When you specify building materials for Arizona projects, you’re dealing with one of the most chemically aggressive environments in North America. Chemical resistance building stone Arizona testing reveals how materials perform under conditions most laboratory tests never capture — acid rain combining with alkaline dust, urban pollution interacting with extreme UV exposure, and pH fluctuations that accelerate surface degradation. You need to understand these testing protocols because your material selections directly determine whether your project delivers 15-year performance or 40-year durability.

The chemistry of stone degradation in Arizona doesn’t follow textbook patterns. You’ll encounter simultaneous attack from acidic precipitation (pH 4.2-5.6 during monsoon season) and alkaline soil contact (pH 8.0-9.2 in caliche-rich substrates). This dual-front chemical assault creates failure modes that standard ASTM testing doesn’t adequately predict. Your specification process must account for these regional conditions through targeted chemical resistance building stone Arizona testing that simulates actual field exposure.

Acid Rain Composition in Arizona Climate Zones

Arizona’s acid rain chemistry differs substantially from eastern United States patterns. You’re working with lower precipitation volumes but higher pollutant concentrations per rainfall event. Phoenix metropolitan area experiences acid deposition primarily during July-September monsoon cycles, when atmospheric moisture combines with nitrogen oxides from vehicle emissions and sulfur compounds from industrial sources. The resulting pH levels range from 4.2 to 5.8, with occasional events measuring below 4.0 in urban corridors.

When you evaluate chemical resistance building stone Arizona testing protocols, you need to understand the seasonal concentration patterns. Dry deposition accumulates on stone surfaces during 9-10 month drought periods, then dissolves rapidly when monsoon rains arrive. This creates acid concentrations on material surfaces that exceed the pH of rainfall itself — sometimes reaching effective pH levels of 3.5-4.0 as deposited compounds dissolve. Your testing methodology should replicate this cyclic exposure pattern rather than continuous immersion scenarios.

The chemical composition of Arizona acid rain includes higher nitrate-to-sulfate ratios compared to industrial eastern regions. You’ll find NO₃/SO₄ ratios frequently exceeding 2:1, driven by vehicle emissions rather than coal combustion. This affects stone testing because nitric acid attacks calcium-based stones differently than sulfuric acid — penetrating deeper into pore structures and creating more extensive subsurface damage before visible surface deterioration appears.

Atmospheric Pollutants Driving Urban Stone Degradation

Urban Arizona environments expose building stone to pollutant combinations that accelerate chemical degradation beyond acid rain alone. You need to account for particulate matter deposition, ozone exposure, and nitrogen dioxide concentrations when you specify materials for metropolitan projects. Building stone suppliers in Arizona durability testing must incorporate these multi-pollutant scenarios to predict realistic performance.

Particulate matter in Phoenix, Tucson, and other urban centers carries chemically active compounds that catalyze stone deterioration. PM2.5 and PM10 particles deposit on stone surfaces, creating microsites where moisture retention extends chemical reaction periods. When you examine building stone suppliers in Arizona durability testing results, look for protocols that include particulate loading followed by acid exposure — this sequence reveals vulnerabilities that clean acid immersion tests miss entirely.

Ozone concentrations in Arizona cities reach 0.08-0.12 ppm during summer months, levels that oxidize certain mineral components in natural stone. Your material evaluation should include ozone exposure testing for stones containing iron compounds, as oxidation creates surface discoloration and structural weakening that appears 3-5 years before acid-related damage becomes visible. Natural building stone suppliers in Arizona chemical tests should document ozone resistance for any material specified in urban applications.

Chemical Testing Protocols and Industry Standards

Standard chemical resistance testing follows ASTM C267 (Chemical Resistance of Mortared Masonry) and ASTM C650 (Resistance of Ceramic Tile to Chemical Substances), but these protocols inadequately address natural building stone performance in Arizona conditions. You’ll achieve more accurate predictions using modified testing sequences that incorporate regional environmental factors. Architectural stone suppliers in Arizona pollution resistance documentation should reference these enhanced protocols.

- You should require cyclic immersion testing rather than continuous submersion, with 12-hour wet cycles followed by 36-hour drying periods at 105°F

- Your test solutions need pH adjustment to match regional acid rain composition, typically pH 4.5 with 2:1 nitrate-to-sulfate ratios

- You must include alkaline exposure phases representing soil contact, using pH 8.5-9.0 solutions to simulate caliche interaction

- You need elevated temperature testing at 120-140°F surface temperatures to replicate summer solar heating effects on chemical reaction rates

- Your protocols should incorporate UV exposure between acid cycles, as photochemical reactions alter surface chemistry

When you review natural building stone suppliers in Arizona chemical tests, examine the duration of accelerated testing. Laboratory protocols typically compress 20-30 years of field exposure into 90-180 day testing cycles. The correlation between accelerated testing and actual performance depends heavily on how accurately test conditions match field exposure patterns specific to Arizona’s climate.

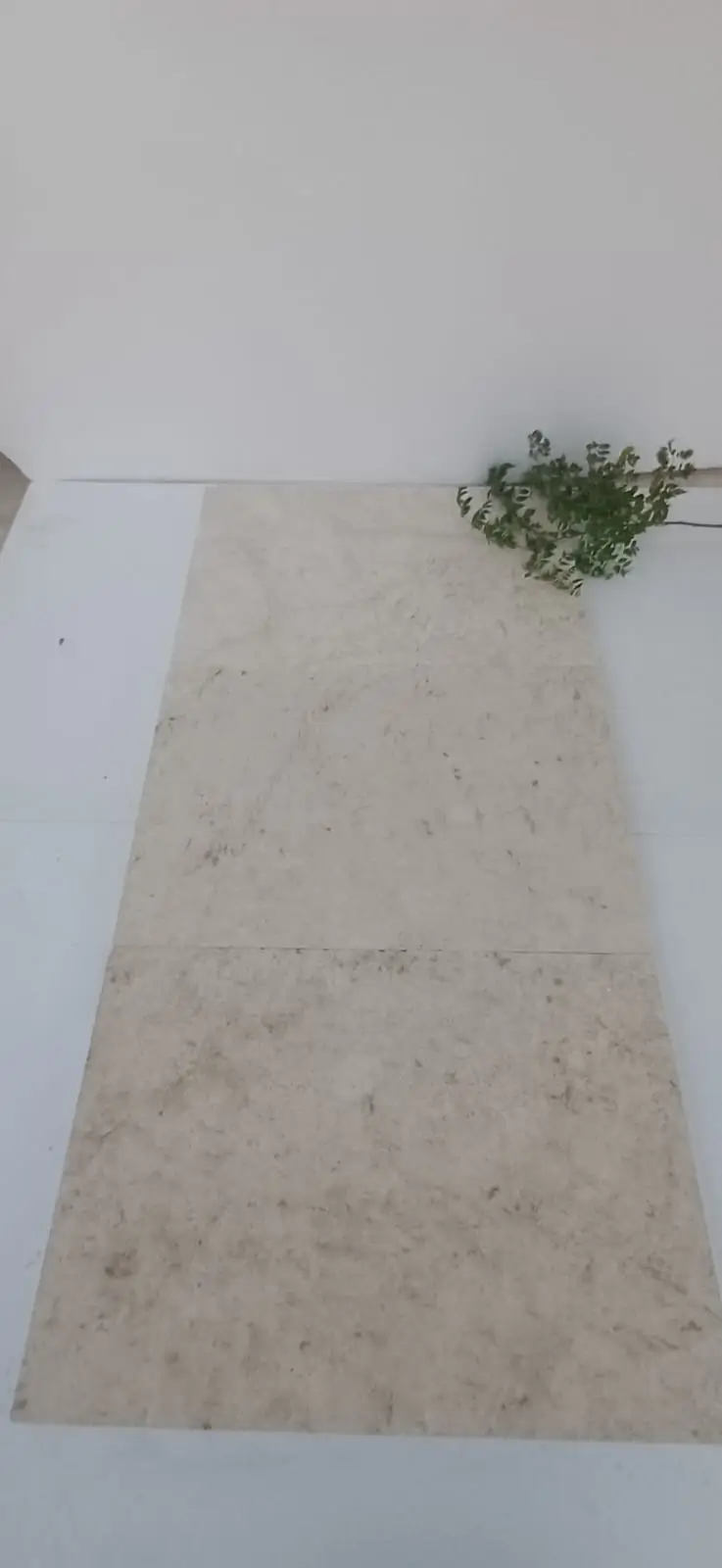

Calcium Carbonate Stone Vulnerability to Acid Attack

Limestone, travertine, and marble contain calcium carbonate (CaCO₃) that reacts directly with acidic solutions through the equation: CaCO₃ + H₂SO₄ → CaSO₄ + H₂O + CO₂. You can expect measurable surface recession rates of 0.8-1.5 mm per decade in urban Arizona environments when you specify these materials without protective treatments. Chemical resistance building stone Arizona testing consistently shows calcium carbonate stones as highest-risk materials for acid-exposed applications.

The reaction kinetics accelerate dramatically when surface temperatures exceed 100°F. Your summer installations will experience chemical attack rates 3-4 times faster than the same material in temperate climates. When you evaluate architectural stone suppliers in Arizona pollution resistance data, pay particular attention to testing performed at elevated temperatures — room-temperature testing underestimates real-world degradation by 60-70%.

Porosity amplifies acid damage in calcium carbonate stones. Materials with interconnected pore structures above 5% allow acid solutions to penetrate 8-12 mm below the surface, creating subsurface gypsum formation that eventually spalls. You should specify chemical resistance building stone Arizona testing that includes depth-of-penetration analysis, not just surface appearance evaluation. For related considerations on material integrity, review our custom natural stone in Tempe for structural performance specifications.

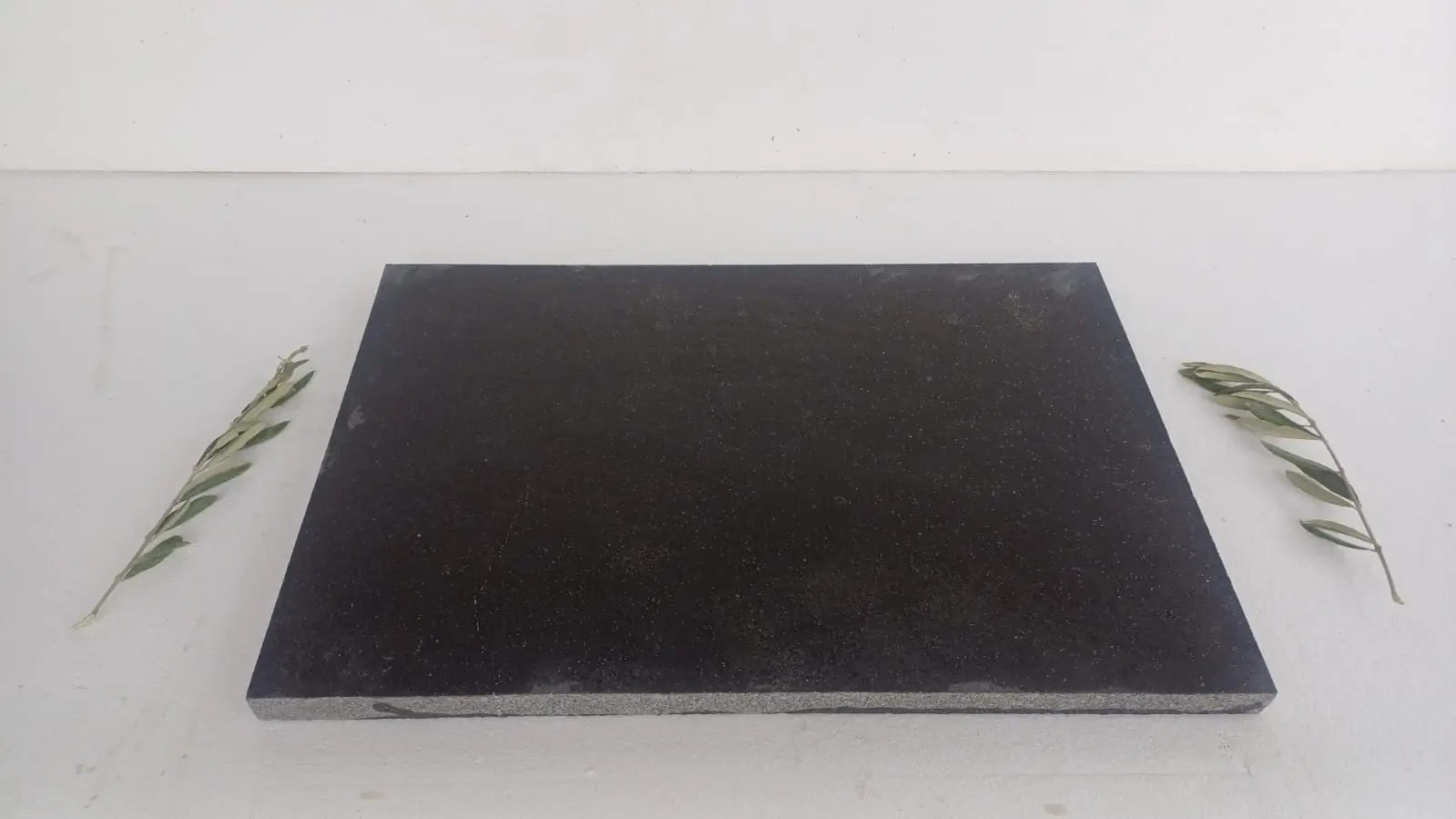

Silicate Stone Chemical Resistance Characteristics

Granite, quartzite, and silicate-based stones demonstrate superior acid resistance compared to carbonate materials. You’re working with silicon dioxide (SiO₂) matrices that don’t react with typical environmental acids at normal temperatures. Natural stone wholesale suppliers Arizona testing shows surface recession rates below 0.1 mm per decade for properly selected silicate stones in urban acid exposure conditions.

However, you need to understand that silicate stones aren’t universally acid-proof. Feldspars and mica components within granite compositions can undergo chemical weathering when exposed to pH below 4.0 combined with elevated temperatures. Your specification should require mineralogical analysis showing quartz content above 60% and feldspar content below 25% for highest-confidence acid resistance performance.

The intergranular bonding in silicate stones determines long-term chemical resistance more than bulk composition. When acid solutions penetrate grain boundaries, they can dissolve cement minerals and create granular disaggregation even when primary minerals remain stable. You should verify that natural stone wholesale suppliers Arizona testing includes micro-structural examination after chemical exposure, documenting whether grain bonding remains intact.

Sandstone Chemical Performance Variables

Sandstone performance under chemical exposure varies dramatically based on cement composition. You’ll encounter silica-cemented, carbonate-cemented, iron oxide-cemented, and clay-cemented varieties — each responding differently to acid and pollutant exposure. Chemical resistance building stone Arizona testing must identify cement type before performance predictions have validity.

Silica-cemented sandstones provide excellent acid resistance comparable to granite. You can expect minimal deterioration in urban Arizona environments when silica cement comprises the intergranular bonding. However, you need to verify cement composition through petrographic analysis — visual inspection cannot reliably distinguish cement types. Building stone suppliers in Arizona durability testing should include thin-section microscopy documenting cement mineralogy.

Carbonate-cemented sandstones fail rapidly under acid exposure. The calcium carbonate cement dissolves preferentially, leaving sand grains with no structural bonding. You’ll observe surface friability within 5-8 years in urban Arizona installations when you specify carbonate-cemented varieties. Your testing protocol should include cement dissolution analysis, measuring weight loss and strength reduction after acid cycling.

Iron oxide cements create moderate acid resistance but suffer oxidation problems. When you specify these materials, you’re accepting gradual rust staining and surface discoloration as inevitable outcomes. The chemical resistance building stone Arizona testing data shows structural integrity remains acceptable, but aesthetic degradation becomes objectionable within 10-15 years in polluted urban environments.

Surface Treatment Options for Chemical Protection

Penetrating sealers provide measurable improvement in chemical resistance for porous stones. You’ll achieve 60-80% reduction in acid penetration depth when you apply silane or siloxane treatments to properly prepared surfaces. However, you need realistic expectations about treatment longevity — reapplication intervals of 3-5 years are standard for Arizona exposure conditions, not the 10-15 year durability some manufacturers claim.

- You should specify penetrating treatments rather than film-forming coatings for building stone applications, as films delaminate under thermal cycling

- Your surface preparation must include acid washing and neutralization before sealer application, removing alkaline construction residues

- You need to verify that warehouse stock has been stored in covered conditions, as UV-degraded surfaces accept sealers poorly

- Your application timing should avoid periods when surface temperatures exceed 90°F, as excessive heat causes premature solvent evaporation

- You must plan reapplication access into building maintenance programs, as inaccessible surfaces will eventually lose protection

Surface densifiers containing lithium silicate react with calcium hydroxide in cement-based stones to form additional calcium silicate hydrate. When you treat limestone or travertine with these products, you’re creating a harder, less permeable surface layer with improved acid resistance. Natural building stone suppliers in Arizona chemical tests demonstrate 40-50% reduction in acid attack rates for densifier-treated carbonate stones.

Long-Term Performance Monitoring Methods

Accelerated laboratory testing provides initial material screening, but you need field performance data to validate long-term durability predictions. Your specification should include provisions for periodic condition assessment at 3-year, 7-year, and 15-year intervals. Architectural stone suppliers in Arizona pollution resistance warranties often depend on documented maintenance compliance, making performance monitoring contractually important.

Surface recession measurement using comparator gauges provides quantitative degradation data. You’ll establish baseline surface profiles immediately after installation, then measure recession depth at inspection intervals. Recession rates above 0.5 mm per 5-year period indicate accelerated deterioration requiring intervention. This measurement approach works for building stone suppliers in Arizona durability testing validation in actual projects.

Petrographic examination of core samples reveals subsurface chemical attack before surface deterioration becomes visible. When you extract 25 mm diameter cores at monitoring intervals, thin-section microscopy documents mineral alteration, cement dissolution, and pore structure changes. This technique identifies developing problems 5-10 years before structural concerns arise, allowing preventive treatment rather than expensive remediation.

Material Selection Decision Framework for Chemical Exposure

Your material selection process should follow a risk-based decision framework that balances chemical resistance requirements against other performance factors. Chemical resistance building stone Arizona testing provides one data input, but you’re simultaneously evaluating thermal performance, slip resistance, aesthetic requirements, and budget constraints. The framework below guides material selection for chemically aggressive Arizona environments.

- You should classify exposure severity as low, moderate, or high based on urban pollution levels and maintenance accessibility

- Your low-exposure applications (residential, suburban) accept carbonate stones with standard sealer protection

- You need moderate chemical resistance (commercial urban, high-traffic) requiring silicate stones or treated carbonates with verified performance data

- You must specify high-resistance materials (industrial, critical infrastructure) using only silica-cemented sandstones or granite with documented acid immersion testing

- Your budget analysis should include lifecycle costs incorporating sealer reapplication and eventual replacement timing

When you evaluate natural building stone suppliers in Arizona chemical tests, weight the testing protocols based on how closely they match your specific project conditions. Testing at pH 3.0 provides excessive conservatism for typical urban environments but appropriate rigor for industrial applications. Your specification should reference test conditions matching anticipated field exposure severity.

Maintenance Program Design for Chemical Resistance

Even chemically resistant materials benefit from maintenance programs that remove deposited pollutants before they concentrate and create aggressive local chemistry. You should develop maintenance protocols appropriate to material type and exposure severity. Natural stone wholesale suppliers Arizona testing includes maintenance effectiveness studies showing properly designed programs extend service life by 40-60%.

Periodic washing with pH-neutral cleaners removes deposited pollutants before acid concentration occurs. Your maintenance schedule should specify quarterly washing for urban high-traffic areas, semi-annual washing for moderate exposure, and annual washing for low-exposure applications. The washing removes particulate matter and soluble salts before monsoon rains activate them into concentrated acid solutions.

You need to neutralize acid deposits when pH testing reveals surface acidity. Dilute alkaline washes (pH 9-10) neutralize acid compounds without damaging stone, but you must thoroughly rinse afterward to prevent alkaline salt deposition. Your maintenance specifications should include pH testing protocols and neutralization trigger points, typically when surface pH drops below 6.0.

Specification Language for Chemical Resistance Requirements

Your project specifications must translate chemical resistance requirements into clear, enforceable language that contractors and suppliers understand. Vague requirements like “chemically resistant stone” create disputes and potential failures. The specification framework below provides actionable language for Arizona projects requiring verified chemical resistance building stone Arizona testing compliance.

Material submittals should include laboratory testing from ASTM-accredited facilities documenting specific performance criteria. You should require testing per modified ASTM C267 with Arizona-specific environmental parameters: pH 4.5 nitric/sulfuric acid mixture, cyclic exposure at 120°F surface temperature, 180-day accelerated exposure equivalent to 25-year field performance. Acceptance criteria specify maximum 2% weight loss, maximum 5% strength reduction, and maximum 0.3 mm surface recession.

Your specifications need to address both material inherent resistance and applied protection systems. When you permit carbonate stones in moderate-exposure applications, specify penetrating sealer treatment with manufacturer’s certification of chemical resistance improvement. Include reapplication schedule requirements and assign maintenance responsibility clearly in specification Division 01.

Best Building Stone Suppliers in Arizona: How Citadel Stone Specifies for Arizona Cities

When you consider Citadel Stone’s building stone suppliers in Arizona capabilities for your project, you’re evaluating materials specifically selected for chemical resistance in Arizona’s unique exposure conditions. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse urban and suburban environments. This section outlines how you would approach chemical resistance considerations for six representative cities, each presenting distinct pollutant exposure profiles and climatic factors affecting stone durability.

Phoenix Urban Exposure

In Phoenix, you’re specifying for Arizona’s highest pollution concentration and most aggressive urban chemistry. The metropolitan area’s 4.9 million residents generate nitrogen oxide levels reaching 0.08 ppm during peak traffic periods, creating acid deposition patterns that accelerate stone degradation. Your material selection would prioritize silicate-based stones with documented resistance to pH 4.5 acid exposure at 130°F surface temperatures. You should account for the urban heat island effect that elevates chemical reaction rates by 25-30% compared to suburban locations. Warehouse inventory planning would need to accommodate 8-12 week lead times for premium chemical-resistant materials meeting Phoenix project specifications.

Tucson Desert Conditions

Tucson applications would require you to address unique dust chemistry combinations affecting chemical resistance building stone Arizona testing interpretation. The surrounding Sonoran Desert contributes alkaline dust with pH 8.5-9.0 that deposits on stone surfaces between monsoon events. When you specify materials here, you need resistance to both acid precipitation and alkaline dust contact — a dual-chemistry challenge that eliminates some material options suitable for Phoenix. Your testing protocols would include alternating acid and alkaline exposure cycles simulating the seasonal pattern. Natural building stone suppliers in Arizona chemical tests specific to Tucson conditions should document performance under this pH cycling scenario.

Scottsdale Specification Priorities

For Scottsdale projects, you would balance chemical resistance requirements with aesthetic expectations for high-end residential and commercial applications. The city’s air quality remains better than central Phoenix, allowing broader material consideration while maintaining durability standards. Your specifications would permit sealed carbonate stones in protected locations (covered entries, shaded courtyards) while reserving silicate materials for full-exposure applications. You should require building stone suppliers in Arizona durability testing demonstrating minimum 25-year projected performance under moderate urban exposure conditions. Project scheduling would account for sealer application requiring 48-72 hours of dry weather, challenging during monsoon season.

Mesa Applications

Mesa’s position in the eastern Phoenix metropolitan area creates moderate pollution exposure with occasional dust events from surrounding agricultural areas. When you specify materials here, you’re addressing standard urban acid rain chemistry plus periodic agricultural chemical exposure from airborne spray drift. Your material selection would emphasize stones with verified resistance to both environmental acids and agricultural chemicals including fertilizers and pesticides. Architectural stone suppliers in Arizona pollution resistance documentation should address this multi-contaminant scenario. You would specify surface treatments providing protection against both acid attack and organic chemical penetration, typically requiring hybrid sealer formulations.

Flagstaff Climate Factors

Flagstaff applications present you with dramatically different chemical resistance challenges compared to desert cities. At 7,000 feet elevation, you’re dealing with higher precipitation volumes, more frequent freeze-thaw cycles, and lower pollution concentrations. Your chemical resistance building stone Arizona testing interpretation needs adjustment for the cooler, wetter climate where acid exposure occurs more frequently but at lower temperatures. The reduced chemical reaction rates at cooler temperatures partially offset the increased moisture exposure. You would prioritize stones with combined chemical resistance and freeze-thaw durability, as the interaction between acid attack and ice formation accelerates degradation beyond either factor alone.

Sedona Aesthetic Integration

Sedona specifications would require you to integrate chemical resistance requirements with strict aesthetic controls matching the region’s distinctive red rock landscape character. Your material palette becomes constrained to sandstones and similar materials complementing natural surroundings, eliminating granite and other visually incompatible options. You should verify that specified sandstones contain silica cement rather than carbonate or iron oxide cement, ensuring chemical durability matches aesthetic requirements. Natural stone wholesale suppliers Arizona testing becomes critical here, as visual similarity to red rock formations doesn’t guarantee chemical resistance. You would specify petrographic analysis confirming cement composition before approving aesthetically appropriate materials for installation.

Performance Expectations and Realistic Outcomes

When you specify chemically resistant building stone based on Arizona testing protocols, you need realistic expectations about long-term performance. No natural stone provides absolute immunity to chemical attack — you’re managing degradation rates to achieve acceptable service life, not preventing deterioration entirely. Chemical resistance building stone Arizona testing predicts performance trends, not guarantees.

Properly selected silicate stones in typical urban Arizona environments should deliver 40-60 year service life with minimal visible degradation. You’ll observe gradual dulling of polished finishes and minor surface texture changes, but structural integrity and functionality remain intact. Your lifecycle cost analysis should assume no major intervention required during this timeframe beyond routine cleaning and sealer reapplication.

Sealed carbonate stones in moderate-exposure applications provide 20-30 year acceptable performance when you implement recommended maintenance programs. You should anticipate visible surface etching becoming apparent after 15-20 years, requiring aesthetic judgment whether appearance remains acceptable. Your specifications should address replacement trigger criteria, typically defined as surface recession exceeding 2 mm or compressive strength reduction exceeding 20%.

Unsealed carbonate stones in high-exposure urban environments fail within 10-15 years. When you specify these materials without protection, you’re accepting replacement as part of lifecycle planning. The initial cost savings rarely justify the eventual replacement expense and disruption, making this approach appropriate only for temporary installations or applications where weathered appearance becomes desirable patina.

Key Takeaways

Your approach to chemical resistance building stone Arizona testing interpretation determines whether specifications deliver intended performance or create premature failure problems. You need testing protocols that match Arizona’s specific environmental conditions — not generic standards developed for different climates. The dual chemistry of acid rain and alkaline soil contact creates unique degradation patterns requiring specialized material evaluation.

Material selection follows risk-based decision frameworks balancing chemical resistance against other performance requirements and budget realities. You’ll specify high-resistance silicate stones for critical long-life applications, moderate-resistance sealed materials for standard commercial work, and accept higher-maintenance options only when aesthetic requirements dictate material choices that compromise chemical durability. Your specifications must translate performance requirements into clear, enforceable language with objective acceptance criteria.

Long-term success depends on maintenance program implementation matching material capabilities and exposure severity. Even the most chemically resistant stones benefit from pollutant removal and periodic resealing. When you integrate testing, specification, and maintenance into comprehensive material management programs, you’ll achieve the 40-60 year service life that justifies natural stone investment. For complementary information on material performance factors, examine Stone density and porosity influence sound absorption performance when finalizing your specifications. Citadel Stone offers design consultation as comprehensive custom natural stone supplier in Arizona services.