When you’re sourcing bluestone supply Arizona finishes for your next project, understanding the performance differences between natural cleft and thermal finishes becomes critical. You’ll find that Arizona’s extreme climate conditions—from Phoenix’s 120°F summer heat to Flagstaff’s freeze-thaw cycles—demand specific surface texture considerations that directly impact long-term durability and user safety. Your finish selection affects everything from slip resistance coefficients to thermal mass behavior, and getting this decision wrong costs you in callbacks and client dissatisfaction.

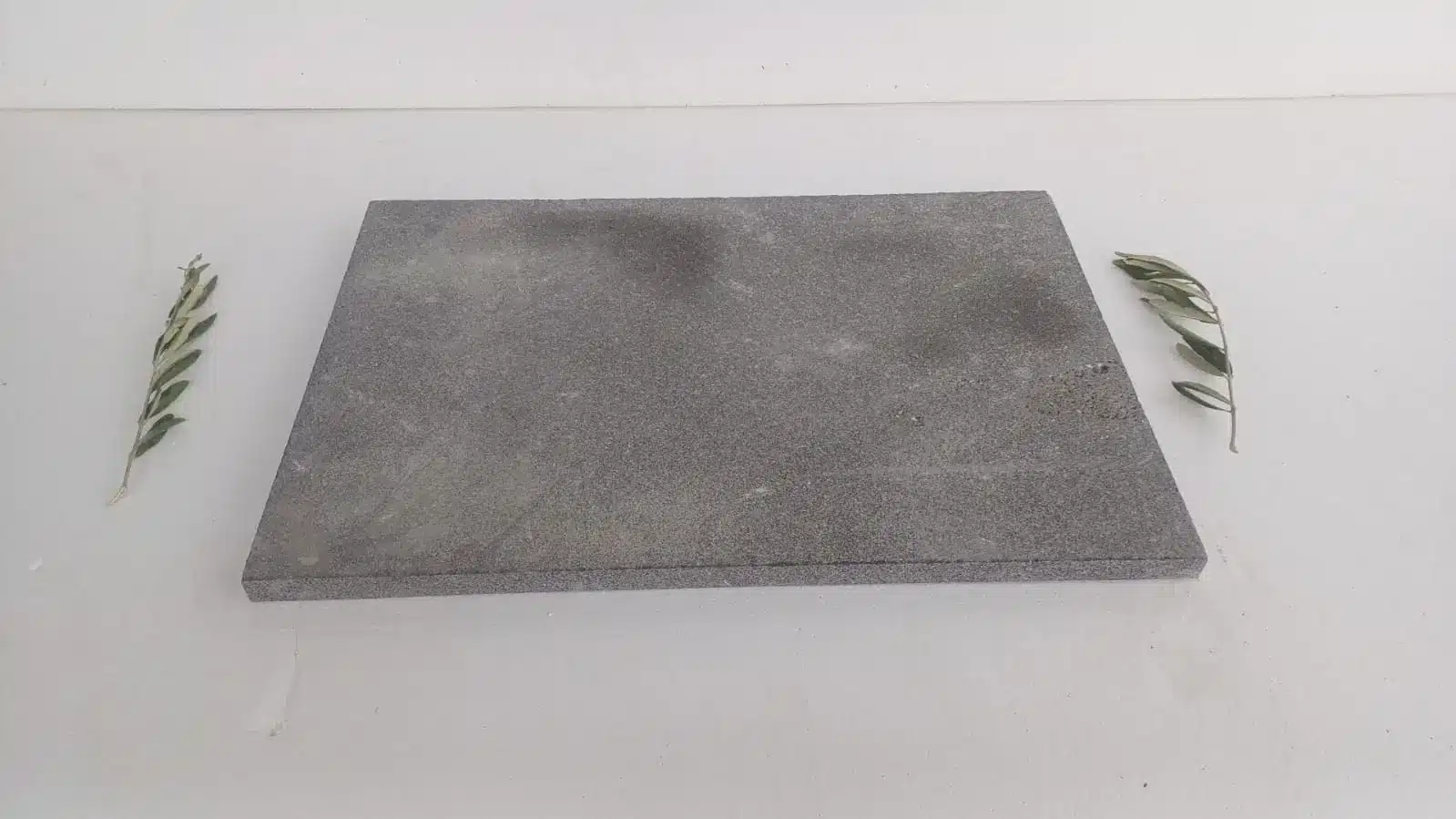

The bluestone supply Arizona finishes market offers two primary surface options, each with distinct performance characteristics. Natural cleft surfaces retain the stone’s original split-face texture, providing inherent slip resistance and a traditional aesthetic. Thermal finishes use high-temperature flame treatment to expose aggregate and create controlled surface roughness. You need to understand how each finish responds to Arizona’s intense UV exposure, thermal cycling that can exceed 50°F daily variation, and dust accumulation patterns that affect maintenance requirements.

Material Composition Affects Finish Performance

Bluestone’s mineral composition determines how well different finishes perform in Arizona environments. You’re working with a dense, fine-grained sandstone that contains quartz, feldspar, and varying amounts of mica and chlorite. The material’s porosity typically ranges from 3-7%, which influences water absorption, stain resistance, and how surface treatments interact with the stone matrix. When you specify bluestone suppliers Arizona finish options, you need to consider how mineral content affects thermal expansion coefficients and surface durability under mechanical wear.

Your specification should address the relationship between stone density and finish longevity. Natural cleft surfaces on high-density bluestone maintain their texture profile for 20-25 years in high-traffic applications. Lower-density material shows accelerated wear patterns, with texture depth reducing by 15-20% within the first decade. Thermal finishes on dense bluestone provide consistent slip resistance throughout their service life because the flame treatment penetrates 2-3mm below the surface, creating a reservoir of exposed aggregate as wear occurs.

The stone’s compressive strength—typically 12,000-18,000 PSI for quality bluestone—directly impacts how finishes withstand Arizona’s environmental stresses. You’ll see better performance from material in the upper range, particularly for thermal finishes where high-temperature exposure during processing creates internal stresses. Bluestone suppliers Arizona cleft vs thermal specifications should include minimum density requirements of 160 pounds per cubic foot to ensure adequate durability in commercial applications.

Natural Cleft Surface Characteristics

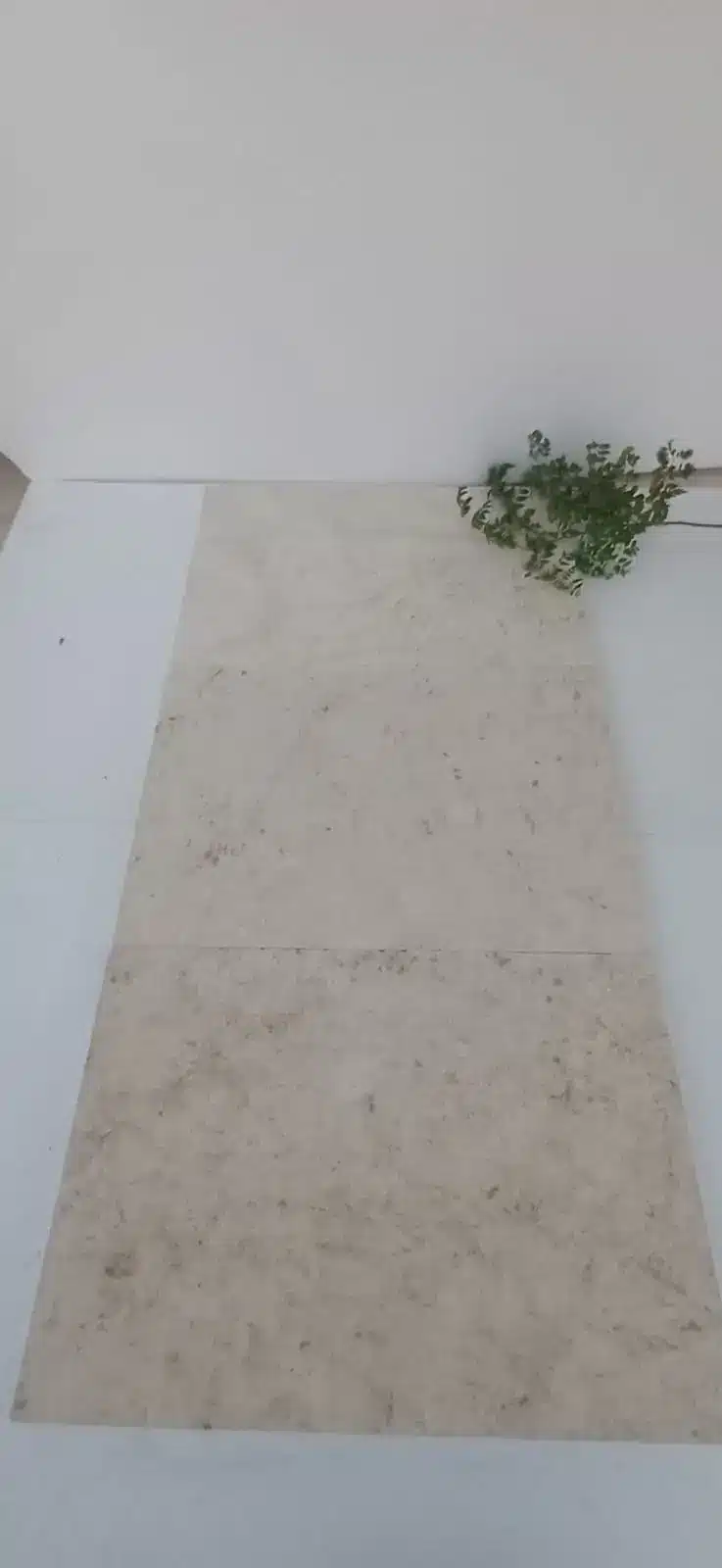

Natural cleft finishes showcase bluestone’s inherent stratification patterns, creating surface textures with 1/8″ to 3/8″ relief variation. When you specify this finish, you’re accepting the stone’s natural split face as it comes from the quarry. The texture provides excellent slip resistance with DCOF ratings typically ranging from 0.52 to 0.68 in dry conditions. You need to understand that this wide range reflects natural variation—no two pieces exhibit identical surface profiles, which creates both aesthetic appeal and specification challenges.

The primary advantage you gain with natural cleft surfaces involves minimal processing requirements, which preserves the stone’s structural integrity. There’s no heat exposure, no mechanical grinding, and no chemical treatment that might compromise long-term performance. Your installations benefit from the material’s natural porosity pattern, which remains undisturbed by processing. This becomes critical in Arizona’s dry climate, where proper moisture vapor transmission prevents subsurface condensation issues that can lead to delamination or spalling.

- You’ll observe texture depth that decreases predictably over time, with high-traffic areas showing 0.02-0.03 inches of wear per decade

- Your slip resistance remains adequate throughout the service life because underlying stone continues to exhibit the same cleft characteristics

- You should expect color consistency advantages, as no heat treatment creates surface oxidation or mineral alteration

- Your maintenance protocols need to address texture valleys where debris accumulates, requiring pressure washing at 1,800-2,200 PSI annually

When you evaluate natural bluestone Arizona textures for pool decks or high-traffic commercial spaces, recognize that surface irregularity affects furniture stability and creates tripping hazards if relief exceeds 1/4″. Your specification should include maximum texture variation tolerances, typically limiting relief to 3/16″ for areas with wheeled traffic or outdoor dining applications. The natural cleft profile also affects joint sand retention—deeper textures hold sand better but create cleaning challenges.

Thermal Finish Processing Outcomes

Thermal finishing exposes bluestone to 1,800-2,200°F flame treatment for 2-4 seconds, causing surface minerals to expand and fracture at different rates. You’re creating a controlled spalling effect that reveals fresh aggregate and produces uniform surface roughness. The process generates 1-2mm of texture depth with more consistent relief patterns than natural cleft surfaces. When you compare bluestone suppliers Arizona cleft vs thermal options, thermal finishes offer predictable slip resistance across entire installations, with DCOF values consistently measuring 0.58-0.64.

Your thermal finish selection involves trade-offs between surface uniformity and color alteration. The high-temperature exposure oxidizes iron-bearing minerals, shifting color tones toward warmer grays and introducing subtle bronze highlights. This color change remains permanent and stable under UV exposure, which matters in Arizona’s intense sunlight conditions. You should evaluate sample panels that have undergone thermal treatment to verify color acceptability for your project’s aesthetic requirements. For additional sourcing options, see Citadel Stone’s wholesale bluestone materials for comprehensive thermal finish specifications.

The thermal process creates micro-fissures throughout the treated surface layer, which affects porosity and water absorption characteristics. You’ll measure absorption rates 8-12% higher on thermally finished surfaces compared to natural cleft material from the same quarry run. This increased porosity requires more aggressive sealing protocols, with initial penetrating sealer application followed by resealing every 3-4 years instead of the 5-7 year cycle typical for natural cleft surfaces. Your maintenance specifications must address this difference to prevent accelerated staining and weathering.

- You obtain surface uniformity that simplifies large-format installations, reducing lippage concerns and creating cleaner sight lines

- Your specification achieves consistent slip resistance across the entire installation, eliminating variability concerns

- You need to account for 5-8% material loss during thermal processing, which affects yield calculations and project budgets

- Your color selection becomes more limited as thermal treatment reduces the range of available tones compared to natural cleft options

Thermal Performance in Arizona Heat

Surface temperature differentials between natural cleft and thermal finishes reach 8-12°F under identical exposure conditions in Phoenix summer sun. You’re dealing with thermal mass behavior where finish texture affects heat absorption and radiation patterns. Thermal finishes with their uniform, slightly rougher surface profile absorb solar radiation more efficiently, reaching peak temperatures 15-20 minutes faster than natural cleft surfaces. This matters significantly for barefoot traffic areas—pool decks, spa surrounds, and resort pathways where surface temperature directly impacts usability.

When you measure surface temperatures at 2:00 PM in July Phoenix conditions, natural cleft bluestone typically peaks at 142-148°F, while thermal finishes reach 150-156°F. Your material selection affects client satisfaction in residential applications and liability exposure in commercial settings. The temperature differential results from surface area geometry—thermal finishes create more exposed surface area per square foot, increasing solar radiation absorption. You can mitigate this through light-colored stone selection, but the texture-driven temperature difference persists across all color ranges.

The bluestone supply Arizona finishes you specify also affects nighttime heat retention and morning warm-up rates. Thermal finishes release stored heat 20-25% faster than natural cleft surfaces due to their increased surface area. You’ll find this creates more comfortable evening conditions but extends the morning period when surfaces remain uncomfortably hot from previous day heating. Your design should incorporate shade structures, water features, or vegetation to moderate thermal mass effects regardless of finish selection.

Slip Resistance Performance Factors

Wet slip resistance becomes your primary safety concern in Arizona pool deck and spa applications, where DCOF values must exceed 0.42 to meet ADA requirements. Natural cleft surfaces typically measure 0.48-0.56 DCOF when wet, while thermal finishes range from 0.52-0.60 DCOF. You gain 8-12% better slip resistance with thermal finishes, but you’re also working with a surface that accumulates calcium deposits more readily in hard water areas. These deposits fill texture valleys and can reduce effective slip resistance by 15-20% within 18-24 months without proper maintenance.

- You should conduct site-specific slip testing using water chemistry that matches local conditions, as Arizona’s high mineral content affects surface traction

- Your specification needs to address texture depth maintenance, requiring periodic pressure washing to remove accumulated deposits

- You’ll find that pool chemical exposure accelerates texture degradation on both finishes, with chlorine and salt systems affecting thermal finishes more aggressively

- Your safety protocols must account for seasonal variation, as monsoon humidity creates different traction conditions than typical dry climate performance

The relationship between texture depth and slip resistance follows a predictable curve until texture exceeds 2mm depth, after which you encounter diminishing returns and increased maintenance requirements. Bluestone surface Arizona specifications should target 1.5-2.0mm texture depth for optimal slip resistance without creating debris accumulation problems. You need to recognize that deeper textures trap fine Arizona dust and organic debris, requiring more frequent cleaning to maintain both appearance and traction performance.

Installation Methodology Differences

Your installation approach varies significantly between natural cleft and thermal finishes due to dimensional consistency differences. Natural cleft material exhibits ±3/16″ thickness variation across individual pieces, while thermal finishes typically maintain ±1/8″ tolerance. You’ll spend 15-20% more installation time with natural cleft surfaces to accommodate thickness variation through base layer adjustment or back-grinding. This labor cost difference often offsets the material cost premium for thermal finishes, making total installed cost comparable.

When you set natural cleft bluestone, you’re constantly adjusting base layer depth to achieve consistent surface plane. Your installation crew needs to maintain 1/8″ maximum lippage across joints, which requires careful piece selection and placement. The irregular bottom surface of natural cleft material also affects mortar coverage—you need to ensure 95% coverage to prevent hollow spots that lead to cracking. Thermal finished material with its more uniform thickness allows faster setting with more consistent mortar coverage and reduced risk of installation defects.

Joint spacing requirements differ between finishes due to edge profile characteristics. Natural cleft pieces often exhibit irregular edges that require 3/8″ to 1/2″ joints to accommodate edge variation and prevent binding. Thermal finishes with saw-cut or guillotined edges allow tighter 1/4″ to 3/8″ joints. Your joint width selection affects thermal expansion accommodation—Arizona’s 50-60°F daily temperature swings create 0.02-0.03 inches of movement per 10 linear feet. Tighter joints increase stress concentration and spalling risk at joint edges.

Maintenance Protocol Requirements

Your maintenance program needs to address the different porosity and texture characteristics of each finish. Natural cleft surfaces require annual pressure washing at 1,800-2,000 PSI to remove accumulated debris from texture valleys. You should avoid exceeding 2,200 PSI, as higher pressures begin to erode the natural cleft texture and accelerate surface wear. Thermal finishes tolerate slightly higher pressure—2,000-2,400 PSI—due to their fire-hardened surface layer, but you still need to maintain consistent nozzle distance to prevent localized erosion.

Sealing protocols differ substantially between finishes. You’ll apply penetrating sealers to both surface types, but thermal finishes require 20-30% more sealer per square foot due to increased porosity from the thermal treatment process. Your initial sealer application should include two coats on thermal finishes versus one coat typically sufficient for natural cleft material. Re-sealing intervals also differ—you need to re-seal thermal finishes every 3-4 years compared to 5-7 years for natural cleft surfaces in comparable applications.

- You should implement quarterly inspections focused on joint sand retention, which differs between finishes due to texture profile variations

- Your cleaning protocols must address Arizona’s dust accumulation patterns, which affect thermal finishes more severely due to their uniform texture valleys

- You need to specify calcium deposit removal for pool deck applications, using mild acid treatments that won’t damage the stone matrix

- Your long-term maintenance planning should account for refinishing costs—thermal surfaces require re-treatment every 15-20 years while natural cleft surfaces typically last 25-30 years before major restoration

Cost Analysis and Value Engineering

Material costs for bluestone supply Arizona finishes typically show thermal finishes commanding 15-25% premium over natural cleft surfaces from the same quarry source. You’re paying for additional processing, material loss during thermal treatment, and the enhanced surface uniformity. However, when you calculate total installed cost including labor, base preparation, and joint material requirements, the cost differential narrows to 8-12%. Your value engineering analysis should consider lifecycle costs including maintenance, sealing, and expected service life before replacement becomes necessary.

When you evaluate bluestone suppliers Arizona finish options from a total cost perspective, natural cleft surfaces demonstrate lower 25-year lifecycle costs in low-traffic residential applications. The reduced sealing frequency and longer surface life before refinishing offset the higher installation labor. For commercial applications with heavy traffic and stringent slip resistance requirements, thermal finishes prove more cost-effective through consistent performance and reduced liability exposure. You should conduct project-specific cost modeling that accounts for traffic levels, maintenance capability, and performance requirements.

Material availability affects project scheduling and cost. Natural cleft bluestone maintains consistent warehouse inventory levels because it requires minimal processing. Thermal finishes often carry longer lead times—6-8 weeks versus 2-3 weeks for natural cleft—because processing capacity limits production rates. Your procurement planning needs to account for these lead time differences, particularly for large projects requiring truck deliveries coordinated with installation schedules. Rush orders for thermal finishes can add 12-18% cost premium when you need to expedite processing.

Color Stability and Aesthetic Aging

Color evolution over time differs significantly between natural cleft and thermal bluestone finishes. Natural cleft surfaces maintain their quarried color with minimal change, showing only subtle lightening from surface weathering over 15-20 year periods. The color stability results from minimal processing that leaves mineral composition undisturbed. When you specify natural bluestone Arizona textures, you’re selecting for long-term color consistency that requires no refinishing to maintain original appearance.

Thermal finishes undergo immediate color alteration during processing, as the 1,800-2,200°F flame exposure oxidizes surface minerals. You’ll observe warming of gray tones and enhancement of any iron content as russet or bronze highlights. This thermally altered color remains stable under Arizona’s intense UV exposure better than many natural stone finishes. Your material selection should include review of thermally treated samples that have undergone accelerated weathering testing to verify color stability meets project requirements.

Arizona’s extreme UV exposure causes 5-8% color fading in most natural stones over 10-year exposure periods. Bluestone supply Arizona finishes demonstrate superior UV stability, with both natural cleft and thermal surfaces showing less than 3% color shift under accelerated testing equivalent to 15 years Arizona sun exposure. You can specify either finish with confidence in long-term color stability, though you should still evaluate samples for initial color acceptability. The thermal finish’s slightly warmer tone complements desert architecture better in many applications, while natural cleft’s cooler gray suits contemporary designs.

Common Specification Mistakes

You’ll encounter recurring specification errors that compromise bluestone installations in Arizona climates. The most frequent mistake involves failing to specify minimum density requirements, allowing suppliers to provide lower-grade material that exhibits premature wear and reduced slip resistance. Your specifications must include minimum density of 160 pounds per cubic foot and maximum porosity of 7% to ensure adequate performance regardless of finish selection. Without these criteria, you’re accepting material that may not survive Arizona’s thermal cycling and UV exposure for the expected service life.

- You often see specifications that fail to address thickness tolerance adequately, leading to installation delays and lippage issues when material arrives

- Your drawings frequently omit expansion joint requirements specific to Arizona’s thermal cycling, resulting in edge spalling and cracking within 3-5 years

- You sometimes specify sealing products incompatible with the stone’s porosity characteristics, causing sealer failure and accelerated staining

- Your maintenance protocols often replicate generic stone care guidelines rather than addressing Arizona’s specific dust, UV, and hard water challenges

Another critical error involves specifying finish types without considering the complete application context. You might specify thermal finishes for their superior slip resistance without accounting for the increased heat retention that makes them unsuitable for barefoot traffic areas. Conversely, specifying natural cleft surfaces for large-format plaza installations creates unnecessary installation complexity and cost. Your finish selection must balance slip resistance, thermal comfort, aesthetic goals, installation efficiency, and maintenance capability within the specific project context.

Citadel Stone: Premier Bluestone Suppliers in Arizona Applications

When you consider Pennsylvania bluestone for Arizona projects, you need guidance that accounts for the state’s unique climate challenges. At Citadel Stone, we provide technical specifications for hypothetical applications across Arizona’s diverse regions, from low-desert heat to high-elevation freeze-thaw zones. This section outlines how you would approach material selection and finish specification for six representative Arizona cities, demonstrating the decision framework you should apply to your specific projects.

Arizona’s climate zones range from USDA Zone 5b in Flagstaff to Zone 10a in Yuma, creating dramatically different performance requirements. You would need to account for temperature extremes spanning 140°F annual range in some locations, combined with UV indices that regularly reach 11+ during summer months. Your finish selection process should address these regional variations through climate-specific performance criteria rather than applying uniform specifications statewide.

Phoenix Heat Considerations

In Phoenix’s extreme heat environment where summer temperatures regularly exceed 115°F, you would prioritize thermal comfort over other finish characteristics. Natural cleft surfaces would provide 8-12°F cooler surface temperatures compared to thermal finishes, making them preferable for pool decks and resort pathways with barefoot traffic. You should specify light-colored bluestone selections that reflect 60-70% of solar radiation rather than darker tones that absorb heat. Your installation would require expansion joints every 12 feet rather than the standard 15-foot spacing to accommodate daily thermal cycling that can reach 50°F variation. When you plan material deliveries from the warehouse, you’d need to schedule for early morning arrival to avoid thermal shock from off-loading hot material onto cooler base layers.

Tucson Dust Management

Tucson’s fine dust conditions would require you to consider texture profile effects on maintenance requirements. Thermal finishes with their uniform texture valleys would trap dust more consistently than natural cleft surfaces, requiring quarterly pressure washing to maintain appearance. You should specify sealed surfaces with penetrating sealers that prevent dust particle embedment while maintaining vapor permeability. Your specification would address monsoon rain patterns that create mud splashing conditions, favoring slightly larger joint widths of 3/8″ to 1/2″ that accommodate cleaning tool access. Installation timing would need to avoid monsoon season when base moisture affects setting bed stability.

Scottsdale Aesthetic Standards

For Scottsdale’s high-end residential and commercial applications, you would focus on appearance consistency and color stability. Thermal finishes would provide the uniform surface presentation preferred in luxury installations, with consistent texture depth and predictable color tones. You should specify full-range bluestone with minimal color variation to achieve the refined aesthetic typical of Scottsdale projects. Your details would include 1/4″ joints with matching polymeric sand to create clean sight lines. At Citadel Stone, we recommend thermal finishes for these applications where appearance uniformity justifies the material cost premium and increased maintenance requirements.

Flagstaff Freeze Protection

Flagstaff’s freeze-thaw exposure would demand your attention to porosity and drainage characteristics. You would specify material with maximum 5% porosity rather than the 7% acceptable in lower elevations, reducing water absorption that drives freeze-thaw damage. Natural cleft finishes would prove advantageous because their lower processing-related porosity better resists moisture intrusion. Your base design would require 6-8 inches of free-draining aggregate rather than the 4-inch minimum sufficient in Phoenix, ensuring rapid water evacuation before freezing occurs. You should detail heated truck delivery requirements for winter installations when ambient temperatures drop below 35°F.

Sedona Color Integration

In Sedona’s red rock landscape, you would select bluestone tones that either complement or deliberately contrast with surrounding geology. Thermal finishes with their warmer, iron-enhanced coloring would harmonize with local stone palette, while natural cleft surfaces in cool gray tones would provide contemporary contrast. You should specify sample panel mockups viewed in Sedona’s unique lighting conditions, as the area’s red dust atmosphere affects color perception. Your sealing protocol would need to address red dust staining potential, using color-enhancing sealers that mask superficial dust accumulation between maintenance cycles.

Yuma Extreme UV Exposure

Yuma’s position as one of the sunniest locations globally would require you to prioritize UV stability in your finish selection. Both natural cleft and thermal finishes demonstrate excellent UV resistance, but you should specify additional protective sealing with UV-inhibitor additives to maximize color stability. Your material selection would favor full-color range bluestone rather than variegated options, as uniform coloring shows less visible fading over time. Installation would need to account for extreme heat during summer months when ground temperatures reach 165°F, requiring modified mortar mixes with extended working time and afternoon installation restrictions. You would specify thermal finishes only for shaded applications where their heat retention disadvantage becomes negligible, reserving natural cleft surfaces for sun-exposed areas where thermal comfort drives finish selection.

Professional Selection Framework

Your finish selection process should follow a systematic evaluation framework that prioritizes performance requirements over aesthetic preferences. Begin by quantifying slip resistance requirements based on traffic patterns and wet exposure probability. Commercial pool decks require minimum 0.52 DCOF wet slip resistance, which both finishes can achieve but thermal surfaces provide with more consistency. You need to document these requirements in your specifications rather than relying on supplier general claims about suitability.

Next, you should evaluate thermal comfort requirements relative to barefoot traffic exposure. Calculate expected surface temperatures using solar radiation data specific to your project location and orientation. When peak surface temperatures would exceed 140°F for more than 2 hours daily, you must specify natural cleft surfaces or implement shading strategies to maintain usability. Your analysis should account for reflected radiation from adjacent surfaces and building facades, which can add 8-12°F to direct solar heating.

Finally, you need to conduct lifecycle cost modeling that includes initial material costs, installation labor, sealing frequency, routine maintenance, and expected service life. For projects with 25+ year design life, the differences in maintenance requirements and refinishing costs often exceed initial material cost differentials. You should request warehouse delivery schedules and truck access requirements early in the planning process to identify any logistical constraints that affect finish selection or project phasing.

Key Takeaways

Your professional specification process requires you to balance multiple performance factors when selecting between natural cleft and thermal bluestone finishes for Arizona applications. The decision framework should prioritize thermal comfort for barefoot traffic areas, slip resistance for wet applications, and aesthetic consistency for high-visibility installations. You need to recognize that neither finish provides universal superiority—each offers specific advantages that match particular application requirements.

When you document specifications, include minimum density requirements, porosity limits, thickness tolerances, and color selection criteria rather than relying solely on finish designation. Your construction details must address Arizona-specific concerns including thermal expansion joint spacing, base drainage capacity, and sealing protocols adapted to local water chemistry and UV exposure. You should maintain communication with material suppliers regarding warehouse stock levels and delivery lead times to ensure finish selection aligns with project schedule constraints. For comprehensive guidance on Pennsylvania bluestone selection criteria, review Pennsylvania bluestone characteristics for Arizona pool deck applications before you finalize your project documents. Citadel Stone’s full-color range makes it diverse bluestone suppliers in Arizona palette options.