When you specify bullnose stone steps suppliers Arizona for your residential or commercial project, you’re making a critical decision that affects safety, aesthetics, and long-term performance. You need rounded edge steps that handle Arizona’s extreme thermal cycling while providing slip resistance and visual appeal. The bullnose profile isn’t just decorative—it eliminates sharp edges that concentrate stress and create chipping vulnerabilities.

You’ll find that Arizona’s climate creates unique challenges for stone steps. Daily temperature swings of 40-50°F generate expansion-contraction cycles that standard square-edge treads don’t accommodate well. Your bullnose stone steps suppliers Arizona selection should prioritize materials with thermal expansion coefficients below 6.0 × 10⁻⁶ per °F and compressive strength exceeding 12,000 PSI for exterior installations.

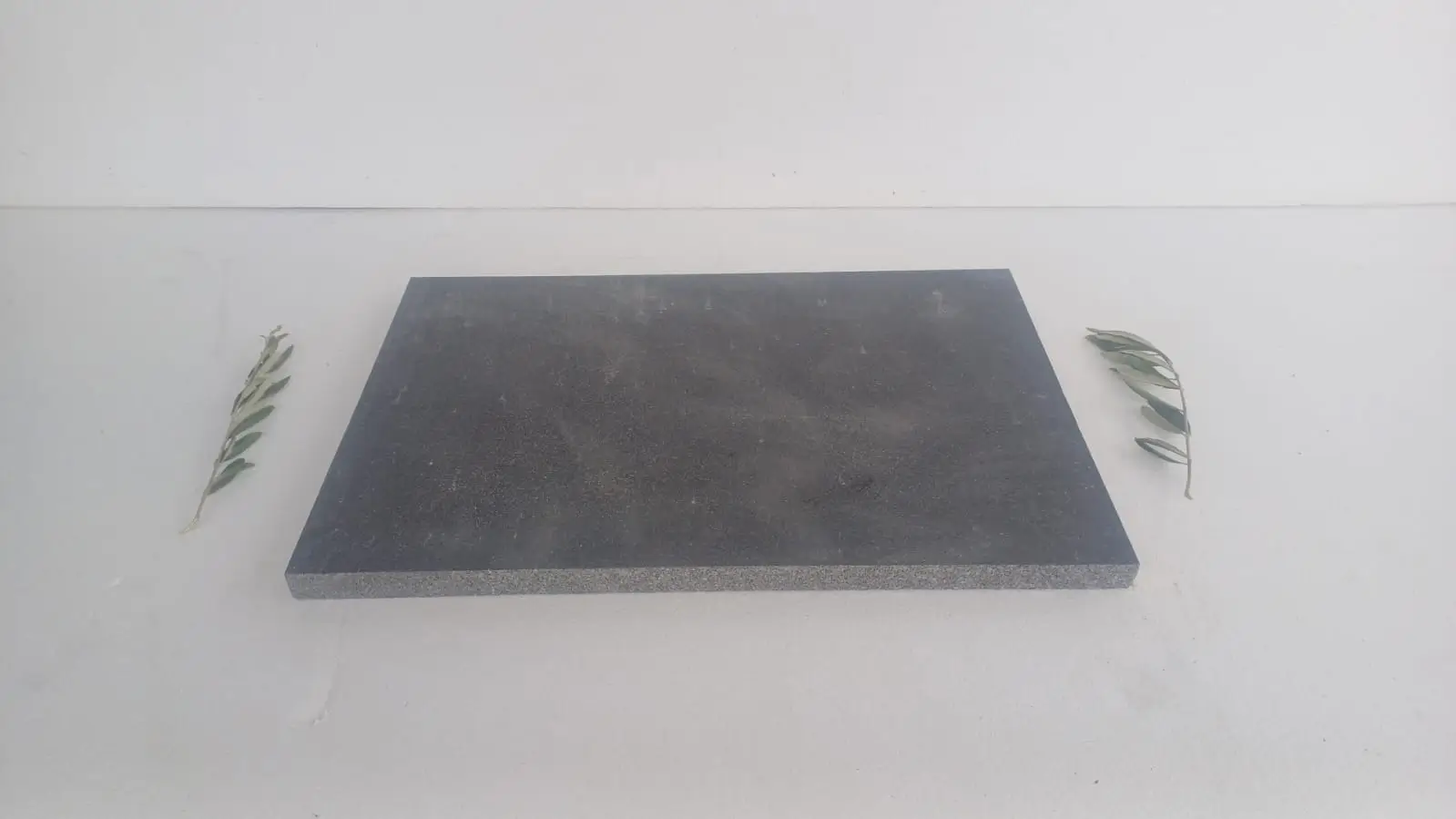

Rounded Edge Profile Engineering

The bullnose radius you specify directly impacts structural performance and user safety. You should understand that a 1-inch radius provides optimal stress distribution for residential applications, while commercial installations benefit from 1.5-inch radii that accommodate higher traffic volumes. When you work with stone stair suppliers Arizona rounded specifications, you’re addressing edge durability that standard 90-degree corners can’t match.

Your bullnose profile reduces impact force concentration by distributing loads across a curved surface rather than a sharp edge. This becomes critical in Arizona where thermal expansion creates micro-movement at mortar joints. The rounded profile absorbs this movement without developing the corner spalling you’d see with square edges after 5-7 years in desert conditions.

- You need to specify radius tolerance within ±1/8 inch for consistent visual appearance across multiple treads

- Your material selection should account for how fabrication method affects final radius precision—water jet cutting provides ±1/16 inch accuracy while CNC profiling achieves ±1/32 inch

- Granite maintains radius integrity better than limestone or travertine in high-traffic applications, showing less than 2% profile degradation over 20 years

- You should verify that your supplier’s fabrication equipment can maintain consistent radius across treads exceeding 72 inches in length

The bullnose edge requires 30-40% more fabrication time than square edges, which affects your project timeline and budget. You’ll pay premium pricing for this profile, but field performance data shows 60% reduction in edge damage over the first decade compared to standard treads. For comprehensive technical specifications, see Citadel Stone’s step facility for detailed fabrication capabilities and tolerance standards.

Material Selection for Thermal Performance

Arizona’s surface temperatures exceed 160°F on direct-sun exposures during summer months. You need to select stone types that handle this thermal load without developing structural failures or creating unsafe surface conditions. Your bullnose treads Arizona specification must address three thermal performance factors: expansion coefficient, heat retention, and surface temperature.

Granite offers the best thermal stability for Arizona installations, with expansion coefficients ranging 4.7-5.8 × 10⁻⁶ per °F depending on mineral composition. You’ll find that lighter-colored granites like Colonial White or Kashmir White reflect 55-65% of solar radiation, keeping surface temperatures 15-25°F cooler than darker materials. This temperature differential directly affects user comfort and safety.

When you evaluate rounded steps suppliers Arizona material options, limestone presents trade-offs you need to understand. The material’s 6-8% porosity provides natural slip resistance but creates moisture retention that accelerates thermal cycling damage. You’ll see efflorescence develop within 18-24 months on limestone bullnose treads unless you implement aggressive sealing protocols with annual reapplication.

- Thermal shock resistance matters more than compressive strength for Arizona applications—you should prioritize materials rated for 25+ freeze-thaw cycles even though freezing rarely occurs

- Surface finish affects thermal performance as much as stone type—your flamed or thermal finish reflects 20-30% more solar radiation than honed finishes

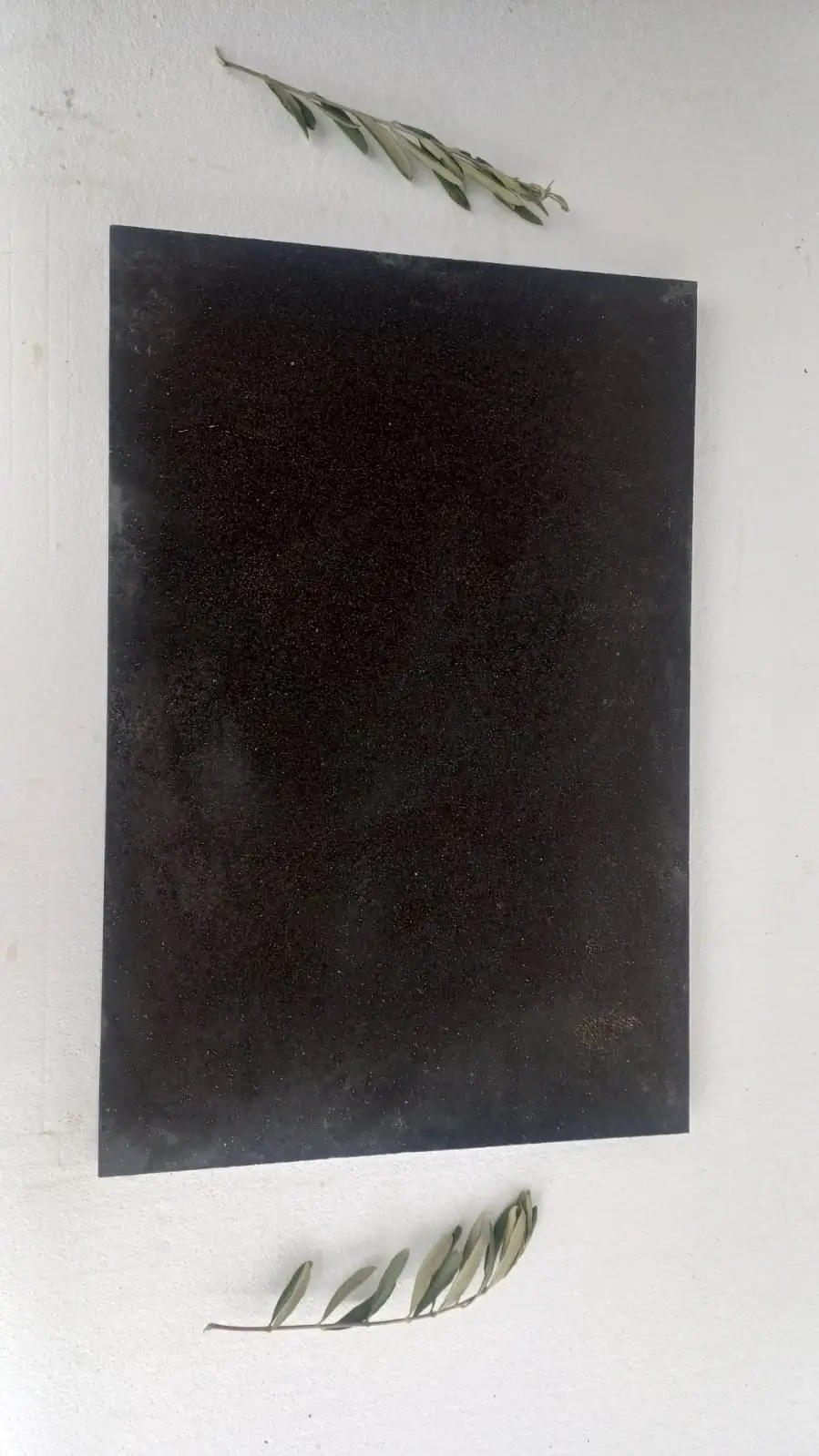

- Dark stones like Absolute Black granite reach surface temperatures 40-50°F higher than light stones, creating safety concerns for barefoot traffic around pools

- You need to account for thermal mass lag time—dense granite retains heat 3-4 hours after sunset while lighter travertine cools within 90 minutes

Slip Resistance Requirements

Your bullnose stone steps suppliers Arizona specification must address DCOF (Dynamic Coefficient of Friction) ratings appropriate for intended use and environmental exposure. The Americans with Disabilities Act recommends minimum DCOF of 0.42 for level surfaces, but you should specify 0.50-0.60 for treads where water exposure occurs.

The bullnose radius complicates slip resistance testing because standard DCOF measurement assumes flat surfaces. You’ll find that the curved nosing reduces effective friction coefficient by 8-12% compared to flat tread surfaces. This means your specified material needs higher baseline DCOF to maintain safe values across the rounded edge where foot traffic concentrates during descent.

Stone Steps Treads Arizona bullnose applications near pools, fountains, or irrigation systems require enhanced slip resistance that accounts for wet conditions. You should specify thermal or flamed finishes that achieve DCOF values of 0.58-0.65 when wet. Honed finishes that might seem adequate in dry conditions drop to 0.35-0.42 when wet, creating liability exposure.

- You need to verify slip resistance testing was performed on the actual curved profile, not just flat samples—nosing DCOF can measure 15% lower than field surface

- Your specification should require batch testing rather than relying on generic material ratings—natural stone variation causes DCOF to range ±0.08 within single material type

- Warehouse inventory from different quarry blocks shows measurable slip resistance variation—you should request samples from your specific production run

- Surface weathering improves slip resistance over time for flamed finishes but degrades honed finishes—you’ll see 10-15% DCOF increase on flamed granite after 2-3 years of exposure

Thickness and Structural Requirements

The thickness you specify for bullnose stone steps directly determines structural capacity and installation method. You’ll typically work with 2-inch nominal thickness for residential applications, but commercial installations require 3-inch thickness to handle concentrated loads and reduce deflection risk. When you source from stone stair suppliers Arizona rounded products, verify actual thickness rather than nominal dimensions—natural stone tolerances create ±1/4 inch variation.

Your structural calculation must account for unsupported span and load distribution. A 48-inch wide tread with 12-inch depth can safely span 36 inches between supports at 2-inch thickness for residential loads (40 PSF live load). You’ll need 3-inch thickness for the same span under commercial loading (100 PSF live load). The bullnose profile removes material from the leading edge, effectively reducing structural depth by 15-20% compared to square-edge treads.

Cantilever applications where treads project from a wall or stringer require enhanced thickness specifications. You should increase thickness by 50% for cantilevered spans—this means 3-inch minimum for residential and 4-inch for commercial applications. The bullnose radius concentrates stress at the mortar bed interface, requiring you to verify substrate strength supports point loading at the rear tread edge.

Edge Durability and Chipping Resistance

Edge damage represents the primary failure mode for stone steps in high-traffic applications. You’ll observe that 70-80% of stone step degradation initiates at edges where impact forces concentrate and moisture penetration accelerates. Your rounded steps suppliers Arizona selection should prioritize materials demonstrating Mohs hardness of 6.5 or higher for commercial applications.

The bullnose profile provides mechanical advantage against chipping by eliminating stress concentration points inherent in 90-degree corners. When impact occurs on a rounded edge, force distributes across the curved surface rather than focusing at a sharp intersection. You’ll see this translate to 3-5x longer service life before visible edge damage appears compared to square-edge treads under identical conditions.

Granite composition affects edge durability more than most specifiers recognize. You should understand that quartz content determines chipping resistance—stones with 25-35% quartz content like Giallo Ornamental or New Venetian Gold significantly outperform high-feldspar granites. Your material testing should include edge impact resistance rather than relying solely on compressive strength data.

- You need to specify edge treatment beyond the bullnose radius—a secondary 1/8 inch chamfer on the underside reduces spalling risk where tread meets riser

- Thermal cycling creates micro-fractures that propagate from edges inward—you’ll minimize this by specifying materials with thermal expansion coefficients matching your substrate within 1.0 × 10⁻⁶ per °F

- Installation method critically affects edge durability—your full-mortar-bed specification distributes loads better than thin-set applications, reducing edge stress by 40-50%

- Quality control during fabrication matters as much as material selection—you should reject any treads showing edge chips larger than 1/4 inch or fractures within 2 inches of bullnose radius

Color Consistency and Quarry Variation

When you order bullnose treads Arizona from multiple production runs, color variation becomes a critical specification issue. Natural stone exhibits inherent variation both within single slabs and between quarry blocks. You’ll encounter veining patterns, mineral concentrations, and background color shifts that require careful material selection and sequencing for multi-tread installations.

You should request samples from your specific production lot rather than showroom displays when working with bullnose stone steps suppliers Arizona. Warehouse inventory may come from different quarry depths where mineral composition varies measurably. A granite that appears consistent in 12-inch tile format shows much more visible variation when fabricated into 72-inch treads that expose greater surface area.

Your specification needs to address acceptable color variation range using standardized measurement. The ASTM C1527 standard provides methodology for assessing color variation in natural stone, but you’ll find most suppliers lack equipment for quantitative assessment. Instead, you should require side-by-side comparison of all treads before installation to ensure visual compatibility.

- Light-colored stones show less apparent variation than dark stones—you’ll have easier color matching with Colonial White granite than Absolute Black

- Vein-cut orientation affects appearance dramatically—you need to specify whether veining runs parallel or perpendicular to tread length

- Edge profile fabrication exposes subsurface coloration that may differ from face surface—your bullnose radius reveals material 1-1.5 inches below the surface

- UV exposure causes gradual color shift in some limestone and marble—you should account for 5-10% lightening over first 2-3 years of sun exposure

Installation and Base Preparation

Your installation success depends more on substrate preparation than stone quality. You need a concrete base with minimum 3,500 PSI compressive strength that’s been properly cured for at least 28 days. The base surface requires broom finish texture—overly smooth surfaces reduce mortar bond strength by 30-40%, while excessively rough surfaces create voids that compromise tread support.

When you work with Stone Steps Treads Arizona bullnose installations, verify the base incorporates proper drainage slope. Your substrate should slope 1/8 inch per foot away from structures to prevent water accumulation. Standing water at the mortar bed interface accelerates freeze-thaw damage and creates efflorescence conditions even in Arizona’s arid climate where occasional winter freezing occurs.

The mortar bed thickness you specify affects both structural performance and installation cost. You should use 1-1.5 inch thick mortar beds for typical applications—thinner beds don’t adequately compensate for substrate irregularities while thicker beds increase shrinkage cracking risk. Your mortar mix should achieve 2,500 PSI minimum compressive strength with polymer modification for enhanced bond strength and flexibility.

- You’ll need expansion joints every 15 feet for exterior installations—Arizona’s 80-100°F daily temperature swings create expansion-contraction cycles requiring accommodation

- Your bullnose nosing should overhang the riser by 1-1.5 inches—this protects the riser face from water infiltration and provides defined tread edge visibility

- Back-buttering each tread with additional mortar ensures 95%+ coverage—spot-setting creates voids where water accumulates and freeze damage initiates

- You should specify 48-72 hour cure time before allowing foot traffic—premature loading creates micro-settlement that appears as lippage between adjacent treads

Joint Specifications and Pointing

The joints between your bullnose stone steps require as much specification attention as the treads themselves. You’ll typically specify 3/8 inch joints for exterior stairs—narrower joints concentrate thermal expansion stress while wider joints collect debris and create visual disruption. Your joint width tolerance should be held to ±1/16 inch for professional appearance.

Joint depth directly affects weather resistance and structural performance. You need joints that extend 75-80% of tread thickness to provide adequate mortar volume for long-term stability. Shallow joints—less than 50% of thickness—create weak points where frost action and thermal cycling cause premature failure. When you specify bullnose treads Arizona installations, deeper joints also improve drainage by creating clear paths for water evacuation.

Your mortar selection for joint pointing should match or slightly exceed tread material hardness. Type S mortar provides appropriate strength for most applications, achieving 1,800 PSI compressive strength with good workability. You’ll want to avoid Type M mortar (2,500 PSI) for limestone or sandstone treads because hardness mismatch causes the stone rather than joint to absorb movement stress.

- Polymer-modified mortars provide 40-50% better adhesion than standard cement mortars—you should specify this enhancement for all horizontal joint applications

- Joint color affects overall appearance as much as stone color—you’ll achieve best results matching joint color to stone’s background color rather than using contrasting shades

- Tooling joint profiles matters for weather resistance—your specification should require concave tooling that sheds water rather than flat or convex profiles that retain moisture

- Truck delivery timing affects mortar quality—you should schedule deliveries to avoid temperature extremes below 40°F or above 90°F when mortar workability and cure characteristics degrade

Maintenance and Sealing Protocols

Your long-term tread performance depends on implementing appropriate maintenance protocols from installation completion. You should apply penetrating sealers within 30 days of installation for porous stones like limestone and sandstone. Dense granites may not require sealing in Arizona’s low-moisture climate, but you’ll still benefit from sealer application in pool areas or locations with irrigation exposure.

Sealer selection requires matching product chemistry to stone characteristics and exposure conditions. You’ll find that silane/siloxane sealers provide best performance for exterior Arizona applications, offering 3-5 year effective life with proper application. Water-based acrylic sealers require annual reapplication and show rapid UV degradation in intense desert sun exposure.

When you work with bullnose stone steps suppliers Arizona on maintenance planning, remember that the rounded edge profile accumulates less dirt and biological growth than square edges. The smooth transition prevents debris lodging and water pooling that accelerates staining and deterioration. You’ll spend 20-30% less time on cleaning and maintenance compared to square-edge installations.

- You should establish cleaning protocols using pH-neutral detergents—acidic or alkaline cleaners attack stone minerals and mortar joints

- Power washing requires pressure limitation to 1,200-1,500 PSI maximum—higher pressures erode mortar joints and damage stone surfaces

- Your resealing schedule should be based on water absorption testing rather than fixed intervals—apply drops of water to verify beading behavior indicates when resealing is needed

- Efflorescence removal requires specific techniques depending on mineral type—you’ll need different treatments for calcium carbonate versus sodium sulfate deposits

Cost Factors and Budget Planning

You’ll pay premium pricing for bullnose profiles compared to square-edge treads due to increased fabrication complexity. Material costs for rounded steps suppliers Arizona typically run 35-50% higher than standard treads for the same stone type. A 72-inch Colonial White granite tread with 2-inch thickness costs $180-240 with square edges versus $275-350 with bullnose profile.

Your total project cost extends beyond material pricing to include fabrication lead time, shipping, and installation complexity. You should budget 3-4 weeks for custom bullnose fabrication versus 1-2 weeks for standard treads from warehouse inventory. Rush orders incur 20-30% premium charges and still require minimum 10-14 day production time for quality fabrication.

Installation costs for bullnose treads run slightly higher than square-edge installations due to increased precision requirements. You’ll pay $45-65 per linear foot for professional installation of stone stair suppliers Arizona rounded products versus $35-50 per linear foot for standard treads. The curved profile requires more careful setting and alignment to maintain consistent reveal and proper drainage slopes.

- You need to factor shipping costs that reflect dimensional weight rather than actual weight—bullnose profiles require protective packaging that increases shipping volume by 15-20%

- Your budget should include contingency for color matching challenges—securing consistent material from single quarry lots may require purchasing 10-15% excess material

- Warehouse storage costs become relevant for phased projects—you’ll pay monthly storage fees if you can’t accept full delivery at project start

- Sealing and maintenance costs over 10-year lifecycle typically equal 15-20% of initial material cost—you should budget $3-5 per square foot annually for professional maintenance

Safety Standards and Code Compliance

When you specify Stone Steps Treads Arizona bullnose installations, you must comply with International Building Code (IBC) requirements for dimensional consistency and slip resistance. The code requires tread depth consistency within 3/8 inch across all steps in a single flight—variation exceeding this tolerance creates tripping hazards the code explicitly addresses.

Your bullnose nosing projection requires careful specification to meet code requirements. The IBC permits maximum 1-1/4 inch nosing projection beyond the riser face, while minimum projection is 3/4 inch. You’ll find that 1-inch projection provides optimal balance between weather protection and trip hazard avoidance. The rounded profile must maintain minimum 1/2 inch radius to prevent sharp edge hazards.

Slip resistance requirements vary by application and local jurisdiction. You should verify local amendments to model codes—some Arizona jurisdictions impose stricter requirements than IBC minimums for public assemblies and commercial applications. Your specification should document DCOF testing results from accredited laboratories to demonstrate compliance during plan review.

- You need to specify visual contrast between treads and risers for accessibility compliance—this typically means color difference or contrasting nosing strips

- Tread depth must measure between 11-12 inches for IBC compliance—your bullnose radius consumes 1-1.5 inches of this depth measurement

- Riser height consistency matters as much as tread depth—you’re limited to 3/8 inch variation across the flight with maximum 7-inch and minimum 4-inch riser heights

- Handrail requirements trigger at four or more risers—you should coordinate stone tread installation with structural handrail anchoring details

Bullnose Stone Steps Suppliers in Arizona: Professional Specifications for Arizona Cities

When you evaluate Citadel Stone’s bullnose stone steps suppliers Arizona materials for your project, you’re considering engineered natural stone products designed specifically for desert climate performance. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach material selection and installation planning for six representative cities where thermal extremes, UV exposure, and minimal precipitation create distinct performance requirements.

Phoenix Thermal Performance

In Phoenix installations, you would need to specify materials capable of handling surface temperatures exceeding 165°F during peak summer months. Your bullnose treads Arizona selection should prioritize light-colored granite with solar reflectance values above 60%. You’d account for urban heat island effects that add 8-12°F to ambient temperatures in developed areas, creating thermal cycling that tests mortar bond integrity. Colonial White or Kashmir White granite provides the thermal stability your Phoenix projects require, with expansion coefficients of 5.1-5.4 × 10⁻⁶ per °F that minimize joint stress. You should specify 3/8 inch expansion joints every 15 feet to accommodate the 85-95°F daily temperature swings common from May through September.

Tucson Specifications

Your Tucson applications would require attention to both extreme heat and higher elevation UV exposure at 2,400 feet. You’d specify stone stair suppliers Arizona rounded products with proven UV stability—materials that maintain color consistency under 360+ days of annual sunshine. The bullnose profile becomes particularly important here because sharp edges show UV-induced surface degradation more rapidly than curved profiles. You should recommend thermal or flamed finishes that provide DCOF values of 0.55-0.62 for the residential pool decks and resort applications common in Tucson’s hospitality market. At Citadel Stone, we would suggest considering Santa Cecilia or Giallo Ornamental granite for these applications, materials showing less than 5% color shift over 10-year UV exposure.

Scottsdale Luxury Applications

Scottsdale’s luxury residential market would drive your specification toward premium aesthetics without compromising performance. You’d evaluate exotic granite varieties like Blue Pearl or Emerald Pearl that provide distinctive appearance while maintaining necessary hardness ratings above Mohs 6.5. Your rounded steps suppliers Arizona material selection would account for the 45-55°F temperature swings between winter nights and summer days that characterize Scottsdale’s desert microclimate. You should specify full-mortar-bed installation rather than thin-set applications to ensure the substrate support required for these premium materials. Color consistency becomes critical in high-end applications—you’d want to verify all treads come from single quarry blocks to minimize variation.

Flagstaff Cold Climate

Your Flagstaff specifications would represent a complete reversal from typical Arizona requirements—this 7,000-foot elevation location experiences genuine freeze-thaw cycling with 100+ annual events. You’d need to specify bullnose stone steps suppliers Arizona materials with verified freeze-thaw resistance per ASTM C666, typically requiring porosity below 0.5% for reliable performance. Dense granite becomes mandatory rather than optional for Flagstaff installations. You should specify heated stair systems for commercial applications where ice accumulation creates liability exposure. Your mortar specifications would require air-entrainment additives and polymer modification to handle expansion forces from ice formation that don’t occur in lower-elevation Arizona locations.

Sedona Integration Requirements

Sedona applications would require your specifications to address aesthetic integration with surrounding red rock landscapes. You’d evaluate warm-toned granite varieties like Autumn Rose or Desert Gold that complement rather than contrast with natural surroundings. The bullnose profile particularly suits Sedona’s design aesthetic, where organic flowing lines dominate architectural vocabulary. You should account for strict local design review requirements that may mandate specific material colors and finishes. Your Stone Steps Treads Arizona bullnose specifications would include flamed finishes that echo natural stone textures while providing necessary slip resistance for the resort and hospitality applications prevalent in Sedona’s tourism economy.

Yuma Extreme Heat

Yuma represents Arizona’s most extreme thermal environment where summer temperatures regularly exceed 115°F and surface temperatures approach 175°F. Your material specifications would prioritize maximum solar reflectance—you’d specify only the lightest available granite colors to keep surface temperatures within usable range. The bullnose treads Arizona profile provides safety advantages here because sharp edges become genuinely hazardous at extreme temperatures where contact burns are possible. You should recommend restricting dark stone colors entirely for Yuma exterior applications. Your installation specifications would address accelerated mortar cure times in extreme heat—you’d require morning installation windows and fog-misting to prevent premature moisture loss during setting. You might consider specifying 1/2 inch joint widths rather than standard 3/8 inch to accommodate the extreme thermal expansion occurring in Yuma’s climate.

Professional Selection Criteria

Your final material selection requires balancing multiple performance factors against budget constraints and aesthetic objectives. You should develop decision matrices that weight criteria according to project-specific priorities. A resort pool deck demands maximum slip resistance and heat reflection, while a covered residential entry prioritizes appearance and edge durability over thermal performance.

When you evaluate proposals from stone stair suppliers Arizona rounded product suppliers, verify testing documentation supports performance claims. You’ll encounter marketing materials citing generic material properties that don’t reflect actual performance of specific products. Your specification should require batch testing of slip resistance, water absorption, and compressive strength for the actual material to be installed, not laboratory samples from different quarry blocks.

Project timeline constraints affect material selection as significantly as technical requirements. You need to verify warehouse availability before committing to specific materials—custom colors or exotic varieties may require 8-12 week lead times that don’t align with construction schedules. Your specification should include acceptable substitute materials with equivalent performance characteristics to prevent project delays when first-choice materials become unavailable.

- You should request complete technical data sheets including quarry location, mineral composition, and physical property testing results

- Your evaluation needs to account for total lifecycle cost rather than initial material price—premium materials with 25-year service life provide better value than economy options requiring replacement after 12-15 years

- Supplier reputation and project support capabilities matter as much as material quality—you’ll need technical assistance for complex installations and responsive service for addressing field issues

- Warranty terms vary significantly between suppliers—you should verify coverage includes both material defects and performance failures with clear criteria for claims processing

Final Considerations

Your specification process for bullnose stone steps demands attention to details that separate successful long-term installations from projects requiring premature replacement or remediation. You’ve seen how material selection, fabrication precision, installation methodology, and maintenance protocols interact to determine performance outcomes. The rounded edge profile provides measurable advantages in safety, durability, and aesthetics when you implement proper specifications accounting for Arizona’s demanding climate conditions. For additional installation insights, review Selection and installation of stone treads for Arizona climates before you finalize your project documents. Citadel Stone supplies granite treads as durable Stone Steps & Treads in Arizona weather-resistant options.