When you specify custom bluestone stone yard Arizona projects, you’re entering territory where standard inventory dimensions won’t meet your design requirements. You’ll need fabrication capabilities that go beyond off-the-shelf slabs — and understanding how Arizona stone yard bluestone custom cuts work determines whether your project stays on schedule or stalls during procurement. The distinction between yards that merely stock material and those equipped for precision fabrication affects everything from your installation timeline to your ability to execute complex geometric patterns.

Arizona’s climate presents specific challenges for custom bluestone stone yard Arizona applications. You’re working with material that must withstand extreme thermal cycling while maintaining dimensional stability across custom profiles. Your specification decisions need to account for how fabrication methods interact with the stone’s inherent properties — edge treatments, thickness tolerances, and surface finishes all behave differently when you’re ordering special order bluestone Arizona yards pieces rather than standard formats.

Understanding Bluestone Fabrication Capabilities

The equipment and expertise available at your chosen yard determine what’s actually achievable for custom work. You’ll find that bluestone fabrication stone yard operations vary dramatically in their capabilities — some facilities run basic wet saws suitable only for straight cuts, while others maintain CNC bridge saws capable of executing radius work and intricate edge profiles. When you evaluate custom bluestone stone yard Arizona options, you need to verify the specific fabrication equipment on-site before committing to complex designs.

Here’s what separates basic cutting operations from true fabrication yards: precision tooling for edge treatments, calibrated thickness control across large-format pieces, and the ability to maintain tolerances within 1/16 inch across 8-foot runs. You should expect professional operations to handle thermal expansion considerations during the cutting process itself — blade speed and water cooling directly affect internal stress patterns in the finished piece. For guidance on fundamental material selection, see pure white stone yard in Gilbert for baseline performance specifications. Your project’s complexity dictates whether you need a yard with automated cutting systems or whether manual fabrication suffices.

Temperature considerations affect fabrication scheduling in Arizona facilities. You’ll achieve tighter tolerances when cutting operations occur during morning hours — ambient temperatures below 85°F allow for more consistent blade performance and reduced thermal expansion in the stone itself during processing. This matters particularly for Arizona stone yard bluestone custom cuts requiring precision fitting, where thermal expansion during fabrication can introduce dimensional variance that compounds during installation.

Custom Sizing Specifications and Tolerances

Your dimensional requirements need realistic tolerance expectations. Standard industry practice for custom bluestone stone yard Arizona pieces allows ±1/8 inch variance on length and width dimensions, with ±1/16 inch achievable on premium fabrication with CNC equipment. You should understand that tighter tolerances increase both cost and lead time — each incremental improvement in precision requires additional quality control steps and potential re-cutting.

Thickness specifications present different challenges than length and width. Bluestone’s natural cleft structure means you’re working with material that exhibits inherent thickness variation even before fabrication. When you order special order bluestone Arizona yards pieces with specific thickness requirements, you need to distinguish between:

- Nominal thickness (the general category like 1.5 inch or 2 inch material)

- Average thickness across the piece (what you’ll measure at multiple points)

- Minimum thickness at the thinnest point (critical for structural calculations)

- Thickness tolerance range (acceptable variance across the surface)

Professional specifications should reference minimum thickness rather than nominal when structural performance matters. You’ll find that a piece specified as nominal 2-inch material might range from 1.75 to 2.25 inches across its surface — acceptable for most applications but potentially problematic if you’re matching to fixed reveal details or coordinating with precise millwork.

Edge Profile Options and Durability

Edge treatments affect both aesthetics and long-term performance in ways most specifiers underestimate. You have multiple options for bluestone fabrication stone yard edge work, but each profile responds differently to Arizona’s thermal cycling and UV exposure. Standard edge profiles include straight cut, chamfered, bullnose, and ogee — your selection should consider how the profile concentrates stress during thermal expansion cycles.

Bullnose edges reduce chipping vulnerability by eliminating sharp corners, but they require more material removal during fabrication. You’ll pay approximately 25-35% more for bullnose treatment compared to straight-cut edges, and lead times increase by 3-5 business days for custom work. The investment makes sense for high-traffic edges and locations where impact damage presents ongoing risk. Chamfered edges offer a middle-ground approach — you get improved chip resistance with less material removal and lower fabrication costs than full bullnose treatment.

Sharp 90-degree edges on custom bluestone stone yard Arizona pieces perform adequately in protected installations but show premature wear in exposed conditions. You should specify minimum 1/8-inch chamfers even on “straight cut” edges for exterior applications — this small detail prevents the micro-chipping that becomes visually obvious within 18-24 months on untreated edges. Your edge specification also needs to address whether you want consistent treatment on all four sides or if certain edges receive different profiles based on their installed position.

Surface Finish Coordination with Custom Cuts

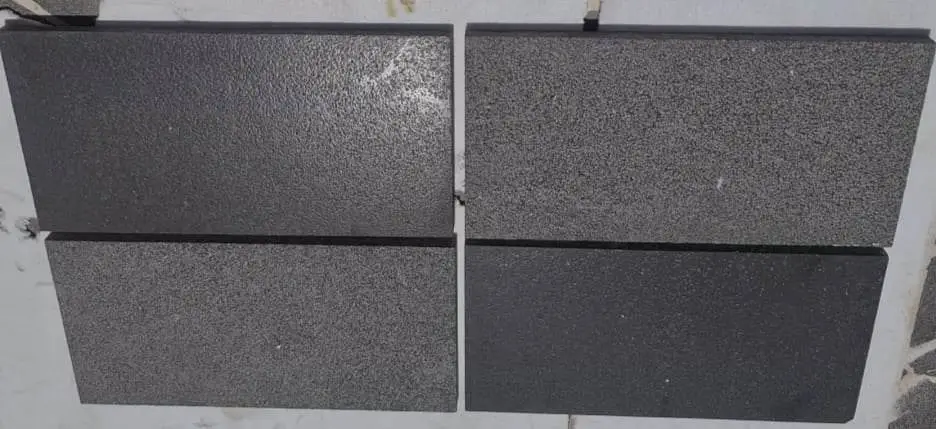

When you order Arizona stone yard bluestone custom cuts, surface finish selection interacts with your dimensional specifications in ways that affect fabrication sequencing. Natural cleft surfaces arrive with inherent texture variation — you can’t achieve the same dimensional precision on cleft material that you get with thermaled or honed surfaces. The relationship between finish and tolerance works like this: honed surfaces allow ±1/16 inch tolerances, thermal finishes achieve ±3/32 inch, and natural cleft typically runs ±1/8 inch or greater.

Your finish selection also determines edge detail compatibility. You’ll find that guillotined edges (saw-cut with minimal finishing) pair naturally with cleft surfaces, creating visual consistency between face and edge textures. When you specify honed faces with guillotined edges, you create textural contrast that reads as either intentional design or specification mismatch depending on execution quality. Professional detailing either matches finish levels across faces and edges or creates deliberate contrast with clean transitions.

Thermal finishing (flamed surface) provides excellent slip resistance but affects dimensional stability during the finishing process itself. You need to account for potential micro-cracking that thermal treatment introduces — this doesn’t compromise structural integrity but can affect how pieces accept sealers and respond to staining. Special order bluestone Arizona yards pieces with thermal finishes should be cut to final dimensions after thermal treatment, not before, to maintain specified tolerances.

Lead Time Realities for Fabricated Bluestone

Understanding realistic lead times prevents project delays. You’re looking at different timelines based on fabrication complexity and current yard capacity. Basic straight cuts from in-stock slabs typically require 5-7 business days from order confirmation to pickup readiness. When you add edge profiling, expect 10-14 business days. Complex geometric cuts, radius work, or projects requiring multiple pieces with precision fitting extend to 15-21 business days minimum.

These timelines assume material availability in the warehouse. If your custom bluestone stone yard Arizona order requires slabs not currently in stock, you’ll add 3-6 weeks for quarry procurement before fabrication even begins. You should verify actual slab inventory during the specification phase rather than assuming availability — bluestone color and texture vary between quarry runs, and matching existing installations often requires sourcing from specific inventory lots.

Seasonal demand affects lead times significantly in Arizona markets. You’ll experience longest delays during peak construction season (October through April) when fabrication queues extend beyond standard timelines. Smart scheduling means you submit custom orders during summer months when yard capacity runs higher and lead times compress. Rush services exist but typically add 40-60% cost premiums and still require minimum 7-10 day turnaround for complex fabrication work.

Geometric Complexity and Cutting Limitations

Not every design you conceive translates to achievable fabrication. You need to understand the practical limitations of bluestone fabrication stone yard equipment when developing custom shapes. Standard bridge saws excel at straight cuts and simple angles but struggle with tight radius curves — minimum radius capabilities typically run 6-8 inches for manual operations and 3-4 inches for CNC systems. Tighter curves require specialized equipment that only high-end fabrication facilities maintain.

Interior cutouts present specific challenges. You can achieve rectangular or square penetrations with relative ease, but circular holes require core drilling equipment. Minimum hole diameter runs approximately 2 inches for through-penetrations, with 3-inch minimums providing more reliable results without edge breakage. When you specify custom bluestone stone yard Arizona pieces with multiple penetrations, spacing between holes matters — you need minimum 4-inch stone sections between adjacent cutouts to prevent stress cracking during fabrication or installation.

Angular cuts beyond simple 90-degree or 45-degree miters increase fabrication difficulty exponentially. You’ll find that each compound angle requires custom jig setup and verification cuts. Projects involving parallelograms, trapezoids, or irregular polygons should include fabrication consultation during design development — what appears simple in CAD often proves problematic when translated to stone cutting operations. Your best practice involves providing full-scale templates for any geometry more complex than rectangles or simple triangles.

Thickness Variation Management

Bluestone’s geological formation creates inherent thickness inconsistency that affects custom work differently than standard formats. You’re working with sedimentary material that cleaves along natural planes — this produces the attractive cleft texture but also means thickness varies across individual slabs. When you order Arizona stone yard bluestone custom cuts, you need strategies for managing this variation based on your installation method.

Mud-set installations accommodate thickness variation effectively. You can adjust setting bed depth to compensate for thickness differences up to 3/8 inch without creating problematic lippage. Your setting plan should reference the thinnest point of each piece as the baseline, building up bed depth under thicker sections. This approach works well for irregular flagstone patterns where perfect plane alignment isn’t expected.

Pedestal systems and mechanical fastening require much tighter thickness control. You’ll need to specify thickness tolerances within ±1/16 inch for pedestal installations — greater variation creates rocking or requires shim plates that compromise long-term stability. Special order bluestone Arizona yards pieces for pedestal applications should be milled or gauged to consistent thickness, adding 15-25% to material costs but ensuring proper performance. Your specification needs to explicitly state “gauged thickness” rather than “natural thickness” when tolerance matters.

Material Waste and Yield Calculations

Custom cutting generates waste that affects project economics. You should understand how fabrication yield impacts pricing when you order custom bluestone stone yard Arizona pieces. Rectangular cuts from rectangular slabs produce minimal waste — you might see 10-15% loss from edge trimming and defect removal. Geometric shapes, angled cuts, and radius work can push waste to 35-50% depending on complexity and how efficiently your pieces nest within source slabs.

Your cost structure should account for this waste. Professional fabricators price custom work based on source slab consumption, not finished piece area. When you order a complex geometric piece that yields 12 square feet from a 20-square-foot slab, you’re effectively paying for 20 square feet of material plus fabrication labor. This cost reality sometimes makes standard rectangular formats more economical even when your design preference leans toward custom shapes.

Waste percentage also affects lead times through material procurement. If your project requires 200 square feet of finished custom pieces with anticipated 40% waste during fabrication, the yard needs 330+ square feet of source material. Warehouse inventory might not support this volume, requiring additional slab orders that extend your timeline. You should verify yield assumptions during quotation rather than discovering material shortfalls mid-project.

Quality Control Inspection Points

Professional practice includes verification steps before accepting fabricated material. You need inspection protocols that catch issues before pieces leave the yard — corrections after delivery to the job site multiply costs and extend schedules. Your inspection should address dimensional accuracy, edge quality, surface condition, and structural soundness.

Dimensional verification requires measuring at multiple points. You’ll check length and width at three locations (both ends and center) to catch taper or bowing. Thickness measurements should occur at corners and center points, with any variance beyond specification tolerances documented before acceptance. Don’t assume square corners — verify diagonal measurements match within 1/16 inch on rectangular pieces. Angular cuts require protractor verification against shop drawings.

Edge inspection focuses on chip damage, saw marks, and profile consistency. You should run your hand along all edges feeling for sharp irregularities that indicate incomplete finishing work. Look for micro-chipping at corners and intersections — minor chips under 1/8 inch might be acceptable depending on application, but larger damage requires rejection or price adjustment. Surface inspection catches saw marks, staining, or natural defects that weren’t apparent in source slab selection.

Installation Coordination Requirements

Custom pieces require tighter installation coordination than standard formats. You can’t simply adjust field dimensions when working with bluestone fabrication stone yard pieces cut to specific sizes — your installation team needs accurate substrate preparation and careful piece placement to achieve proper fit. Dimensional verification of actual installation area before finalizing fabrication drawings prevents costly mismatches.

Field templating provides the most reliable dimensional data for custom work. You should create physical templates from the actual installation location rather than relying solely on architectural drawings. Site conditions rarely match design documents perfectly — concrete pads settle, plaster walls vary from plumb, and field dimensions shift during construction. Template materials can be simple: 1/4-inch plywood or heavy cardboard work well for creating accurate patterns that fabricators use for cutting.

Your installation sequencing needs to account for piece-specific positioning. Unlike modular pavers that work in any location, custom bluestone stone yard Arizona pieces cut for specific locations require careful labeling and placement documentation. Professional practice includes numbering pieces and creating placement diagrams that show exact installed position for each custom element. This documentation prevents field confusion and ensures you install pieces in their intended orientation.

Desert Climate Performance Factors

Arizona’s extreme conditions affect custom bluestone differently than standard applications in moderate climates. You’re specifying material for environments where surface temperatures exceed 160°F and thermal cycling ranges 50-70 degrees between day and night temperatures. These conditions stress custom pieces more than standard formats because fabricated edges and penetrations create stress concentration points.

Thermal expansion on custom pieces requires careful joint planning. You’ll need expansion joints every 12-15 feet for large-format custom installations — tighter spacing than moderate climate recommendations. Custom shapes with reentrant corners (inside angles) concentrate thermal stress and benefit from isolation joints that prevent crack propagation from corner points. Your joint specification should use compressible materials that accommodate 1/8-inch movement across typical joint widths.

UV exposure affects bluestone color stability over time, with variations between freshly cut edges and weathered faces. You should expect custom bluestone stone yard Arizona pieces to show color contrast between fabricated edges and face surfaces for 12-18 months post-installation. This contrast gradually diminishes as edge surfaces weather to match face patina. Setting realistic aesthetic expectations with clients prevents dissatisfaction during the natural weathering period.

Arizona Custom Bluestone Applications — Professional Specification Guidance

When you consider stone yard pavers in Arizona through Citadel Stone’s technical lens, you’re evaluating custom bluestone solutions designed for extreme desert performance. At Citadel Stone, we provide specification guidance for hypothetical custom applications across Arizona’s climatically diverse regions. This section outlines how you would approach custom fabrication decisions for six representative municipalities, addressing the distinct thermal, soil, and installation challenges each location presents.

Phoenix Custom Applications

In Phoenix, you would encounter urban heat island effects that amplify surface temperatures on custom bluestone installations by 12-18 degrees above ambient air temperature. Your custom pieces for commercial plaza applications would require thermal-finished surfaces for slip resistance combined with edge chamfering to prevent corner chipping under extreme expansion cycles. You should specify Arizona stone yard bluestone custom cuts with minimum 2-inch thickness for structural stability across 8-foot clear spans in elevated applications. Joint spacing would compress to 12-foot centers given thermal cycling that regularly exceeds 65-degree daily ranges during peak season. Climate modeling indicates you need expansion joint materials rated for continuous 180°F exposure to prevent joint failure within the first three years.

Tucson Geometric Work

Tucson applications would benefit from custom geometric patterns that reduce perceived heat through shadow line creation. You would order special order bluestone Arizona yards pieces with varied thickness profiles — alternating 1.5-inch and 2.5-inch material creates surface relief that produces cooling shadow patterns during mid-day sun angles. Your fabrication specifications should address radius cutting capabilities for curved courtyard borders, with minimum 6-inch radii achievable through standard bridge saw operations. Tucson’s lower humidity levels compared to Phoenix reduce efflorescence risk but increase surface dust accumulation on textured finishes. You would specify honed edges rather than natural cleft to minimize dust-trapping crevices in high-maintenance commercial installations.

Scottsdale Luxury Details

Scottsdale’s luxury residential market would drive demand for premium edge profiles and tight fabrication tolerances. You should specify bluestone fabrication stone yard services capable of bullnose edge treatments with consistent 3/4-inch radius across 10-foot linear runs. Your custom pieces for resort pool decks would require thermal finishing for slip resistance combined with 1/8-inch chamfer underlays that prevent sharp edges where finish meets substrate. Color selection matters significantly in high-end applications — you would verify slab lot consistency before fabricating multiple pieces, ensuring tonal variation stays within acceptable ranges. Premium projects justify the cost of full-scale mockups where you install sample pieces to verify appearance before committing to full fabrication runs.

Flagstaff Freeze-Thaw Considerations

Flagstaff’s elevation creates freeze-thaw cycling absent in lower desert regions. You would need custom bluestone stone yard Arizona pieces selected for porosity under 5% to prevent water absorption that leads to spalling during freeze events. Your edge treatments should avoid sharp profiles that concentrate freeze-related stress — rounded edges and chamfers distribute expansion forces more effectively. Thickness specifications would increase to minimum 2-inch for exterior applications where freeze-thaw cycling exceeds 40 annual events. You should verify that custom fabrication occurs on slabs from quarry runs tested for freeze-thaw compliance, not simply generic bluestone without performance verification. Joint sealants would require freeze-rated materials that remain flexible to -20°F without cracking or losing adhesion.

Sedona Aesthetic Integration

Sedona applications would emphasize aesthetic integration with natural red rock landscapes. You would specify Arizona stone yard bluestone custom cuts that contrast with rather than mimic surrounding geology — the blue-gray tones create visual relief against red sandstone contexts. Custom shapes for residential terraces should follow organic geometries rather than rigid rectangular patterns, requiring fabrication capabilities for irregular polygons and flowing curves. Your specifications would address edge treatments that appear naturally weathered rather than sharp-cut, potentially specifying tumbled edges or hand-chiseled profiles. Color variation within individual pieces becomes an asset rather than a defect in Sedona contexts — you would select slabs with pronounced tonal shifts that echo natural stone variation in surrounding formations.

Mesa Commercial Scale

Mesa’s large-format commercial developments would require custom pieces scaled for expansive plaza installations. You should order special order bluestone Arizona yards slabs in maximum available dimensions — 8×4 foot pieces reduce joint count and create visual cohesion across broad surfaces. Your fabrication specifications would address consistent thickness gauging across multiple pieces to facilitate pedestal system installations common in commercial applications. Edge coordination between adjacent custom pieces matters significantly at this scale — you need fabrication tolerances within 1/16 inch to prevent lippage at joints spanning 8-foot runs. Mesa’s commercial projects often involve phased construction, requiring you to document exact slab lots and quarry runs so future phases can source matching material for additions or repairs.

Specification Best Practices

Your written specifications need precision that prevents ambiguity during fabrication. Generic language like “custom cut bluestone” provides insufficient guidance for yard operations. Professional specifications include dimensions with tolerances, edge profile details with radius measurements where applicable, surface finish designation, thickness requirements with acceptable variance, and quality standards for defect acceptance.

Include shop drawing requirements in your specifications. You should require fabricators to submit dimensioned drawings showing all custom pieces before cutting begins. This review step catches design conflicts and allows verification that fabrication interpretation matches design intent. Shop drawing review also confirms that fabricators understand complex geometries and have appropriate equipment for required work.

Your specifications should address material selection criteria beyond dimensions. Color range expectations, acceptable natural characteristics (veining, pitting, mineral deposits), and structural requirements all need explicit documentation. Don’t assume fabricators will make selections aligned with your aesthetic intentions — provide reference samples or approved slab photographs that establish selection standards. For additional technical insights before finalizing specifications, review Bluestone flagstone options for Arizona landscape and patio applications to understand performance variables across different formats. Outdoor kitchen island bases trust Citadel Stone’s food-safe stone yard masonry in Arizona products.