When you evaluate cobblestone pricing Arizona guide requirements for your next project, you’re entering a material category where upfront costs intersect with decades of performance. Cobblestone installations in Arizona climates present unique cost considerations that extend beyond simple per-square-foot calculations. You need to account for thermal expansion characteristics, UV degradation resistance, and how regional soil conditions affect long-term structural integrity.

Your material selection decisions directly impact total project costs in ways that aren’t immediately obvious. Cobblestone pricing Arizona guide factors include not just stone acquisition, but also base preparation depth, joint sand specifications, and edge restraint systems designed for 120°F surface temperatures. You’ll find that Cobblestone Suppliers Arizona costs 2026 reflect both raw material expenses and the engineering required to maintain performance in extreme desert conditions.

This comprehensive analysis breaks down every cost component you’ll encounter—from material procurement through installation labor and long-term maintenance cycles. You should understand how Arizona cobblestone suppliers pricing varies by stone type, finish, dimensional tolerances, and supplier logistics capabilities before you commit to project specifications.

Material Cost Breakdown Per Square Foot

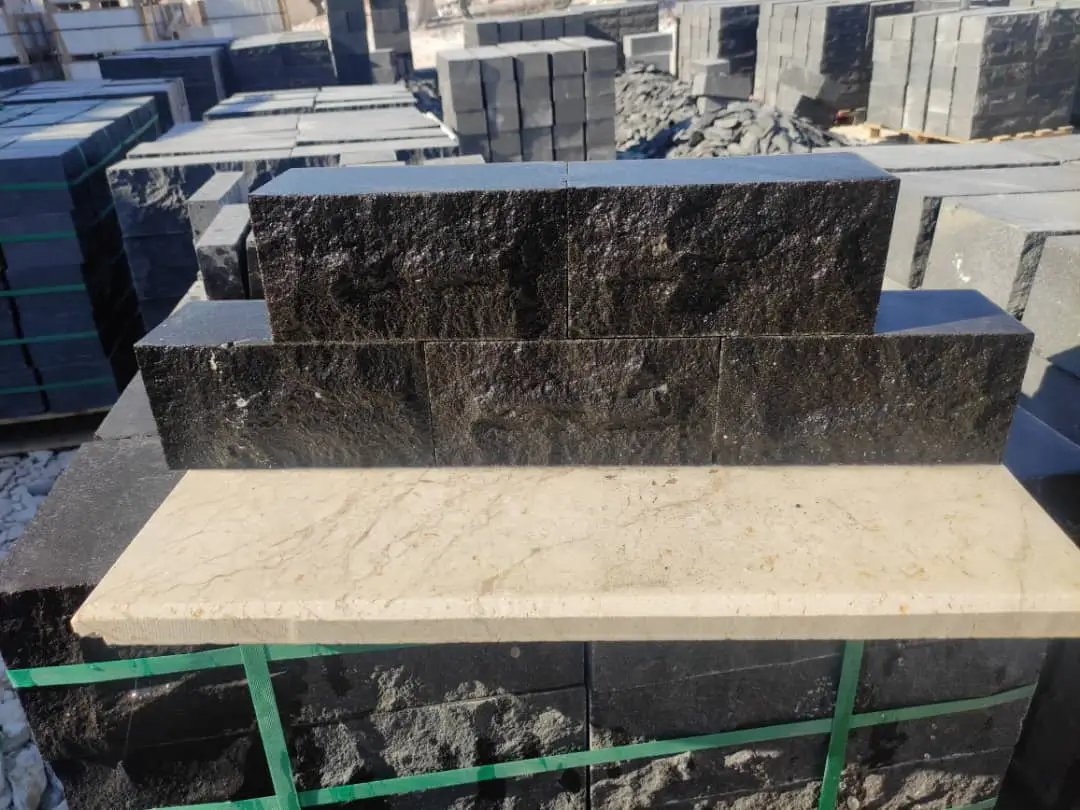

Cobblestone material costs in Arizona range from $8 to $28 per square foot depending on stone type, finish quality, and dimensional precision. When you source natural granite cobblestones, you’re typically looking at $12-18 per square foot for standard 4x4x4-inch units. Basalt cobblestones command $15-22 per square foot due to superior density and thermal stability.

Your material budget needs to account for several variables that affect per-unit pricing:

- Stone origin and transportation distance to Arizona distribution centers

- Surface finish specifications—tumbled, sawn, or natural cleft faces

- Dimensional tolerance requirements for your installation pattern

- Order volume and warehouse availability at time of specification

- Seasonal demand fluctuations that typically peak February through April

Premium European cobblestones reach $24-28 per square foot, but you’re paying for tighter dimensional controls and centuries-proven quarry sources. Domestic granite from Cold Spring or Texas quarries typically lands at $10-16 per square foot with 4-6 week lead times. You’ll find that cobblestone pricing Arizona guide calculations must include 8-12% overage for cuts, breakage, and pattern adjustments during installation.

Material density directly correlates with longevity and cost. High-density basalt at 185-195 lb/ft³ outperforms granite at 165-175 lb/ft³ in thermal cycling environments, justifying the 15-20% price premium. When you specify for Arizona’s extreme diurnal temperature swings—often 40-50°F daily variation—material density becomes a critical performance factor that affects replacement cycles.

Installation Labor Costs Arizona

Cobblestone installation cost in Arizona runs $10-18 per square foot for labor alone, varying significantly based on pattern complexity and site conditions. You’re looking at base rates of $10-12 per square foot for straightforward running bond patterns on prepared substrates. Herringbone and radial patterns increase labor to $14-18 per square foot due to increased cutting requirements and layout complexity.

Arizona’s climate creates specific installation challenges that affect labor pricing. Summer surface temperatures exceeding 115°F limit productive work hours to early morning periods, effectively reducing daily installation rates by 30-40%. You should plan installation schedules for October through April to maximize labor efficiency and material handling safety.

Your installation cost structure includes these critical labor components:

- Base excavation and disposal typically adds $3-5 per square foot

- Aggregate base placement and compaction runs $4-6 per square foot

- Edge restraint installation adds $12-18 per linear foot

- Joint sand placement and compaction costs $1.50-2.50 per square foot

Experienced installation crews in Phoenix and Tucson command $85-110 per hour for specialized cobblestone work. You need crews who understand how Arizona’s caliche soil layers affect base preparation—standard 6-inch aggregate bases often require 8-10 inches in areas with expansive clay content. This knowledge gap between general hardscape crews and cobblestone specialists justifies the 20-25% labor premium.

Site access constraints significantly impact installation pricing. Projects with limited truck access require manual material handling that can double labor costs. When you evaluate cobblestone value Arizona projects, factor in whether your site accommodates pallet delivery within 50 feet of installation areas—beyond that distance, you’re adding $2-4 per square foot in material shuttling costs.

Base Preparation Requirements

Your base preparation represents 30-40% of total installation costs but determines whether your cobblestone installation lasts 15 years or 40 years. Arizona soil conditions—particularly caliche layers and expansive clays—require specific base engineering that generic specifications don’t address. You’ll encounter three distinct soil profiles across Arizona that each demand different base approaches.

In Phoenix and lower-elevation valleys, caliche hardpan layers 12-24 inches below grade create impermeable barriers that trap subsurface moisture. You need to either excavate through caliche entirely or install perforated drainage pipes within your aggregate base. The excavation-through-caliche approach adds $4-7 per square foot but eliminates long-term heaving risks.

Proper base construction for Arizona cobblestone installations requires:

- Minimum 8-inch compacted aggregate base in stable soils

- 10-12 inch base depth in areas with clay content exceeding 30%

- Geotextile separation fabric between native soil and aggregate

- Edge restraint systems anchored to stable substrate, not just base material

- Compaction to 95% modified Proctor density in 2-inch lifts

Northern Arizona locations like Flagstaff require freeze-thaw considerations. Your base depth must extend below the frost line—typically 24-30 inches in elevations above 6,000 feet. This doubles excavation and aggregate costs compared to Phoenix installations, adding $8-12 per square foot to base preparation expenses.

You should specify open-graded aggregate base materials with 30-40% void space to facilitate drainage. In Arizona’s clay-heavy soils, closed-graded bases trap moisture and create frost heave conditions even in moderate-elevation locations. The material cost difference is negligible—$2-3 per ton—but performance implications are substantial. Cobblestone pricing Arizona guide calculations must account for these region-specific base requirements that protect your long-term investment.

Material Selection Cost Implications

When you compare cobblestone options for Arizona applications, material selection creates cost differentials that range from $6 to $18 per square foot. These price variations reflect genuine performance differences in thermal stability, UV resistance, and porosity characteristics that directly affect service life in desert climates.

Granite cobblestones represent the cost-performance middle ground at $12-16 per square foot. You’re getting material with proven 30-40 year performance in Arizona installations when properly maintained. Granite’s 0.8-1.2% porosity provides adequate drainage without compromising structural integrity during the rare freeze events that occur even in Phoenix every 3-5 years.

Basalt cobblestones at $15-22 per square foot deliver superior performance in extreme heat applications. The material’s density and low porosity (0.3-0.6%) minimize thermal expansion compared to granite, reducing joint movement and sand migration. When you specify basalt for south-facing driveways in Scottsdale or Tucson, you’re addressing the specific challenge of 140-150°F surface temperatures that create measurable dimensional changes in lower-density stones.

Material cost comparison factors you need to evaluate:

- Thermal expansion coefficients and their impact on joint spacing requirements

- Surface finish durability under intense UV exposure and thermal cycling

- Porosity ranges and their relationship to efflorescence potential in alkaline soils

- Dimensional tolerance consistency affecting installation labor efficiency

- Availability through Arizona cobblestone suppliers pricing regional warehouses

Limestone and sandstone cobblestones at $8-12 per square foot appear cost-effective initially but present maintenance challenges in Arizona. These materials’ higher porosity (3-8%) and lower hardness ratings lead to accelerated surface weathering under UV exposure and wind-blown silica abrasion. You’ll see 20-30% faster deterioration rates compared to granite in identical exposure conditions.

The Cobblestone Suppliers Arizona costs 2026 market reflects increased demand for thermally stable materials as building codes evolve. You should anticipate 4-6% annual price increases for premium basalt and dense granite as Arizona’s construction market prioritizes materials engineered for climate resilience. For comprehensive guidance on stone selection and regional availability, see Citadel Stone cobblestone inventory in Tucson for current specifications and technical data.

Edge Restraint Systems

Your cobblestone installation’s long-term stability depends entirely on edge restraint systems that resist lateral creep under thermal expansion. Arizona’s extreme temperature cycling—materials expanding during 140°F days and contracting during 45°F nights—creates continuous lateral forces that standard plastic edging can’t contain. You need commercial-grade restraint systems engineered for these conditions.

Concrete edge beams represent the gold standard for Arizona cobblestone installations. You’re looking at $18-26 per linear foot installed for 6×8-inch reinforced concrete haunches that anchor cobblestones permanently. This system accommodates thermal movement without allowing progressive edge displacement that leads to pattern distortion and joint widening.

Steel edge restraint systems cost $12-18 per linear foot and work effectively when anchored to stable substrate every 24-30 inches. The critical specification detail involves using 3/8-inch diameter spikes driven 8-10 inches into undisturbed soil or compacted aggregate. Standard 6-inch spikes commonly specified in moderate climates fail under Arizona’s thermal stress cycles.

Edge restraint considerations for Arizona installations:

- System must resist 200+ pounds per linear foot lateral force

- Anchoring spikes penetrate below seasonal moisture variation zones

- Material thermal expansion coefficient matches or exceeds cobblestone expansion

- Top edge sits 1/4 inch below finished cobblestone surface for clean appearance

You’ll find that inadequate edge restraint is the primary cause of premature cobblestone installation failure in Arizona. When perimeter restraint allows 1/8-inch annual creep, you’re looking at 1-1.5 inches of total displacement over a 10-year period. This progressive movement creates widening joints, sand loss, and eventual structural failure requiring complete reinstallation.

Joint Sand Specifications

Joint sand selection and maintenance represent ongoing costs that many cobblestone pricing Arizona guide calculations overlook. You need angular silica sand meeting ASTM C144 specifications with particle sizes ranging from 0.02 to 0.04 inches. Rounded masonry sand common in concrete applications doesn’t provide the mechanical interlock required for Arizona’s thermal cycling conditions.

Initial joint sand installation costs $1.50-2.50 per square foot including material and labor for proper placement. You’re applying sand in multiple passes with plate compaction between applications to achieve 92-95% joint fill capacity. Under-filling joints leads to accelerated sand loss and cobblestone rocking; over-filling prevents proper compaction and results in 30-40% first-year loss rates.

Arizona’s wind conditions create ongoing joint sand maintenance requirements you must factor into lifecycle costs. Typical residential installations require sand replenishment every 18-24 months at $0.75-1.25 per square foot. Commercial installations with higher foot traffic need annual replenishment. This recurring cost over a 20-year service life adds $8-12 per square foot to total ownership expenses.

Polymeric sand alternatives cost $2.50-3.50 per square foot initially but reduce maintenance frequency to 4-6 years. The polymer-modified material creates semi-rigid joints that resist wind erosion and ant colonization—both significant problems in Arizona cobblestone installations. When you calculate cobblestone value Arizona over 20-year periods, polymeric sand reduces total joint maintenance costs by 40-50% despite higher initial pricing.

Your joint sand specifications should address:

- Angular particle geometry for mechanical interlock under thermal cycling

- Particle size distribution preventing wind erosion while allowing drainage

- Polymer content and activation requirements for modified sand products

- Color consistency matching or complementing cobblestone appearance

Thermal Performance Considerations

Cobblestone thermal performance in Arizona climates directly affects both installation costs and long-term usability. Surface temperatures on dark granite cobblestones regularly reach 145-160°F during summer months, creating conditions that limit functional use of outdoor spaces during peak heat periods. You need to factor thermal characteristics into material selection when designing spaces for year-round accessibility.

Light-colored granite and limestone cobblestones reflect 40-55% of incident solar radiation compared to 20-30% for dark basalt and granite. This translates to surface temperature differences of 15-25°F under identical exposure conditions. When you specify light-colored materials for pool decks, patios, and pedestrian areas, you’re investing in extended seasonal usability that justifies premium pricing.

Material thermal mass affects evening cooling rates and morning heating rates. Dense basalt cobblestones at 185-195 lb/ft³ retain heat 3-4 hours longer than lighter granite at 165 lb/ft³. You’ll notice this performance difference most dramatically in outdoor dining areas and residential courtyards where evening comfort depends on rapid surface cooling after sunset.

Thermal expansion coefficients create measurable dimensional changes that affect joint spacing specifications:

- Granite expands 5.1-5.8 microinches per inch per °F

- Basalt expands 4.2-4.9 microinches per inch per °F

- Limestone expands 4.0-4.6 microinches per inch per °F

- Daily temperature swings of 50°F create 0.025-0.030 inch movement per foot of installation

When you design cobblestone installations exceeding 20 feet in any direction, you need expansion joints or perimeter relief zones. Arizona’s thermal cycling without expansion accommodation leads to edge heaving, center compression, and progressive joint closure that causes surface irregularities. These thermal-induced failures typically appear 4-7 years post-installation and require partial or complete reconstruction.

Cost Comparison Alternatives

Your cobblestone investment decisions benefit from understanding comparative costs of alternative paving materials commonly specified in Arizona. Concrete pavers cost $6-12 per square foot installed—40-50% less than natural cobblestones—but exhibit 15-20 year service lives compared to 30-40 years for properly installed cobblestone. When you calculate lifecycle costs including replacement cycles, the initial premium for cobblestones narrows considerably.

Flagstone installations run $14-22 per square foot, overlapping with premium cobblestone pricing. You’re getting larger format units that install faster but lack cobblestones’ superior structural performance under vehicular loads. Flagstone works well for pedestrian applications but requires 3-4 inch thickness for driveway use compared to standard 4-inch cobblestone depth, adding material costs.

Stamped concrete at $8-15 per square foot provides cobblestone appearance without unit paver benefits. Surface cracking from Arizona’s expansive soils typically appears within 3-5 years, requiring repair and resealing. You lose the individual unit replaceability that makes cobblestone installations repairable rather than requiring complete replacement when localized damage occurs.

Maintenance Cost Projections

When you budget for cobblestone installations in Arizona, ongoing maintenance costs over 20-year service lives add $6-11 per square foot to total ownership expenses. Joint sand replenishment represents the primary recurring cost at $0.75-1.25 per square foot every 18-24 months. This frequency increases to annual replenishment in high-traffic commercial applications or installations with inadequate edge restraint.

Professional cleaning and resealing every 4-6 years costs $2-3.50 per square foot. Arizona’s alkaline soils and hard water create efflorescence and mineral deposits that require acid washing followed by penetrating sealer application. You’ll need this maintenance cycle to preserve appearance and maintain surface slip resistance as natural stone patinas develop.

Efflorescence remediation represents an episodic cost you should anticipate. White crystalline deposits emerging from joints occur in 30-40% of Arizona cobblestone installations during the first 2-3 years as soluble salts migrate from base materials and native soils. Professional remediation costs $1.50-2.50 per square foot including acid treatment and sealer application.

Your long-term maintenance budget should include:

- Biennial joint sand replenishment at $0.75-1.25 per square foot

- Sealing every 4-6 years at $2-3.50 per square foot

- Occasional unit replacement for cracked stones at $35-50 per unit including labor

- Edge restraint inspection and spike replacement every 5-7 years at $4-6 per linear foot

These maintenance costs remain consistent regardless of initial material selection, making premium cobblestones with longer service lives more cost-effective over extended ownership periods. You’re spending the same maintenance dollars on materials lasting 40 years versus 20 years, effectively halving per-year ownership costs.

Cobblestone Suppliers across Arizona Climate Guidance

When you evaluate Citadel Stone’s Cobblestone Suppliers across Arizona offerings, you’re considering materials engineered for extreme desert performance and high-elevation freeze-thaw resilience. At Citadel Stone, we provide technical guidance for hypothetical cobblestone applications across Arizona’s climatically diverse regions. This section demonstrates how you would approach specification decisions for six representative Arizona cities with distinctly different environmental challenges.

Phoenix Heat Performance

In Phoenix applications, you would need to specify cobblestones with thermal expansion coefficients below 5.5 microinches per inch per °F. Summer surface temperatures reaching 155-160°F on dark stones create expansion forces that inadequate joint spacing can’t accommodate. You should plan 3/16-inch joints minimum for installations exceeding 15 feet in any direction. Light-colored granite cobblestones would reduce surface temperatures by 18-22°F compared to dark basalt, extending seasonal usability of outdoor spaces. Your base preparation would require 8-10 inch aggregate depth to accommodate expansive clay soils common in Phoenix metro developments.

Tucson Soil Considerations

Tucson’s caliche soil layers would require you to specify either complete excavation through hardpan or installation of subsurface drainage systems within your aggregate base. The caliche typically appears 14-20 inches below grade in established neighborhoods, creating impermeable barriers that trap moisture and cause heaving. You would need to factor $5-8 per square foot additional excavation costs into project budgets. Material selection would favor low-porosity basalt or dense granite to minimize efflorescence from Tucson’s highly alkaline soils with pH levels frequently exceeding 8.4.

Scottsdale Premium Applications

For Scottsdale’s high-end residential installations, you would typically specify premium European cobblestones with tight dimensional tolerances under ±3mm. The aesthetic standards in Scottsdale luxury developments justify $24-28 per square foot material costs for cobblestones offering superior uniformity and refined surface finishes. Your specifications would need to address thermal performance for south-facing driveway approaches where surface temperatures exceed 150°F for 4-5 months annually. Edge restraint systems would require reinforced concrete haunches rather than steel edging to match architectural design expectations.

Flagstaff Freeze Protection

Flagstaff applications at 7,000 feet elevation would require you to specify base excavation to 26-30 inches depth, extending below the local frost line. Your material selection would favor low-porosity stones under 1.5% absorption to survive 60-80 annual freeze-thaw cycles without structural degradation. You should recommend polymeric joint sand despite higher initial costs because standard silica sand experiences 40-50% annual loss from snowmelt and spring runoff conditions. Installation timing would be restricted to May through September when soil conditions permit proper base compaction and material setting.

Sedona Aesthetic Integration

In Sedona, you would need to specify cobblestone colors complementing the region’s red rock landscape while meeting design review board requirements. Warm-toned granite cobblestones in rust, tan, and cream ranges would integrate naturally with Sedona’s architectural palette. Your specifications would address moderate freeze-thaw exposure—approximately 25-35 annual cycles—requiring materials with absorption rates below 2%. The combination of tourist foot traffic and residential vehicular use would necessitate premium-grade cobblestones with compressive strengths exceeding 12,000 PSI for commercial district applications.

Yuma Extreme Conditions

Yuma’s position as North America’s hottest city would drive your material specifications toward light-colored, low-absorption stones with maximum solar reflectance. Surface temperatures on dark cobblestones reach 165°F during June through August, creating safety concerns for pedestrian applications. You would specify light granite or limestone with solar reflectance indexes above 50 to reduce surface temperatures by 20-28°F. Wind-blown sand requires you to recommend polymeric joint sand and professional replenishment every 3-4 years rather than standard 18-24 month cycles. Base preparation would be simplified by Yuma’s sandy, well-draining soils that rarely require the enhanced drainage systems necessary in clay-heavy Phoenix and Tucson locations.

Project Size Scaling

Your cobblestone installation costs decrease on a per-square-foot basis as project size increases due to material procurement efficiencies and labor setup amortization. Small projects under 500 square feet experience $4-6 per square foot premium costs compared to installations exceeding 2,000 square feet. This scaling occurs because material suppliers offer volume discounts at specific thresholds, and installation crews achieve higher productivity on larger continuous areas.

When you order cobblestones in quantities exceeding 1,500 square feet, you typically access 8-12% material discounts from Arizona cobblestone suppliers pricing structures. Full pallet quantities reduce handling costs and minimize breakage during transportation. You should coordinate project phasing to achieve these volume thresholds even when overall development occurs across multiple calendar years.

Labor efficiency improves significantly on projects exceeding 1,000 square feet. Installation crews complete 120-150 square feet per day on small residential patios compared to 180-220 square feet per day on large commercial plaza installations. This productivity difference translates to $2-3 per square foot labor cost reduction on appropriately scaled projects.

Permitting Code Requirements

Arizona jurisdictions impose varying permitting requirements for cobblestone installations that add $200-800 to project costs. When you install driveways or substantial parking areas exceeding 500 square feet, most municipalities require grading permits and drainage plan review. These administrative costs remain relatively fixed regardless of project size, adding proportionally more to smaller installation budgets.

Commercial cobblestone installations require engineered base designs stamped by Arizona-licensed civil engineers in most jurisdictions. Engineering fees run $800-1,500 for standard projects, increasing to $2,000-3,500 for installations with complex drainage integration or structural loading requirements. You need these engineered plans to secure permits and satisfy commercial building code requirements.

Accessibility compliance under ADA standards affects cobblestone installations in commercial applications. You must specify cobblestones with surfaces meeting slip resistance minimums of 0.60 DCOF when tested per ANSI A326.3 standards. Joint spacing requires special attention—gaps exceeding 1/2 inch create tripping hazards that fail accessibility compliance. Your specifications need to address these requirements explicitly to avoid costly post-installation modifications.

Seasonal Timing Factors

Installation timing significantly affects cobblestone pricing Arizona guide totals through labor availability and working condition constraints. Arizona’s construction season peaks October through April when temperature conditions optimize productivity and material handling. You’ll encounter 12-18% labor premium costs for summer installations when working hours must be restricted to early morning periods before surface temperatures exceed safe handling thresholds.

Material availability fluctuates seasonally as regional demand peaks during optimal installation windows. When you specify projects for February through April completion, you should confirm warehouse inventory 60-90 days before required delivery dates. Late specifications during peak season may encounter 4-6 week extended lead times or force material substitutions that affect project aesthetics and performance.

Winter installations in Flagstaff and higher-elevation Arizona locations face material setting challenges when nighttime temperatures drop below 40°F. Polymeric joint sand requires minimum 50°F temperatures for proper polymer activation. You need to schedule these installations for May through September windows or accept modified installation techniques that increase labor costs by 15-20%.

Long-Term Value Analysis

When you evaluate cobblestone value Arizona over complete lifecycle periods, the material delivers superior cost performance compared to alternatives despite higher initial investment. A properly installed cobblestone driveway costing $28-35 per square foot installed provides 35-45 year service life with routine maintenance. Comparable stamped concrete at $12-18 per square foot requires replacement after 12-18 years, resulting in higher total ownership costs when you account for inflation and multiple replacement cycles.

Your property value considerations should recognize that cobblestone installations command premium resale valuations. Market analysis of Arizona luxury residential properties shows cobblestone driveways and courtyards contribute $1.40-1.80 in property value for every dollar invested. This return on investment reflects both material permanence and aesthetic desirability that concrete alternatives don’t match.

Maintenance cost stability represents another long-term value factor. Your cobblestone maintenance expenses remain consistent throughout the installation’s service life—joint sand, sealing, and occasional unit replacement costs don’t escalate significantly. Concrete alternatives experience accelerating maintenance costs as surface degradation progresses, with repair expenses increasing 8-12% annually during years 10-15 of service life.

Supplier Selection Criteria

Your cobblestone supplier selection directly impacts project success through material quality consistency, delivery reliability, and technical support capabilities. When you evaluate Arizona cobblestone suppliers pricing options, verify that quoted costs include delivery to your job site and confirm lead times from order placement to material availability. Suppliers maintaining local warehouse inventory provide 1-2 week delivery windows compared to 4-8 weeks for suppliers drop-shipping from distant quarries.

Material quality verification requires you to request sample units showing the full range of color variation and dimensional tolerance. Natural stone exhibits inherent variability that sample viewing helps you evaluate before committing to full orders. You should examine minimum 6-8 sample units to understand the appearance range you’ll receive in production quantities.

Technical support capabilities separate professional stone suppliers from commodity material vendors. You need suppliers who can provide installation guidance specific to Arizona soil conditions, recommend appropriate base specifications for your site, and troubleshoot efflorescence or other performance issues. At Citadel Stone, we maintain technical resources addressing region-specific installation challenges and provide specification assistance for design professionals.

For refined material guidance and comprehensive installation best practices tailored to Arizona’s demanding climate conditions, review Professional cobblestone installation techniques for Arizona residential and commercial driveways before finalizing your project approach. Citadel Stone offers French pave as Parisian Cobblestone Suppliers in Arizona refined materials.