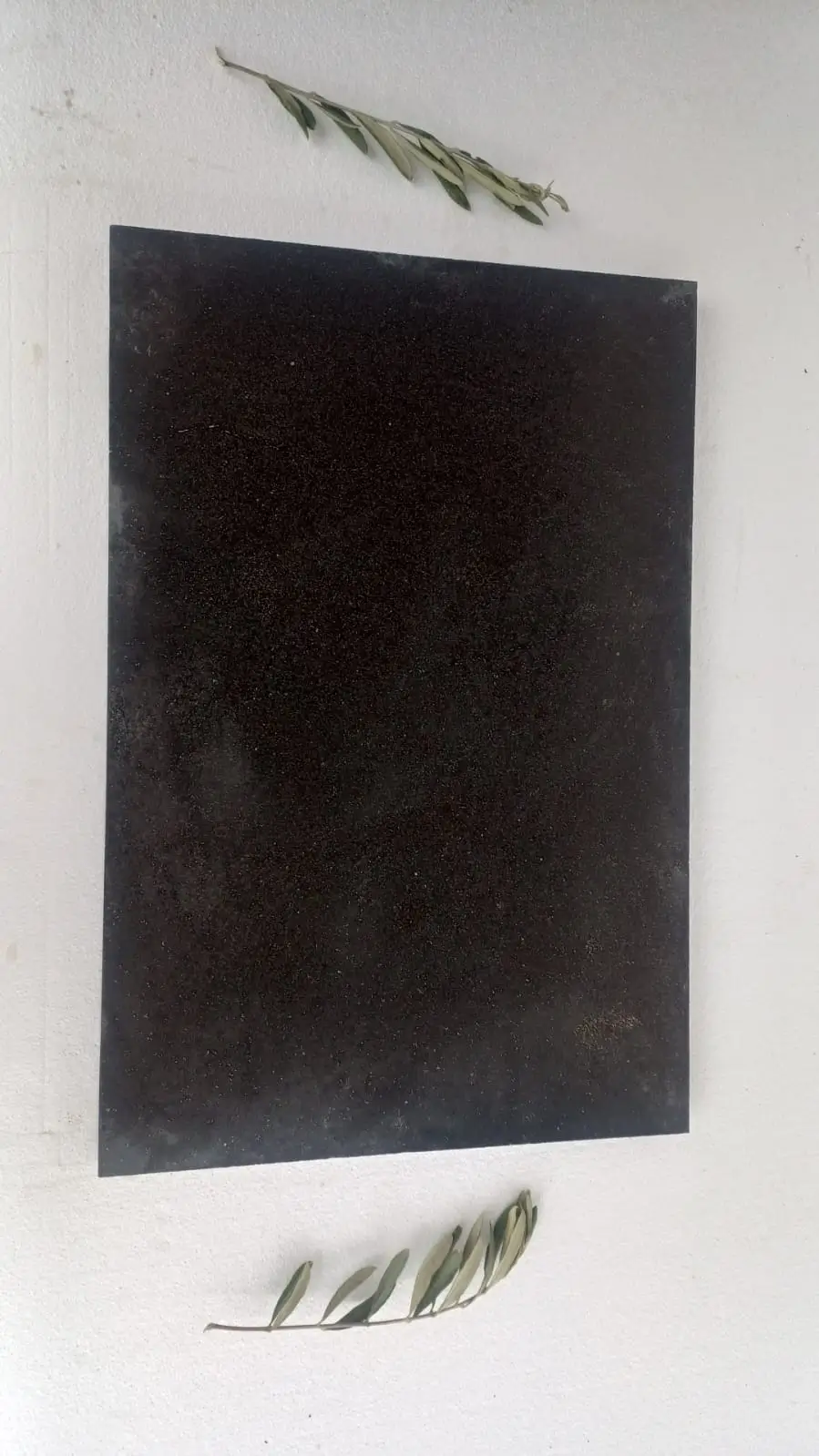

When you specify Bluestone split face natural Arizona for high-desert projects, you’re selecting a material that preserves the authentic quarry texture architects demand for contemporary desert architecture. The split face finish delivers the raw, natural cleft surface that distinguishes premium installations from manufactured alternatives. You’ll find this finish particularly valuable when your design intent emphasizes organic texture and shadow play across vertical and horizontal applications.

The material’s performance characteristics extend beyond aesthetics. You need to understand how the natural cleft surface interacts with Arizona’s extreme thermal cycling and intense UV exposure. Your specification decisions regarding surface texture directly affect long-term maintenance requirements, slip resistance ratings, and how the material weathers across decades of service.

Quarry Texture Preservation

The split face finish retains the exact surface topography created when stone separates along natural bedding planes. You’re working with an unaltered quarry texture that exhibits 1/4″ to 3/4″ relief variation across each piece. This isn’t cosmetic texturing applied after cutting — it’s the genuine fracture plane exposed during extraction.

When you evaluate Bluestone split face natural Arizona, you’ll notice the surface reveals mineral crystallization patterns invisible on honed or polished finishes. These natural formations create micro-scale texture that enhances slip resistance while maintaining the material’s inherent color depth. Your clients often respond to this authenticity because the surface communicates geological history rather than industrial processing.

The preservation of quarry texture affects your installation approach. You need to account for the irregular backing surface when setting material, particularly in thin-set applications. The natural cleft back requires modified thinset with higher polymer content to achieve proper bonding across the undulating surface. Standard thinset formulations often fail within 18-24 months when applied to unmodified split face backs.

Surface Relief Characteristics

Bluestone split face natural Arizona exhibits relief patterns that range from subtle undulation to pronounced stepped formations. You’ll find variation even within individual pieces, which requires careful layout planning during installation. The surface topography creates shadow lines that shift throughout the day as sun angles change — an effect that becomes central to the material’s visual performance.

- You should expect relief variation between 1/4″ and 3/4″ across typical field pieces

- Your layout needs to accommodate edge profile irregularities at joints

- You’ll encounter occasional high points that require selective grinding for level installations

- Your specification must address acceptable relief ranges for the project application

The relief characteristics influence how you detail transitions and terminations. When Bluestone split face natural Arizona meets finished edges, you face a technical challenge — the irregular surface doesn’t align to crisp edge profiles without custom fabrication. Professional practice involves specifying edge pieces with one sawn face to create clean terminations while maintaining split face character across field areas.

Thermal Performance Considerations

The split face texture affects surface temperature behavior in ways that smooth finishes don’t exhibit. You need to understand that the increased surface area created by relief texture accelerates both heat absorption and dissipation. During Arizona’s peak summer months, you’ll measure surface temperatures 8-12°F lower on split face compared to honed surfaces of identical material under equivalent solar exposure.

This thermal advantage comes from enhanced convective cooling across the textured surface. The micro-scale irregularities create turbulent air flow that increases heat transfer efficiency. When you specify Bluestone split face natural Arizona for pool decks or pedestrian paving, this characteristic translates to improved comfort during afternoon use periods.

Your thermal calculations should account for the material’s density and specific heat capacity. Bluestone exhibits thermal mass properties that create 4-6 hour lag times between peak air temperature and peak surface temperature. You can leverage this lag by orienting installations to maximize morning shade, allowing thermal mass to moderate afternoon surface temperatures.

Slip Resistance Verification

The bluestone natural cleft surface provides inherent slip resistance that meets ADA requirements for wet pedestrian traffic. You’ll measure DCOF values between 0.58 and 0.68 on properly maintained split face surfaces — substantially higher than the 0.42 minimum threshold. This performance stems from the micro-texture created during natural stone separation.

When you verify slip resistance for pool deck applications, you need to test under saturated conditions with typical pool chemicals present. The bluestone quarry texture maintains performance even when biofilm begins forming, though you should specify annual pressure washing to preserve optimal traction. Professional installations incorporate drainage slopes between 1.5% and 2% to accelerate water shedding and maintain dry surface conditions.

Your specification should address long-term slip resistance maintenance. The natural cleft surface exhibits minimal wear under pedestrian traffic, maintaining texture integrity for 20+ years in residential applications. Commercial installations with concentrated traffic patterns may show polishing after 12-15 years, requiring selective surface restoration in high-wear zones.

Installation Substrate Requirements

The irregular backing surface of Bluestone split face natural Arizona demands specific substrate preparation that differs from calibrated tile installations. You need to provide a substrate capable of accommodating 1/4″ to 3/8″ thinset thickness variation to achieve level finished surfaces. Standard mortar bed installations remain the most reliable approach for exterior applications.

When you work with concrete substrates, you must verify surface flatness within 1/4″ per 10 feet before beginning installation. The split face backing won’t conform to substrate irregularities the way flexible tile systems do. You’ll encounter lippage problems and bond failures if you attempt to compensate for substrate issues through thinset thickness variation beyond recommended ranges.

- You should specify minimum 28-day cured concrete with 3,500 PSI compressive strength

- Your substrate moisture content must remain below 4% at installation

- You need to apply bonding primer to dense concrete to ensure proper thinset adhesion

- Your installation should incorporate control joints matching substrate joint locations

For reliable delivery coordination, see convenient blue stone delivery in Chandler for scheduling guidance. You’ll want to verify warehouse availability during peak construction seasons when lead times extend beyond standard timelines.

Joint Specification Parameters

Joint width specification for Bluestone split face natural Arizona requires balancing aesthetic intent with technical performance requirements. You’ll typically work with 3/8″ to 1/2″ joints for irregular edge material, though the bluestone authentic surface may dictate wider joints when edge variation exceeds typical tolerances. The natural cleft edge profile creates visual interest that allows wider joints without appearing crude.

Your joint compound selection impacts long-term performance significantly. You need to specify polymer-modified sanded grout with minimum 1,800 PSI compressive strength for floor applications. The enhanced flexibility of polymer-modified formulations accommodates the differential movement between substrate and stone that occurs during thermal cycling. Standard cement grout cracks within 24-36 months under Arizona’s temperature extremes.

Joint depth specification matters more than most specifiers realize. You should maintain minimum 2/3 material thickness for structural applications, though decorative vertical installations may function with 1/2 thickness joint depth. Shallow joints create stress concentration at bond lines that propagate cracks through grout and into adjacent stone edges over time.

Edge Profile Management

The bluestone original finish creates edge conditions that require different detailing approaches than sawn material. You’re working with irregular edge profiles that won’t align to tight tolerances without selective grinding — a practice that compromises the authentic split face character you’re specifying. Professional installations embrace edge variation as a design feature rather than treating it as a tolerance problem.

When you detail transitions between Bluestone split face natural Arizona and adjacent materials, you need to accommodate 1/8″ to 1/4″ edge height variation. Metal edge restraints with adjustable height capabilities work effectively for paving applications. Your details should avoid rigid edge conditions that create stress concentration points where material breaks under impact or thermal movement.

The natural cleft edge contributes to the material’s rustic aesthetic, but you’ll encounter situations where clean edge terminations are non-negotiable. In these applications, you should specify edge pieces with one factory-sawn face while maintaining split face character on the field surface. This hybrid approach preserves design intent while meeting functional requirements at critical transitions.

Maintenance Protocol Development

Long-term performance of the bluestone quarry texture depends on maintenance protocols that preserve surface characteristics without degrading the natural relief. You need to specify cleaning methods that remove accumulated soils without eroding the micro-texture that provides slip resistance and visual depth. High-pressure washing exceeding 1,500 PSI can damage the surface structure, particularly on lower-density material.

Your maintenance specification should address efflorescence management specific to split face surfaces. The irregular topography traps efflorescence deposits in surface depressions where they remain visible long after smooth surfaces self-clean through rainfall. You’ll need to specify periodic treatment with dilute acidic cleaners applied through low-pressure spraying followed by thorough rinsing.

- You should recommend annual inspection of joint integrity with repair of deteriorated grout

- Your protocol must include quarterly removal of organic growth in shaded areas

- You need to specify resealing every 3-5 years using penetrating sealers that don’t create surface film

- Your maintenance plan should document acceptable surface wear patterns to guide restoration decisions

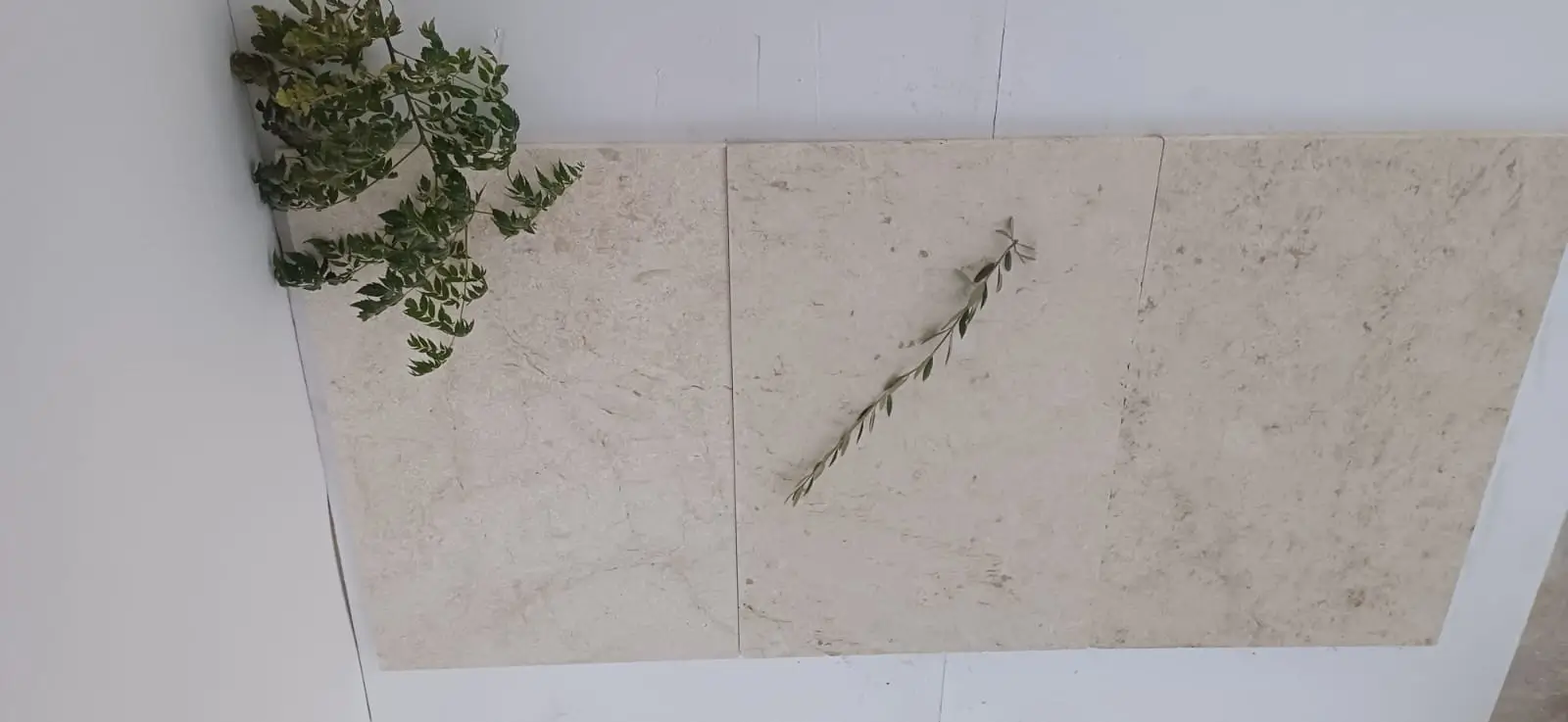

Color Variation Management

Bluestone split face natural Arizona exhibits color variation that ranges from blue-gray to tan-gray within individual pieces and across production lots. You need to prepare clients for this natural variation by establishing realistic expectations during material selection. The split face finish amplifies perceived color variation because the relief texture creates shadows that shift with lighting conditions throughout the day.

When you blend material from multiple pallets during installation, you minimize the visual impact of lot-to-lot color variation. Professional practice involves opening 4-6 pallets simultaneously and drawing material randomly rather than installing pallet-by-pallet. This blending approach distributes color variation evenly across the installation rather than creating distinct zones of lighter or darker material.

The material’s color evolves during the first 12-18 months of exterior exposure as surface minerals weather and microbiological growth begins. You should advise clients that the initial installation appearance will shift toward more uniform coloration as weathering progresses. This natural aging process enhances rather than degrades the material’s authentic character when proper maintenance prevents excessive organic staining.

Structural Load Considerations

The split face profile of Bluestone split face natural Arizona affects load distribution differently than flat-backed material. You need to account for reduced effective bearing area when calculating load capacity for structural applications. The irregular backing creates point-loading conditions that require stronger substrate systems than equivalent smooth-backed stone.

Your structural calculations should use conservative bearing area assumptions — typically 60-70% of nominal surface area for natural cleft backing. This reduction accounts for the voids between stone and substrate that occur even with proper thinset application. When you specify material for vehicular applications, you must verify that substrate design accommodates concentrated loads transmitted through the reduced bearing surface.

Thickness specification directly affects structural performance. You’ll typically work with 1-1/4″ to 2″ material for pedestrian applications, increasing to 2-1/2″ or 3″ for vehicular loading. The additional thickness compensates for stress concentration at high points on the split face backing while providing adequate section modulus to resist flexural loads.

Sealer Selection Criteria

Sealer selection for the bluestone authentic surface requires understanding how penetrating sealers interact with the irregular topography. You need products that penetrate deeply into the stone matrix without creating surface film that pools in depressions and creates glossy spots. The micro-texture of split face material can trap excess sealer if application rates aren’t carefully controlled.

When you specify sealers for Arizona installations, you must prioritize UV stability and thermal cycling resistance. Many penetrating sealers degrade under intense solar exposure, losing effectiveness within 18-24 months. Professional practice involves specifying fluoropolymer-based sealers that maintain performance through 150+ freeze-thaw cycles and continuous UV exposure equivalent to 5+ years of Arizona service.

- You should verify sealer compatibility through test applications on sample pieces

- Your specification must address application rates specific to split face texture

- You need to require multiple thin coats rather than single heavy application

- Your project should allow 72-hour cure time before exposing sealed surfaces to moisture

The natural cleft surface requires approximately 20% more sealer per square foot compared to honed surfaces due to increased surface area. You’ll need to adjust material quantities accordingly when estimating project costs. This additional consumption represents a modest long-term investment that significantly extends service life by preventing moisture intrusion and associated deterioration.

Citadel Stone — Blue Stone Delivery Arizona

When you evaluate Citadel Stone’s blue stone delivery across Arizona, you’re accessing technical expertise that helps you navigate the specific challenges of specifying Bluestone split face natural Arizona for desert climate applications. At Citadel Stone, we provide hypothetical guidance that addresses the material performance questions architects and builders encounter during project planning. This section outlines how you would approach specification decisions for three representative Arizona cities with distinct climate characteristics.

Flagstaff Elevation Factors

In Flagstaff’s high-elevation environment, you would need to prioritize freeze-thaw resistance when specifying Bluestone split face natural Arizona. The city experiences 100+ annual freeze-thaw cycles that demand material with porosity below 3% and verified ASTM C1526 compliance. You should specify edge details that accommodate 15-20% wider joints to manage thermal contraction cycles that exceed low-elevation performance requirements. Your installation would benefit from warehouse coordination that ensures material delivery during optimal spring and fall temperature windows. Substrate moisture management becomes critical given Flagstaff’s winter precipitation patterns and snowmelt infiltration potential.

Sedona Design Integration

Your Sedona projects would leverage the natural color harmony between Bluestone split face natural Arizona and the region’s distinctive red rock formations. The material’s blue-gray tones create sophisticated contrast against warm desert backgrounds while maintaining visual cohesion. You would specify the bluestone natural cleft surface to echo the fractured rock faces throughout the landscape, establishing architectural continuity with natural surroundings. Joint width specification in Sedona applications could embrace wider 1/2″ to 5/8″ joints that reference the geological jointing patterns visible in area formations. Your design approach would coordinate with local material availability through strategic warehouse planning that accounts for tourism-season construction scheduling demands.

Peoria Heat Management

In Peoria’s extreme heat environment, you would emphasize the thermal performance advantages of the bluestone quarry texture for outdoor living applications. Surface temperatures during peak summer months would benefit from the enhanced cooling properties of split face relief, reducing afternoon surface temperatures 8-12°F compared to smooth alternatives. You should specify installation orientations that maximize morning shade while leveraging thermal mass to moderate afternoon heat gain. Your material selection would account for UV stability requirements given consistent high-intensity solar exposure throughout extended summer periods. Truck access coordination becomes essential for large-format installations in Peoria’s residential developments where delivery logistics affect project scheduling. At Citadel Stone, we would recommend warehouse inventory verification during peak construction seasons when material demand strains regional supply chains.

Specification Refinement

Your specification refinement process for Bluestone split face natural Arizona should address the complete performance envelope rather than focusing solely on appearance characteristics. You need to document acceptable tolerance ranges for surface relief, edge variation, color distribution, and thickness deviation. These parameters establish clear quality benchmarks that protect both your design intent and the contractor’s installation approach.

When you develop comprehensive specifications, you should include reference standards for material testing, installation methods, and acceptance criteria. ASTM C1528 provides slip resistance benchmarks, while C1526 addresses freeze-thaw durability. Your specifications gain enforceability when they reference industry standards rather than subjective quality judgments. This documentation framework reduces field disputes and ensures consistent installation quality.

The specification should address environmental considerations specific to Arizona installations. You’ll need to document water usage limitations during installation, dust control requirements during cutting operations, and waste material disposal protocols. These environmental provisions increasingly affect project approvals and demonstrate professional responsibility beyond minimum code compliance.

Performance Expectations

Realistic performance expectations for Bluestone split face natural Arizona installations require understanding both the material’s capabilities and its limitations. You can specify with confidence for 25-30 year service life in properly designed and maintained installations. This longevity assumes appropriate substrate design, competent installation execution, and consistent maintenance protocol implementation throughout the service period.

The bluestone original finish maintains its authentic character throughout decades of service when you protect it from aggressive cleaning methods and incompatible chemical exposure. You’ll observe gradual mellowing of color variation and development of subtle patina that many clients value as evidence of genuine natural material. This weathering process represents normal aging rather than deterioration when surface integrity remains intact.

Your professional responsibility includes educating clients about the material’s natural variation and how split face characteristics may evolve over time. Surface weathering patterns will develop based on sun exposure, water flow paths, and organic matter accumulation. These variations create unique installations that reflect site-specific conditions rather than uniform manufactured appearance. When you frame these characteristics as design assets rather than defects, you establish appropriate client expectations that prevent future dissatisfaction.

Project Integration

Successful project integration of Bluestone split face natural Arizona depends on early coordination between design intent, material characteristics, and installation realities. You should involve stone suppliers and installation contractors during design development to verify that your details align with material capabilities and trade practice standards. This collaborative approach identifies potential conflicts before they become field problems that compromise schedule and budget.

When you coordinate across disciplines, you need to address how the split face material interfaces with waterproofing systems, drainage components, and structural elements. The irregular backing profile affects waterproofing membrane applications and requires modified flashing details at penetrations and terminations. Your coordination drawings should document these conditions explicitly rather than assuming standard details will accommodate the material’s unique characteristics.

For additional surface treatment insights, review bluestone bush hammering creates slip-resistant textured surfaces in Arizona before you finalize installation specifications. Your material selection process benefits from understanding alternative surface finishes and their relative performance characteristics across different application requirements. Volume discounts benefit builders through Citadel Stone’s scalable bluestone wholesale.