When you’re planning a desert landscape renovation in Arizona, you’ll quickly discover that decomposed granite landscape stone yard Arizona options solve multiple design challenges simultaneously. You need materials that handle extreme heat, require minimal water, and maintain visual appeal through brutal summers. Decomposed granite delivers on all three fronts while offering cost advantages over traditional hardscaping materials.

Your material selection process should start with understanding what makes DG uniquely suited to Arizona conditions. The natural permeability prevents water pooling during monsoon season, and the thermal properties keep surface temperatures manageable even in 115°F heat. You’ll find that DG installations in Arizona consistently outperform alternatives when properly specified and installed.

Understanding DG Composition and Performance

Decomposed granite consists of weathered granite particles ranging from sand-sized to small gravel. When you examine quality DG material, you’ll notice a blend of particle sizes that compact together naturally. This gradation creates structural stability while maintaining the permeability your landscape needs for proper drainage.

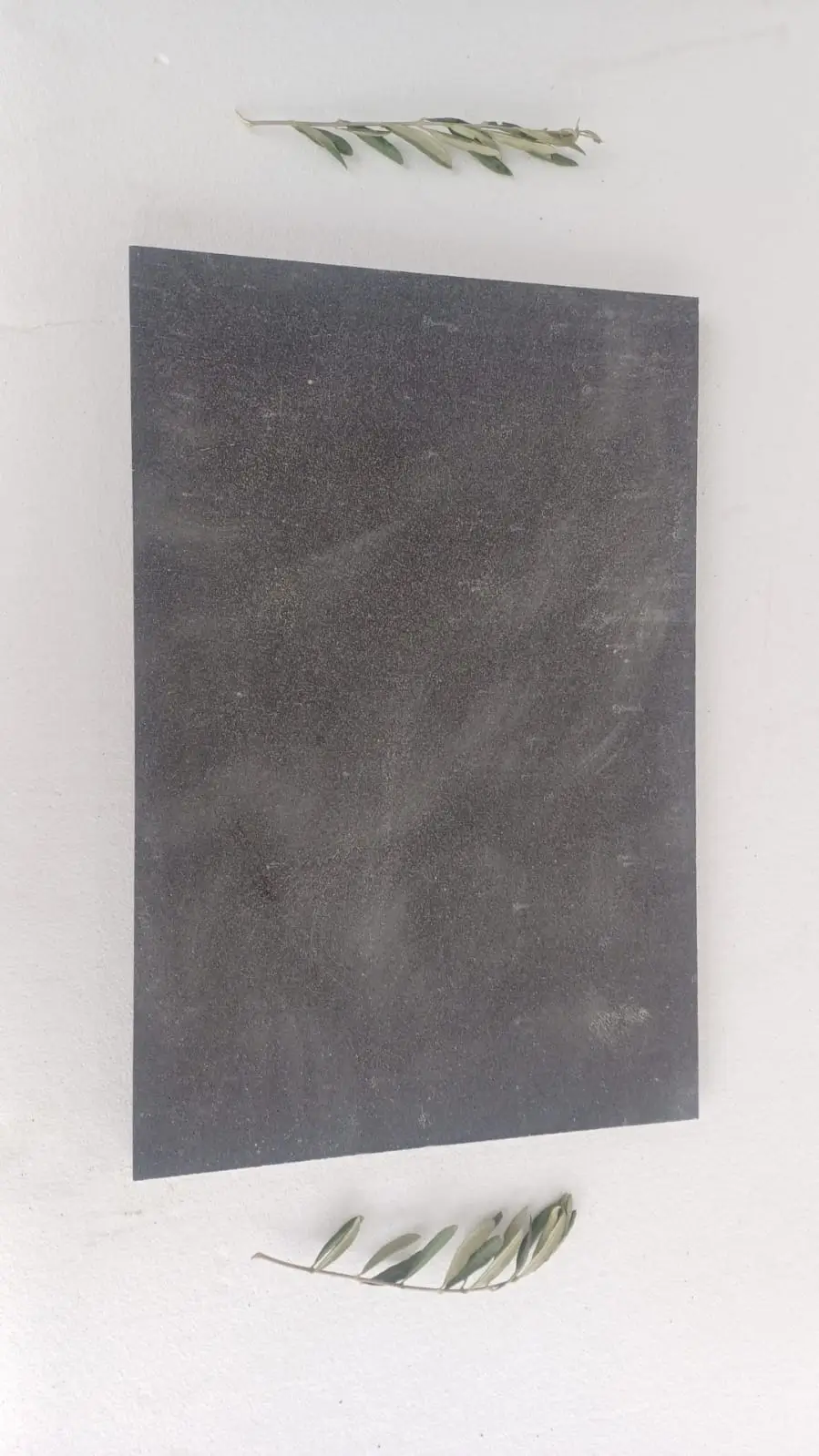

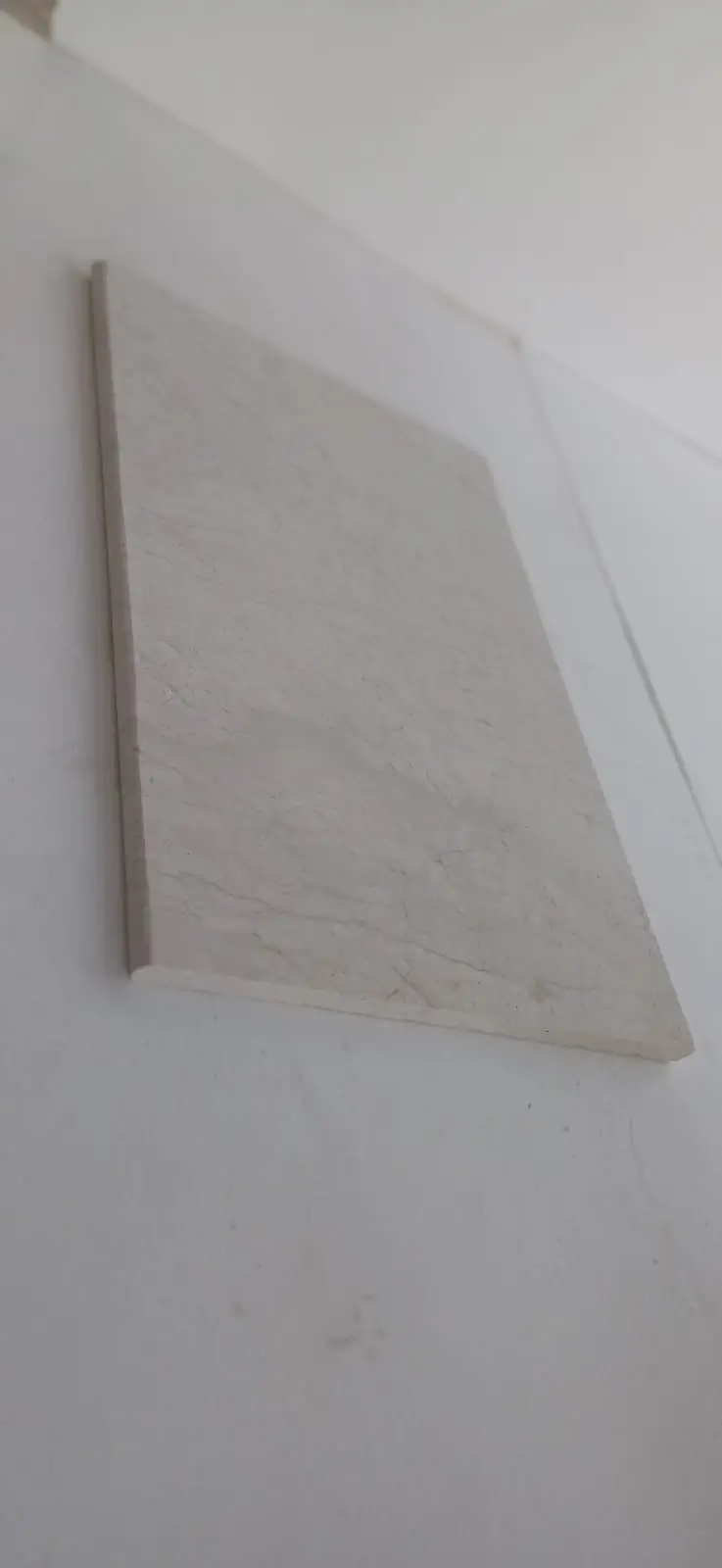

The color variations in decomposed granite landscape stone yard Arizona inventory reflect the parent granite’s mineral composition. You can specify materials ranging from warm desert gold to cooler gray tones, depending on your project’s aesthetic requirements. The fines content—particles smaller than 1/4 inch—determines how well the material compacts and holds its shape under traffic.

Your specification needs to address the ratio between fines and larger aggregates. Professional installations typically use DG with 30-40% fines content. Below 30%, you’ll see loose material that won’t compact properly. Above 40%, the material becomes too clay-like and can harden excessively, creating surface cracking issues within 18-24 months.

Particle Size Specifications for Arizona Conditions

When you evaluate Arizona landscape stone supplies DG options, particle size distribution directly affects performance longevity. The material should pass through a 3/8-inch screen with no more than 10% retained on a #4 sieve. This sizing creates the ideal balance between compaction potential and surface texture.

You’ll want to verify sieve analysis data from your supplier before committing to large quantities. The gradation curve tells you whether the material will perform as expected or create maintenance problems down the line. Materials with poor gradation separate during installation, causing fines migration and structural instability within the first year.

- You should specify maximum particle size of 3/8 inch for foot traffic areas

- Your vehicular access paths require 1/4-inch minus material for better compaction

- You need at least 60% of material passing a #8 sieve for proper binding

- You’ll achieve optimal results when clay content stays below 8%

Sourcing DG from Stone Yard Landscape Arizona Facilities

Your material procurement strategy should account for regional sourcing advantages. When you work with stone yard landscape Arizona decomposed granite suppliers, you’re accessing materials that naturally match the desert palette. Local quarrying reduces transportation costs and ensures material consistency across project phases.

The difference between quality suppliers becomes apparent in particle uniformity and contamination levels. You need clean material without organic debris, clay lumps, or excessive dust. These contaminants create installation problems and accelerate deterioration under Arizona’s intense UV exposure and thermal cycling.

Warehouse inventory management affects your project timeline more than most specifiers anticipate. You should confirm material availability for your total required volume before finalizing specifications. Quality DG can experience seasonal shortages, particularly during peak landscape season from October through April when everyone’s avoiding summer installation challenges.

Color Selection and Thermal Performance

The color you specify for landscape stone yard DG colors Arizona projects directly impacts surface temperature and user comfort. Lighter tones reflect 40-50% of solar radiation, while darker materials absorb significantly more heat. This difference translates to 15-20°F surface temperature variations during peak afternoon hours.

Your thermal comfort calculations need to account for albedo values when selecting DG colors. Desert gold and tan varieties maintain lower surface temperatures than gray or reddish materials. For pathways and high-traffic areas, you’ll want to prioritize lighter colors that won’t burn feet through shoe soles during summer months.

Color stability matters as much as initial appearance. You should understand that all DG fades somewhat under Arizona’s relentless UV exposure. Quality materials maintain their color range for 5-7 years before requiring top-dressing to refresh appearance. Cheaper materials can fade noticeably within 18 months, requiring more frequent maintenance interventions.

Installation Depth and Base Preparation

When you plan decomposed granite landscape stone yard Arizona installations, base preparation determines long-term success more than any other factor. You need a minimum 3-inch compacted base layer before placing DG. This subbase prevents settling and maintains consistent surface elevation through seasonal moisture changes.

Your base material selection should complement DG characteristics. Class 5 road base or crushed aggregate with 1.5-inch maximum size works well for most applications. You’ll compact this layer to 95% density using a plate compactor or roller, creating a stable platform that won’t shift under traffic loads.

The DG layer itself requires proper thickness based on intended use. For foot traffic areas, you should specify 3-4 inches of uncompacted DG. Vehicular applications need 5-6 inches to prevent rutting and maintain surface integrity. You’ll lose approximately 30% of thickness during compaction, so calculate your material requirements accordingly.

- You need landscape fabric between subbase and DG to prevent fines migration

- Your edge restraints must extend below DG depth to contain material effectively

- You should compact DG in 2-inch lifts for maximum density

- You’ll achieve best results with 6-8 compaction passes per lift

Edge Containment Systems

Your DG installation requires robust edge restraint to prevent material migration and maintain defined borders. Steel edging works exceptionally well in Arizona conditions, resisting thermal expansion better than plastic alternatives. You should specify minimum 3/16-inch thickness steel with stakes every 3-4 feet for straight runs and every 2 feet on curves.

When you consider minus material stone yard Arizona installations, edge detail becomes critical for long-term appearance. DG wants to spread laterally under traffic and water flow. Without proper containment, you’ll see edges eroding within months, requiring constant maintenance to restore clean lines.

The top edge of your restraint system should sit 1/2 inch above finished DG surface. This reveals a clean border line while preventing material spillover during maintenance operations. You need to verify that stakes penetrate at least 8 inches into undisturbed soil for adequate holding power in sandy Arizona soils.

Compaction Techniques and Moisture Requirements

Achieving proper compaction requires you to understand moisture’s role in DG installation. The material needs 8-10% moisture content during compaction for optimal particle binding. Too dry, and particles won’t interlock. Too wet, and you’ll create a muddy mess that won’t compact properly and takes days to cure.

Your installation crew should apply water in light passes before each compaction cycle. The material should feel slightly damp to the touch but not wet enough to leave mud on your hand. This moisture level allows fines to act as a binding agent between larger particles, creating a stable monolithic surface.

You’ll want to use a vibratory plate compactor weighing at least 200 pounds for residential applications. Commercial projects need 300-400 pound machines to achieve adequate density. The compaction pattern should overlap previous passes by 4 inches, working from edges toward center to prevent edge distortion.

Stabilization Additives and When to Use Them

When you’re working on slopes exceeding 3% grade or high-traffic applications, stabilized DG offers significant advantages. Natural DG can migrate on slopes and ruts under heavy use. Stabilizers bond particles together while maintaining permeability, creating a surface that resists erosion and displacement.

You have two primary stabilizer options: organic and synthetic. Organic stabilizers use plant-based resins that break down over 5-7 years, requiring reapplication. Synthetic acrylic binders last 10-15 years but cost more initially. Your selection should balance project budget against expected service life and maintenance commitment.

The application process requires precise moisture management. You’ll apply stabilizer at manufacturer-recommended rates, typically 5-7% by weight. After thorough mixing, you place and compact the material just like natural DG. The curing period extends 72 hours minimum, during which you need to protect the surface from traffic and water intrusion.

Drainage Considerations for Monsoon Season

Arizona’s monsoon season tests every landscape installation, and your DG specifications need to account for intense rainfall events. While DG offers excellent permeability under normal conditions, you still need to design positive drainage away from structures and through the DG surface layer.

When you plan grading, maintain minimum 2% slope for DG pathways and patios. This ensures water moves across the surface rather than ponding. For installations adjacent to buildings, you should increase slope to 3-4% for the first 10 feet to protect foundations from moisture intrusion during heavy rains.

Your subsurface drainage becomes critical in areas with clay-heavy soils common around Phoenix and Tucson. You may need to incorporate French drains or channel drains to intercept subsurface water flow. These systems prevent saturation of the DG base layer, which causes settling and surface irregularities over time.

- You should verify soil percolation rates before finalizing drainage design

- Your design must direct water toward approved discharge points

- You need to account for roof runoff volumes in adjacent DG areas

- You’ll prevent erosion by limiting concentrated flow across DG surfaces

Maintenance Requirements and Long-Term Performance

Your DG installation requires periodic maintenance to preserve appearance and functionality. You should plan for annual raking to redistribute material and break up any surface crusting. This simple maintenance extends service life significantly and maintains the desired aesthetic throughout the year.

Weed control presents an ongoing challenge in DG applications. The material’s permeability, while excellent for drainage, also allows weed seeds to germinate. You’ll need to apply pre-emergent herbicides in early spring and fall to minimize weed pressure. Hand-pulling weeds when they first appear prevents root systems from establishing and damaging surface integrity.

Material replenishment becomes necessary every 3-5 years depending on traffic levels. You’ll lose approximately 10-15% of surface material annually through wind erosion, foot traffic displacement, and breakdown of fines. Budget for top-dressing applications of 1/2 to 1 inch to maintain proper depth and appearance.

For comprehensive guidance on related applications, see Citadel Stone’s Tempe landscape yard for technical specifications across multiple material categories.

Cost Analysis and Budget Planning

When you calculate project costs for decomposed granite landscape stone yard Arizona installations, you need to account for multiple variables beyond material price per ton. Material costs typically range from $45-$75 per ton depending on color selection and delivery distance. You’ll use approximately 1.5 tons per cubic yard, so calculate your volume requirements carefully.

Installation labor represents 60-70% of total project cost for properly executed DG work. Your crew needs to excavate existing material, prepare the base, install edging, place and compact DG, and perform final grading. Professional installation averages $8-$12 per square foot for basic applications, increasing to $15-$20 for complex designs with multiple elevation changes.

You should compare DG costs against alternative hardscape materials to understand value propositions. Concrete paving runs $12-$18 per square foot installed, while natural stone can exceed $25-$35 per square foot. DG delivers 40-60% cost savings while providing excellent performance in appropriate applications.

Common Installation Mistakes to Avoid

The most frequent error you’ll encounter is insufficient base preparation. Contractors often skip proper excavation depth or use inadequate base material to save time. This creates settling problems within the first year and voids any installation warranty. You need to verify base specifications during construction observation, not after problems emerge.

Improper compaction represents another critical failure point. When installers don’t achieve adequate density, the surface remains loose and migrates under traffic. You’ll see low spots developing and edges eroding rapidly. Your specification should require density testing on larger projects to confirm compaction meets 90% minimum standard.

- You must avoid installing DG during extreme heat when moisture evaporates too quickly

- Your crew shouldn’t compact material that’s too wet or completely dry

- You need to prevent truck traffic across finished DG during construction closeout

- You should never install DG directly against wood structures without separation

Citadel Stone Landscape Stone Yard in Arizona — Specifying DG for Diverse Climates

When you evaluate Citadel Stone’s landscape stone yard in Arizona offerings for your project, you’re accessing premium decomposed granite materials engineered for extreme desert conditions. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach specification and installation considerations for six representative cities throughout the state.

Your material selection strategy needs to account for significant climate variations across Arizona. Northern high-desert locations experience freeze-thaw cycles that southern desert cities never see. You’ll need to adjust DG specifications based on elevation, average annual rainfall, and temperature extremes for each specific project location.

Phoenix Heat Specifications

In Phoenix installations, you would prioritize lighter-colored DG materials that maintain lower surface temperatures during extreme summer heat. Your specification should address thermal performance explicitly, targeting materials with albedo values above 0.45 to reduce heat island effects. You’d want to verify that the DG supplier can provide consistent color batches across the project’s total volume requirements, which becomes critical for large commercial installations. The intense UV exposure in Phoenix requires you to specify materials with proven fade resistance over 5-year performance periods.

Tucson Drainage Requirements

Tucson’s clay-heavy soils would require you to design more robust subsurface drainage systems beneath DG installations. Your base preparation specifications should include geotextile separation fabric and potentially a gravel drainage layer to prevent clay intrusion into the DG structure. You’d need to account for monsoon rainfall intensity that can exceed 2 inches per hour during peak events. The alkaline soil conditions common in Tucson require you to verify that stabilizers, if used, remain effective in high-pH environments above 8.5.

Scottsdale Aesthetic Standards

In Scottsdale’s luxury landscape market, you would specify premium-grade DG with tighter particle size distribution for superior surface finish. Your material selection should emphasize color consistency and minimal fines content to prevent tracking into adjacent hardscape areas. You’d want to incorporate stabilized DG in high-visibility areas where surface perfection matters most to discerning clients. The high-end market expectations would drive you toward materials from proven quarries with documented long-term performance in similar upscale installations throughout the region.

Flagstaff Freeze-Thaw Performance

Flagstaff’s elevation and winter conditions would require you to reconsider standard DG applications entirely. You’d need to specify stabilized DG exclusively to prevent heaving and surface degradation during freeze-thaw cycles that occur 80-100 times annually. Your edge restraint systems should account for frost depth penetration to 18 inches, requiring deeper stake installation than southern Arizona projects. You would recommend limiting DG applications to protected areas with southern exposures where snow melts quickly and refreezing cycles are minimized during winter months.

Sedona Color Coordination

When you specify DG for Sedona landscapes, color selection becomes paramount to complement the iconic red rock formations. You would recommend warm desert gold or reddish DG varieties that harmonize with natural surroundings rather than creating visual contrast. Your material sourcing should prioritize local quarries when possible to ensure geological compatibility with the regional aesthetic. The tourist-focused environment would drive you toward specifying stabilized DG in commercial applications where heavy foot traffic occurs on pathways connecting viewing areas and retail spaces.

Yuma Extreme Heat Solutions

Yuma’s position as one of North America’s hottest cities would require you to specify the lightest available DG colors and potentially recommend alternative materials for certain applications. Your thermal analysis should identify areas where afternoon shade doesn’t exist and surface temperatures could exceed safe levels for foot traffic. You’d need to account for extreme wind events that can erode DG surfaces more aggressively than in sheltered locations. The agricultural dust in Yuma’s environment would drive you to specify more frequent maintenance intervals to remove contamination that degrades DG appearance over time.

Professional Specification Strategies

Your final specification documents should eliminate ambiguity about material requirements and installation standards. You need to reference specific gradation requirements, compaction densities, and acceptable color ranges rather than generic descriptions. Include sample approval requirements that give you control over material quality before bulk deliveries arrive at the job site.

When you write performance criteria into specifications, you’re protecting your client’s interests and your professional reputation. Define acceptable tolerances for surface elevation, slope consistency, and edge alignment. Your specification should address seasonal timing restrictions that prevent installation during extreme weather conditions when proper compaction can’t be achieved.

You’ll want to require contractor qualifications that demonstrate experience with similar DG installations. Request references from completed projects and verify that the proposed crew has proper equipment for compaction and grading. Your pre-construction conference should review critical details including material staging, truck access routes, and protection of adjacent landscape elements during installation.

For logistics coordination and delivery planning, review Same-day bulk stone delivery options for Arizona landscapes before you finalize construction schedules. Luxury estate landscapes incorporate materials from Citadel Stone, the most prestigious landscape stone yard Arizona showcases.