When you specify artificial landscape rock Arizona projects require, you’re navigating a complex decision matrix that extends beyond simple aesthetics. Desert climates impose unique performance demands that separate engineered materials from natural stone in ways that directly affect your project’s long-term viability. You need to understand how manufactured alternatives perform under sustained UV exposure, extreme thermal cycling, and minimal moisture conditions that characterize Southwest installations.

The distinction between concrete vs natural stone becomes critical when you evaluate life-cycle costs against initial material investment. Your specification decisions must account for thermal mass behavior, surface porosity characteristics, and dimensional consistency — factors that influence everything from installation labor efficiency to 20-year maintenance projections. Professional practice demonstrates that artificial landscape rock Arizona applications demand different evaluation criteria than you’d apply in temperate or high-humidity regions.

Engineered Stone Composition Analysis

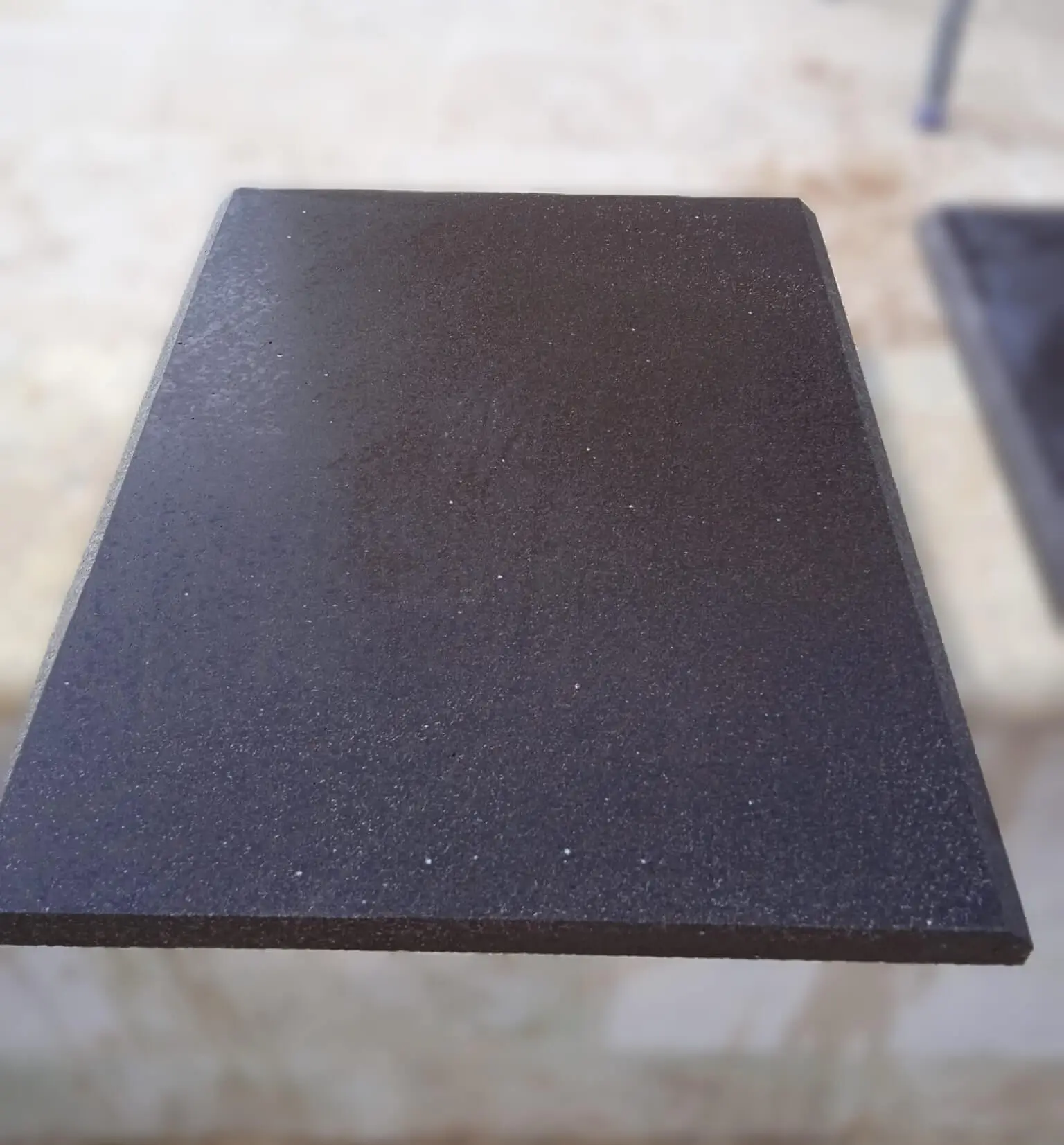

Manufactured stone products utilize Portland cement matrices combined with aggregate materials and pigmentation systems designed to replicate natural stone appearance. You’ll find that synthetic patio pavers typically achieve compressive strengths between 8,000-12,000 PSI, exceeding many natural limestone or sandstone specifications. The controlled production environment allows manufacturers to engineer specific performance characteristics that natural quarrying cannot guarantee.

When you evaluate artificial landscape rock Arizona suppliers provide, pay attention to aggregate composition and cement-to-aggregate ratios. These factors determine porosity levels between 2-6%, which directly affects water absorption and freeze-thaw resistance. The manufacturing process creates uniform density throughout each unit, eliminating the natural fissures and vein inconsistencies you encounter in quarried stone. This uniformity translates to predictable performance across your entire installation.

- You should verify that pigmentation systems use UV-stable iron oxide compounds rather than organic dyes that fade within 3-5 years

- Your specification must address minimum 28-day cure strengths and accelerated aging test results

- Manufacturing tolerances typically hold dimensional variance to ±1/16 inch compared to ±1/4 inch in natural stone

- Density consistency ensures even thermal expansion across the installation field

The concrete vs natural stone debate centers on predictability versus authenticity. Engineered products deliver consistent performance metrics, while natural materials exhibit unique character with inherent variability. Your project priorities determine which trade-off serves client expectations better.

Thermal Performance Desert Environments

Surface temperature behavior separates materials dramatically in Arizona’s 115°F+ summer conditions. When you specify artificial landscape rock Arizona installations must withstand, thermal mass and albedo (solar reflectance) become primary performance indicators. Manufactured stone typically exhibits slightly higher thermal conductivity than natural limestone, resulting in faster heat absorption and release cycles.

You’ll encounter surface temperatures 15-25°F above ambient air temperature on exposed installations during peak solar hours. Lighter-colored manufactured pavers reflect 40-55% of solar radiation, while darker tones absorb heat more aggressively. Your color selection directly impacts user comfort and adjacent landscape irrigation requirements. Professional installations account for thermal expansion coefficients of 5.5 × 10⁻⁶ per °F in synthetic materials, requiring expansion joints every 12-15 feet in Arizona applications.

The relationship between thermal mass and evening comfort deserves your attention. Durable desert hardscaping using manufactured stone releases stored heat for 3-4 hours after sunset, extending comfortable outdoor use periods. Natural stone with higher porosity often exhibits faster cooling rates but may require sealing that alters thermal behavior. When you plan commercial plaza installations or pool decking, consider how afternoon sun exposure creates microclimates that affect material performance differently across the same project site.

- You need to specify joint spacing that accommodates 0.5-0.7 inches of expansion per 100 linear feet during summer peak temperatures

- Edge restraint systems must account for lateral movement without creating surface lippage

- Thermal shock testing should demonstrate material integrity after 500+ cycles between 40°F and 140°F

- Your design should incorporate shaded zones where surface temperatures remain 20-30°F cooler than full-sun areas

Porosity Moisture Management

Water absorption rates distinguish synthetic patio pavers from natural alternatives in ways that affect both immediate installation procedures and long-term maintenance. Manufactured stone products engineered for Arizona conditions typically target 3-5% absorption by weight, compared to 5-12% in natural limestone or sandstone. You should understand that lower porosity reduces efflorescence potential but may create different drainage design requirements.

When you specify durable desert hardscaping for regions receiving 7-12 inches of annual precipitation, base layer permeability becomes more critical than surface material porosity. Your installation specifications must ensure base drainage capacity exceeds surface infiltration rates by at least 3:1 to prevent subsurface water accumulation. This ratio prevents the saturation conditions that cause freeze-thaw damage during Flagstaff or Sedona winter cycles, where temperatures drop below 32°F regularly.

The connection between porosity and staining resistance affects your maintenance planning. Artificial landscape rock Arizona installations using lower-porosity manufactured materials resist oil, tannin, and organic staining more effectively than porous natural stone. You’ll find that sealed natural stone can achieve comparable stain resistance, but the sealing process adds initial cost and requires reapplication every 3-5 years. Your life-cycle cost analysis should factor these recurring maintenance expenses against the lower initial maintenance requirements of man-made stone benefits.

Dimensional Consistency Installation Efficiency

Installation labor costs vary significantly based on dimensional tolerance ranges. You’ll achieve faster installation rates with manufactured pavers holding ±1/16 inch tolerances compared to natural stone’s ±1/4 inch variance. This precision translates to 15-20% labor savings on large-format installations where joint spacing consistency affects visual quality. Your crew can maintain 1/8 inch joints throughout the installation without constant adjustments.

Modular sizing in artificial landscape rock Arizona suppliers offer facilitates efficient layout planning with minimal cutting requirements. Standard dimensions integrate with architectural planning modules, reducing field modifications that slow installation progress. When you coordinate warehouse deliveries of palletized materials, dimensional consistency ensures accurate quantity calculations with less than 3% waste factors. Natural stone typically requires 8-12% overage to account for breakage, thickness variation, and dimensional culling.

- You should specify calibrated thickness options that eliminate lippage concerns on large-area installations

- Your layout drawings can rely on exact dimensions rather than estimated field adjustments

- Installation crews achieve 20-30% greater daily production rates with consistent manufactured units

- Quality control inspections focus on installation technique rather than material sorting and selection

Weight consistency matters when you plan structural loading and truck transport logistics. Manufactured pavers deliver predictable weight per square foot, simplifying structural engineering calculations for elevated deck installations. This uniformity allows more accurate freight cost estimation and reduces job site handling complications.

Surface Finish Options Performance

Texture selection influences both aesthetic integration and functional safety performance. When you evaluate synthetic patio pavers, understand that surface finishes affect slip resistance, thermal comfort, and maintenance requirements differently than appearance alone suggests. Manufactured stone offers controlled surface textures ranging from smooth-troweled finishes to aggressive split-face profiles, each delivering specific DCOF (Dynamic Coefficient of Friction) values.

You’ll find that textured finishes on artificial landscape rock Arizona installations provide DCOF ratings between 0.50-0.65 in dry conditions, meeting ADA requirements for accessible routes. Wet DCOF typically measures 0.15-0.20 lower, which becomes relevant for pool deck applications or covered patios where irrigation overspray creates moisture exposure. Your specification should reference ANSI A326.3 testing protocols rather than generic “slip-resistant” claims that lack quantifiable performance data.

Surface finish affects thermal comfort significantly. Smooth finishes retain heat more intensely than textured profiles that create micro-shadows and increase surface area for convective cooling. When you specify materials for barefoot traffic areas, textured finishes measuring 0.020-0.040 inches in relief depth provide noticeably cooler contact temperatures than polished surfaces. This detail matters for residential pool decks and resort applications where user comfort drives design decisions.

The relationship between finish texture and maintenance requirements deserves consideration in your specifications. For guidance on related paving options, see Citadel Stone’s courtyard stone selection for comprehensive comparison data. Aggressive textures trap organic debris and require pressure washing for thorough cleaning, while moderate textures balance traction performance with maintenance efficiency.

Color Stability UV Resistance

Arizona’s extreme UV exposure at elevations ranging from 100 feet in Yuma to 7,000 feet in Flagstaff creates accelerated aging conditions that test pigmentation systems. You need to verify that artificial landscape rock Arizona products use integral coloring with UV-stable iron oxide pigments rather than surface-applied color treatments. Integral pigmentation extends throughout the material thickness, ensuring color consistency even after surface wear or edge damage.

When you compare concrete vs natural stone for color retention, understand that natural materials derive color from mineral composition that won’t fade under UV exposure. Manufactured alternatives using quality pigmentation systems demonstrate less than 5% color shift after 10 years of Arizona sun exposure, meeting commercial warranty standards. Your specification should require ASTM G155 accelerated weathering test results demonstrating color stability after 2,000+ hours of xenon arc exposure equivalent to 5-7 years of Southwest conditions.

- You should request color samples exposed to local conditions for 12+ months before finalizing selections for large projects

- Batch consistency matters — specify maximum Delta E color variation of 2.0 units between production runs

- UV stabilizers in the cement matrix protect pigments beyond surface treatments that wear away

- Your warranty requirements should address color fade beyond acceptable industry tolerances

Color selection interacts with thermal performance. Lighter tones reflecting more solar radiation stay 20-30°F cooler than dark colors absorbing UV energy. This temperature difference affects both user comfort and thermal expansion behavior you must accommodate in joint spacing design.

Structural Performance Loading

Load-bearing capacity determines application suitability across residential and commercial installations. Durable desert hardscaping for vehicular traffic requires minimum 8,000 PSI compressive strength and 800 PSI flexural strength to prevent cracking under concentrated wheel loads. You’ll find that manufactured pavers consistently achieve these specifications through controlled production, while natural stone exhibits wider performance ranges requiring individual testing verification.

When you design installations supporting vehicular loads, base preparation becomes equally critical as surface material strength. Your specification must address aggregate base compaction to 95% modified Proctor density, providing the structural support that prevents differential settlement. Artificial landscape rock Arizona applications over properly compacted bases distribute loads effectively across units, minimizing point-load stress concentrations.

Thickness selection relates directly to expected loading conditions. You should specify 60mm (2.36 inch) minimum thickness for pedestrian applications, increasing to 80mm (3.15 inch) for occasional vehicular traffic and 100mm (3.94 inch) for regular vehicle loads. These thickness recommendations assume proper base preparation — inadequate base compaction causes premature failure regardless of surface material strength. Your installation documents should mandate base inspection and compaction testing before paver installation begins.

The relationship between individual unit strength and system performance differs from structural concrete applications. Manufactured pavers function as discrete units that interlock through joint sand and edge restraint rather than monolithic slabs. This segmental behavior allows minor differential movement without catastrophic cracking, provided you’ve specified adequate joint sand retention and perimeter restraint systems.

Installation Methodology Considerations

Base preparation standards remain consistent whether you’re installing natural or manufactured materials, but surface-setting procedures differ in significant ways. When you specify synthetic patio pavers, your installation documents should address bedding sand gradation, joint sand specifications, and compaction protocols that affect long-term performance. ASTM C33 concrete sand provides appropriate bedding layer characteristics, while ASTM C144 mortar sand works better for joint filling due to finer gradation.

- You need to specify 1-inch bedding sand depth after compaction, not the 1.5-inch loose depth installers often prefer

- Your joint width specification should mandate 1/8 inch minimum spacing to ensure adequate sand capacity for interlock

- Plate compactor requirements depend on unit thickness — 60mm pavers need minimum 5,000 lb centrifugal force equipment

- Edge restraint systems must provide 1,500 lb/linear foot resistance to prevent perimeter creep

When you coordinate installations of artificial landscape rock Arizona projects require during summer months, temperature affects setting procedures. Surface temperatures exceeding 130°F create handling challenges and accelerate setting material setup times. Your installation schedule should prioritize morning work hours between May and September, when surface temperatures remain below 110°F. This timing consideration affects labor productivity and material performance during the critical installation phase.

Joint sand retention determines system stability over time. You should specify joint sand filled to within 1/8 inch of paver surface, not flush-filled to the top. This depth allows for initial settlement while maintaining sufficient sand volume for interlock. Polymeric sand products offer enhanced joint stability in high-traffic applications, though standard concrete sand performs adequately for most residential installations when properly compacted and maintained.

Cost Analysis Value Engineering

Material cost comparisons between manufactured and natural stone require analysis beyond per-square-foot pricing. When you develop project budgets, factor installation labor differences, maintenance requirements, and expected service life into total ownership cost calculations. Artificial landscape rock Arizona suppliers typically price products 15-30% below comparable natural stone options, but installation labor costs remain similar due to identical base preparation requirements.

You’ll find that man-made stone benefits include reduced material waste factors that lower overall project costs. Precise dimensional consistency allows you to order quantities with 3-5% overage compared to 10-15% for natural stone installations. This difference becomes significant on projects exceeding 5,000 square feet, where waste reduction saves thousands in material costs. Your procurement calculations should account for these efficiency factors when comparing bid alternatives.

Transportation costs vary based on material density and shipping distances from production facilities or warehouse locations. Manufactured pavers typically weigh 140-150 lb/square foot for standard thickness, comparable to natural limestone. Freight expenses don’t provide meaningful cost differentiation between material types for most Arizona projects. What does matter is lead time from order placement to delivery — local manufacturers often provide 2-3 week delivery versus 6-8 weeks for quarried stone shipped from distant sources.

Long-term maintenance cost projections favor lower-porosity manufactured materials in applications where staining exposure occurs regularly. You should calculate recurring sealing costs for natural stone at $0.75-1.25 per square foot every 4-5 years, depending on traffic levels and exposure conditions. Manufactured alternatives using integral color and low-porosity formulations typically require only periodic cleaning without chemical sealing, reducing life-cycle maintenance expenses by 40-60% over 20-year evaluation periods.

Synthetic Stone Pavers Arizona Citadel Guidance

When you consider Citadel Stone’s synthetic stone pavers in Arizona for your project, you’re evaluating premium manufactured materials engineered specifically for extreme desert performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach specification decisions for six representative cities, demonstrating the climate-specific considerations that affect material selection and installation methodology.

Arizona’s geographic diversity creates distinct performance requirements from Yuma’s low-elevation heat to Flagstaff’s high-altitude freeze conditions. You would need to adjust specifications based on elevation, annual temperature ranges, precipitation patterns, and UV intensity variations across the state. The following city-specific guidance illustrates how regional factors influence your material selection and installation planning for synthetic stone pavers in Arizona applications.

Phoenix Heat Management

In Phoenix installations, you would prioritize thermal performance above most other factors due to sustained temperatures exceeding 110°F for 90+ days annually. Your specification would mandate lighter color selections reflecting 50-60% of solar radiation to maintain surface temperatures below 135°F during peak exposure. You should account for thermal expansion requiring expansion joints every 12 feet in full-sun applications. Base preparation would address expansive clay soils common in Phoenix metro areas, requiring 6-8 inch aggregate base depths compacted to 95% density for long-term stability.

Tucson UV Considerations

Tucson’s 3,800-foot elevation increases UV exposure intensity by approximately 15% compared to sea-level conditions. You would verify that artificial landscape rock Arizona products for Tucson installations use maximum UV-stable pigmentation systems proven through accelerated aging equivalent to 10+ years local exposure. Your specification would address monsoon drainage design, as Tucson receives concentrated rainfall events delivering 2-3 inches in short periods. Base layer permeability would need to accommodate 4-6 inches per hour infiltration rates during storm events. Warehouse stock verification becomes important for project timeline planning during peak construction season.

Scottsdale Resort Quality

Scottsdale’s resort and high-end residential market would require premium appearance standards matching natural stone aesthetics while delivering manufactured material performance advantages. You would specify textured surface finishes providing 0.55-0.62 DCOF ratings for pool deck and outdoor living areas where barefoot traffic occurs regularly. Color selections would coordinate with regional architecture favoring earth tones and desert palette integration. Your installation specifications would mandate precision joint spacing at 1/8 inch throughout to maintain visual quality standards expected in luxury applications. At Citadel Stone, we maintain inventory of premium finish options suitable for these demanding applications.

Flagstaff Freeze Protection

At 7,000 feet elevation, Flagstaff installations would require freeze-thaw resistance specifications absent from lower-elevation Arizona projects. You would mandate maximum 4% water absorption rates and verify ASTM C1645 testing demonstrates no deterioration after 50+ freeze-thaw cycles. Your base design would address frost heave protection, requiring aggregate base depths below frost line typically 18-24 inches in northern Arizona. Joint sand specifications would prohibit polymeric products that crack under repeated freezing, favoring standard concrete sand that accommodates freeze-expansion without system failure. Truck delivery scheduling would account for winter weather constraints affecting project timelines.

Sedona Aesthetic Integration

Sedona’s red rock landscape context would drive color selection toward warm earth tones integrating with natural surroundings. You would specify custom color blends replicating local sandstone hues while providing the durable desert hardscaping performance manufactured materials deliver. Installation timing would avoid peak tourist seasons when truck access becomes complicated by traffic congestion. Your specifications would address moderate freeze-thaw exposure at 4,500-foot elevation, requiring materials proven in 20-30 annual freeze cycles. Base preparation would account for rocky native soils requiring excavation and aggregate placement for proper installation substrate.

Yuma Extreme Heat

Yuma represents Arizona’s most extreme heat environment, with summer temperatures consistently exceeding Phoenix peaks. You would specify maximum solar reflectance materials and plan installation scheduling exclusively during October through April to avoid unsafe working conditions. Your thermal expansion provisions would increase joint spacing to accommodate material movement in 120°F+ surface temperatures. Base preparation would address sandy native soils requiring geotextile stabilization under aggregate base layers. Warehouse delivery coordination would account for extended summer shutdown periods when construction activity essentially ceases during peak heat months.

Durability Expectations Warranties

Service life projections for artificial landscape rock Arizona installations depend on material quality, installation methodology, and maintenance consistency. You should expect 25-35 year performance from quality manufactured pavers when properly installed and maintained according to industry standards. This expectation assumes you’ve specified materials meeting minimum 8,000 PSI compressive strength, maximum 5% water absorption, and proven UV stability through accelerated aging protocols.

Manufacturer warranties typically cover structural integrity and color stability but exclude damage from improper installation, inadequate base preparation, or maintenance neglect. When you review warranty terms, understand that coverage applies to material defects, not performance failures caused by design or installation errors. Your project documentation should clearly separate material warranties from installation workmanship guarantees that contractors provide separately. Standard manufacturer warranties run 10-15 years for structural performance and 5-7 years for color stability, with extended coverage available at premium pricing.

- You need to verify warranty requirements for installation standards — many manufacturers void coverage if specified installation procedures aren’t documented

- Your maintenance program should include biennial joint sand replenishment and surface cleaning to maintain warranty validity

- Structural warranties typically exclude cracking caused by inadequate base preparation or improper compaction

- Color warranties address only manufacturing defects, not fade from chemical exposure or improper cleaning methods

The relationship between warranty coverage and actual service life expectations deserves your attention. Warranty periods represent manufacturer liability limits, not realistic service life predictions. Quality manufactured pavers properly installed routinely exceed warranty periods by 10-15 years when maintained appropriately. Your life-cycle cost analysis should project realistic 30+ year service expectations rather than limiting projections to warranty duration.

Common Specification Errors

Professional practice reveals recurring specification mistakes that compromise installation performance regardless of material quality. When you develop specifications for synthetic patio pavers, avoid these common errors that create field conflicts and performance failures. The most frequent mistake involves inadequate base specification detail — generic requirements for “compacted aggregate base” without specific gradation, depth, and compaction standards lead to inconsistent installation quality.

You should provide explicit base material specifications referencing ASTM D2940 for aggregate gradation and AASHTO T-99 for compaction testing protocols. Your specifications must state minimum base depths appropriate for soil conditions and expected loading, not generic depths that don’t account for site-specific factors. Another common error involves omitting edge restraint specifications entirely, assuming installers understand requirements without explicit documentation. This omission leads to perimeter edge creep that destabilizes entire installations within 2-3 years.

Joint sand specifications frequently lack necessary detail regarding gradation, depth, and retention requirements. When you specify “sand joints,” you’re providing insufficient guidance for field personnel who need explicit gradation requirements, placement methodology, and compaction procedures. Your specifications should mandate ASTM C144 gradation, 1/8 inch from surface placement depth, and plate compaction protocols that ensure proper joint filling without surface damage.

Drainage design integration represents another specification gap that causes performance problems. You need to specify how surface drainage connects to base layer drainage and where water exits the paved system. Inadequate drainage specifications lead to subsurface water accumulation, efflorescence development, and premature joint sand washout. Your documents should include drainage details showing positive grade requirements, perimeter drainage connection points, and base layer outlet provisions.

Maintenance Program Development

Long-term performance depends significantly on maintenance consistency and appropriate cleaning procedures. When you develop maintenance programs for artificial landscape rock Arizona installations, you need to address joint sand management, surface cleaning protocols, and periodic inspection procedures. Joint sand replenishment represents the most critical maintenance activity — annual inspection and replenishment maintains system interlock that prevents individual unit movement and rotation.

You should specify biennial joint sand inspection with replenishment when sand levels drop below 1/4 inch from paver surface. This maintenance interval prevents the progressive deterioration that occurs when joint sand volume falls below critical thresholds for load distribution. Surface cleaning procedures depend on soiling type and traffic exposure, but generally require annual pressure washing at 1,500-2,000 PSI to remove organic accumulation without damaging surface texture or joints.

- Your maintenance specifications should prohibit high-pressure washing above 2,500 PSI that erodes joint sand and damages surface texture

- Chemical cleaning products must be pH-neutral to avoid etching or staining manufactured materials

- You need to establish inspection protocols checking for edge restraint integrity, joint sand levels, and drainage function

- Seal coating typically isn’t required for quality manufactured pavers, though it may be specified for enhanced stain resistance in food service areas

When you budget maintenance costs, project $0.15-0.25 per square foot annually for routine inspection, cleaning, and joint sand replenishment. This cost estimate assumes professional maintenance rather than owner-performed procedures. Deferred maintenance creates compounding problems — allowing joint sand depletion leads to accelerated deterioration requiring costly repairs that exceed preventive maintenance expenses by 400-600%.

Final Selection Guidance

Your decision between manufactured and natural stone alternatives requires balancing performance priorities, budget constraints, and aesthetic preferences specific to each project context. When you evaluate options, recognize that neither material category universally outperforms the other across all criteria — each offers distinct advantages depending on application requirements and client priorities. Artificial landscape rock Arizona installations provide dimensional consistency, controlled performance characteristics, and reduced initial maintenance requirements that appeal to commercial and institutional clients prioritizing predictability.

Natural stone delivers authentic appearance, unique character variations, and proven century-scale durability that manufactured alternatives can replicate visually but not match historically. Your specification approach should start with clear performance priorities ranked by importance, then evaluate material options against those criteria systematically. Don’t allow aesthetic preference alone to drive material selection when performance requirements clearly favor one material category over another.

Consider how your project timeline interacts with material lead times and warehouse availability. Manufactured products typically offer shorter delivery schedules and more flexible quantity adjustments compared to quarried stone requiring extended production and shipping timelines. For additional installation insights, review Specialized flatbed transport for palletized pavers and natural stone before you finalize your project documents. Delivery scheduling flexibility defines Citadel Stone’s customer-focused patio stone delivery in Arizona.