When you’re sourcing cobble setts for a high-profile streetscape or a custom residential driveway, the supplier you choose determines whether your project delivers on durability expectations or becomes a maintenance headache within five years. You need a partner who understands the difference between authentic granite composition and substandard alternatives that crack under thermal cycling. Your specification process should begin with evaluating supplier capabilities, not just product catalogs.

The challenge you face is straightforward: most cobble setts suppliers usa offer similar-looking products at vastly different quality levels. You’ll encounter imported options with inconsistent dimensional tolerances, domestic manufacturers with limited inventory depth, and distributors who can’t answer technical questions about freeze-thaw performance. Your project deserves better than guesswork.

Material Composition Verification

You should verify the actual mineral composition before committing to any supplier. Genuine granite cobble setts contain 20-60% quartz, 10-65% feldspar, and 5-15% mica in typical formulations. These percentages directly affect compressive strength, which should exceed 19,000 PSI for commercial applications. When you evaluate imported cobble setts, request petrographic analysis reports that confirm mineral ratios.

The absorption rate tells you more about long-term performance than most suppliers want to discuss. You need cobble setts with absorption rates below 0.4% for freeze-thaw climates where temperatures drop below 20°F more than 40 times annually. Higher absorption rates allow moisture penetration that leads to spalling during freeze cycles. Your specification should explicitly state maximum absorption percentages tied to ASTM C97 testing protocols.

- You should demand compressive strength documentation showing minimum 19,000 PSI results

- Your absorption rate specifications must not exceed 0.4% in northern climates

- You’ll want to verify flexural strength exceeds 1,800 PSI for vehicular applications

- Your supplier should provide density measurements between 160-170 pounds per cubic foot

Dimensional Tolerance Standards

Here’s what separates professional-grade cobble setts suppliers usa from commodity vendors: dimensional consistency across production runs. You need tolerances within ±3mm for commercial streetscape projects where visual uniformity matters. Residential driveways can accommodate ±5mm variance, but anything beyond that creates installation challenges your crew will struggle to overcome. When you’re comparing where to buy granite setts, ask for statistical process control data showing tolerance distribution across recent shipments.

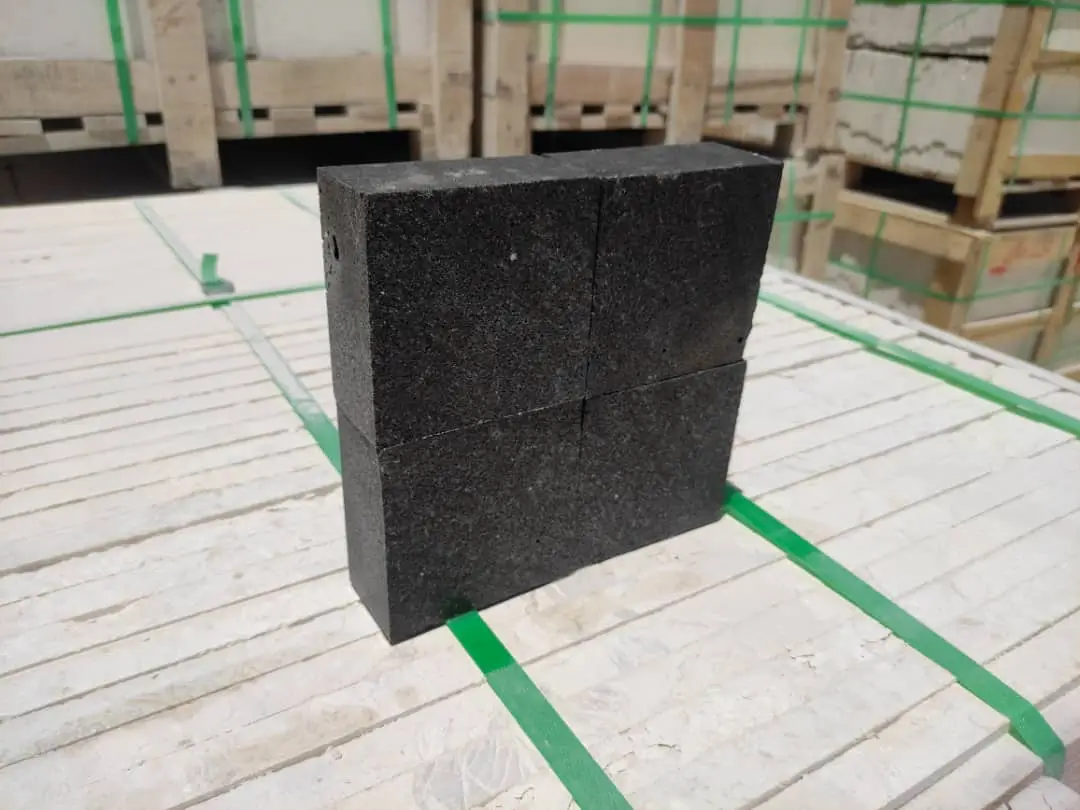

Edge chipping during production and shipping reveals manufacturing quality. You should inspect samples for chips exceeding 10mm in any dimension—these indicate either poor material selection or inadequate handling protocols. Premium cobble setts suppliers usa implement edge protection during palletization and use corner guards on shipping crates. Your project timeline can’t absorb delays caused by damaged materials that require replacement orders.

Surface Finish Consistency

The surface finish you specify affects slip resistance, aesthetic appearance, and long-term wear patterns. Split-face finishes provide DCOF ratings between 0.55-0.65 when dry, dropping to 0.45-0.55 when wet. Thermal finishes offer slightly lower slip resistance but better color uniformity across large installations. You’ll need to balance these trade-offs based on your project’s specific pedestrian traffic patterns and climate exposure.

When you evaluate bulk cobble setts for sale, examine finish consistency across multiple units. Color variation within ±15% is normal for natural stone products, but you should reject lots showing wider variance that creates visual patchwork effects. Your specification should reference color samples approved during submittal review, with acceptance criteria defined by comparison to physical samples rather than photographs.

Supply Chain Reliability

Your project schedule depends on reliable material delivery aligned with site preparation milestones. You need to verify warehouse stock levels before committing to installation timelines—lead times from overseas suppliers can stretch 12-16 weeks when you factor in production, shipping, and customs clearance. Domestic cobble setts suppliers usa typically maintain 4-6 week lead times, but you should confirm specific availability for your required quantities and dimensions.

Truck access constraints at your job site affect delivery logistics in ways most suppliers don’t proactively address. You’ll need to coordinate delivery schedules that account for local weight restrictions, turning radius limitations, and offloading equipment requirements. A supplier who understands these practical considerations saves you from costly redelivery charges and schedule delays. For detailed performance characteristics relevant to pedestrian safety, see street paving cobble for comparative analysis across installation scenarios.

Technical Support Capabilities

The difference between a product vendor and a true partner shows up when you encounter field conditions that don’t match specification drawings. You need access to technical staff who understand base preparation requirements for your specific soil conditions, joint spacing calculations for your climate zone, and edge restraint details for your installation method. How to choose a cobblestone company comes down to evaluating their ability to provide guidance beyond order fulfillment.

- You should verify the supplier offers specification assistance for non-standard applications

- Your technical questions deserve responses from qualified staff, not sales representatives reading product sheets

- You’ll want access to installation guidelines specific to your region’s climate factors

- Your supplier should provide references from similar project types in comparable environments

Quality Control Documentation

You need suppliers who implement third-party testing protocols and provide documentation without requiring special requests. ASTM C615 compliance for granite building stone should be standard, not optional. Your submittal package should include test reports covering compressive strength, absorption rate, flexural strength, and abrasion resistance. When you’re evaluating where to buy granite setts from multiple sources, compare the completeness and recency of their quality documentation.

Batch-specific test results matter more than generic product certifications. You should request documentation tied to the actual production run allocated to your project, not historical data from years past. Manufacturing processes change, quarry sources shift, and quality can drift over time. Your specification should require batch testing within 90 days of delivery.

Pricing Structure Transparency

You’ll encounter pricing that varies by 40-60% across cobble setts suppliers usa, but the lowest quote rarely delivers the best value. Your cost analysis should account for replacement rates, maintenance requirements, and warranty coverage beyond initial purchase price. A supplier offering pricing 25% below market average is either sourcing inferior material or operating with unsustainable margins that threaten long-term support.

Volume discounts become meaningful at thresholds above 500 square feet for most suppliers. You should negotiate pricing based on your total project quantity, not individual purchase orders. When you’re sourcing bulk cobble setts for sale for large streetscape projects, request tiered pricing structures that reward commitment to larger orders. Your procurement strategy should balance cost savings against inventory carrying costs and storage limitations.

Warranty Coverage Evaluation

Standard material warranties cover manufacturing defects but exclude installation-related failures and normal weathering. You need clarity on what constitutes a warrantable defect versus expected performance variation. Spalling that occurs within 24 months typically indicates material quality issues, while color fading over 5-7 years represents normal aging. Your supplier’s warranty terms should specify replacement obligations, not just refund policies that leave you scrambling for substitute materials mid-project.

- You should verify warranty duration extends at least 24 months from installation date

- Your warranty coverage must include replacement material and freight costs for defective units

- You’ll want exclusions clearly defined to avoid disputes over normal wear versus defects

- Your supplier should maintain adequate inventory to fulfill warranty replacements without lengthy delays

Environmental Compliance Verification

When you’re specifying imported cobble setts, verify compliance with environmental regulations that affect both quarry operations and manufacturing processes. You need documentation showing adherence to emissions standards, waste management protocols, and worker safety requirements. LEED projects require specific environmental product declarations that many suppliers can’t provide. Your specification should identify required certifications early enough to allow supplier qualification before bidding.

The carbon footprint associated with international shipping adds 15-25% to the environmental impact of imported cobble setts compared to domestic alternatives. You should calculate transportation emissions as part of your sustainability analysis, especially for projects targeting specific green building certifications. Some cobble setts suppliers usa offer regionally sourced materials that reduce transportation distances and associated emissions.

Sample Evaluation Protocol

You can’t properly assess material quality from photographs or small hand samples. You should request full-size units representing the dimensional range and finish variations you’ll encounter in production quantities. Your evaluation should include at least 12 pieces that allow you to verify color consistency, dimensional accuracy, and surface finish quality across a statistically meaningful sample size.

Field testing for slip resistance requires wet and dry measurements under conditions simulating actual use. You’ll need DCOF testing per ANSI A137.1 standards if your project involves pedestrian plaza applications or ADA compliance requirements. Laboratory test results don’t always correlate with field performance, especially for textured finishes where surface profile variation affects friction coefficients. Your sample evaluation should include on-site testing that replicates expected service conditions.

Citadel Stone Cobble Setts Across the United States

When you consider Citadel Stone’s cobble setts for your United States project, you’re evaluating manufactured stone products engineered for consistent performance across diverse climate zones. At Citadel Stone, we provide technical guidance for hypothetical applications throughout the country’s varied regions. This section outlines how you would approach specification decisions for six representative cities.

The United States presents climate challenges ranging from humid subtropical conditions to continental temperature extremes. You need cobble setts that accommodate freeze-thaw cycling in northern regions while managing thermal expansion in southern heat zones. Your material selection should account for regional soil conditions, precipitation patterns, and temperature variance that affect long-term performance.

Rhode Island Considerations

In Rhode Island applications, you would prioritize freeze-thaw resistance for installations experiencing 80-100 annual freeze cycles. Your specification should address absorption rates below 0.4% to prevent moisture-related spalling during winter months. The coastal proximity in many Rhode Island locations requires you to consider salt exposure from deicing operations, though direct marine exposure remains minimal for most inland streetscape projects. You’d typically specify 80mm thickness for vehicular applications and 60mm for pedestrian-only installations. Your base preparation would need to account for New England’s frost depth requirements, extending below 48 inches in most jurisdictions.

Delaware Specifications

Delaware installations would balance moderate freeze-thaw exposure with higher humidity levels affecting long-term color retention. You’d encounter 40-60 annual freeze cycles requiring absorption specifications below 0.5%, less stringent than northern requirements but still critical for material longevity. Your installation timing should avoid late fall and early spring when temperature fluctuations create challenging setting conditions. The mid-Atlantic clay content in Delaware soils requires you to design base systems with enhanced drainage capacity exceeding standard 4-inch aggregate depths. You would typically recommend permeable base layers extending 8-10 inches to manage subsurface moisture migration.

Louisiana Thermal Management

Louisiana’s subtropical climate shifts your focus from freeze-thaw to thermal expansion and high humidity performance. You’d specify joint spacing accommodating thermal movement coefficients applied to 95°F temperature swings during summer months. Your base preparation needs to address expansive clay soils prevalent throughout Louisiana, requiring stabilization treatments or engineered aggregate systems that resist seasonal soil movement. The high annual precipitation totaling 60+ inches demands drainage systems capable of managing intense rainfall events. You would design installations with minimum 2% slope gradients directing water away from building foundations and toward designated collection points.

Ohio Durability Requirements

Ohio projects would address continental climate extremes ranging from sub-zero winter temperatures to 90°F summer peaks. You’d encounter 60-80 annual freeze cycles requiring robust material specifications matching New England standards. Your installation schedule should avoid November through March when freeze-thaw activity creates unsuitable setting conditions. The Midwest’s alkaline soil conditions in many Ohio regions affect efflorescence potential, requiring you to specify base materials with neutral pH characteristics. You would recommend warehouse coordination ensuring material delivery aligns with optimal spring and fall installation windows when temperature stability supports proper curing.

Illinois Urban Considerations

Illinois installations, particularly in Chicago’s urban environment, would prioritize deicing salt resistance and thermal cycling durability. You’d specify premium-grade cobble setts with enhanced density characteristics resisting salt penetration during harsh winter maintenance programs. Your base system design needs to accommodate frost heave potential in northern Illinois counties where frost depth extends below 42 inches. The urban heat island effect in metropolitan areas adds 8-12°F to ambient temperatures, requiring you to account for elevated thermal expansion beyond rural baseline calculations. You would design joint spacing systems incorporating 15-20% additional expansion capacity compared to rural installations.

Michigan Performance Standards

Michigan’s Great Lakes influence creates unique moisture and freeze-thaw demands you’d address through stringent material specifications. You would require absorption rates below 0.35% for installations in counties experiencing 100+ annual freeze cycles with high ambient humidity. Your specification should address the lake-effect precipitation patterns delivering 80-120 inches of annual snowfall in western Michigan regions. The extended winter season limits your installation window to May through September for optimal curing conditions. You’d coordinate truck deliveries during dry-weather periods when site access remains reliable and base preparation can proceed without weather-related delays.

Final Selection Criteria

Your supplier selection process should weight technical capability and reliability alongside pricing considerations. You need partners who understand that successful cobble setts installations depend on material quality, delivery reliability, and ongoing support. The lowest-cost option rarely delivers the best long-term value when you factor in replacement costs, maintenance requirements, and warranty support. How to choose a cobblestone company ultimately centers on finding suppliers who demonstrate consistent quality, maintain adequate inventory, and provide technical guidance beyond order processing.

Your professional specification process requires you to balance performance requirements with budget constraints while maintaining project schedule integrity. For additional guidance on surface characteristics critical to pedestrian safety, review slip resistance and traction performance of cobble setts before you finalize project documents. Citadel Stone provides nationwide US shipping on high-strength manufactured cobble setts, ideal for long-lasting streetscapes and custom driveways.