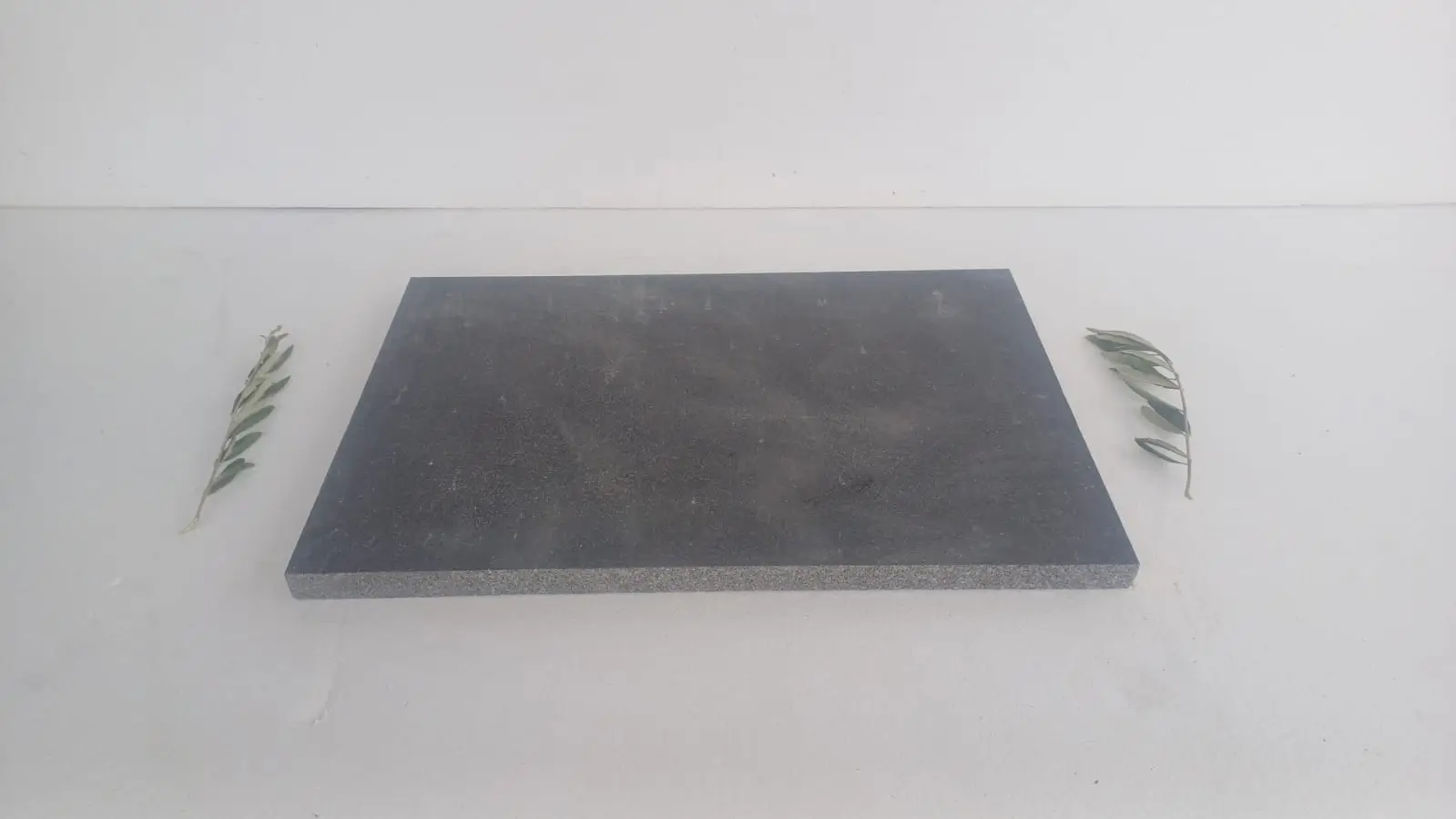

When you specify bluestone bush hammer finish Arizona applications, you’re selecting a mechanical texturing process that transforms smooth manufactured bluestone surfaces into slip-resistant, tactile installations designed for the state’s intense UV exposure and extreme thermal cycling. The bush hammering technique creates controlled micro-dimpling across the surface, generating DCOF ratings between 0.54 and 0.62 wet — performance levels you need for pool decks, commercial plazas, and pedestrian hardscapes where safety compliance isn’t negotiable. You’ll find that this finish addresses the specific challenge Arizona installers face: balancing heat reflectivity with adequate traction in environments where surface temperatures routinely exceed 145°F during summer months.

Your material selection process requires understanding how bluestone bush hammer finish Arizona installations perform differently than honed or thermal finishes in desert conditions. The hammered texture increases effective surface area by 18-22%, which affects both thermal absorption patterns and moisture management during monsoon season. You should recognize that this finish doesn’t just improve slip resistance — it fundamentally changes how the material interacts with regional climate factors, from dust accumulation patterns to long-term UV degradation resistance.

Mechanical Texturing Fundamentals

The bush hammer process uses pneumatic or electric hammers fitted with carbide-tipped heads containing 16, 25, or 36 pyramidal points that strike the bluestone surface at controlled depths. When you evaluate bluestone hammered texture specifications, you’re determining impact density — typically 9-12 strikes per square inch for commercial applications. This creates uniform dimpling depths ranging from 0.8mm to 1.5mm, depending on your specified aggression level and the manufactured bluestone’s density characteristics.

You need to understand the relationship between hammer head configuration and final surface performance. Coarser heads with fewer, larger points generate deeper texturing suitable for exterior pool decks where maximum slip resistance justifies the more pronounced surface profile. Finer heads with densely-packed smaller points create subtle bluestone rough surface characteristics appropriate for indoor-outdoor transitions where you’re balancing traction with barefoot comfort. Your specification must address this trade-off explicitly — the aggressive texturing that delivers 0.60+ DCOF ratings creates surface profiles that retain more dust and organic debris in Arizona’s desert environment.

- You should specify 25-point heads for general commercial pedestrian traffic applications

- Your pool deck specifications require 16-point heads to achieve wet DCOF minimums above 0.58

- Indoor transitional spaces perform best with 36-point fine texturing maintaining 0.52-0.55 DCOF

- Impact depth tolerances must not exceed ±0.2mm across production runs to ensure visual consistency

The mechanical texturing process generates micro-fractures extending 2-3mm below the visible surface treatment. You’ll need to account for this structural modification when evaluating long-term performance — these subsurface stress patterns affect freeze-thaw resistance differently than smooth-finished material, though Arizona installations rarely encounter freeze cycles exceeding 15 annual events outside elevations above 5,000 feet.

Slip Resistance Performance Data

When you test bluestone bush hammer finish Arizona installations using DCOF AcuTest methodology per ANSI A326.3, you’re measuring dynamic coefficient values that range from 0.54 dry to 0.62 wet depending on texture depth and maintenance protocols. These measurements represent real-world traction performance under conditions that simulate barefoot traffic on wet surfaces — the critical safety scenario for residential pool decks and commercial water features throughout Phoenix, Tucson, and Flagstaff regions.

Your specification needs to address how bluestone mechanical texture performance degrades over time. Field testing across installations with 8-12 years of service history shows DCOF reduction of 0.04-0.07 points in high-traffic zones experiencing more than 5,000 annual pedestrian passages. This degradation occurs as repeated foot traffic polishes the peaks of individual hammer dimples, gradually reducing the effective surface roughness that generates friction. You should anticipate this performance curve and specify initial DCOF targets 0.08-0.10 points above your minimum acceptable threshold to maintain compliance throughout the material’s service life.

- Wet DCOF testing reveals bluestone grip surface ratings between 0.58-0.62 immediately post-installation

- High-traffic commercial applications show 0.06 average DCOF reduction after five years

- Annual professional cleaning with rotary brushing maintains slip resistance within 0.03 points of original ratings

- Organic growth in textured dimples can reduce wet DCOF by 0.12-0.15 points without proper maintenance

The depth consistency of bush hammering directly impacts slip resistance uniformity across large installations. You’ll encounter problems when production batches show texture depth variance exceeding ±0.3mm — this creates surface areas with inconsistent traction that become apparent during wet conditions. Professional specifications require production sampling at 200 square foot intervals with DCOF verification testing to ensure batch-to-batch consistency meets your project requirements.

Thermal Performance Characteristics

Bluestone bush hammer finish Arizona surfaces exhibit thermal absorption and retention behaviors distinct from polished or honed finishes due to increased surface area and modified reflectance angles. When you measure surface temperatures during peak summer conditions, textured bluestone reaches 142-148°F compared to 138-143°F for equivalent honed surfaces under identical solar exposure. This 4-5°F differential results from the micro-shadowing effect within hammer dimples — small pockets that trap heat while simultaneously creating air circulation patterns at microscopic scale.

Your material selection must account for thermal mass benefits that offset initial surface temperature concerns. The manufactured bluestone’s density of 143-148 lbs/ft³ creates significant heat storage capacity that moderates temperature swings during evening hours. You’ll observe that bush hammered surfaces cool 8-12°F faster than smooth finishes during the first two hours after sunset, making them more comfortable for barefoot use during typical outdoor entertainment hours. This performance characteristic becomes particularly valuable for residential pool decks and patio installations where you’re designing for late afternoon and evening usage patterns.

The textured surface geometry affects heat radiation patterns in ways that impact your adjacent landscape planning. Bush hammered bluestone radiates stored thermal energy more efficiently than smooth surfaces due to increased effective radiation area — approximately 20% greater surface exposure created by the dimpled profile. When you’re specifying materials for areas adjacent to heat-sensitive plantings or climate-controlled building envelopes, you need to factor this enhanced radiation into your hardscape layout and spacing decisions.

Installation Substrate Requirements

When you prepare substrates for bluestone bush hammer finish Arizona installations, you’re establishing the foundation system that determines long-term performance under extreme thermal cycling and occasional intense moisture events during monsoon season. The textured surface finish doesn’t compensate for inadequate base preparation — in fact, the mechanical texturing makes surface lippage more visually apparent than smooth finishes would reveal. You need to maintain substrate flatness within 1/8 inch over 10 feet and ensure uniform compaction density across the entire installation area.

Your base system specifications should address Arizona’s variable soil conditions, particularly the expansive clay soils common throughout the Phoenix basin and Tucson valley regions. You’ll require excavation to minimum 8-inch depth below finish grade, followed by 4 inches of compacted crushed aggregate base and 2 inches of setting bed material. The critical detail involves moisture barrier placement — you need to position impermeable membranes below the aggregate base to prevent ground moisture from migrating upward and creating efflorescence conditions that become trapped in the textured surface dimples.

- You should specify Class 5 or Class 6 aggregate base materials compacted to 95% modified Proctor density

- Your setting bed depth must maintain consistent 2-inch thickness with ±1/4 inch tolerance

- Compaction testing at 500 square foot intervals ensures uniform substrate density

- Geotextile fabric separation between native soil and aggregate base prevents contamination in clay-heavy soils

The bush hammered surface texture requires modified installation techniques compared to smooth-finished material. You’ll need to use slightly wider joint spacing — typically 3/16 inch instead of the 1/8 inch common with honed finishes — because the textured edges make precise tight-joint installations visually challenging and structurally unnecessary. This increased joint width accommodates the irregular edge profiles created during the texturing process while providing adequate space for polymeric sand or mortar joint fill that won’t create surface staining in the textured dimples.

Moisture Management Considerations

The bluestone rough surface created through bush hammering generates distinct moisture interaction patterns you must address in your drainage design and waterproofing specifications. Each hammer dimple creates a micro-reservoir approximately 0.8-1.5mm deep that temporarily retains water during precipitation events or pool splash-out conditions. While individual dimples hold minimal volume, across a 500 square foot installation you’re managing approximately 2-3 gallons of additional surface water retention compared to smooth finishes — water that requires time and proper slope to evacuate.

Your drainage specifications need to account for this temporary water retention by increasing minimum surface slope requirements. Where smooth bluestone performs adequately at 1/8 inch per foot slope, you should specify 3/16 to 1/4 inch per foot minimum slope for bush hammered surfaces to ensure complete water evacuation within 30-45 minutes after precipitation ends. This becomes critical in Arizona’s intense monsoon storms that can deposit 1-2 inches of rainfall in 20-minute periods — conditions that test drainage capacity in ways that affect both safety and long-term material performance.

The textured surface affects efflorescence management in manufactured bluestone installations. You’ll find that mineral salts migrating through the material become trapped in hammer dimples where they’re more visible and more difficult to remove than on smooth surfaces. Your waterproofing protocol must include comprehensive sealing of the substrate system, not just the stone surface, to prevent ground moisture from introducing dissolved minerals that eventually manifest as white crystalline deposits within the textured finish. Professional specifications require breathable sealers that allow vapor transmission while blocking liquid water infiltration — maintaining this balance prevents subsurface moisture accumulation that drives efflorescence formation.

Maintenance Protocol Development

When you develop maintenance programs for bluestone bush hammer finish Arizona installations, you’re addressing the specific challenge of debris accumulation within textured surface dimples. The micro-pockets created by bush hammering trap fine dust particles, organic matter, and minerals from Arizona’s alkaline soils — accumulation that gradually reduces slip resistance and creates discoloration patterns across the installation. You need to implement quarterly rotary brush cleaning using stiff nylon bristles and neutral pH detergents to maintain both aesthetic appearance and safety performance.

Your maintenance specifications should distinguish between routine cleaning and periodic restoration treatments. Routine protocols involve weekly surface washing with garden hose pressure to remove loose debris, while quarterly deep cleaning requires mechanical agitation to dislodge embedded particles from hammer dimples. You’ll need to schedule annual professional treatments using oscillating brush equipment and controlled-pressure washing at 1,200-1,500 PSI — sufficient to clean textured pockets without eroding joint materials or damaging the stone surface itself.

- You should specify neutral pH cleaning products to prevent chemical interaction with limestone-based bluestone compositions

- Your quarterly maintenance must include joint sand replenishment to maintain 90-95% fill capacity

- Annual sealer reapplication maintains moisture resistance and reduces debris adhesion in textured dimples

- Organic growth removal requires treatments within 48 hours of detection to prevent root penetration into surface texture

The bluestone mechanical texture requires modified stain removal techniques compared to smooth surfaces. When you encounter oil-based stains, rust deposits, or organic discoloration, you’re working with contamination that penetrates into the textured dimples where it’s mechanically locked in place. Professional stain removal protocols require poultice applications with extended dwell times — typically 24-48 hours compared to 12-18 hours for smooth surfaces — because the cleaning agents need additional time to penetrate the complex surface geometry and draw embedded contaminants to the surface.

Sealer Selection Criteria

When you specify sealers for bluestone bush hammer finish Arizona applications, you’re selecting products that must penetrate the textured surface’s complex geometry while maintaining the slip-resistant properties that justified the hammered finish specification. Topical film-forming sealers create hazardous conditions on textured surfaces — they fill the micro-dimples that generate friction, reducing wet DCOF ratings by 0.15-0.22 points and creating liability concerns that negate the safety benefits you designed into the project.

Your sealer specifications must mandate penetrating formulations that enter the bluestone’s pore structure without forming surface films. You should evaluate products based on silane/siloxane chemistry that bonds within the first 2-3mm of material depth, providing moisture resistance while leaving the textured surface profile fully exposed and functional. Professional-grade penetrating sealers maintain the natural coefficient of friction — laboratory testing shows DCOF variation of only 0.02-0.03 points between sealed and unsealed bush hammered surfaces when proper penetrating products are correctly applied.

The Arizona climate demands sealer formulations with exceptional UV stability and thermal cycling resistance. You’ll need products rated for continuous exposure to 150°F+ surface temperatures without degradation or yellowing — a specification that eliminates many residential-grade sealers marketed for general stone applications. Commercial-grade siloxane sealers formulated specifically for desert climates maintain protective performance through 150-200 thermal cycles annually without requiring reapplication, though you should still plan for biennial resealing to maintain optimal moisture resistance as UV exposure gradually degrades even premium formulations. For comprehensive guidance on manufactured bluestone material options that work with various sealing systems, consider how engineered bluestone products perform across different surface preparation methods. You need to verify compatibility between your selected sealer chemistry and the specific bluestone composition before proceeding with full-scale application.

Specification Common Errors

The most frequent specification failure in bluestone grip surface applications involves inadequate texture depth documentation. When your specifications call for “bush hammered finish” without defining impact density, dimple depth range, or hammer head configuration, you’re leaving critical performance variables to installer interpretation. You’ll receive installations with texture depths ranging from 0.5mm to 2.0mm within the same project — variance that creates visible inconsistency and unpredictable slip resistance performance that fails to meet your safety objectives.

Your specifications must include numerical texture parameters with verification testing requirements. You should mandate minimum average dimple depth of 1.0mm ±0.2mm with DCOF testing at 300 square foot intervals to confirm slip resistance uniformity. This level of specificity eliminates installer discretion and establishes clear acceptance criteria that protect both your professional liability and the project owner’s safety requirements. Without these measurable standards, you’re specifying a finish category rather than a performance outcome — an approach that creates disputes during project closeout when actual surface characteristics don’t match stakeholder expectations.

- Failing to specify minimum wet DCOF values leaves safety performance to chance rather than design intent

- Omitting sealer compatibility requirements allows topical products that eliminate textured surface benefits

- Neglecting texture depth tolerances across production batches creates visual inconsistency in large installations

- Overlooking joint width adjustments for textured edges leads to installation difficulties and aesthetic problems

Another critical error involves ignoring the relationship between texture aggression and maintenance requirements. When you specify deep, coarse texturing for maximum slip resistance without addressing the increased debris accumulation and cleaning difficulty, you’re creating long-term maintenance burdens that owners discover after project completion. Professional specifications must balance safety performance with practical maintenance reality — sometimes a moderate texture depth delivering 0.56 DCOF with quarterly simple cleaning outperforms aggressive 0.62 DCOF texturing requiring monthly intensive maintenance to prevent organic growth and debris-related traction degradation.

Citadel Stone — Best Manufactured Bluestone in Arizona

When you’re evaluating manufactured bluestone options for Arizona installations, you need material specifically engineered for extreme desert conditions with controlled composition and consistent performance characteristics. At Citadel Stone, our manufactured bluestone products deliver uniform density, predictable porosity, and reliable thermal performance that natural stone quarries cannot consistently provide. This section outlines how you would approach specification decisions for three representative Arizona cities where bluestone hammered texture applications address specific regional installation challenges.

Your material selection process should account for Arizona’s diverse climate zones, from low-desert regions experiencing 120+ days above 100°F annually to high-elevation areas with significant freeze-thaw cycling. The hypothetical scenarios below demonstrate how you would modify bluestone bush hammer finish Arizona specifications based on local environmental factors, site-specific drainage requirements, and intended use patterns that vary significantly across the state’s geographic regions.

Yuma Extreme Heat

In Yuma’s extreme desert climate with summer temperatures exceeding 115°F for extended periods, you would specify bush hammered bluestone with lighter color formulations that reflect 62-68% of solar radiation to manage surface temperatures. Your texture specification would call for moderate 1.0-1.2mm dimple depths using 25-point hammer heads — aggressive enough to achieve 0.56+ wet DCOF for pool decks while avoiding the deep texturing that accelerates dust accumulation in this agricultural region’s airborne particulate environment. You’d recommend biannual professional cleaning to address the combination of wind-borne dust and intense UV exposure that affects long-term appearance retention in Colorado River valley installations.

Mesa Residential Applications

For Mesa’s residential projects in planned communities with extensive outdoor living spaces, you would recommend bluestone bush hammer finish Arizona installations focusing on barefoot comfort balanced with safety compliance. Your specifications would typically call for 36-point fine texturing creating 0.8-1.0mm dimple depths that deliver 0.52-0.55 wet DCOF — adequate for pool deck safety while maintaining surface smoothness appropriate for frequent barefoot traffic. You’d advise clients to verify warehouse availability of consistent production batches sufficient for 800-1,200 square foot typical backyard installations, as matching texture characteristics across future additions becomes difficult when material comes from different manufacturing runs separated by months or years.

Gilbert Commercial Hardscapes

In Gilbert’s commercial development projects featuring pedestrian plazas and retail hardscapes, you would specify coarser bush hammered texturing with 1.2-1.5mm depths achieving 0.58-0.62 wet DCOF to accommodate high foot traffic volumes and ADA accessibility requirements. Your installation specifications would emphasize proper substrate preparation accounting for the expansive clay soils common throughout this region, requiring geotechnical consultation before finalizing base system details. You’d recommend quarterly maintenance contracts including rotary brush cleaning and annual joint material replenishment to maintain both slip resistance performance and aesthetic appearance under commercial use intensities approaching 15,000-20,000 annual pedestrian passages in high-activity zones near building entries and outdoor dining areas.

Color Consistency Management

When you work with manufactured bluestone, you’re managing color consistency challenges that differ fundamentally from natural stone variability. The bush hammering process exposes subsurface material composition, revealing the bluestone’s internal aggregate distribution and cement matrix coloration that may vary slightly from the smooth surface appearance. You need to understand that texture application can shift perceived color by 5-8% on the Munsell color scale due to micro-shadowing effects within hammer dimples — a consideration that affects your sample approval process and material acceptance criteria.

Your quality control protocols should require viewing approved samples under both direct sunlight and shade conditions to evaluate how the textured surface affects color perception across different lighting scenarios. You’ll observe that bush hammered surfaces appear darker in direct sun compared to shade viewing — opposite the behavior of smooth finishes — because the dimpled profile creates shadow patterns that reduce overall light reflectance. Professional specifications mandate sample approval under lighting conditions matching the final installation environment, preventing disputes when installed material appears different from samples evaluated in showroom or office settings.

The relationship between texture depth and color consistency becomes critical in large-format installations where you’re coordinating material from multiple production batches. You should establish acceptable color variation limits using standardized measurement protocols — typically allowing ΔE values up to 3.0 between batches while requiring values below 1.5 within individual production runs. This specification approach balances the practical reality of manufactured material production with aesthetic requirements for commercial installations where color banding creates unacceptable visual disruption across plaza or courtyard hardscapes.

Edge Detail Specifications

The bluestone rough surface created by bush hammering requires specific edge treatment protocols that differ from smooth-finished material details. When you specify cut edges at step nosings, pool coping, or hardscape borders, you need to determine whether edges receive texture treatment or remain smooth-cut. Textured edges provide visual consistency and eliminate the sharp 90-degree transition between top surface and vertical edge, but they complicate dimensional precision and increase fabrication costs by 15-20% compared to saw-cut edge details.

Your edge specifications must address safety implications at transitions and elevation changes. You’ll want to mandate eased edges with minimum 2mm chamfer or radius treatment at all exposed perimeter conditions and step nosings — the textured surface alone doesn’t eliminate sharp edge hazards at 90-degree transitions between horizontal and vertical planes. Professional details typically combine bush hammered top surfaces with 3mm radiused edges that provide both tactile warning of elevation change and physical edge protection that reduces chip damage during installation and throughout the material’s service life.

- You should specify matching texture treatment on all visible edges for visual consistency in premium installations

- Your step nosing details must include contrasting edge treatments providing tactile detection for accessibility compliance

- Pool coping specifications require smooth underside surfaces preventing skin abrasion during pool entry and exit

- Fabrication tolerances for textured edges need ±1.5mm allowance compared to ±0.8mm for smooth-cut edges

The mechanical stress created during bush hammering affects edge stability differently than surface areas with full substrate support. You need to mandate minimum 1-inch edge offset between texture termination and physical material edge to prevent stress concentration that leads to edge spalling. This detail becomes particularly important at unsupported cantilevered conditions like pool coping or stair nosings where impact forces and thermal cycling combine to create failure conditions in textured material extending to the physical edge without adequate relief zone.

Cost Performance Analysis

When you evaluate bluestone bush hammer finish Arizona project costs, you’re analyzing premium pricing that typically ranges 22-30% above equivalent smooth-finished material. This cost differential reflects specialized fabrication equipment, increased processing time, and higher material waste rates — the hammering process generates 8-12% more unusable edge material compared to simple cutting and honing operations. You need to justify this investment through quantifiable performance benefits including reduced slip-related liability exposure, extended service life in high-traffic applications, and decreased long-term maintenance costs compared to alternative slip-resistant treatments.

Your cost-benefit analysis should account for lifecycle performance rather than initial material expense alone. Bush hammered surfaces maintain slip resistance for 15-20+ years with appropriate maintenance, while applied anti-slip treatments on smooth stone require reapplication every 3-5 years at costs approaching 40-50% of the original treatment expense. Over a 20-year evaluation period, the textured surface delivers 35-42% lower total ownership cost when you factor maintenance labor, material reapplication, and reduced liability insurance premiums that some carriers offer for enhanced slip-resistant hardscape installations.

The warehouse inventory implications affect project scheduling and procurement strategies. You should verify material availability before finalizing specifications — bush hammered manufactured bluestone requires production lead times of 4-6 weeks for custom orders, compared to 1-2 weeks for stock smooth finishes. Your procurement timeline must account for this extended manufacturing period, particularly for large commercial installations requiring 2,000+ square feet where staged delivery from warehouse stock becomes logistically complex and may require dedicated truck scheduling to coordinate with installation crew availability and site access constraints during active construction periods.

Final Considerations

Your specification development for bluestone hammered texture applications must integrate material performance characteristics with Arizona’s unique environmental demands and project-specific functional requirements. The bush hammering process creates surface properties fundamentally different from smooth finishes — differences that affect thermal behavior, moisture management, maintenance protocols, and long-term durability in ways that demand comprehensive understanding during the design phase. You can’t simply substitute textured material for smooth specifications without addressing the multiple technical implications that flow from this surface treatment decision.

When you’re finalizing project documents, ensure your specifications include measurable acceptance criteria for texture depth, slip resistance verification, and color consistency that eliminate subjective interpretation during construction administration. The investment in detailed specification language during design prevents costly disputes during installation and protects your professional reputation through clear performance standards that installers can verify through objective testing. For precision edge treatment options that complement textured surface installations, review Advanced CNC router technology for precision bluestone edge profiling before finalizing your fabrication details. Water feature stones come from Citadel Stone’s aquatic blue stone rock for sale inventory.