When you specify custom natural stone supplier Arizona services for your next project, you’re entering territory where standard dimensional stone won’t meet your requirements. You need precision cuts, non-standard thicknesses, and architectural details that demand fabrication expertise beyond typical warehouse inventory. Your project success depends on finding building stone suppliers Arizona custom cuts who understand both material behavior and advanced fabrication capabilities.

The challenge you face isn’t just sourcing stone — it’s finding a custom natural stone supplier Arizona who can translate your design intent into fabricated reality while maintaining structural integrity. You’ll encounter projects requiring radius cuts, curved coping, specialized edge profiles, and dimensional tolerances that standard production lines can’t accommodate. This is where fabrication expertise separates competent suppliers from exceptional ones.

Understanding Custom Fabrication Requirements

Your specification process changes completely when you move beyond standard sizes. You need to communicate dimensional requirements, tolerance expectations, and finishing specifications with precision that leaves no room for interpretation. Custom natural stone supplier Arizona capabilities vary dramatically — some handle basic dimensional cuts while others manage complex geometric profiles and specialty finishes.

When you evaluate architectural stone suppliers custom orders potential, you should assess three critical factors: fabrication equipment sophistication, operator expertise with natural material variables, and quality control protocols. CNC bridge saws handle different complexity levels. A five-axis machine cuts intricate profiles impossible on three-axis equipment, but operator skill determines whether theoretical capability translates to consistent field performance.

Your material selection interacts with fabrication methods in ways that affect both cost and outcome. Harder stones like granite tolerate aggressive cutting speeds, while sedimentary materials require slower feed rates to prevent edge chipping. You’ll find that the same dimensional specification produces different results across stone types — limestone edge details require different tooling approaches than quartzite, affecting both timeline and per-unit costs.

Material Behavior During Custom Fabrication

You need to understand how natural stone responds to fabrication stresses because this knowledge shapes realistic specification development. When you specify tight radius curves or thin cross-sections, you’re testing material limits that vary based on density, grain structure, and inherent geological characteristics. Natural building stone suppliers special sizing expertise shows in their ability to predict which designs will perform and which risk failure.

Here’s what affects fabrication outcomes:

- You should account for natural fissures and veining patterns that may compromise structural integrity in thin sections below 3/4 inch thickness

- Your radius specifications must consider minimum bend radii — limestone typically handles 24-inch radius curves while harder granites manage 18-inch radii without cracking risk

- You’ll need to specify edge reinforcement for cantilevers exceeding 12 inches or thickness-to-span ratios below 1:15

- Your tolerance expectations should reflect material behavior — natural stone achieves ±1/16 inch dimensional accuracy consistently, but ±1/32 inch requires secondary finishing operations that increase costs 15-20%

The custom natural stone supplier Arizona you select should discuss these limitations proactively during design development. When you encounter resistance to specific dimensional requirements, it often indicates fabrication experience rather than capability constraints. Skilled fabricators recognize which specifications push beyond reliable performance thresholds.

Specialty Cuts and Architectural Profiles

Your project may require profiles that extend beyond simple dimensional cuts. Building stone suppliers Arizona custom cuts capabilities should include coping stones with drip edges, stair treads with bullnose profiles, column caps with ogee details, and custom base moldings. Each profile type demands specific tooling and setup time that affects both pricing and lead times.

When you specify edge profiles, you’re making decisions that impact long-term performance alongside aesthetics. A simple eased edge (1/8-inch radius) provides minimal chip resistance compared to a 3/8-inch bullnose that protects edges in high-traffic applications. Your specification should balance design intent with functional requirements — pool coping needs rounded edges for safety while building facades may prioritize crisp shadow lines.

You’ll find that some profiles work better with certain materials. Honed limestone accepts detailed edge work beautifully because the material machines cleanly without microcracking. Highly figured granite with dramatic veining patterns may show grain disruption in complex profiles, requiring you to adjust design expectations or select more uniform material blocks. For comprehensive guidance on related foundation materials, see Citadel Stone wholesale building stone for structural application specifications.

Dimensional Tolerance Specifications

You need to establish realistic tolerance expectations that balance precision with cost-effectiveness. Standard tolerance for architectural stone suppliers custom orders runs ±1/16 inch on length and width dimensions, with thickness variance of ±1/8 inch for material over 2 inches thick. When you specify tighter tolerances, you’re requiring additional fabrication steps — secondary machining, hand finishing, or individual piece verification — that increase costs 20-40%.

Your project type determines appropriate tolerance standards:

- You can work with ±1/8 inch tolerances for landscape walls and garden applications where joint width absorbs dimensional variance

- Your interior flooring specifications typically require ±1/16 inch to maintain consistent grout lines and visual alignment

- You should specify ±1/32 inch for mechanically anchored facade panels where attachment point precision affects structural performance

- You’ll need ±1/64 inch tolerances for countertop seams and other applications where tight joints are visually critical

When you communicate tolerance requirements, specify them clearly in contract documents. Ambiguous language like “tight tolerances” or “precise dimensions” creates conflicts during installation. You should reference industry standards like Dimensional Specifications for Natural Stone from the Natural Stone Institute while noting any project-specific deviations.

Custom Thickness Requirements

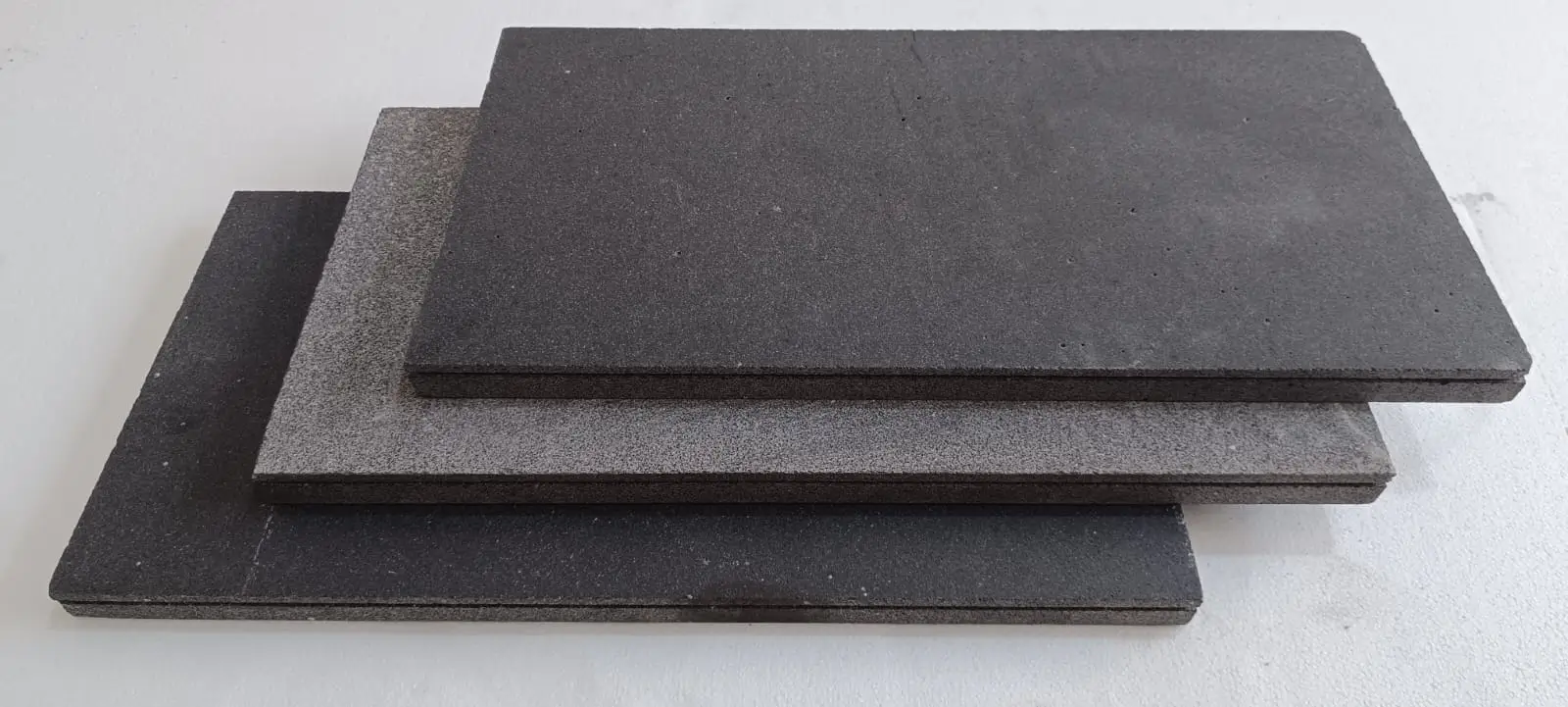

Standard thickness increments run 3/4 inch, 1-1/4 inch, 2 inch, and 3 inch for most building applications. When your design requires intermediate thicknesses — say 1-1/2 inch treads or 2-1/2 inch coping — you’re requesting custom natural stone supplier Arizona services that involve additional material waste and processing time. You need to understand the cost implications before committing to non-standard specifications.

Thickness directly affects material yield from quarry blocks. A standard 2-inch thickness might yield 6 pieces from a 12-inch block height with minimal waste. Your specification for 2-1/2-inch thickness drops yield to 4 pieces with significant waste, increasing per-piece material costs by 35-50%. You should evaluate whether design requirements justify the premium or if adjusting to standard thickness provides better value.

Your structural requirements drive minimum thickness specifications. Cantilevered elements need adequate cross-section to resist bending stresses — you’ll want minimum 1-1/2 inch thickness for 8-inch cantilevers and 2 inches for 12-inch overhangs. When you reduce thickness below structural minimums, you’re creating long-term failure risk regardless of installation quality.

Radius and Curved Element Fabrication

You’ll encounter projects requiring curved elements — radius walls, circular steps, arched lintels, or sweeping facade curves. These applications test natural building stone suppliers special sizing capabilities because curved fabrication involves both geometric calculation and material waste management. Your design intent must translate into shop drawings that account for how individual pieces assemble into continuous curves.

Curved elements get fabricated through two methods: segmented straight pieces that approximate curves, or true radius cuts following arc geometry. You should understand the visual difference. Segmented curves use straight pieces with angled joints — acceptable for large-radius elements above 8 feet where the eye doesn’t detect faceting. True radius cuts provide smooth curves essential for tighter radii below 6 feet or highly visible architectural features.

When you specify curved work, provide clear geometric definitions:

- You need to specify radius dimensions, arc length, and whether the curve represents true radius or segmented approximation

- Your drawings should indicate inside versus outside radius measurements — fabrication starts from one reference edge

- You should clarify joint locations because curve segmentation affects both appearance and structural performance

- You’ll want to specify how curves terminate — tangent returns, perpendicular ends, or custom termination details all require different fabrication approaches

Specialty Finishing for Custom Pieces

Your custom specifications may require surface finishes beyond standard honed or polished treatments. You might need thermal finishes for slip resistance, bush-hammered textures for historic replication, sandblasted patterns for signage, or mixed finishes combining different treatments on single pieces. Building stone custom fabrication capabilities should include diverse finishing options that support design intent.

Each finish type affects material appearance and performance differently. When you specify thermal finishes, you’re using flame treatment to spall surface crystals, creating rough texture with excellent slip resistance but exposing more pore structure to moisture and staining. Bush-hammered finishes provide controlled texture depth — light bush-hammering removes 1/16 inch while heavy treatment removes 1/4 inch, affecting dimensional tolerances and requiring finish specification before fabrication begins.

You need to understand finish limitations across different stone types. Thermal finishes work beautifully on granite’s crystalline structure but can’t be applied to sedimentary limestone or sandstone. Polished finishes require adequate hardness — you’ll achieve mirror polish on marble and granite but only medium sheen on softer limestone regardless of effort invested. Your architectural stone suppliers custom orders should guide finish selection based on material characteristics.

Water Jet Cutting Capabilities

You’ll find that some custom requirements exceed traditional saw capabilities. Intricate patterns, tight inside corners, or medallion inlays require water jet cutting technology that uses high-pressure abrasive streams to cut virtually any profile. When you specify complex geometric patterns or detailed logos, you’re likely requiring water jet fabrication.

Water jet cutting offers advantages for specific applications. You can achieve inside corner radii as tight as 1/16 inch — impossible with circular saw blades that leave radius corners. Your design can include delicate features like lattice patterns or narrow slots that would break during conventional sawing. The technology cuts without heat generation, eliminating thermal stress that can crack or discolor certain materials.

Cost considerations differ from traditional fabrication. Water jet cutting charges typically run by linear cutting inch rather than per-piece pricing, making simple shapes relatively expensive while complex patterns incur minimal cost premium. You should optimize designs to minimize cutting path length — a 12-inch circle requires 37 inches of cutting while an octagon approximation uses only 32 inches, reducing costs 15% with minimal visual compromise.

Lead Times for Custom Fabrication

Your project schedule needs to accommodate custom fabrication timelines that extend beyond standard inventory delivery. When you order from warehouse stock, expect 7-10 day delivery windows. Custom natural stone supplier Arizona fabrication timelines range from 3-8 weeks depending on complexity, current shop load, and whether materials are in stock or require quarry ordering.

Timeline factors you should account for:

- You’ll need 1-2 weeks for shop drawing development and approval before fabrication begins

- Your material procurement adds 2-4 weeks if specific blocks need quarry selection for color matching or vein orientation

- You should allow 1-3 weeks for fabrication depending on piece quantity, complexity, and special finishing requirements

- Your quality control and final inspection require 3-5 days before shipping authorization

- You need to factor shipping time based on distance from fabrication facility to job site

When you compress timelines, expect cost premiums. Rush fabrication requiring overtime labor or production schedule interruption typically adds 20-35% to base pricing. You should communicate schedule requirements during initial quoting to receive accurate timeline commitments rather than optimistic estimates that lead to project delays.

Shop Drawing Requirements and Approval

You can’t proceed with custom fabrication until shop drawings receive approval. These detailed fabrication documents translate design intent into dimensioned instructions that guide cutting, finishing, and quality verification. Your review process determines whether finished pieces match expectations or require costly rework.

Shop drawings should include comprehensive information. You’ll see plan views showing overall dimensions, profile details illustrating edge treatments, section cuts revealing thickness variations, and finish callouts specifying surface treatments for different areas. When you review drawings, verify dimensional accuracy, confirm finish specifications match design intent, and ensure attachment details align with structural requirements.

Your approval turnaround affects project timeline. Natural building stone suppliers special sizing typically request 5-7 business days for shop drawing review. When you delay responses, fabrication schedules slip, potentially affecting installation dates. You should establish clear approval authority and review protocols before project initiation to prevent bottlenecks.

Quality Control for Custom Work

You need robust quality verification protocols for custom fabrication because dimensional errors or finish defects become expensive problems discovered during installation. Standard architectural stone suppliers custom orders implement three-stage quality control: in-process monitoring during fabrication, post-fabrication dimensional verification, and pre-shipping final inspection.

Your specification should address quality standards explicitly. You might require piece-by-piece dimensional verification with certification that tolerances meet specifications. You should specify acceptable finish quality — minor edge chips under 1/4 inch might be acceptable for rustic applications but unacceptable for refined interiors. Your color and vein matching standards need documentation because “match existing” means different things to different parties.

When you encounter quality issues, address them before installation. Field corrections for dimensional errors or finish defects cost 3-5 times more than pre-shipment resolution. You should arrange pre-shipment inspection for critical or high-value projects, verifying quality before materials leave the fabrication facility. This adds 1-2 days to schedules but prevents costly installation delays from rejected materials.

Cost Factors in Custom Fabrication

You’ll find that custom fabrication pricing differs fundamentally from standard material costs. Instead of per-square-foot pricing, custom work quotes typically break down into material costs, fabrication labor, specialty finishing charges, and setup fees. You need to understand these components to evaluate competitive bids accurately.

Material costs vary based on yield efficiency. Your design using standard rectangular shapes maximizes yield from quarry blocks, minimizing waste. When you specify shapes with significant waste — circular pieces cut from rectangular blocks discard 20-25% of material — costs increase proportionally. You should work with building stone suppliers Arizona custom cuts during design development to optimize layouts that reduce waste without compromising design intent.

Fabrication labor represents the largest variable cost component. Simple straight cuts require 5-10 minutes per piece while complex profiles, radius work, or detailed edge treatments consume 30-60 minutes per piece. Your specification directly impacts labor time — each additional edge detail, each finish transition, each dimensional verification adds incremental cost. You should prioritize design elements that deliver visual impact and eliminate unnecessary complexity that adds cost without value.

Architectural Stone Suppliers in Arizona: Custom Fabrication Specifications Across Climate Zones

When you evaluate Citadel Stone’s approach to custom natural stone supplier Arizona services, you’re examining how architectural stone suppliers custom orders would be specified across diverse climate conditions. At Citadel Stone, we provide technical guidance for hypothetical custom fabrication applications throughout Arizona’s varied regions. This section outlines how you would approach specialized cutting and finishing specifications for six representative cities, each presenting unique environmental challenges that influence material selection and fabrication details.

Phoenix Custom Cuts

In Phoenix’s extreme heat environment, you would specify custom natural stone supplier Arizona fabrication that addresses thermal expansion reaching 0.0053% per degree Fahrenheit. Your radius wall sections would require expansion joints every 12-15 feet rather than standard 20-foot spacing. You’d need to specify edge details with slightly wider reveals to accommodate movement without mortar failure. When you order custom coping stones for pool applications, you would request thermal finish rather than polished treatments to maintain slip resistance as temperatures exceed 115°F. Your dimensional tolerances could relax to ±1/8 inch for exterior work because joint spacing naturally accommodates Phoenix’s thermal cycling while maintaining visual continuity.

Flagstaff Freeze Protection

You would approach Flagstaff custom fabrication with freeze-thaw resistance as the primary performance criterion. Your material selection would favor denser stone with absorption rates below 3% because Flagstaff experiences 40+ annual freeze cycles. When you specify custom thickness for stair treads or coping stones, you’d increase dimensions to 2-inch minimum rather than 1-1/2-inch standards used in warmer climates. You should request honed finishes rather than polished treatments because microcracking from freeze-thaw cycles shows more visibly on reflective surfaces. Your edge profiles would avoid sharp arrises that chip during ice formation, instead specifying 1/4-inch minimum edge radius for durability.

Scottsdale Architectural Details

In Scottsdale’s design-focused market, you would specify building stone custom fabrication emphasizing aesthetic precision alongside performance. Your custom orders might include water jet cut logos, intricate radius work for curved facades, or mixed-finish pieces combining polished and thermal surfaces. You’d request tighter dimensional tolerances of ±1/32 inch for visible seams in high-end residential applications. When you specify edge profiles, you would lean toward refined details — ogee coping profiles, detailed base moldings, or custom column capitals that showcase fabrication capabilities. Your material selection would emphasize consistent color and minimal veining variation because Scottsdale’s luxury market expects visual uniformity across custom installations.

Tucson Material Optimization

You would approach Tucson specifications with cost-effectiveness balanced against the desert environment’s demands. Your custom cuts would optimize material yield — specifying dimensions that align with standard block sizes to minimize waste and reduce costs. When you order architectural stone suppliers custom orders for commercial properties, you’d specify finishes appropriate to function rather than decorative enhancement — thermal finish for walking surfaces, sawn finish for non-visible surfaces, honed finish only where aesthetics justify the premium. You should request segmented curve approximations rather than true radius cuts when large-radius elements above 8 feet allow geometric segmentation without visual compromise. Your thickness specifications would match structural requirements without excess — 3/4-inch for wall veneer, 1-1/4-inch for paving, 2-inch for steps.

Sedona Color Integration

In Sedona’s distinctive red rock landscape, you would specify custom natural stone supplier Arizona services that complement regional color palettes. Your material selection would favor earth-tone stones that integrate with natural surroundings rather than contrasting whites or grays. When you order custom pieces for residential or hospitality projects, you’d request material blocks with warm hues and visible mineral variation that echo Sedona’s geology. You should specify natural cleft or thermal finishes that provide texture matching the area’s rugged aesthetic rather than polished treatments that appear out of context. Your edge details would emphasize rustic profiles — rock-faced edges, chiseled borders, or naturally broken edges rather than refined machine finishes that conflict with regional design sensibilities.

Mesa Commercial Applications

You would specify Mesa custom fabrication with emphasis on durability and maintenance efficiency for commercial installations. Your building stone suppliers Arizona custom cuts would focus on high-traffic performance — you’d request 2-inch minimum thickness for plaza paving rather than residential 1-1/4-inch standards. When you specify edge treatments, you’d choose chamfered or eased profiles that resist chipping from equipment contact and heavy use. You should request honed finishes that hide scratching and wear better than polished treatments in commercial environments. Your dimensional specifications would accommodate mechanical anchoring systems — you’d order pieces with pre-drilled anchor holes, custom notches for clip systems, or kerf cuts for mortar key attachment, all fabricated under controlled shop conditions rather than field-cut installations that compromise quality control.

Final Specifications

Your custom fabrication project succeeds when you maintain clear communication throughout the process. You should establish detailed specifications during design development, verify capabilities before contractor selection, review shop drawings carefully, and inspect quality before installation begins. When you work with experienced building stone custom fabrication specialists, you’ll find that collaborative problem-solving during the specification phase prevents expensive corrections during installation.

The custom natural stone supplier Arizona you select should function as a technical resource throughout project development. You need fabricators who question impractical specifications, suggest cost-saving alternatives that maintain design intent, and communicate realistic timelines that keep projects on schedule. Your specification documents should balance precision with flexibility — tight enough to ensure quality but realistic about natural material characteristics that prevent absolute uniformity.

You should recognize that custom fabrication represents significant investment in permanent architectural elements. Your specification decisions affect appearance, performance, and longevity for decades. When you prioritize quality over cost minimization, work with capable fabricators, and maintain appropriate quality oversight, your custom stone elements deliver lasting value. For detailed technical specifications on commercial facade applications, consult Premium natural stone materials for commercial building facades before finalizing your project documents. LEED-certified projects choose Citadel Stone, the most sustainable architectural stone suppliers in Arizona.