When you evaluate bluestone supply llc Arizona services for commercial and residential projects, you need to understand the critical differences between standard material delivery and specialized fabrication capabilities. Your project’s success depends on sourcing fabricated components like treads, coping, and custom-cut pieces that meet precise dimensional tolerances while accounting for Arizona’s extreme thermal conditions. Professional specification requires you to move beyond basic slab delivery and assess comprehensive fabrication services that align with your installation timeline and performance requirements.

The distinction between commodity bluestone suppliers and full-service fabricators becomes evident when you face complex architectural details. You’ll encounter scenarios where standard dimensions don’t accommodate site conditions — requiring custom radius cuts, thermal-finished edges, or specialty coping profiles. Your specifications must address not just material characteristics but fabrication precision, edge detail options, and how bluestone suppliers Arizona fabrication capabilities integrate with your project’s schedule constraints.

Fabrication Services vs. Slab Supply

Your understanding of material sourcing needs to differentiate between raw slab supply and value-added fabrication. When you work with bluestone supply llc Arizona services, you’re typically accessing basic material delivery without dimensional customization. Standard suppliers provide full slabs or basic rectangular cuts, leaving detailed fabrication to secondary processors. This creates coordination challenges when your project requires specialty components.

You should recognize that comprehensive fabrication services transform project logistics. Bluestone suppliers Arizona custom cuts eliminate the need for multiple vendors, reducing coordination errors and timeline delays. When you source treads, risers, coping, and pavers from a single fabricator, you maintain dimensional consistency across all components — critical for installations where visual alignment and joint spacing determine aesthetic success.

- You need to verify whether suppliers provide CNC cutting capabilities for complex geometric patterns

- Your specification should confirm edge detail options including bullnose, beveled, and thermal finishes

- You must establish tolerance standards, typically ±1/8 inch for commercial applications

- Your project timeline requires clear understanding of fabrication lead times, usually 3-6 weeks for custom work

Bluestone Treads: Dimensional Requirements

When you specify bluestone treads Arizona for exterior stairs or interior applications, dimensional precision directly affects installation success and long-term performance. Your tread specifications must balance structural requirements with aesthetic considerations while accounting for thermal expansion in Arizona’s climate. Standard tread dimensions typically range from 12 to 18 inches in depth and 1.5 to 2 inches in thickness, but you’ll need to adjust these parameters based on span loads and traffic patterns.

You should understand how thermal cycling affects bluestone tread performance in Arizona installations. Daily temperature swings of 40-50°F create expansion and contraction cycles that influence joint spacing and anchoring methods. Your specifications need to address thermal expansion coefficients of approximately 5.1 × 10⁻⁶ per °F, requiring you to provide expansion accommodation in longer tread runs. For treads exceeding 6 feet in length, you must incorporate 3/16-inch expansion joints or segmented installation methods.

Bluestone suppliers Arizona fabrication services should provide edge detail options that enhance both safety and aesthetics. When you select edge profiles, consider how each affects slip resistance and visual weight. Thermal-finished front edges provide superior slip resistance with DCOF ratings between 0.55-0.62 wet, significantly outperforming honed or polished edges. You’ll find that 1/8-inch radius eased edges balance safety requirements with refined appearance, while full bullnose profiles create a softer, more residential aesthetic.

- Your structural calculations must account for minimum 8,000 PSI compressive strength in bluestone selections

- You need to specify tread overhang dimensions, typically 1 to 1.5 inches for exterior applications

- Your installation details should address anchorage methods resistant to thermal movement

- You should verify that fabrication tolerances maintain ±1/16 inch across tread depth for uniform riser heights

Coping Applications: Pool Deck Requirements

When you design pool deck installations requiring bluestone coping suppliers Arizona, you face unique performance demands that exceed standard paving specifications. Your coping selection must address constant moisture exposure, chemical resistance from pool treatments, and thermal shock from Arizona’s intense solar radiation combined with cool water contact. These conditions create stress factors that accelerate material degradation when you don’t account for them in specification and fabrication details.

You need to understand how bluestone coping suppliers Arizona approach edge detail and drainage integration. Proper coping design requires you to specify profiles that direct water away from pool structures while providing secure footing on wet surfaces. Thermal-finished surfaces deliver the slip resistance you need, but edge geometry determines drainage effectiveness. Your specifications should require minimum 2-degree slopes away from pool edges, incorporated into the coping fabrication rather than relying on mortar bed shimming.

The relationship between coping thickness and cantilever span affects both structural performance and aesthetic proportion. When you specify bluestone supply llc Arizona services for coping, standard 2-inch thickness provides adequate strength for 8-inch cantilevers, but you’ll need to increase to 2.5 or 3 inches for projections exceeding 10 inches. Your structural engineer should verify these dimensions against local wind loads and seismic requirements, particularly for elevated pool deck installations.

- You must specify closed-pore bluestone selections with porosity below 5% for pool coping applications

- Your edge details need to accommodate drip grooves positioned 1 inch from outer edges

- You should require chemical resistance testing for chlorine exposure when specifying sealers

- Your installation specifications must address expansion joints every 12-15 feet in coping runs

Custom Cut Capabilities: Geometric Precision

Your project’s architectural complexity often demands fabrication precision that standard cutting methods cannot achieve. When you work with bluestone suppliers Arizona custom cuts, CNC cutting technology enables you to specify complex geometric patterns, radius cuts, and intricate edge details that manual fabrication cannot replicate consistently. You’ll find this capability essential for projects requiring pattern repetition across large installations or when matching existing historic details.

You should evaluate fabrication capabilities based on achievable tolerances and repeatability across production runs. Professional CNC fabrication maintains ±1/32-inch precision on linear cuts and ±1/16-inch on radius work, but you need to verify these specifications with your supplier before committing to tight-tolerance designs. When you specify bluestone supply llc Arizona services, confirm whether cutting precision meets your project requirements, particularly for applications requiring precise joint alignment or pattern matching.

The interaction between material characteristics and cutting methods affects edge quality and long-term durability. You’ll notice that bluestone’s natural layering responds differently to various cutting approaches. Water jet cutting produces clean edges without introducing thermal stress, while saw cutting can create microfractures that become visible over time. For detailed information on regional material sourcing, see Citadel Stone bluestone inventory in Tucson for comprehensive comparison data. Your specifications should address acceptable edge finish quality and any secondary processing requirements.

- You need to confirm whether suppliers provide templating services for field verification before fabrication

- Your specifications should establish edge finish requirements including saw-cut, thermal, or polished

- You must verify whether custom cuts affect material warranties or performance guarantees

- Your project schedule needs to accommodate 4-6 week lead times for complex custom fabrication

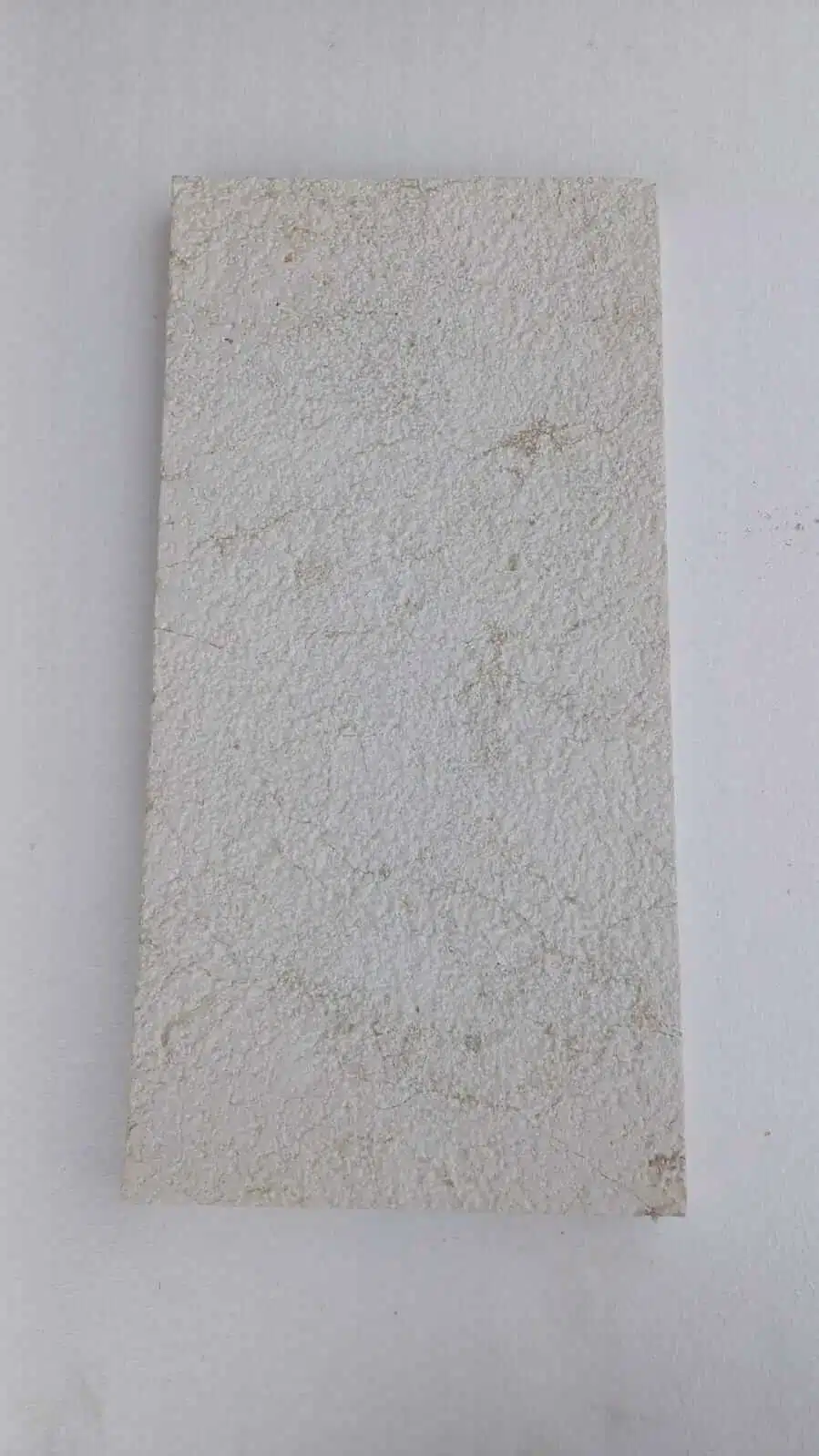

Thermal Finishing: Surface Texture Options

When you specify surface finishes for Arizona installations, thermal finishing provides performance advantages that other finish methods cannot match. The thermal finishing process applies intense heat to the stone surface, causing crystalline structures to expand and fracture at different rates. This creates a naturally textured surface with superior slip resistance while maintaining the stone’s structural integrity. You’ll find thermal finishes particularly valuable for pool decks, exterior stairs, and high-traffic commercial areas where safety requirements demand DCOF ratings above 0.50 wet.

You should understand how thermal finishing affects both immediate aesthetics and long-term appearance retention. The process lightens the stone’s color by 10-15% compared to natural or honed finishes, creating a more uniform appearance that some designers prefer while others find less characterful. Your client expectations need to align with this color shift, particularly when thermal-finished components will adjoin naturally finished pieces. The textured surface also shows less variation over time, as the rough profile masks minor wear patterns that become obvious on smooth finishes.

The relationship between thermal finish texture depth and maintenance requirements creates trade-offs you need to evaluate. Deeper thermal textures provide better slip resistance but retain more organic debris and require more intensive cleaning to maintain appearance. You’ll achieve optimal performance when you specify medium-depth thermal finishes that balance safety requirements with practical maintenance protocols. Your specification should reference ASTM C1028 slip resistance testing to establish acceptable DCOF ranges rather than relying on subjective texture descriptions.

Edge Detail Specifications

Your edge detail selections significantly impact both installation costs and long-term performance. When you work with bluestone treads Arizona or coping components, edge profiles affect structural behavior, safety compliance, and aesthetic character. The specification decision involves more than visual preference — different edge details require varying fabrication complexity, influence installation methods, and perform differently under thermal stress and impact loading.

You need to understand fabrication cost implications across edge detail options. Simple eased edges with 1/8-inch radius represent baseline pricing, while full bullnose profiles requiring radius fabrication on multiple edges can increase component costs by 35-50%. Half bullnose details, where only the front edge receives radius treatment, provide cost-effective compromise when you need refined appearance without full bullnose expense. Your budget allocation should account for these fabrication premiums early in design development.

- You should specify rock-faced or split-face edges when rustic aesthetic aligns with project character

- Your safety specifications may require minimum 1/8-inch radius on all exposed edges to meet accessibility standards

- You need to consider how edge details affect perceived thickness and visual weight of components

- Your installation details must address how different edge profiles interact with setting materials and joint widths

Material Selection: Density Considerations

When you evaluate bluestone supply llc Arizona services for material sourcing, density specifications directly correlate with performance expectations and application suitability. Bluestone density ranges from 150 to 165 pounds per cubic foot depending on quarry source and specific mineral composition. You’ll find that higher-density selections provide superior compressive strength and freeze-thaw resistance, while lower-density varieties may offer better workability during fabrication and reduced structural loading.

You should verify density specifications through ASTM C97 testing documentation rather than relying on generic supplier claims. When you specify materials for structural applications like treads or heavy-load paving, minimum density requirements of 160 PCF ensure adequate performance under repeated loading cycles. Your structural calculations must incorporate actual density values, as the 15 PCF range across bluestone varieties represents significant variance in dead load calculations for elevated deck installations.

The relationship between density and porosity affects both immediate installation requirements and long-term maintenance expectations. You’ll notice that higher-density bluestone typically exhibits lower porosity, reducing water absorption and improving stain resistance. This becomes critical in Arizona installations where dust, pollen, and mineral-rich irrigation water create persistent staining challenges. Your material specifications should establish maximum porosity limits, typically 3-5% by volume for exterior applications, verified through ASTM C97 water absorption testing.

Arizona Climate Impact Specifications

Your material specifications must account for Arizona’s extreme climate conditions that exceed standard installation parameters. Daily temperature swings of 40-50°F during spring and fall create continuous expansion and contraction cycles that stress both materials and installation systems. You need to understand how these thermal cycles interact with bluestone’s physical properties to prevent installation failures that become apparent 12-24 months after completion.

When you design installations using bluestone supply llc Arizona services, solar radiation intensity requires specific attention. Arizona’s high-altitude locations and minimal cloud cover create UV exposure levels that accelerate color fading in some stone varieties. You should specify colorfast bluestone selections that maintain appearance under intense UV exposure, typically verified through ASTM G155 accelerated weathering testing. The thermal mass properties of bluestone become both advantage and challenge — while the material moderates temperature swings effectively, surface temperatures under direct Arizona sun can reach 150-170°F, creating safety concerns for barefoot traffic around pools.

- You must design expansion joints every 12-15 feet in large paving installations to accommodate thermal movement

- Your specifications should require sealers with UV inhibitors specifically formulated for high-altitude environments

- You need to account for accelerated efflorescence potential in areas with mineral-rich groundwater and low humidity

- Your installation timeline should avoid mid-summer work when surface temperatures prevent proper mortar curing

Installation Methodology: Setting Bed Requirements

When you specify installation methods for bluestone treads Arizona or coping components, setting bed selection determines both immediate installation success and long-term performance. Your installation specifications must address substrate preparation, mortar selection, and curing requirements that align with Arizona’s climate challenges. The setting bed creates the critical interface between stone components and structural substrate, transferring loads while accommodating differential movement.

You should understand how mortar selection affects installation performance in Arizona’s temperature extremes. Standard masonry mortars formulated for moderate climates often fail under Arizona’s rapid temperature cycling and low humidity conditions. You’ll achieve better results when you specify polymer-modified mortars with extended working times and enhanced flexibility. Your installation specifications should reference ANSI A108.5 mortar bed requirements, modified for Arizona conditions with maximum aggregate sizes of 1/4 inch and minimum 1-inch bed thickness under treads and coping.

The relationship between setting bed thickness and thermal movement accommodation requires careful specification. You need to provide sufficient bed depth to allow trowel manipulation for proper stone placement while avoiding excessive thickness that reduces structural stability. Your details should specify 1 to 1.5-inch mortar beds for tread and coping installations, with 80-90% back-butter coverage to ensure continuous support without creating voids that allow deflection under loading.

Quality Verification: Inspection Protocols

Your project quality assurance requires inspection protocols that verify fabrication precision before installation begins. When you receive bluestone suppliers Arizona fabrication components, dimensional verification catches errors while correction remains practical. You should establish inspection procedures that check critical dimensions, edge detail execution, and surface finish consistency against approved samples. This verification process typically reveals 3-5% of components requiring refinishing or replacement — addressing these before installation prevents costly field corrections.

You need to implement systematic inspection covering both aesthetic and performance criteria. Your inspection protocol should document color and texture variation across the shipment, ensuring consistency matches approved samples. For components like bluestone treads Arizona, you must verify that dimensional tolerances maintain uniform riser heights within ±1/16 inch across all pieces. Edge detail execution requires particular attention, confirming that radius profiles, thermal finishes, and drip grooves meet specification requirements.

- You should conduct pre-installation meetings with installers to review quality standards and acceptable tolerances

- Your inspection process must document any material defects with photography before installation proceeds

- You need to verify that thermal-finished surfaces meet specified DCOF slip resistance requirements through field testing

- Your quality control should include random thickness verification, particularly for coping with specified cantilever dimensions

Citadel Stone: Best Bluestone Supply in Arizona Specification Approach

When you consider Citadel Stone’s Bluestone Supply in Arizona for your project, you’re evaluating comprehensive fabrication capabilities designed to meet diverse architectural requirements across the state. At Citadel Stone, we provide technical guidance for hypothetical applications spanning Arizona’s varied climate zones and project types. This section outlines how you would approach specification decisions for six representative cities, considering regional conditions that influence material selection and installation methodology.

Phoenix Commercial Treads

In Phoenix, you would encounter extreme heat exposure requiring careful material selection for exterior tread applications. Your specifications would need to address thermal-finished surfaces for slip resistance while accounting for surface temperatures that regularly exceed 160°F during summer months. You should consider how the urban heat island effect amplifies thermal stress, requiring expansion joint spacing of 12 feet maximum in continuous tread runs. For commercial installations in downtown Phoenix, you would specify minimum 2-inch thickness treads to handle heavy pedestrian traffic while maintaining structural integrity under thermal cycling. Your edge details would typically incorporate 1/8-inch eased edges for ADA compliance, with drip grooves positioned to direct monsoon runoff away from building entries.

Tucson Pool Coping

Your Tucson pool deck projects would require bluestone coping suppliers Arizona capable of delivering components resistant to intense UV exposure combined with chemical pool treatments. You would specify closed-pore bluestone selections with maximum 4% porosity to minimize water absorption in this high-evaporation climate. The thermal shock from 150°F sun-heated stone meeting cool pool water demands that you incorporate proper expansion accommodation in coping installations. Your specifications would address bullnose edge profiles for pool coping, providing comfortable edge contact while directing water runoff. You should consider how Tucson’s mineral-rich water affects efflorescence potential, requiring you to specify appropriate sealers and maintenance protocols for long-term appearance retention.

Scottsdale Custom Residential

When you design for Scottsdale’s luxury residential market, you would emphasize custom fabrication capabilities including radius cuts and specialty edge details. Your projects would typically require bluestone suppliers Arizona custom cuts for curved stair treads, serpentine pool coping, and custom-patterned paving. You should specify CNC fabrication precision of ±1/32 inch to ensure pattern alignment across large installations. Scottsdale’s design-conscious clientele would drive you toward refined edge details like full bullnose profiles and honed-then-thermal combination finishes. Your material selections would need to complement desert contemporary architecture while maintaining performance under intense solar exposure. You would verify that custom components meet the same structural and slip resistance standards as standard fabricated pieces, particularly for treads and pool coping applications.

Flagstaff Freeze-Thaw Performance

Your Flagstaff installations would require fundamentally different specifications addressing freeze-thaw cycling absent in lower-elevation Arizona locations. You would need to specify bluestone supply llc Arizona services providing material with proven freeze-thaw resistance through ASTM C666 testing. At 7,000-foot elevation, Flagstaff experiences 100+ annual freeze-thaw cycles that demand maximum 5% porosity in bluestone selections. Your tread specifications would incorporate deeper thermal finishing for enhanced traction during snow and ice conditions. You should address how moisture penetration combined with freezing temperatures affects edge spalling, requiring you to specify sealed edges and proper drainage design. Your installation timeline would need to avoid winter months when freeze conditions prevent proper mortar curing. You would verify that all fabricated components receive appropriate sealing before installation to minimize water infiltration during the critical first winter exposure.

Sedona Natural Aesthetic

When you approach Sedona projects, you would balance bluestone’s gray-blue tones with the surrounding red rock landscape aesthetic. Your material specifications would likely incorporate natural or thermal finishes rather than polished surfaces that contrast with Sedona’s organic design vocabulary. You should consider how bluestone treads Arizona integrate with native flagstone and iron oxide-rich materials common in Sedona architecture. The tourist-heavy commercial district would require you to specify slip-resistant thermal finishes on treads and walkways while maintaining refined appearance. Your edge details would typically favor subtly eased or rock-faced profiles that complement rather than compete with natural stone elements. You would address how intense UV exposure at 4,500-foot elevation accelerates color shifts, specifying colorfast bluestone varieties and UV-resistant sealers to maintain long-term appearance consistency with project design intent.

Mesa Value Engineering

Your Mesa projects would often require value engineering approaches that maintain performance while meeting budget constraints. You would work with bluestone suppliers Arizona fabrication services to optimize component sizing, reducing custom cutting requirements where possible. Standard tread depths of 12 or 14 inches would replace custom dimensions when building geometry permits. Your specifications would incorporate cost-effective half bullnose details on treads rather than full bullnose profiles, concentrating refinement on visible edges while using simple eased details on hidden edges. You should consider how standardized component sizing affects procurement lead times and costs, potentially reducing fabrication schedules by 2-3 weeks. Your edge detail specifications would balance safety requirements with fabrication economy, specifying minimum compliant details rather than premium profiles. You would evaluate whether project requirements truly demand custom fabrication or whether standard dimensions serve functional needs adequately. For additional installation insights, review Wholesale bluestone distributors serving Arizona contractors and builders before you finalize your project documents. Citadel Stone’s thermal finish inventory exceeds bluestone supply llc in Arizona textured options.