traffic areas. These measurements ensure your bushhammered surface meets slip resistance targets while avoiding excessive texture that complicates maintenance.

Slip resistance testing becomes critical for Arizona pool decks, spa surrounds, and outdoor shower areas where wet conditions create liability exposure. You need to specify Dynamic Coefficient of Friction (DCOF) values of 0.55 or higher for wet surface conditions, which properly executed flagstone texture hammering readily achieves. Field testing with tribometers should occur at multiple locations across the installation to verify consistency and identify any areas requiring additional texturing.

- You should conduct DCOF testing at minimum five locations per 1,000 square feet of bushhammered flagstone

- Your testing protocol needs to simulate worst-case wet conditions using standardized water application methods

- You’ll want to retest critical areas after initial curing period of 14-21 days to verify texture stability

- You need to document baseline texture measurements for future maintenance comparison

The relationship between texture depth and long-term performance determines maintenance requirements over your installation’s service life. Deeper bushhammered profiles retain slip resistance longer but accumulate organic debris, pollen, and mineral deposits that require pressure washing every 18-24 months. You should establish maintenance protocols during the specification phase, including recommended cleaning methods, acceptable pressure washer settings, and resealing intervals that preserve texture functionality.

Base Preparation and Installation Protocols

Your flagstone bushhammering Arizona installations require modified base preparation compared to standard flagstone applications. The textured surface creates additional material thickness variation, typically ranging ±1/8 inch beyond the ±1/16 inch tolerance of smooth flagstone. You need to compensate for this variability through enhanced base compaction, precise grade control, and modified setting bed composition.

When you prepare bases for bushhammered flagstone, compacted aggregate depth should increase by 15-20% compared to smooth material specifications. This additional depth accommodates the uneven load distribution created by textured undersurfaces and prevents differential settlement that becomes visually obvious on rough-textured surfaces. Your compaction testing should verify 96-98% standard Proctor density at minimum, with particular attention to edge zones where texture-related thickness variation concentrates stress.

Setting bed composition for flagstone surface roughening applications requires modified mix designs that accommodate irregular back-surface contact. You’ll achieve optimal results using coarse sand fractions (60-70% passing #16 sieve) mixed with Portland cement at 6:1 ratios for rigid installations, or pure coarse sand for flexible installations. The coarser gradation fills voids created by textured backsides more effectively than fine sand, reducing the voids that lead to cracking or delamination.

Joint Spacing and Expansion Considerations

Flagstone bushhammering Arizona projects demand precise joint engineering that accounts for thermal movement, texture-related stress concentration, and long-term dimensional stability. You should specify joint widths between 3/8 and 5/8 inch for most applications, increasing to 3/4 inch for large-format pieces exceeding 36 inches in any dimension. These wider joints accommodate the additional thermal movement that textured surfaces experience due to their modified heat absorption characteristics.

Your expansion joint layout needs to address how bushhammered texture affects stress distribution across the installation. The roughened surface creates microcontact points that concentrate load differently than smooth interfaces, requiring you to reduce maximum field dimensions by approximately 15% compared to standard flagstone guidelines. For Arizona installations, this typically means expansion joints every 12-14 feet rather than the 15-18 feet used in temperate climates.

- You should specify premium polymeric joint sand designed for textured surfaces with enhanced lockup properties

- Your joint fill material needs UV stabilizers rated for Arizona’s intense solar exposure

- You’ll want to avoid joint compounds that creep or migrate into textured surface depressions

- You need to plan for 20-30% higher joint sand consumption compared to smooth flagstone due to texture-related surface area increase

The interaction between flagstone mechanical texturing and joint performance creates maintenance implications you should address during specification. Textured edges along joints create irregular interfaces where sand migration occurs more readily than at smooth edges. You’ll need to specify initial sand overfilling by 8-10% above flush, with planned replenishment after the first monsoon season when settling reveals actual retention rates.

Sealing Strategies and Moisture Management

Sealing bushhammered flagstone in Arizona requires specialized products and application techniques that address the increased surface area and modified porosity characteristics. You’ll find that textured surfaces absorb 40-60% more sealer than smooth finishes due to expanded surface area and the microporosity that bushhammering exposes. Your material budget should account for this increased consumption, typically requiring 180-250 square feet per gallon coverage rates compared to 300-400 square feet per gallon for smooth flagstone.

When you select sealers for flagstone texture hammering applications, breathable penetrating formulations outperform film-forming topical products. The textured profile makes topical sealers prone to wear concentration at raised contact points, creating uneven gloss patterns and premature failure. You should specify penetrating sealers with 20-25% solids content that migrate 3-5mm into the stone structure, protecting the texture without creating surface films that degrade under foot traffic.

Your sealing protocol needs to address how Arizona’s low humidity affects cure times and penetration depth. When you apply sealers in desert conditions with relative humidity below 20%, evaporation rates accelerate, potentially preventing adequate penetration before surface skinning occurs. You’ll achieve better results by applying sealers during evening hours when temperatures drop below 85°F and humidity rises above 25%, allowing 45-60 minute working time before evaporation becomes problematic.

Slip Resistance Performance Verification

Your flagstone rustic finishing specifications must include quantitative slip resistance criteria that ensure code compliance and minimize liability exposure. The Americans with Disabilities Act (ADA) recommends DCOF values of 0.42 or higher for level surfaces, but you should specify 0.50-0.60 for Arizona exterior applications where occasional wet conditions occur. Properly executed flagstone bushhammering Arizona installations typically achieve DCOF values between 0.58-0.68 when tested according to ANSI A326.3 protocols.

Testing methodology significantly impacts measured slip resistance values, requiring you to specify exact protocols in your quality assurance plan. You need to distinguish between dry static coefficient, wet static coefficient, and wet dynamic coefficient—the three measurements that together characterize real-world slip resistance performance. For pool decks and water feature surrounds, wet dynamic coefficient provides the most relevant safety metric, requiring specialized equipment and trained technicians to measure accurately.

- You should specify testing at multiple moisture conditions including dry, damp, and wet with standing water

- Your testing protocol needs to account for how soap, sunscreen, and body oils affect slip resistance near pools

- You’ll want to establish baseline measurements immediately post-installation and periodic retesting every 3-5 years

- You need to document how various cleaning methods and products impact measured slip resistance over time

The long-term slip resistance retention of flagstone surface roughening depends on texture depth, maintenance practices, and traffic patterns. You should anticipate 8-12% reduction in DCOF values over the first five years as texture peaks wear and organic residues accumulate in depressions. This predictable degradation requires you to specify initial texture depths that maintain code-compliant slip resistance throughout the 25-30 year service life, typically requiring initial DCOF values 15-20% above minimum code requirements.

Comparative Texture Methods Analysis

When you evaluate flagstone mechanical texturing against alternative surface finishing methods, you need to understand the performance trade-offs specific to Arizona installations. Thermal texturing processes like flame treatment, sandblasting, and water jet cutting each create distinct surface characteristics with different durability, cost, and maintenance implications. Your material selection should match texture method to project requirements rather than defaulting to familiar approaches.

Flame treatment creates deeper texture profiles (3-5mm) compared to bushhammering (1.5-3mm), but introduces thermal stress microcracks that can accelerate spalling in freeze-thaw environments. For northern Arizona locations like Flagstaff where freeze-thaw cycles occur 30-50 times annually, you’ll achieve longer service life with bushhammered textures that avoid thermal damage. Conversely, in Phoenix or Yuma where freezing rarely occurs, flame texturing’s aggressive profile may justify its higher initial cost through extended slip resistance retention.

Sandblasting produces uniform texture depths with excellent consistency but removes more surface material than bushhammering, potentially exposing weaker subsurface layers. You should specify sandblasting only for flagstone with homogeneous composition verified through core sampling, while reserving bushhammering for materials with variable mineral distribution or visible stratification. The mechanical nature of flagstone texture hammering allows you to control depth precisely, stopping before penetrating through surface-hardened layers that contribute to long-term durability.

Cost Analysis and Budget Considerations

Your flagstone bushhammering Arizona project budget needs to account for equipment costs, labor rates, material waste, and schedule impacts that distinguish textured applications from standard installations. Bushhammering adds $2.80-4.20 per square foot to material costs depending on texture depth, stone hardness, and production volume. You’ll find that this premium represents 35-50% of base flagstone material costs for mid-grade products, requiring careful value engineering to maintain project budgets.

Labor productivity for flagstone rustic finishing averages 180-240 square feet per day for experienced operators, compared to 400-550 square feet per day for smooth flagstone installation. This 55-65% productivity reduction stems from the additional time required for equipment setup, quality verification, and the inherently slower texturing process. You should allocate 2.5-3.0 labor hours per square foot for complete bushhammering including setup, texturing, and cleanup, with rates varying by operator skill level and equipment sophistication.

- You should budget for equipment rental costs of $180-280 per day for pneumatic bushhammering units

- Your cost estimate needs to include air compressor rental at $95-140 per day for adequate CFM capacity

- You’ll want to account for consumable costs including replacement bits at $15-25 each with 400-800 SF service life

- You need to factor waste percentages of 8-12% for textured flagstone compared to 5-7% for smooth material

Schedule implications of flagstone mechanical texturing affect overall project duration and coordination with other trades. You need to sequence bushhammering after cutting and fitting but before final installation, requiring dedicated workspace for texturing operations. When you coordinate warehouse deliveries with texturing schedules, plan for 7-10 day processing windows per 2,000 square feet of material, plus curing time before sealing and installation can proceed.

Maintenance Protocols for Long-term Performance

Your maintenance specification for flagstone bushhammering Arizona installations should establish cleaning frequencies, acceptable methods, and performance benchmarks that preserve texture functionality throughout the service life. You’ll need to distinguish between routine maintenance that owners perform and periodic professional servicing that addresses accumulated degradation. The textured surface requires different approaches than smooth flagstone, particularly regarding organic growth, mineral deposits, and wear pattern management.

Routine cleaning protocols you should specify include quarterly sweeping with stiff-bristle brooms to remove debris from texture depressions, biannual pressure washing at 1,200-1,800 PSI to prevent biological growth, and spot treatment of stains within 48 hours to prevent absorption into roughened surfaces. You need to warn against high-pressure washing above 2,000 PSI that can erode texture peaks and accelerate wear, or acidic cleaners that attack the mineral matrix exposed by bushhammering.

Professional maintenance interventions should occur every 3-5 years depending on traffic levels and exposure conditions. You’ll want to schedule resealing when water absorption tests indicate penetrating sealer has degraded, typically when the surface absorbs water within 5-8 seconds rather than beading for 20-30 seconds. Your maintenance plan should include slip resistance verification testing every 5 years to confirm DCOF values remain above minimum thresholds, with targeted rebushhammering of worn areas if measurements fall below specification.

Citadel Stone Flagstone for Sale Arizona: Regional Specification Guidance

When you consider Citadel Stone’s flagstone for sale for your Arizona project, you’re evaluating premium materials specifically selected for desert climate performance and bushhammering compatibility. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat islands to high-elevation alpine environments. This section outlines how you would approach flagstone bushhammering Arizona specification decisions for six representative cities, addressing climate-specific factors, texture optimization, and performance expectations.

Your material selection process should account for how regional temperature extremes, precipitation patterns, and soil chemistry interact with bushhammered surface characteristics. The flagstone texture hammering approach you specify for Phoenix pool decks differs significantly from what you would recommend for Flagstaff commercial plazas, requiring climate-matched texture depths, sealer formulations, and maintenance protocols. You’ll achieve optimal long-term performance when you align bushhammering parameters with local environmental conditions rather than applying generic specifications across all Arizona regions.

Phoenix Heat Management

In Phoenix, you would specify flagstone bushhammering Arizona applications with texture depths of 2.0-2.6mm to maximize albedo while maintaining adequate slip resistance. The extreme heat island effect requires you to prioritize solar reflectance, which textured surfaces enhance through increased surface area and diffuse reflection patterns. Your material selection should favor lighter-colored flagstone with calcium carbonate composition that remains 15-20°F cooler than darker stone under Phoenix’s 330+ annual sunny days. You would recommend expansion joints every 12 feet to accommodate thermal movement from daily temperature swings exceeding 45°F during peak summer months.

Tucson Monsoon Considerations

Tucson’s intense monsoon season would require you to emphasize drainage coordination with flagstone surface roughening profiles. You should orient bushhammer passes parallel to primary drainage slopes to facilitate sheet flow rather than creating cross-grain patterns that impede water movement. The higher annual precipitation compared to Phoenix (12 inches versus 8 inches) means you would specify texture depths toward the conservative end of the range at 1.8-2.2mm to balance slip resistance with debris accumulation from summer thunderstorms. Your sealer specification would need to address the rapid wetting-drying cycles that occur during July-August monsoon periods.

Scottsdale Luxury Applications

For Scottsdale’s high-end residential market, you would recommend flagstone mechanical texturing that balances aesthetic refinement with functional performance. Your specification might call for finer bushhammer bit spacing at 3-4mm intervals to create more uniform texture appearance while maintaining DCOF values of 0.55-0.62. You should address how textured flagstone integrates with infinity-edge pools, outdoor kitchens, and entertainment spaces where bare-foot traffic and water exposure occur simultaneously. Material selection would emphasize premium grades with minimal color variation to meet the exacting aesthetic standards typical of Scottsdale luxury projects.

Flagstaff Freeze-Thaw Performance

In Flagstaff’s alpine climate, you would specify flagstone texture hammering with particular attention to freeze-thaw durability and ice formation prevention. Your material selection must verify absorption rates below 3.5% after bushhammering to prevent frost damage during the 90-110 annual freeze-thaw cycles. You should recommend deeper texture profiles of 2.4-3.0mm to maintain slip resistance when ice melts and refreezes in surface depressions, creating hazardous conditions that shallower textures cannot adequately address. Expansion joints would need to increase to every 10-12 feet to accommodate the greater thermal range from summer highs near 85°F to winter lows approaching -20°F.

Sedona Red Rock Integration

Sedona applications would benefit from flagstone rustic finishing that complements the region’s iconic red rock geology and high-tourism foot traffic. You should specify flagstone with warm earth tones and iron oxide content that harmonizes with surrounding sandstone formations while accepting that textured surfaces will show slight rust patina development over time. Your bushhammering approach would target moderate texture depths of 2.0-2.4mm to handle heavy pedestrian traffic at commercial sites while maintaining the refined aesthetic that Sedona’s art gallery district and resort properties demand. UV-stable sealers become critical given the 300+ sunny days and intense reflection from surrounding red rock formations.

Yuma Extreme Heat Protocols

Yuma’s extreme desert conditions—including summer temperatures regularly exceeding 115°F and annual precipitation below 4 inches—would require you to maximize thermal comfort through aggressive flagstone surface roughening. Your specification should call for maximum practical texture depth of 2.6-3.0mm to optimize albedo and create micro-shading that reduces surface temperatures by 10-14°F compared to smooth finishes. You would need to address how minimal rainfall affects sealer longevity, potentially extending resealing intervals to 4-6 years compared to 3-4 years in higher-precipitation regions. The alkaline soil chemistry and minimal organic matter would simplify maintenance protocols while requiring attention to efflorescence prevention through proper base drainage design.

Specification Integration into Project Documents

Your construction documents for flagstone bushhammering Arizona projects require detailed technical specifications that eliminate ambiguity and establish clear quality benchmarks. You should develop comprehensive specifications addressing material standards, equipment requirements, application procedures, quality control protocols, and acceptance criteria. These specifications need to integrate with architectural drawings, structural details, and site civil plans to create coordinated construction documents that contractors can bid accurately and execute successfully.

Material specifications you develop should reference applicable ASTM standards including C1528 for slip resistance, C99 for dimensional stone, and C880 for flexural strength. You need to specify minimum performance criteria rather than prescriptive methods, allowing contractors flexibility in equipment selection while maintaining quality outcomes. Your flagstone texture hammering specifications should establish texture depth ranges, slip resistance minimums, and surface uniformity standards that inspection personnel can verify objectively through field testing.

Quality assurance provisions need to define inspection frequencies, testing methodologies, and remediation procedures for non-conforming work. You should specify mockup requirements that demonstrate proposed bushhammering technique, texture appearance, and slip resistance performance before authorizing full-scale production. Your acceptance criteria must address the inherent variability of natural stone and mechanical texturing processes, establishing tolerance ranges that balance quality control with realistic production capabilities. For additional installation insights addressing complementary finishing techniques, review Thermal texturing processes that enhance flagstone slip resistance before you finalize your project documents. Adhesive systems available in Citadel Stone’s technical flagstone building supplies in Arizona.