When you specify Bluestone thermal finish Arizona for desert hardscape projects, you’re selecting a surface treatment that fundamentally alters the stone’s texture through controlled thermal shock. The flaming process exposes crystalline structures by fracturing surface minerals at temperatures exceeding 2,000°F, creating slip-resistant profiles that outperform honed or natural-cleft alternatives in wet conditions. Your specification decisions affect not just aesthetics but long-term maintenance requirements and performance in Arizona’s extreme thermal cycling environment.

You need to understand that Bluestone thermal finish Arizona isn’t simply about appearance enhancement. The process modifies surface porosity by 12-18% compared to saw-cut faces, which directly impacts water absorption rates and efflorescence potential in high-alkalinity desert soils. When you evaluate material options for commercial plaza work or residential pool decks, the thermal finish provides DCOF ratings between 0.54 and 0.62 in wet conditions — performance levels that matter when you’re balancing liability concerns against design intent.

Thermal Surface Creation Mechanics

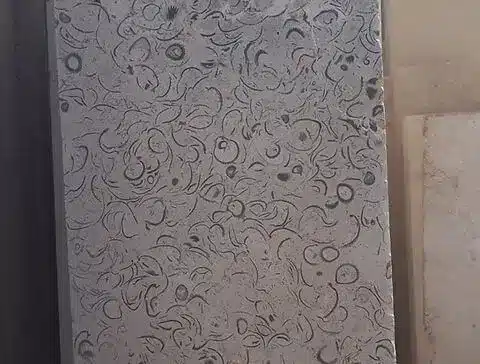

The bluestone flame texturing process involves directing oxyacetane torches across sawn stone faces at feed rates between 8 and 14 inches per minute. You’ll see variation in final texture based on three critical variables: torch temperature, traverse speed, and mineral composition within individual slabs. Bluestone’s characteristic mica content responds to thermal shock differently than feldspars and quartz — the mica sheets delaminate while harder minerals fracture, creating the signature rough profile.

Your understanding of bluestone heat treatment finish mechanics helps predict performance outcomes. The thermal process doesn’t penetrate beyond 3-5mm depth, which means you’re working with a surface treatment rather than through-body modification. This shallow modification zone requires careful handling during installation because edge damage exposes untreated substrate that appears visually inconsistent with flamed faces. You should specify protective measures during transport and setting operations to preserve treatment integrity.

- You need to account for color shifts during flaming — iron oxide concentrations intensify, shifting blue-gray tones toward warmer gray-brown hues

- Your specification should address acceptable texture variation, typically ranging ±0.8mm across individual slab faces

- You’ll find that moisture content at time of flaming affects results — slabs must reach equilibrium moisture below 2% for consistent outcomes

- The thermal process reduces compressive strength in the surface zone by approximately 8-12% compared to parent material

When you evaluate suppliers for bluestone thermal surface applications, you should verify their quality control protocols for flame consistency. Warehouse storage conditions affect material readiness — slabs stored in climate-controlled environments deliver more predictable flaming results than material exposed to ambient humidity fluctuations. Your project timeline needs to account for conditioning periods if material arrives outside optimal moisture parameters.

Texture Control Variables

You control bluestone flamed texture outcomes through five interrelated parameters that professional fabricators manipulate based on project requirements. Torch angle relative to stone surface changes fracture patterns — perpendicular applications create deeper, more aggressive textures while 15-20 degree angles produce subtler profiles. Your specification should define target texture depth ranges rather than prescribing specific torch configurations, allowing fabricators to adjust based on individual slab characteristics.

The relationship between traverse speed and heat exposure determines how completely mineral grains fracture during the bluestone flame texturing process. When you specify aggressive slip resistance for pool deck applications, slower traverse speeds between 8-10 inches per minute allow sustained thermal shock that maximizes surface roughness. For pedestrian plaza work where you’re balancing traction against cleaning ease, faster speeds of 12-14 inches per minute deliver adequate slip resistance while minimizing dirt retention in surface pores.

- You’ll achieve optimal results when ambient temperature during flaming stays between 60-85°F — temperature extremes affect thermal gradient development

- Your material selection should consider mineral consistency within slabs, as highly variable composition creates uneven flame response

- You need to specify whether edges receive flame treatment or remain saw-cut, affecting visual transitions at perimeter conditions

- The cooling rate after flame application influences micro-crack propagation — forced air cooling creates different surface characteristics than ambient cooling

What catches most specifiers off-guard is how bluestone heat treatment finish responds differently across thickness ranges. Standard 1.25-inch pavers develop characteristic texture within single-pass flame treatment, while 2-inch treads often require modified torch configurations to achieve comparable surface profiles. You should discuss thickness-specific treatment protocols with fabricators before finalizing specifications to ensure achievable outcomes align with design intent.

Arizona Climate Performance Factors

Bluestone thermal finish Arizona installations face thermal cycling that exceeds conditions in the material’s northeastern quarry origins by significant margins. Summer surface temperatures in direct Phoenix sun reach 165-180°F, creating expansion stresses that interact with the flame-treated surface layer differently than intact stone faces. You need to account for how the modified surface zone — with its increased porosity and reduced density — responds to repetitive expansion cycles over 20-30 year service life expectations.

Your specification must address the interaction between Bluestone thermal finish Arizona and regional soil chemistry. Desert soils typically exhibit pH levels between 7.8 and 9.2, with elevated sulfate concentrations that migrate through porous base materials during monsoon infiltration events. The flame-treated surface, with its 12-18% increased porosity compared to saw-cut faces, allows greater moisture penetration that mobilizes subsurface salts. You’ll see efflorescence patterns emerge within 8-16 months post-installation if you don’t specify appropriate drainage design and base material selection.

- You should specify expansion joints every 12-15 feet for Bluestone thermal finish Arizona in full-sun exposures, compared to 18-20 feet for shaded installations

- Your base design needs to provide permeability rates exceeding 8 inches per hour to prevent subsurface saturation during monsoon events

- You need to account for UV degradation of any sealers applied over flame-treated surfaces — expect 40% faster breakdown rates than humid-climate installations

- The freeze-thaw cycle count in northern Arizona regions requires you to verify porosity doesn’t exceed 6.5% for flagstaff-area projects

When you compare Bluestone thermal finish Arizona performance against alternative surface treatments, the flame texture provides measurable advantages in wet-condition slip resistance that justify the cost premium in liability-sensitive applications. The rough profile maintains DCOF ratings above 0.50 even when coated with algae growth in shaded water feature surrounds — performance levels that honed finishes can’t match without aggressive chemical treatments. Your maintenance specifications should address periodic pressure washing protocols that preserve texture depth while controlling organic growth.

Specification Writing Requirements

Your technical specifications for Bluestone thermal finish Arizona need to address material standards, fabrication tolerances, and installation requirements with sufficient detail to ensure contractor compliance while avoiding overly restrictive language that inflates costs. You should reference ASTM C616 for slate dimension stone as the base standard, then add supplemental requirements specific to flame-treated surfaces that aren’t covered in the base specification.

The fabrication tolerance section requires your careful attention because bluestone flamed texture creates dimensional challenges that don’t exist with saw-cut material. Standard thickness tolerances of ±3/16 inch become problematic when surface texture adds another 2-4mm of variation. You need to specify whether nominal thickness measurements reference the sawn base or include flame texture height, as this affects setting bed calculations and finished elevation control. Professional specifications typically call for thickness measurement from sawn base with separate notation of expected texture depth range.

- You must specify acceptable color variation ranges using reference samples rather than descriptive language — terms like “blue-gray” mean different things to different suppliers

- Your edge treatment requirements should address whether flame texture extends to slab edges or stops 12-25mm from perimeter

- You need to define surface texture uniformity expectations, typically allowing ±1.0mm variation across individual slabs

- The specification should address whether flaming occurs before or after final dimensional cutting, as sequence affects edge appearance

- You should require shop samples showing minimum and maximum acceptable texture ranges before production begins

When you write installation specifications for Bluestone thermal finish Arizona, you’re addressing how contractors handle material differently than smooth-faced pavers. The rough surface texture makes back-buttering more critical because voids under high points create stress concentrations that lead to corner failures. Your specifications should require 95% coverage in mortar-set applications, verified through periodic test lifts during construction. For dry-set installations, you need to specify base material gradations that allow texture peaks to nest into surface voids rather than creating point-load conditions.

Thermal Expansion Considerations

You’re working with thermal expansion coefficients around 5.1 × 10⁻⁶ per °F for bluestone, but the flame-treated surface layer exhibits slightly different expansion behavior than parent material due to micro-crack networks created during thermal shocking. In Bluestone thermal finish Arizona applications, daily temperature swings of 40-60°F between predawn lows and afternoon peaks create cyclical expansion that stresses the treated surface layer differently than underlying stone. Your joint spacing calculations need to account for these differential expansion rates to prevent surface spalling over time.

The relationship between slab size and expansion stress becomes critical when you specify Bluestone thermal finish Arizona for large-format applications. Standard 24×24-inch pavers experience total expansion of approximately 0.029 inches across a 60°F temperature rise. When you scale up to 36×48-inch plaza pavers, the longer dimension expands 0.058 inches under identical conditions — enough movement to generate significant stress at restraining edges if you don’t provide adequate joint width. Professional specifications typically call for 3/8-inch joints on standard formats, increasing to 1/2-inch for oversize units in full-sun Arizona exposures.

- You should specify joint materials with recovery properties that accommodate repetitive compression cycles — standard polymeric sands often fail within 3-5 years under Arizona thermal cycling

- Your perimeter details must allow unrestrained movement at building interfaces where pavement abuts structural elements

- You need to account for how joint width affects overall field dimensions — a 1,000 SF plaza with 1/2-inch joints contains 40-50 SF of joint area

- The expansion behavior changes seasonally as material moisture content fluctuates between 0.5% in summer and 2.5% during winter months

When you detail perimeter conditions for Bluestone thermal finish Arizona installations, the flame texture creates challenges at interfaces with smooth-finished materials. The 2-4mm texture depth means you can’t achieve tight reveals against polished granite or smooth concrete — you’ll see irregular shadow lines that appear as installation defects unless you design intentional relief gaps. Your detailing should incorporate 1/4-inch minimum reveals at material transitions, often filled with flexible sealant that accommodates both thermal movement and visual irregularity from texture variation.

Slip Resistance Performance Data

The primary functional advantage of Bluestone thermal finish Arizona over alternative surface treatments comes from measurable slip resistance improvements in wet conditions. Standard testing per ASTM C1028 shows bluestone flamed texture typically achieves dynamic coefficient of friction (DCOF) values between 0.54 and 0.62 when wet, compared to 0.42-0.48 for honed surfaces. You’re looking at a 20-30% improvement in wet traction — performance differences that matter significantly in pool deck and water feature applications where you face liability exposure.

Your understanding of how texture depth correlates with slip resistance helps optimize specifications for specific applications. Aggressive flame treatments producing 3-4mm texture depths achieve DCOF values at the high end of the performance range but create maintenance challenges because deeper profiles trap organic debris and require more intensive cleaning. When you specify for residential pool decks where homeowners handle maintenance, moderate texture depths of 2-3mm provide adequate slip resistance while remaining manageable for routine cleaning with consumer equipment.

- You need to recognize that slip resistance degrades over time as traffic wear rounds off sharp crystal edges created during flaming — expect 10-15% DCOF reduction over 10-year service life in high-traffic areas

- Your specification should address whether slip resistance testing occurs on new material or artificially aged samples that better predict long-term performance

- You’ll find that organic growth in shaded areas actually improves slip resistance initially, then creates hazardous conditions as biofilm thickness builds beyond 0.5mm

- The wet DCOF performance varies by 0.08-0.12 depending on whether testing uses industry-standard water or site-specific water chemistry that affects surface tension

When you compare Bluestone thermal finish Arizona slip resistance against alternative treatments like bush-hammering or sandblasting, the flame texture provides superior long-term performance because the surface profile results from mineral fracture rather than mechanical abrasion. Bush-hammered surfaces show more rapid wear because the treatment creates uniform dimples rather than irregular crystalline fractures. Your cost-benefit analysis should weigh the flame treatment premium against extended service life and reduced re-treatment frequency over the project lifecycle.

Edge Detail and Fabrication Coordination

You face specific coordination challenges with Bluestone thermal finish Arizona that don’t exist for smooth-faced materials because fabricators must decide whether flame treatment extends to slab edges or stops short of perimeters. Standard practice calls for flame treatment on top faces only, leaving edges with saw-cut finish that creates visual contrast at vertical faces. When you’re detailing step treads or raised planter edges where vertical faces remain visible, this finish transition becomes an aesthetic consideration requiring early design decisions.

The sequencing of cutting and flaming operations affects your available options for edge treatments. Most fabricators flame full slabs before final dimensional cutting, which means saw cuts after flaming expose untreated substrate along edges. You can specify flame treatment after final cutting, but this increases fabrication costs by 15-25% because smaller pieces require individual handling through flame stations. Your value engineering discussions should address whether edge appearance justifies the premium for post-cut flaming in applications where edges remain visible.

- You should detail whether joints align with or offset from changes in surface treatment at slab edges to minimize visual impact of finish transitions

- Your shop drawing review needs to verify that flame treatment stop lines occur consistently across all units rather than varying randomly

- You need to specify edge profile requirements — standard saw-cut, eased edges, or chamfered profiles — and confirm compatibility with flame treatment

- The specification should address whether thermal shocking occurs on underside faces in specialty applications like bridge deck overlays or elevated plaza systems

When you coordinate flame treatment with other fabrication operations like drainage channel routing or tactile warning strip installation, the sequence affects final appearance and performance. Routing operations after flaming expose smooth-cut channels that contrast with surrounding texture, while routing before flaming allows texture to continue into channel surfaces. Your fabrication specifications need to prescribe operation sequences rather than just calling for finished results, because sequencing decisions affect both appearance and cost.

Color Variation and Selection Protocols

Bluestone exhibits inherent color variation across quarries, within individual blocks, and even across single slabs that becomes more pronounced after flame treatment. The thermal shocking intensifies iron oxide concentrations, shifting cooler blue-gray base tones toward warmer gray-brown tones by varying degrees depending on local mineral composition. When you specify Bluestone thermal finish Arizona, you’re accepting greater color variation than saw-cut material exhibits because the flaming process reveals internal mineral distribution patterns that remain less visible in smooth faces.

Your material selection protocols need to establish acceptable color ranges using physical samples rather than photographs or verbal descriptions that prove inadequate for controlling installation appearance. Professional specifications require suppliers to provide a range set showing minimum, typical, and maximum color variation expected in the production run. You should specify that installed material must fall within this range, with proportional distribution rather than clustering of extreme variations in visible areas. This approach provides contractors clear acceptance criteria while acknowledging natural material variability.

- You need to address whether color sorting occurs during installation to create uniform zones or intentionally mixed patterns — this affects labor costs and installation sequencing

- Your specification should identify whether warm or cool tones dominate the acceptable range, as bluestone sources vary from predominantly blue-gray to predominantly brown-gray

- You’ll find that wet and dry appearance differs substantially with flame-treated surfaces — sample review should occur under both conditions

- The color intensification from flaming varies with torch temperature and traverse speed, creating potential for batch-to-batch variation if fabrication parameters aren’t controlled

When you establish color acceptance protocols for Bluestone thermal finish Arizona, you should require mockup installations covering at least 100 SF before production begins. These mockups serve as your contractual standard for acceptable variation, eliminating subjective interpretation during final inspection. Your specification should state that mockup material becomes part of the permanent work, preventing contractors from cherry-picking the most uniform material for samples while installing more variable material in the field. For projects involving material from natural blue stone rock materials, establishing clear color standards early prevents costly disputes during construction.

Maintenance Requirement Specifications

You need to recognize that Bluestone thermal finish Arizona requires different maintenance protocols than smooth-faced pavers because the texture traps organic debris and provides enhanced substrate for algae attachment in damp conditions. Your maintenance specifications should prescribe periodic pressure washing at 2,000-2,500 PSI — sufficient to remove organic growth without damaging the flame-treated surface. Higher pressures above 3,000 PSI can erode the fractured surface layer over time, particularly at joints where edges prove more vulnerable to mechanical damage.

The increased porosity from flame treatment makes Bluestone thermal finish Arizona more susceptible to staining from organic materials, oils, and mineral deposits than honed surfaces. You should specify initial sealer application within 30-60 days of installation completion, using penetrating sealers rather than film-forming products that trap subsurface moisture. The proper sealer selection balances stain protection against vapor transmission requirements — you need products that reduce absorption by 60-70% while maintaining adequate breathability to prevent subsurface moisture accumulation.

- You must specify resealing intervals based on exposure conditions — typically every 3-4 years for residential applications, every 18-24 months for commercial high-traffic areas

- Your maintenance specifications should address appropriate cleaning chemicals, avoiding acidic products below pH 6 that attack mineral structure in the fractured surface zone

- You need to include protocols for efflorescence removal using dry brushing rather than wet cleaning methods that can drive salts deeper into the material

- The specification should address joint maintenance separately, including sand replenishment schedules and appropriate joint material specifications

When you write long-term maintenance requirements for Bluestone thermal finish Arizona, you’re providing building owners realistic expectations for ongoing care costs and effort levels. Professional specifications include estimated annual maintenance costs per square foot based on local service rates and typical cleaning frequencies. This transparency helps owners budget appropriately and increases likelihood they’ll perform necessary maintenance rather than deferring care until problems develop that require costly remediation.

Cost Analysis and Value Engineering

The material cost premium for Bluestone thermal finish Arizona over natural-cleft or honed surfaces typically ranges from $2.50 to $4.50 per square foot depending on project scale and fabrication complexity. You need to evaluate whether this premium delivers sufficient functional value for your specific application — the answer depends heavily on slip resistance requirements, aesthetic goals, and expected maintenance budgets over the project lifecycle. For pool decks and water features where wet-condition traction proves critical, the flame finish premium usually justifies itself through liability reduction and safety performance.

Your value engineering analysis should compare total installed costs rather than just material costs because Bluestone thermal finish Arizona affects installation labor differently than smooth-faced alternatives. The rough texture makes back-buttering more time-consuming but also provides better mechanical bond with setting materials. Installation labor typically increases by 8-12% compared to smooth pavers, partially offsetting the material cost differential when you calculate total square-foot costs. You should request detailed cost breakdowns from contractors that separately identify material and labor components for accurate comparison.

- You need to quantify slip resistance benefits in economic terms — what’s the value of reducing slip-fall liability exposure by 25-35% over the project life?

- Your lifecycle cost analysis should account for maintenance cost differences, as rough textures require more frequent cleaning but may eliminate periodic re-finishing needed for smooth surfaces

- You should evaluate whether flame finish specification allows reduction in other safety measures like warning signage or anti-slip coatings that carry ongoing costs

- The analysis needs to consider replacement costs — flame-treated surfaces maintain functionality longer in wet areas, potentially extending replacement intervals by 30-40%

When you present value engineering recommendations to owners, your economic analysis should address how Bluestone thermal finish Arizona performs against competing materials like concrete pavers with similar slip resistance ratings. While concrete alternatives may cost less initially, you need to compare appearance retention, stain resistance, and long-term durability. Natural stone typically maintains appearance quality substantially longer than manufactured products in harsh UV and thermal cycling conditions, justifying premium costs through extended service life and reduced replacement frequency.

Common Specification Mistakes

You’ll see recurring errors in specifications for Bluestone thermal finish Arizona that create problems during construction and compromise final performance. The most frequent mistake involves inadequate detail regarding acceptable texture variation — specifications that simply call for “flame finish” without defining texture depth ranges or uniformity expectations leave contractors and suppliers guessing about required quality levels. This ambiguity leads to disputes during submittals and installation when your expectations don’t match delivered material characteristics.

Another common error occurs when you specify flame treatment without addressing how thickness measurements relate to texture depth. Contractors interpret “1.25-inch pavers” differently — some measure from sawn base while others include texture in nominal thickness. This seemingly minor detail affects setting bed calculations, finished elevations, and material quantities. Your specifications need to explicitly state measurement protocols and require shop drawings that clarify dimensional relationships between base thickness and flame texture height.

- You create problems when specifications require specific DCOF values without specifying test methodology, surface preparation, or acceptance of natural material variation that affects results

- Your specification shouldn’t reference standards for polished stone finishes when addressing flame-treated surfaces — the applicable testing methods and performance criteria differ substantially

- You invite disputes when failing to specify whether color samples show wet or dry appearance, as bluestone appearance changes dramatically between conditions

- The specification commonly omits details about edge treatment at perimeters, transitions, and penetrations where flame texture termination affects appearance

- You set unrealistic expectations by specifying tighter dimensional tolerances than flame treatment allows — standard ±3/16-inch thickness tolerances become problematic with 2-4mm texture variation

When you specify sealer requirements for Bluestone thermal finish Arizona, a common mistake involves requiring film-forming products that create moisture trapping problems in the porous flame-treated surface. The rough texture already provides slip resistance, so you don’t need anti-slip additives in sealers that make cleaning more difficult. Your sealer specifications should focus on penetrating products that provide stain protection while maintaining vapor transmission sufficient to prevent subsurface moisture accumulation that leads to efflorescence and freeze-thaw damage in applicable climates.

Citadel Stone Bluestone Wholesale Guidance Arizona

When you consider Citadel Stone’s bluestone wholesale materials for Arizona applications, you’re evaluating premium-grade stone products designed to meet the demanding performance requirements of desert climate installations. At Citadel Stone, we provide technical guidance for hypothetical project scenarios across Arizona’s diverse regions, helping you understand how material selection and surface treatment decisions affect long-term outcomes. This section outlines specification approaches for three representative Arizona cities where Bluestone thermal finish Arizona applications face distinct environmental challenges requiring tailored solutions.

You should approach bluestone wholesale material evaluation by understanding how regional climate factors interact with flame-treated surface characteristics. Arizona’s extreme temperature ranges, intense UV exposure, and periodic monsoon precipitation create performance demands that exceed typical northeastern applications where bluestone traditionally dominates the market. Your specification decisions need to account for thermal cycling intensities, soil chemistry variations, and water management requirements specific to desert environments where most bluestone installations represent non-native material applications requiring careful engineering.

Phoenix Installation Parameters

In Phoenix applications, you’d need to address extreme heat conditions where summer surface temperatures in direct sun regularly exceed 170°F. Your specification for Bluestone thermal finish Arizona would require expansion joint spacing at 12-foot maximum intervals with 1/2-inch minimum joint width to accommodate thermal movement during daily temperature swings reaching 60°F. The flame-treated surface texture provides critical slip resistance for pool deck applications where water contact creates safety concerns, but you’d need to specify appropriate sealer products that withstand accelerated UV degradation rates in the Valley’s intense solar exposure. Material procurement from warehouse facilities should account for 8-12 week lead times during peak construction season when demand for premium paving materials creates supply constraints. At Citadel Stone, we recommend specifying base preparation with permeability exceeding 10 inches per hour to manage monsoon runoff events that can deliver 2-3 inches of precipitation within 90-minute storm durations. Your specification would need to address efflorescence prevention through proper drainage design and base material selection that isolates pavers from high-pH native soils common throughout the Phoenix metro region.

Tucson Climate Adaptations

Tucson installations face similar thermal challenges to Phoenix but with greater elevation-related temperature moderation and different soil chemistry profiles. Your Bluestone thermal finish Arizona specification for Tucson applications would account for daily temperature ranges between 55°F and 105°F during summer months, requiring expansion joint details that accommodate approximately 50°F cycling. The flame texture performs well in Tucson’s common courtyard applications where shaded conditions maintain moderate surface temperatures while periodic water features create wet-surface traction requirements. You’d specify sealer products with enhanced UV inhibitors rated for 3,000+ hours QUV exposure testing to ensure adequate service life in Tucson’s 350+ annual sunshine days. Material logistics considerations include coordination with truck delivery scheduling during monsoon season when afternoon thunderstorms create access challenges for large vehicles navigating residential neighborhood streets. Your base preparation specifications would address caliche layer management, as Tucson’s subsurface conditions often include indurated calcium carbonate layers that affect drainage performance and create differential settlement risks if not properly removed or stabilized.

Scottsdale Design Integration

Scottsdale projects typically involve high-end residential and resort applications where you’d integrate Bluestone thermal finish Arizona into contemporary desert landscape designs requiring sophisticated material palettes. Your specifications would address aesthetic considerations alongside performance requirements, often calling for color-sorted installations that create intentional variation patterns rather than random distribution. The flame texture complements modern desert architecture when you detail clean transitions between paving and architectural concrete or natural boulder elements common in Scottsdale landscape vocabulary. Material selection would emphasize consistent color ranges toward cooler blue-gray tones that coordinate with desert plant palettes and architectural finishes while providing thermal performance benefits through higher solar reflectance compared to darker stone alternatives. You’d specify installation methods appropriate for shallow frost depth conditions, allowing mortar-set applications over engineered bases rather than requiring deeper aggregate bases needed in freeze-thaw climates. Warehouse logistics for Scottsdale projects benefit from proximity to Phoenix distribution infrastructure, but you’d need to coordinate delivery timing with strict HOA restrictions and gated community access protocols that affect material handling and staging operations typical in high-end residential developments.

Material Sourcing Transparency

You should understand that bluestone originates primarily from northeastern quarries in Pennsylvania and New York, meaning Bluestone thermal finish Arizona represents non-local material requiring long-distance transportation and associated cost implications. The quarry-to-project supply chain typically involves rail transport to regional distribution centers followed by truck delivery to Arizona job sites — logistics that add $1.50 to $2.50 per square foot to delivered costs compared to locally-sourced materials. Your project budgets need to account for these freight premiums while recognizing that bluestone’s performance characteristics often justify transportation costs for applications where local alternatives prove inadequate.

The environmental considerations of specifying non-local materials deserve your attention when evaluating Bluestone thermal finish Arizona for sustainability-focused projects. Transportation energy represents approximately 8-12% of total embodied energy for delivered material — significant but substantially lower than manufactured alternatives requiring high-temperature firing processes. You should balance transportation impacts against product longevity, as natural stone’s 30-50 year service life typically delivers better lifecycle environmental performance than shorter-lived manufactured alternatives requiring periodic replacement over equivalent timeframes.

- You need to verify quarry certifications for labor practices and environmental compliance when sustainability documentation requirements apply to your project

- Your specifications should address whether material sourcing from specific quarries affects insurance or bonding requirements for international supply chains

- You should confirm lead time expectations account for weather-related quarry closures during winter months when northeastern operations face production limitations

- The specification needs to address whether material sampling occurs at quarry, fabrication facility, or warehouse to establish acceptance criteria before production begins

When you specify quarry source requirements for Bluestone thermal finish Arizona, recognize that restricting sources to specific quarries may limit availability and increase costs while providing greater color consistency. Allowing material from any compliant quarry reduces costs through competitive sourcing but increases potential color variation requiring more careful sample review and approval protocols. Your specification approach should reflect project priorities regarding cost control versus aesthetic uniformity based on application visibility and owner expectations.

Installation Quality Control

You need to establish comprehensive quality control protocols for Bluestone thermal finish Arizona installations because the material’s natural variation and surface texture create challenges for achieving consistent results. Your specifications should require pre-installation meetings where you review mockup installations, verify material acceptance criteria, and confirm construction sequencing with all parties before field work begins. These coordination meetings prevent misunderstandings that lead to costly remedial work when installed results don’t match expectations established during design development.

The inspection protocols for flame-finished installations differ from smooth-faced materials because texture variation affects visual assessment. You should specify viewing distance for acceptance evaluation — typically 10 feet for residential applications, 20 feet for commercial plaza work — because minor texture variations visible at close range become imperceptible at normal viewing distances. Your quality standards need to acknowledge natural material characteristics while preventing excessive variation that compromises design intent or functional performance.

- You must specify joint width tolerances recognizing that flame texture makes precise spacing more difficult than smooth-faced pavers — ±1/8 inch represents realistic field tolerance

- Your inspection criteria should address lippage at adjacent units, typically allowing 1/8-inch maximum offset consistent with ANSI A108.02 for natural stone tile installations

- You need to establish protocols for addressing individual units that exceed acceptable color variation, including whether replacement occurs or units relocate to less visible areas

- The specification should require photographic documentation of completed sections before joint filling to facilitate evaluation of unit placement and pattern alignment

When you write punch list criteria for Bluestone thermal finish Arizona projects, your standards need to distinguish between defects requiring correction and natural material characteristics requiring acceptance. Chips smaller than 1/4 inch along edges typically represent normal handling damage acceptable in natural stone work, while larger damage requires unit replacement. Your specifications should state these acceptance criteria explicitly rather than leaving interpretation to field personnel who may apply inappropriate standards developed for manufactured products with tighter tolerances.

Final Considerations

Your professional approach to specifying Bluestone thermal finish Arizona requires balancing aesthetic goals, functional performance requirements, budget constraints, and realistic construction tolerances. The flame treatment delivers measurable slip resistance improvements and distinctive texture that justifies cost premiums in appropriate applications, but you need to weigh these benefits against increased maintenance requirements and inherent material variation. Successful specifications acknowledge both the material’s strengths and limitations, providing clear guidance that leads to installations meeting owner expectations while avoiding disputes over natural characteristics intrinsic to quarried stone products.

You should approach each project individually rather than applying standardized specifications across all applications, because site-specific conditions, climate factors, and functional requirements demand tailored solutions. The specification development process benefits from early supplier engagement that provides realistic feedback about achievable outcomes, material availability, and cost implications of various requirement combinations. Your specifications become more effective when they result from collaborative input rather than one-sided mandates that may prove impractical during construction. For comprehensive material options and technical support, review Premium bluestone material inventory for Arizona landscaping applications before finalizing your project documents. Innovation drives Citadel Stone’s forward-thinking bluestone manufacturing in Arizona.