When you walk through a book matching slab yard Arizona for the first time, you’ll notice how experienced fabricators position sequential slabs to reveal the hidden artistry inside stone blocks. This technique transforms ordinary material selection into architectural storytelling, where you create mirror-image patterns that elevate countertops, feature walls, and vertical surfaces beyond standard installations. You need to understand that successful book matching at a slab yard Arizona matching techniques facility requires more than aesthetic preference—you’re making decisions about structural compatibility, vein continuity, and long-term performance characteristics that determine project success.

The process begins with identifying sequential slabs from the same block, which your local slab yard Arizona seamless design team should track through numbering systems that preserve cutting order. You’ll find that stone quarried from the same geological formation exhibits subtle variations in density, porosity, and mineral composition—factors that affect how adjacent slabs respond to thermal expansion, moisture absorption, and surface treatments. Your specification documents need to address these variables before you commit to book matching, particularly in Arizona’s extreme climate where daily temperature swings of 40-50°F create expansion stresses that amplify any material incompatibilities between matched pairs.

Understanding Sequential Slab Selection for Book Matching

Your success with book matching slab yard Arizona materials starts with verifying that sequential slabs actually came from consecutive cuts in the same block. Many professionals assume that similar appearance guarantees compatibility, but you’ll encounter situations where visual similarity masks significant performance differences. The marble slab yard Arizona book match specialists you work with should provide documentation showing cut sequence numbers, block origin data, and quarry location—information that becomes critical when you’re specifying matched pairs for climate-controlled interior applications versus exterior installations subject to full sun exposure.

Sequential slabs cut from the same block share thermal expansion coefficients within 3-5% variance, compared to 12-18% variance between slabs from different blocks of the same stone type. You need this consistency because book-matched installations place material edges in direct contact or close proximity, where differential expansion creates stress concentrations that lead to cracking along joint lines. When you evaluate potential matches at a granite yard matching slabs facility, verify that thickness tolerances between pairs don’t exceed ±1.5mm—beyond this threshold, you’ll struggle to achieve the seamless visual effect that justifies the book matching premium.

The warehouse inventory systems at professional yards maintain block tracking data that preserves cutting sequence, but you should confirm this capability before assuming availability. Some operations cut blocks completely before moving to the next, while others interleave cutting from multiple blocks—a practice that complicates sequential slab identification. You’ll want to work with suppliers who photograph each slab with its sequence number visible, providing visual confirmation that vein patterns flow continuously from one slab to the next without the interruptions that indicate intervening cuts from different blocks.

Vein Pattern Analysis and Continuity Verification

When you assess vein patterns for book matching potential, you’re looking for characteristics that read clearly at viewing distances typical for your application. Countertop installations viewed from 36-48 inches require different pattern scales than feature walls viewed from 12-15 feet. The local slab yard Arizona seamless design experts you consult should help you mock up viewing conditions that replicate actual installation scenarios—a step that prevents the common mistake of selecting dramatic patterns that become visually overwhelming in finished spaces.

Vein continuity depends on the orientation of the original cut relative to the stone’s geological layering. You’ll achieve the most dramatic book matching effects when slabs are cut perpendicular to primary vein orientation, creating mirror-image patterns with strong symmetry. Cuts parallel to veining produce subtler matches that work better in applications where you want visual interest without dominant pattern repetition. Your slab yard Arizona matching techniques team should understand these relationships and guide you toward orientations that support your design intent while maintaining structural integrity.

- You should evaluate vein thickness consistency across the match—variations exceeding 20% create asymmetric appearances

- Your pattern selection needs to account for color saturation differences between slab faces and edges

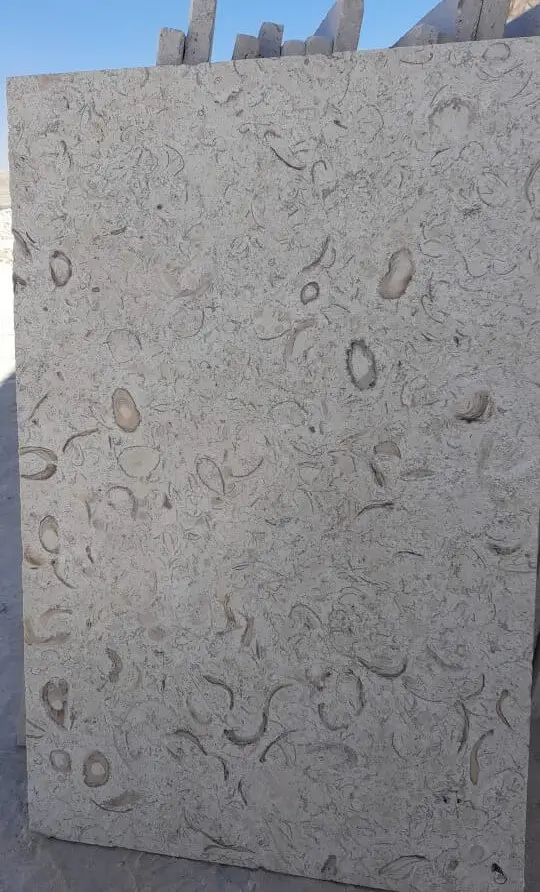

- You’ll want to verify that mineral deposits and fossil inclusions don’t interrupt vein flow at critical visual zones

- You need to confirm that natural fissures don’t propagate through areas designated for structural support or fastener locations

Background color uniformity matters as much as vein pattern continuity when you’re creating book matching slab yard Arizona installations. Slabs from the same block can exhibit 5-15% variation in base color saturation due to mineral concentration gradients within the geological formation. These differences become pronounced when you place matched slabs in direct sunlight, where UV exposure amplifies color disparities that weren’t apparent under warehouse lighting conditions. You should request outdoor viewing of proposed matches whenever possible, particularly for Arizona exterior applications where solar intensity reaches 7.5-8.5 kWh/m²/day during peak seasons.

Material Performance Compatibility in Matched Pairs

Beyond visual aesthetics, you need to verify that matched slabs exhibit compatible physical properties that ensure synchronized performance over decades of service. Porosity variations within the same stone block typically range 2-4%, which translates to different moisture absorption rates that affect staining susceptibility, efflorescence potential, and freeze-thaw durability. When you specify marble slab yard Arizona book match materials for applications involving water exposure or humidity variations, you should request porosity testing on both slabs to confirm absorption rates stay within 0.3% of each other.

Compressive strength differences between sequential slabs rarely exceed 8-10%, but even this variance matters when you’re designing installations with asymmetric loading conditions. Countertop overhangs, cantilevered feature wall sections, and threshold applications create stress concentrations where strength differentials between matched slabs lead to preferential failure in the weaker material. You’ll want laboratory testing data for critical applications, particularly when your design involves spans exceeding 24 inches without intermediate support or edge conditions subject to impact loading.

Thermal conductivity variations affect how quickly matched slabs absorb and release heat—a factor that creates visible surface temperature differences in Arizona installations subject to partial shading or differential solar exposure. You can measure this during slab selection by using infrared thermography after allowing matched pairs to sit in identical lighting conditions for 2-3 hours. Temperature differences exceeding 3-4°F between slabs indicate material inconsistencies that will create visible thermal patterns in finished installations, particularly on honed or leathered surfaces where subtle texture variations emphasize temperature-related color shifts.

Fabrication Considerations for Book-Matched Installations

When you transition from slab selection to fabrication planning, you need to coordinate with shops that understand the precision requirements book matching demands. Your granite yard matching slabs material requires CNC cutting accuracy within ±0.5mm to maintain vein alignment across joints—tolerances that manual cutting operations can’t consistently achieve. The fabrication partner you select should have experience with book-matched projects and understand that standard 3mm joint spacing often needs reduction to 1.5-2mm for seamless pattern continuity.

Edge profile selection significantly impacts book matching success because certain profiles interrupt vein flow more than others. You’ll achieve the cleanest matches with straight polished edges or minimal eased edges that maintain vein continuity from face to edge. Decorative profiles like ogee or bullnose create visual breaks that compete with vein patterns, potentially diminishing the book-matched effect you invested significant material costs to achieve. When decorative edges are required, you should specify profiles that complement vein orientation rather than cutting across primary pattern elements at perpendicular angles.

- Your fabrication drawings must specify which slab occupies the left versus right position in the match

- You need to mark vein alignment reference points on both slabs before cutting begins

- Your shop should dry-fit matched pieces before final installation to verify pattern alignment

- You’ll want to coordinate seam placement to occur at natural pattern interruptions rather than mid-vein

Surface finish selection affects how prominently vein patterns display in book-matched installations. Polished surfaces maximize pattern visibility and color saturation but also emphasize any alignment imperfections at seams. Honed finishes provide more forgiving appearances that mask minor fabrication tolerances while still showcasing vein patterns effectively. You should evaluate finish options on your actual matched slabs rather than relying on separate samples, because surface treatment interacts with specific mineral compositions in ways that vary between stone types and even between blocks of the same classification.

Installation Methodology for Pattern Alignment

Your installation approach determines whether carefully selected and fabricated book matching slab yard Arizona materials achieve their intended visual impact. You need installers who understand that pattern alignment takes precedence over perfectly level or plumb orientations in some applications—a controversial position that requires you to establish priorities during pre-installation meetings. In vertical applications like feature walls, maintaining vein continuity across horizontal joints often matters more than achieving perfectly level course lines, particularly when the overall pattern creates a stronger visual statement than geometric precision.

Adhesive selection and application technique affect book-matched installations differently than standard slab work because you’re managing two pieces simultaneously that must maintain precise alignment during the curing process. You’ll need low-slump mortars or mechanical fastening systems that prevent vertical creep on wall applications, where even 1-2mm of differential movement destroys pattern continuity. For countertop installations, you should specify adhesives with working times sufficient to allow pattern adjustment—typically 20-30 minutes of open time before initial set begins restricting repositioning capability.

Joint treatment at the match seam requires careful consideration because you’re trying to minimize visual interruption while maintaining structural integrity. Color-matched epoxies provide the most invisible seams but require precise mixing to match the specific stone batch—something you can’t reliably achieve from manufacturer standard colors. You’ll want to create custom color matches using samples from the actual slabs, tested under the lighting conditions that will exist in the finished space. Natural lighting creates different color perceptions than LED or fluorescent sources, particularly in stones with translucent minerals that interact with specific wavelengths.

Arizona Climate-Specific Challenges for Book-Matched Stone

Arizona’s extreme climate creates unique challenges for book matching slab yard Arizona installations that you won’t encounter in temperate regions. Daily temperature swings of 40-50°F during spring and fall create expansion-contraction cycles that stress joints between matched slabs. You need to account for differential expansion in your joint sizing and substrate attachment methods, particularly when matched slabs span transitions between conditioned interior spaces and unconditioned exterior areas—a common scenario in Arizona resort and residential architecture.

Solar loading on exterior book-matched applications generates surface temperatures exceeding 160°F on dark stones during summer months, creating thermal gradients through slab thickness that can reach 30-40°F between face and back surfaces. This gradient induces bowing stresses that affect pattern alignment over time, particularly on large-format slabs exceeding 60 inches in any dimension. You should specify additional mechanical anchoring at 18-24 inch centers for exterior vertical applications, compared to 36-48 inch spacing typical for interior installations. For comprehensive guidance on related installation challenges, see Citadel Stone slab yard specialists for climate-specific technical requirements.

Low humidity conditions in Arizona—often 10-15% during late spring and early summer—affect adhesive curing rates and can cause premature surface drying that weakens bond strength. You need to monitor job site humidity and adjust installation procedures when conditions fall below 30% relative humidity, typically by misting application areas or using adhesive formulations specifically designed for arid climate conditions. These specialized products cost 15-20% more than standard formulations but prevent the bond failures that occur when conventional adhesives cure too rapidly in desert environments.

Cost Analysis and Material Efficiency Considerations

When you evaluate the economics of book matching, you’re typically looking at 40-60% material cost premiums compared to standard slab installations—a factor driven by the need to purchase sequential slabs from the same block and accept higher waste percentages during fabrication. Your local slab yard Arizona seamless design supplier should provide transparent pricing that accounts for the reduced inventory flexibility book matching requires, since you’re committing to specific sequential pieces that can’t be substituted if dimensional or quality issues emerge during fabrication.

Material efficiency in book-matched projects typically runs 15-25% lower than standard installations because you’re constrained by the dimensions and usable areas of matched pairs. You can’t optimize cutting layouts across multiple unrelated slabs to minimize waste—instead, you’re working within the specific dimensions of your sequential pieces. This constraint particularly affects projects requiring multiple matched sets, where you might need to purchase 8-10 slabs to yield 3-4 usable matched pairs after accounting for quality variations and dimensional requirements.

- You should budget 45-70% premium over standard material costs for book-matched specifications

- Your project timeline needs to account for 2-4 additional weeks for sequential slab sourcing and verification

- You’ll encounter 20-30% higher fabrication costs due to precision alignment requirements and reduced efficiency

- You need to plan for 15-20% waste increases compared to standard slab installations

Return on investment for book matching becomes clear in high-visibility applications where the dramatic visual impact justifies premium costs. Entry feature walls, primary living space fireplaces, and master suite vanities represent appropriate applications where you’re creating focal points that define space character. You should evaluate whether book matching provides proportional value for secondary spaces or applications where viewing distances exceed 20 feet—beyond this distance, the mirror-image effect that defines book matching becomes difficult to perceive, potentially making standard slab installation more cost-effective.

Alternative Matching Techniques Beyond Book Matching

While book matching creates mirror-image symmetry, you should understand alternative matching techniques that might better serve specific design objectives. Four-way matching arranges four sequential slabs in a radial pattern, creating kaleidoscopic effects appropriate for large-format floor medallions or expansive wall installations. This technique requires exceptional vein symmetry in the base material and demands even tighter fabrication tolerances than standard book matching—typically ±0.3mm alignment accuracy to maintain pattern continuity across all four quadrants.

Slip matching offers a different aesthetic where you place sequential slabs side-by-side without mirroring, creating continuous vein flow that emphasizes horizontal movement rather than symmetrical balance. You’ll find this approach works particularly well with linear vein patterns or stratified stones where mirroring would create visually chaotic patterns. Slip matching reduces fabrication complexity compared to book matching while still requiring sequential slab specification to maintain vein continuity—making it 20-30% less expensive than book matching while delivering distinctive visual character.

Random matching represents the opposite extreme, where you deliberately select slabs from different blocks to create varied, non-repetitive patterns. This approach suits applications where you want visual diversity rather than symmetry, and it offers maximum material flexibility since you’re not constrained to sequential pieces from single blocks. Your marble slab yard Arizona book match supplier maintains broader inventory options for random matching projects, often reducing lead times by 50-70% compared to book-matched specifications. The trade-off involves accepting that performance characteristics like porosity and thermal expansion may vary more significantly across your installation—something you need to address through appropriate joint sizing and substrate attachment methods.

Quality Verification Protocols Before Purchase Commitment

Before you commit to purchasing book matching slab yard Arizona materials, you need systematic verification protocols that confirm both aesthetic and performance requirements. Your inspection process should begin with photographic documentation of each slab under consistent lighting conditions, creating permanent records that establish baseline appearance before fabrication begins. You’ll want multiple exposures showing the full slab, detailed vein pattern areas, and edge conditions—documentation that becomes critical if disputes emerge regarding material quality or pattern matching success.

Physical measurements verify thickness consistency, overall dimensions, and flatness tolerances that affect fabrication feasibility. You should check multiple points across each slab with precision measuring tools—not just edge measurements that might not reflect internal thickness variations. Flatness deviations exceeding 3mm over a 2-meter span create fabrication challenges that increase costs and potentially compromise pattern alignment. Your granite yard matching slabs team should provide access to slabs positioned vertically or horizontally as needed for thorough inspection, not stacked in configurations that prevent proper evaluation.

- You need to photograph matched pairs positioned side-by-side to verify vein continuity before purchase

- Your inspection should include UV light examination to reveal repairs or resin fills not visible under standard lighting

- You should verify that slab numbering or marking systems clearly identify cutting sequence and orientation

- You’ll want written confirmation of block origin and quarry location for warranty and future matching purposes

Non-destructive testing provides additional verification for critical applications where performance requirements justify the expense. Ultrasonic testing reveals internal fissures or delamination risks not visible on slab surfaces—defects that could compromise structural integrity or propagate during fabrication. Portable testing equipment allows on-site evaluation at the slab yard Arizona matching techniques facility, providing immediate results that inform your purchase decision without requiring laboratory submission delays.

Long-Term Maintenance Planning for Matched Installations

Your maintenance planning for book-matched installations needs to account for the fact that you’re managing multiple slabs that must age uniformly to maintain visual continuity. Differential wear patterns, inconsistent cleaning practices, or uneven sealer application create appearance variations between matched slabs that become increasingly noticeable over time. You should develop maintenance protocols that ensure identical treatment of all matched surfaces, specifying cleaning products, application frequencies, and resealing schedules that maintain performance and appearance consistency.

Sealer selection becomes more critical in book-matched applications because any color-enhancing or glossy products must perform identically across all matched pieces. You’ll find that even slabs from the same block can absorb sealers differently due to micro-variations in porosity and mineral composition. You should test your selected sealer on samples from each matched slab before applying to the full installation, verifying that appearance enhancement occurs uniformly. This testing phase typically requires 7-10 days to allow sealer curing and confirm that no differential darkening or sheen variations emerge after initial application.

Staining incidents require immediate attention in book-matched installations because you can’t selectively refinish one slab without creating appearance differences that destroy pattern continuity. Your maintenance plan should include emergency response protocols for spills or staining events, with pre-identified restoration specialists who understand that any remedial work must address all matched pieces simultaneously—even if damage affects only one slab. This requirement increases restoration costs but maintains the visual investment that justifies book matching specifications.

Citadel Stone Slab Yard Arizona — Specification Guidance Across Diverse Climates

When you consider Citadel Stone’s stone slab yard in Arizona for your projects, you’re evaluating premium materials and technical guidance designed for extreme climate performance. At Citadel Stone, we provide hypothetical specification support for book matching applications across Arizona’s diverse regions, from low-desert heat to high-elevation freeze-thaw zones. This section outlines how you would approach material selection and installation planning for six representative cities, addressing the climate-specific challenges that determine long-term performance in book-matched natural stone installations.

The guidance provided represents best practices for hypothetical projects, illustrating the technical considerations you should address when specifying book matching slab yard Arizona materials. Each city profile examines thermal factors, moisture conditions, and installation variables that affect matched slab performance, helping you make informed decisions that balance aesthetic objectives with durability requirements.

Phoenix Heat Management

In Phoenix, you would encounter extreme summer temperatures regularly exceeding 115°F, creating surface temperatures on dark stones that reach 160-180°F in direct sun exposure. Your book-matched exterior specifications should favor lighter-colored materials that reflect solar radiation more effectively, reducing thermal expansion stress on joints between matched slabs. You’ll need to specify joint compounds with high-temperature stability and plan installation schedules that avoid peak summer months when ambient temperatures make proper adhesive curing difficult. Warehouse lead times in the Phoenix metro typically range 7-12 business days for sequential slab verification and delivery coordination.

Tucson Elevation Considerations

Tucson’s 2,400-foot elevation creates temperature ranges slightly less extreme than Phoenix but with greater diurnal variation—factors that increase thermal cycling stress on book-matched installations. You would need to account for the higher UV intensity at this elevation, which accelerates color fading in certain stone types and affects sealer longevity. Your maintenance schedules should anticipate resealing intervals 15-20% shorter than sea-level applications. The monsoon season brings intense rainfall that tests drainage design around book-matched exterior features, requiring you to verify that water management systems prevent differential moisture exposure between matched slabs.

Scottsdale Luxury Applications

Scottsdale projects typically emphasize high-end residential and resort applications where book matching creates signature design elements. You would specify premium marble or exotic granite materials that justify book matching investments through dramatic vein patterns and superior finish quality. Your installation planning should address the expectation for seamless pattern continuity that defines luxury markets, requiring fabrication shops with proven precision capabilities. Climate conditions mirror Phoenix parameters, but your specifications often involve climate-controlled interior applications where thermal stress factors decrease while expectations for perfect aesthetic execution increase substantially compared to standard commercial projects.

Flagstaff Freeze-Thaw Performance

At 7,000 feet elevation, Flagstaff experiences freeze-thaw cycles that create entirely different performance requirements than low-desert locations. You would need to specify materials with maximum porosity ratings below 0.5% for exterior book-matched applications, ensuring that moisture absorption doesn’t lead to spalling or delamination during freeze events. Your joint compound selection becomes critical, requiring products specifically rated for freeze-thaw exposure with expansion-contraction capability that accommodates temperature swings from -10°F to 85°F across the annual cycle. Truck access to project sites may be limited during winter months, requiring you to coordinate deliveries during favorable weather windows.

Sedona Red Rock Context

Sedona’s distinctive red rock landscape influences material selection for book-matched installations, where you’re often working to either complement or contrast with the dominant geological context. You would evaluate whether your matched slabs harmonize with regional stone colors or provide deliberate contrast that creates visual focal points. The 4,500-foot elevation creates moderate climate conditions less extreme than Phoenix but still requiring attention to UV resistance and thermal expansion. Local aesthetic preferences often favor natural stone finishes like honed or leathered surfaces that feel contextually appropriate, requiring you to verify that vein patterns in your selected book matching slab yard Arizona materials read clearly through these less reflective surface treatments.

Mesa Commercial Specifications

Mesa’s significant commercial and institutional development creates opportunities for book-matched installations in corporate lobbies, government facilities, and healthcare environments. You would need to balance aesthetic impact with budget constraints typical of commercial projects, potentially selecting book matching for high-visibility entry areas while using standard slab installations for secondary spaces. Your specifications should address slip resistance requirements for public spaces, often necessitating honed or textured finishes that may reduce pattern visibility compared to polished surfaces. Commercial project timelines typically demand faster procurement and installation schedules, requiring you to verify warehouse inventory availability before committing to book-matched specifications that might extend lead times beyond project critical paths.

Warranty and Support Considerations

When you invest in book matching slab yard Arizona materials, you need clear warranty coverage that addresses the unique vulnerabilities of matched installations. Standard slab warranties typically cover material defects but may not extend to pattern matching accuracy or long-term alignment maintenance—factors you should clarify before purchase. Your warranty evaluation should confirm coverage for performance characteristics like porosity, compressive strength, and dimensional tolerances, establishing clear remedies if supplied materials fail to meet specified parameters.

Installation warranties separate from material warranties cover fabrication accuracy and setting workmanship, but you should verify that these warranties specifically address pattern alignment obligations in book-matched applications. Standard alignment tolerances of ±3mm may be inadequate for book matching where ±1mm represents the threshold for acceptable visual continuity. You’ll want written confirmation that your installation contractor assumes responsibility for achieving pattern alignment to your specified tolerances, with clear remediation processes if initial installation fails to meet requirements.

Long-term support becomes relevant for maintenance interventions or damage repair scenarios where you need to access original material data or locate additional slabs from the same block for future modifications. Your slab yard Arizona matching techniques supplier should maintain permanent records of block origin, cutting sequence, and performance testing data that facilitate future material matching if additions or repairs become necessary years after initial installation. This documentation capability represents a significant differentiator between professional suppliers who understand book matching commitments and commodity yards focused on transactional slab sales.

Final Selection Strategies

Your final material selection synthesizes aesthetic preferences, performance requirements, and budget realities into specifications that achieve project objectives while managing risk. You should establish clear decision criteria before beginning slab yard visits, defining priorities for factors like vein pattern drama, background color uniformity, and material performance characteristics. This framework prevents the common mistake of selecting visually compelling slabs that prove incompatible with project requirements once you evaluate complete specification parameters.

Mock-up development provides valuable verification before you commit to full-scale installation, particularly for projects involving multiple matched sets or complex pattern coordination across large surfaces. You can create physical mock-ups using actual slab samples positioned to simulate final installation conditions, evaluating how pattern scale, viewing distance, and lighting conditions affect perceived appearance. Digital mock-ups using high-resolution slab photography offer less expensive alternatives for preliminary evaluation, though they can’t fully replicate the three-dimensional qualities and surface characteristics that influence final appearance.

Your professional specification process requires you to balance performance requirements with budget constraints while ensuring long-term durability across Arizona’s demanding climate conditions. For additional installation insights, review warranty coverage terms for natural stone slab purchases before you finalize your project documents. Contractors reduce overhead through Citadel Stone’s builder-focused stone supply yard in Arizona account programs.