When you plan visits to evaluate natural stone materials, understanding how blue stone yard shopping Arizona environments operate changes everything about your selection process. You’re not just viewing inventory — you’re assessing thermal performance potential, porosity characteristics, and installation compatibility in conditions that reach 120°F surface temperatures. The difference between showroom samples and actual yard inventory becomes critical when you need to verify color consistency across 2,000 square feet of material.

Your ability to physically inspect full-pallet quantities reveals details that specification sheets never capture. You’ll notice how desert dust affects surface appearance during storage, how shade structures create color variations across inventory sections, and why moisture content at the time of viewing matters for accurate color assessment. These factors directly impact your project outcomes in ways most specifiers don’t anticipate until installation begins.

Yard Inspection Protocols

The blue stone yard selection process requires systematic evaluation methods that account for Arizona’s unique environmental conditions. When you inspect inventory during peak afternoon hours, surface temperatures on stored materials can exceed ambient air temperature by 40-50°F, creating thermal stress patterns that reveal material quality. You should examine at least three separate pallets from different production runs to identify acceptable variation ranges.

Your inspection protocol needs to address these critical factors:

- You must verify dimensional consistency across random samples, checking for thickness variations that exceed ±3/16 inch tolerance

- Your surface finish evaluation should occur on wetted samples, as Arizona’s 8-12% humidity creates misleading dry appearances

- You need to assess edge conditions on at least 20% of pieces, looking for spalling indicators that suggest freeze-thaw vulnerability

- Your color matching should compare pieces at consistent moisture levels, as water absorption rates affect apparent hue by 15-20%

The blue stone yard inventory viewing process becomes complicated when warehouse stock includes materials from multiple quarry sources. You’ll find that geographic origin affects performance characteristics more significantly than most literature suggests — Northeastern quarries produce material with 4-6% porosity, while mid-Atlantic sources range from 6-9%. This difference determines long-term efflorescence potential in alkaline soil conditions common throughout Phoenix and Tucson metro areas.

Material Verification Techniques

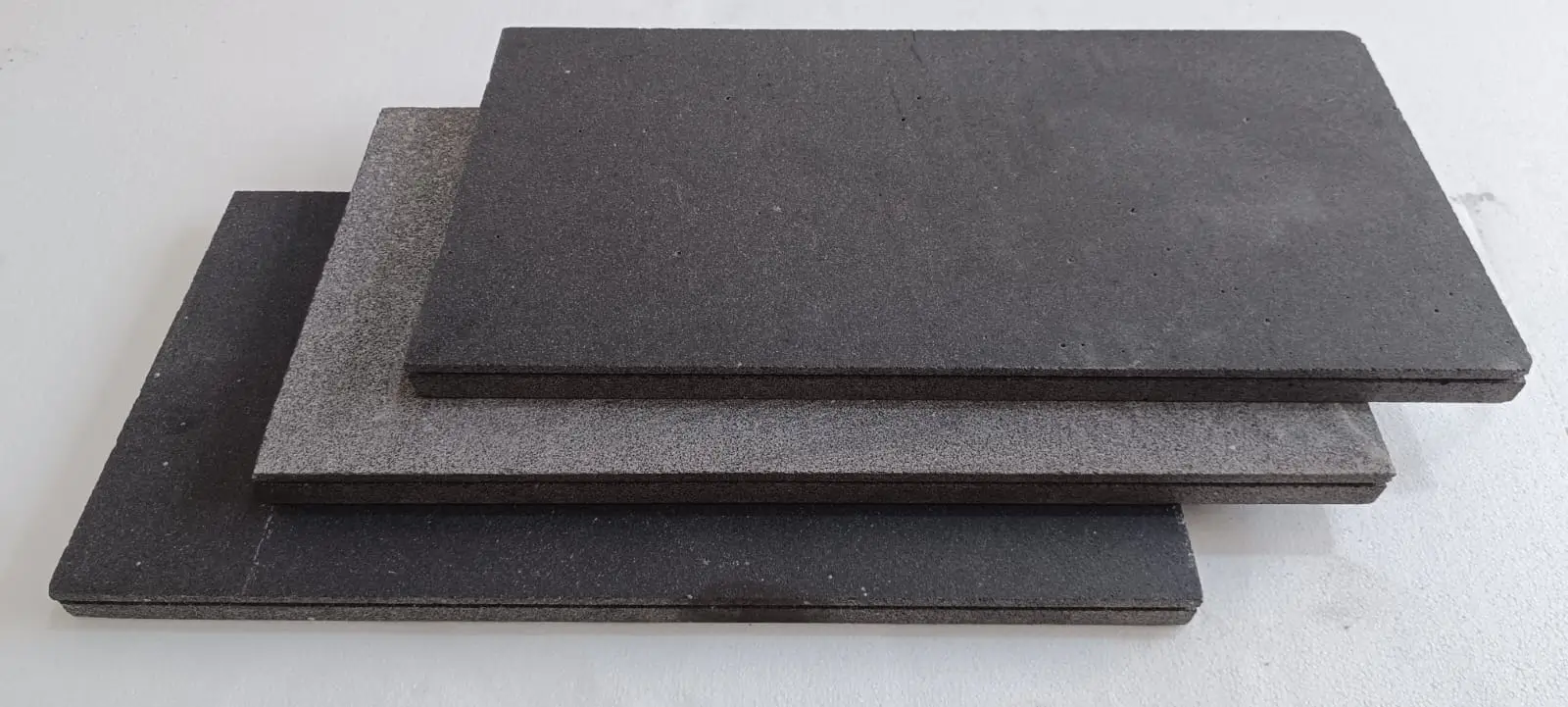

During blue stone yard material inspection, you’re evaluating properties that determine 20-year performance outcomes. The split-face texture typical of bluestone creates surface area variations that affect heat retention and slip resistance in ways you won’t see in polished materials. When you run your hand across thermal-finished surfaces, you should feel consistent aggregate exposure without sharp protrusions that indicate incomplete processing.

Professional verification requires you to test absorption characteristics using the field water test — apply water to five random pieces and observe penetration rates. Material that darkens within 3-5 seconds indicates porosity above 7%, which requires enhanced sealing protocols for Arizona installations. You’ll need to account for this during specification development, as sealer costs add $1.80-$2.40 per square foot to project budgets.

The blue stone yard customer experience should include access to technical documentation that specifies compressive strength, flexural strength, and absorption rates. You can’t rely on visual assessment alone — demand ASTM C1527 test results showing minimum 12,000 PSI compressive strength for pedestal applications and 8,000 PSI for traditional sand-set installations. These numbers aren’t arbitrary; they’re the difference between structural integrity and premature failure in high-traffic environments.

Color Consistency Assessment

Color variation in bluestone materials ranges from light gray-blue to deep charcoal with brown and green mineral inclusions. When you evaluate inventory during the blue stone yard selection process, you need to understand that acceptable variation spans a wider range than most architectural specifications allow. Your project documents should define color tolerance using physical samples, not photographs or printed color charts that misrepresent actual appearance.

Here’s what affects color perception during yard visits:

- Time of day changes apparent hue by affecting shadow depth in textured surfaces — morning light emphasizes blue tones while afternoon sun brings out warm mineral content

- Recent precipitation creates temporary darkening that takes 4-8 hours to dissipate in Arizona’s dry climate

- Dust accumulation from surrounding yard operations can obscure true color by depositing buff or tan sediment on surfaces

- Storage position affects weathering patterns, with top pallet layers showing more UV exposure than protected interior pieces

For comprehensive material options, see Citadel Stone bluestone available in Sedona for regional inventory variations. You’ll discover that elevation differences between Phoenix valley locations and northern Arizona yards create distinct weathering patterns that affect long-term appearance stability.

Porosity Performance Factors

The interconnected pore structure in bluestone materials determines critical performance characteristics including freeze-thaw durability, efflorescence susceptibility, and stain resistance. When you conduct blue stone yard material inspection, porosity assessment should follow ASTM C97 protocols, though field evaluation methods provide practical guidance. You’re looking for material with porosity between 3-7% for optimal performance in Arizona’s extreme climate conditions.

Your specification decisions need to account for how porosity interacts with local environmental factors. Arizona’s alkaline soils (pH 7.8-8.4) combined with material porosity above 6% create conditions where subsurface salts migrate through the stone matrix, appearing as white efflorescence deposits within 12-18 months of installation. You can mitigate this through proper base preparation and drainage design, but material selection remains the primary control factor.

During the blue stone yard customer experience, you should request absorption testing data or perform field verification. The practical method involves weighing a dry sample, submerging it for 24 hours, then reweighing — absorption above 4% by weight indicates porosity that requires additional sealing investment. You’ll want to factor this into your material selection criteria, as high-porosity materials demand biennial resealing versus triennial maintenance for denser alternatives.

Thermal Mass Considerations

Bluestone’s thermal mass properties create performance characteristics that significantly impact Arizona installations. The material’s volumetric heat capacity ranges from 32-36 BTU per cubic foot per degree Fahrenheit, producing a 4-6 hour lag time between peak air temperature and peak surface temperature. When you plan outdoor living spaces, this thermal behavior determines usability during evening hours when surface temperatures remain elevated long after ambient cooling occurs.

You need to understand the trade-off between thermal mass benefits and afternoon surface temperatures. Your clients will experience bluestone surfaces reaching 145-165°F during July and August peak conditions — approximately 15-20°F hotter than light-colored limestone alternatives. The evening retention benefit means surfaces stay warm until 10-11 PM, which clients either appreciate or find problematic depending on usage patterns.

The blue stone yard inventory viewing should include discussion of thermal performance relative to project orientation and shade structures. You’ll find that west-facing installations without overhead protection create surface conditions that exceed comfort thresholds for barefoot traffic. Your specification documents need to address either shade integration, supplemental cooling systems, or material substitution for these exposure conditions.

Dimensional Tolerance Verification

During blue stone yard shopping Arizona visits, dimensional accuracy assessment reveals manufacturing quality that directly affects installation labor costs. You’re evaluating thickness consistency, length/width tolerances, and edge straightness — variations that compound across large installations to create layout complications. Industry standards allow ±1/4 inch thickness variation within individual pieces and ±3/8 inch across production lots, but tighter tolerances reduce field cutting requirements.

Your measurement protocol should randomly sample at least 15 pieces from different pallets, using calibrated tools rather than visual estimates. You’ll discover that thermal-finished materials typically exhibit better dimensional consistency than natural cleft products, with thickness variations averaging ±3/16 inch versus ±5/16 inch respectively. This difference translates to 12-18% variation in installation time when you’re setting large-format pavers on pedestal systems.

Professional blue stone yard selection process methods include verifying square corners and straight edges using framing squares and straightedges. Material with edge bowing exceeding 1/8 inch per linear foot creates joint spacing inconsistencies that become visually apparent in geometric patterns. You should reject lots that don’t meet this standard or adjust your layout design to accommodate natural edge variation through irregular joint spacing.

Surface Finish Impact

Surface texture variations in bluestone materials range from naturally split cleft faces to thermal-finished surfaces and honed appearances. Each finish type creates distinct performance characteristics for slip resistance, heat retention, and maintenance requirements. When you evaluate options during the blue stone yard material inspection process, you’re determining long-term usability factors that affect client satisfaction.

Natural cleft surfaces provide DCOF slip resistance ratings of 0.58-0.65 in dry conditions and 0.48-0.55 when wet, meeting ADA requirements for most applications. The irregular surface profile creates high initial traction but shows accelerated wear in high-traffic locations where foot traffic polishes surface peaks. You should anticipate visible wear patterns appearing within 5-7 years in commercial plaza applications or residential entries with daily use exceeding 50 passes.

Thermal-finished surfaces produced through torch treatment create DCOF ratings of 0.50-0.56 dry and 0.42-0.48 wet — still code-compliant but requiring more careful specification near pool decks and water features. The advantage lies in consistent texture that resists wear pattern development, maintaining appearance uniformity for 12-15 years in equivalent traffic conditions. Your blue stone yard customer experience should include walking on sample installations to assess texture preferences under realistic conditions.

Edge Detail Specifications

Edge treatment significantly affects both aesthetic outcomes and structural performance in bluestone installations. During your blue stone yard selection process, you’ll choose between natural hand-cut edges, sawn edges, and thermal-treated edges — each offering distinct advantages for specific applications. The decision impacts material costs by $3-$8 per linear foot and affects installation complexity.

Consider these edge specification factors:

- Natural hand-cut edges provide rustic character but require skilled installation to manage irregular profiles and achieve consistent joint spacing

- Sawn edges deliver precise dimensions that simplify layout but create sharper corners susceptible to chipping during handling and installation

- Thermal-treated edges combine dimensional accuracy with slightly rounded profiles that resist impact damage while maintaining clean visual lines

- Chamfered edges reduce trip hazards in transition areas but add fabrication costs of $2.50-$4.00 per linear foot

Your specification documents need to address edge treatment relative to installation method and expected use patterns. You’ll find that sand-set applications tolerate natural edge variations more readily than mortar-set installations, where precise edges become critical for achieving professional joint appearance. The blue stone yard inventory viewing should include examination of edge quality across multiple pieces to ensure consistent fabrication standards.

Quality Indicators Assessment

Professional blue stone yard material inspection requires recognizing quality indicators that predict long-term performance. You’re looking for absence of structural defects including hairline cracks, delamination planes, and excessive iron oxide inclusions. These characteristics become apparent through systematic examination techniques that go beyond casual visual scanning.

When you tap bluestone pieces with a metal tool, quality material produces a clear ringing tone while defective pieces create dull thuds indicating internal fractures or weak bedding planes. This acoustic testing method identifies problems that won’t appear through visual inspection alone. You should reject any pieces that exhibit dull tones or mark them for use in low-stress applications like garden borders rather than structural pavement.

Iron oxide inclusions appear as rust-colored spots or streaking that can expand through oxidation cycles after installation. During the blue stone yard customer experience, you need to determine acceptable inclusion levels based on project aesthetic standards. Minimal inclusions (less than 3% surface coverage) often enhance natural character, while heavy concentrations (above 8%) indicate material that will develop progressive staining requiring ongoing maintenance intervention.

Inventory Availability Logistics

Material availability directly impacts project scheduling and budget management. When you conduct blue stone yard shopping Arizona visits, you’re assessing current inventory levels against project requirements while accounting for lead time variables. The reality of material supply chains means that warehouse stock you view today may not remain available through your procurement timeline.

You should verify these logistics factors during yard visits:

- Current inventory quantities must exceed your project requirements by 12-15% to account for breakage, cutting waste, and future repair needs

- Material production cycles for special orders typically range from 8-12 weeks from quarry to Arizona distribution points

- Truck delivery scheduling requires 5-10 business day lead times during peak construction season

- Your hold deposits typically secure inventory for 30-45 days, requiring careful coordination with project milestone dates

The blue stone yard selection process becomes complicated when specifications require material from single production lots to ensure color consistency. You’ll need to verify that visible inventory represents adequate volume or negotiate extended hold periods while additional material ships from source quarries. This planning prevents mid-project material substitutions that create visible color banding in finished installations.

Pricing Structure Factors

Material pricing varies based on factors beyond simple square footage calculations. During your blue stone yard inventory viewing, you’re evaluating cost components including material grade, dimensional specifications, surface finish, edge treatment, and delivery logistics. Understanding these pricing elements helps you optimize specifications to achieve design intent within budget constraints.

Base material costs for standard 1.5-inch thermal bluestone typically range from $12-$18 per square foot for full-pallet quantities, with pricing increasing for custom thicknesses or special finishes. You’ll find that natural cleft materials generally cost 15-20% less than thermal-finished alternatives, while honed surfaces command premium pricing of 25-35% above base rates. These differentials become significant on projects exceeding 1,000 square feet.

Your procurement strategy should account for economy of scale advantages — full pallet purchases (typically 400-500 square feet per pallet) reduce per-unit costs by 8-12% compared to partial pallet pricing. The blue stone yard customer experience should include detailed quotations that separate material costs from delivery fees, which range from $150-$400 depending on distance and site accessibility for truck access.

Installation Compatibility Review

Material characteristics must align with planned installation methods to ensure successful outcomes. When you perform blue stone yard material inspection, you’re verifying compatibility between stone properties and installation system requirements. The same material that performs excellently in sand-set applications may prove problematic for thin-set mortar installations if thickness tolerances exceed acceptable ranges.

Sand-set installations over compacted aggregate bases accommodate thickness variations up to ±3/8 inch through bedding layer adjustments, making them suitable for natural cleft bluestone with irregular backs. You’ll achieve proper drainage and stability when base preparation includes 6-8 inches of compacted road base overlaid with 1-1.5 inches of leveling sand. This system tolerates material irregularities while providing structural support for vehicular loads up to 8,000 pounds.

Mortar-set applications require tighter dimensional tolerances and consistent back surfaces to ensure proper adhesion. Your specifications for these installations should limit thickness variation to ±3/16 inch and specify thermal-finished backs for maximum mortar contact. The blue stone yard selection process must verify these characteristics, as standard inventory may not meet mortar-set requirements without additional fabrication that adds $2-$4 per square foot to material costs.

Best Blue Stone Yard Arizona Projects

When you evaluate Citadel Stone’s blue stone yard options for your Arizona projects, you’re considering premium materials engineered for extreme climate performance with mineral compositions that resist thermal degradation. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse environmental zones, from low-desert valleys to high-elevation plateau regions. This section outlines how you would approach specification decisions for three representative cities with distinct climate challenges.

Arizona’s geographic diversity creates varying performance requirements that affect your material selection criteria. You need to account for elevation differences of 6,000 feet across the state, creating temperature ranges from sub-zero winter conditions to sustained summer peaks above 115°F. Your specifications must address these extremes while considering local soil chemistry, precipitation patterns, and installation season constraints that affect curing and setting processes.

Chandler Commercial Plaza

For a hypothetical 3,200-square-foot commercial plaza application in Chandler, you would specify thermal-finished bluestone in 24×24-inch format with sawn edges to achieve the clean contemporary aesthetic typical of Chandler’s modern development patterns. Your installation would require mortar-set application over structural concrete substrate to support concentrated loads from commercial furniture and pedestrian traffic exceeding 200 daily passes. You’d need to address thermal expansion through 3/8-inch joints filled with flexible polymeric sand that accommodates movement coefficients of 5.3 × 10⁻⁶ per degree Fahrenheit. The project would benefit from evening installation scheduling during May through September to avoid setting complications from surface temperatures exceeding 135°F during afternoon hours.

Tempe Residential Courtyard

Your hypothetical 1,800-square-foot residential courtyard design in Tempe would utilize natural cleft bluestone in irregular flagstone format to complement Southwestern architectural character prevalent throughout established Tempe neighborhoods. You’d recommend sand-set installation over 8 inches of compacted decomposed granite base material, selected for compatibility with local caliche soil conditions that create expansion pressures during monsoon moisture infiltration. Your specification would address 12-foot expansion joint intervals with concealed metal edge restraints to prevent lateral migration during thermal cycling. The design would incorporate 40% shade coverage through integrated pergola structures to reduce peak surface temperatures below the 150°F threshold that affects barefoot comfort during summer evening use periods when the courtyard experiences primary activity.

Surprise Pool Deck

For a hypothetical 2,400-square-foot pool deck installation in Surprise, you would select thermal-finished bluestone with enhanced slip resistance treatment achieving minimum 0.52 DCOF ratings when wet. Your design would specify 2-inch thickness material to provide structural capacity for unsupported spans over pool equipment vaults and to deliver thermal mass that moderates afternoon surface temperatures through evening recreation periods. You’d address water management through 2% minimum slope away from pool perimeter combined with 1/2-inch joint spacing that facilitates rapid drainage while preventing trip hazards. The specification would require white polymeric joint sand that reflects solar radiation to reduce joint temperature differentials that accelerate sand degradation. Your installation timeline would avoid June through August peak temperatures that compromise adhesive curing in thin-set applications, instead targeting October through April construction windows when ambient conditions support proper material bonding and minimize thermal stress during initial cure cycles.

Selection Optimization

Your blue stone yard shopping Arizona experience culminates in selection decisions that balance aesthetic preferences, performance requirements, and budget constraints. You’ve gathered technical data through systematic inspection protocols, verified inventory availability against project timelines, and assessed installation compatibility with planned construction methods. The final optimization phase involves weighing trade-offs between competing priorities to achieve optimal project outcomes.

Professional specification development requires you to prioritize performance factors based on actual use patterns rather than theoretical conditions. You’ll find that slip resistance becomes paramount for pool surrounds and entries, while thermal performance determines usability for afternoon-exposed patios and entertainment areas. Your material selection must address the dominant performance requirement while ensuring adequate capability across secondary factors.

The comprehensive approach to blue stone yard selection process methodology ensures you’ve evaluated all critical decision factors before procurement commitment. For additional insights on material sourcing strategies, review Geographic distribution networks for bluestone material suppliers in Arizona before you finalize your project specifications and vendor selection. Complete offerings make Citadel Stone comprehensive bluestone supplies in Arizona source.