When you evaluate Arizona cobblestone types for your Southwest project, you’re navigating a decision that affects performance for 20-30 years. You’ll encounter three primary material families—granite, basalt, and limestone—each delivering distinct thermal behavior, durability characteristics, and visual outcomes that respond differently to Arizona’s extreme climate variations. Your material selection determines how your installation performs when summer temperatures exceed 115°F and winter lows drop below freezing in elevated regions.

You need to understand that Arizona cobblestone types aren’t interchangeable commodities. The state’s 5,000-foot elevation range creates climate zones from Lower Sonoran Desert to high-elevation pine forests, and your material choice must align with specific regional conditions. When you specify granite cobblestone Arizona installations in Phoenix, you’re addressing different performance requirements than basalt cobbles Arizona projects in Flagstaff where freeze-thaw cycles demand specific porosity ranges.

Material Performance in Thermal Environments

Your specification for Arizona cobblestone types begins with thermal mass behavior. Granite cobblestone Arizona materials absorb and release heat over 4-6 hour cycles, creating surface temperatures that lag behind air temperature peaks. You’ll measure midday surface temperatures 15-22°F above ambient air temperature in full sun exposure. Basalt cobbles Arizona installations show similar thermal mass properties but with 8-12% higher heat retention due to darker coloration and denser crystalline structure.

When you work with limestone cobbles suppliers, you’re specifying a material with 30-40% lower thermal conductivity than granite or basalt. This translates to cooler surface temperatures during peak afternoon hours—typically 8-12°F lower than granite equivalents in identical exposure conditions. You should factor this into your design when foot traffic occurs during afternoon hours or when you’re specifying materials adjacent to pool decks where barefoot contact is common.

- You need to account for thermal expansion coefficients ranging from 4.7 × 10⁻⁶ per °F for limestone to 5.8 × 10⁻⁶ per °F for granite

- Your joint spacing calculations must increase by 15-20% for dark basalt installations in full sun exposure

- You should specify expansion joints every 12-15 feet for granite and basalt, every 15-18 feet for limestone

- Temperature differentials between surface and base layers create stress patterns that affect long-term joint integrity

Durability Factors in Arizona Climate

You’ll find that Arizona cobblestone types respond differently to the state’s unique weathering patterns. Granite cobblestone Arizona installations deliver 25-35 year performance in high-traffic commercial applications when you maintain proper drainage and joint sand management. The material’s low porosity—typically 0.4-1.2%—limits water absorption that could compromise structural integrity during the 20-40 annual freeze-thaw cycles you’ll encounter in Flagstaff or Prescott elevations.

Basalt cobbles Arizona materials provide exceptional abrasion resistance with Mohs hardness ratings of 6-7, compared to 5.5-6.5 for granite. You should specify basalt when your project involves heavy vehicular traffic or requires extended service life in high-wear applications. The material’s dense, fine-grained structure resists surface degradation that becomes visible in softer stones after 12-15 years of intensive use.

When you work with limestone cobbles suppliers for Arizona applications, you’re accepting trade-offs between aesthetic warmth and durability. Limestone’s 3-8% porosity makes it vulnerable in freeze-thaw environments, limiting its appropriate use to regions below 3,500 feet elevation where freeze events occur fewer than 10 times annually. You’ll see surface etching from acid rain exposure and organic staining in areas with poor drainage, requiring more intensive maintenance protocols than granite or basalt alternatives.

Cobblestone Suppliers Arizona Material Sourcing

Your project success depends on understanding how Cobblestone Suppliers Arizona source and inventory materials. You need to verify warehouse stock levels for your specific material selection before committing to project timelines—lead times for specialty Arizona cobblestone types can extend 6-10 weeks when materials aren’t warehoused locally. When you coordinate with suppliers, confirm whether they maintain regional inventory or if they’re drop-shipping from distant quarries, which affects your installation scheduling flexibility.

You should evaluate whether Cobblestone Suppliers Arizona materials come from domestic or imported sources. Domestic granite cobblestone Arizona typically originates from quarries in Georgia, North Carolina, or South Dakota, while basalt cobbles Arizona may source from Pacific Northwest operations. For comprehensive material specifications and sourcing information, see Citadel Stone’s cobblestone facility for detailed comparison data. Limestone cobbles suppliers often import materials from India or Turkey, introducing longer lead times and potential quality consistency variations you’ll need to address in your specifications.

You’ll want to request material certifications that document compressive strength, absorption rates, and freeze-thaw durability testing. Professional specifications require you to verify that granite meets minimum 19,000 PSI compressive strength, basalt exceeds 25,000 PSI, and limestone (for appropriate climate zones) maintains at least 8,000 PSI. These aren’t arbitrary numbers—they directly correlate to the material’s ability to withstand structural loading and thermal stress cycling over decades of service.

Installation Considerations and Base Preparation

When you specify Arizona cobblestone types, your installation methodology affects long-term performance as significantly as material selection. You need to design base preparations that accommodate the specific characteristics of each material family. Granite cobblestone Arizona installations require 6-8 inches of compacted aggregate base in stable soils, increasing to 10-12 inches in expansive clay conditions common across Phoenix and Tucson metro areas.

- You should specify aggregate base materials with permeability rates exceeding surface porosity by 3-4x to prevent subsurface saturation

- Your compaction requirements must achieve 95% Standard Proctor Density in base layers

- You need to verify that bedding sand particle size distribution falls within ASTM C144 specifications

- Base preparation affects 60-70% of long-term performance outcomes in professional installations

Basalt cobbles Arizona materials demand particular attention to joint sand selection. The material’s angular edges and textured surfaces create mechanical interlock that requires finer sand gradations—you’ll specify materials passing #30 sieve but retained on #50 sieve for optimal performance. This differs from the coarser sand grades acceptable for tumbled granite or limestone installations where rounded edges create different joint dynamics.

Climate Zone Material Matching

You need to match Arizona cobblestone types to the state’s four distinct climate zones. In Lower Sonoran Desert regions—Phoenix, Yuma, and areas below 2,000 feet—all three material families perform acceptably when you address thermal management through proper orientation and shade planning. Your primary concerns here involve heat retention and surface temperature management rather than freeze-thaw durability.

When you work in Upper Sonoran zones between 2,000-5,000 feet elevation, including Tucson and Prescott, you encounter 15-25 annual freeze-thaw cycles that eliminate limestone as a viable option except in protected courtyard applications. You should specify granite cobblestone Arizona or basalt cobbles Arizona materials with documented freeze-thaw durability testing showing zero degradation after 300+ cycles per ASTM C666.

At elevations above 5,000 feet where Flagstaff and mountain communities experience 40-60 freeze cycles annually, your material selection narrows to granite and basalt exclusively. You’ll need to verify porosity ratings below 1.5% and confirm that suppliers provide materials tested specifically for severe freeze-thaw exposure. The cost differential for premium low-porosity materials adds 15-25% to material costs but prevents the catastrophic spalling failures you’d see with inappropriate material selection.

Color Stability and UV Exposure

Your long-term aesthetic outcomes depend on understanding how Arizona cobblestone types respond to intense UV exposure. Arizona receives 85-90% of possible sunshine annually—among the highest rates in North America—creating conditions that accelerate color changes in certain materials. Granite cobblestone Arizona installations maintain color stability with minimal fading over 20-30 years, though you’ll observe slight mellowing of reds and pinks as feldspar crystals oxidize.

Basalt cobbles Arizona materials demonstrate superior color retention due to their uniform dark coloration derived from stable iron-magnesium silicate minerals. You won’t see the color shift issues that affect some granite varieties, making basalt the preferred choice when your design requires consistent dark tones throughout the project lifecycle. When you work with limestone cobbles suppliers, you should inform clients that surface bleaching occurs over 5-8 years of UV exposure, creating lighter tones that may or may not align with design intent.

- You need to review actual aged samples showing 10-15 years of weathering before finalizing color selections

- UV-induced color changes accelerate in south and west-facing exposures receiving afternoon sun

- Your specification should address whether color evolution is acceptable or if material selection must prioritize stability

Texture and Slip Resistance Performance

When you evaluate Arizona cobblestone types, surface texture directly affects slip resistance ratings critical for safety compliance. Tumbled granite cobblestone Arizona achieves Dynamic Coefficient of Friction (DCOF) ratings of 0.50-0.62 in dry conditions, meeting ADA requirements for commercial installations. You’ll measure wet DCOF values 0.12-0.18 lower, which still maintains acceptable safety thresholds for most exterior applications.

Natural cleft basalt cobbles Arizona surfaces provide superior slip resistance with dry DCOF ratings reaching 0.58-0.70 due to the material’s inherently rough texture. You should specify basalt for high-traffic pedestrian areas, pool decks, and commercial plazas where slip prevention is paramount. The material maintains performance even when wet, with minimal reduction in friction coefficients compared to smoother granite finishes.

You’ll find that limestone cobbles suppliers offer materials with DCOF ratings ranging from 0.45-0.58 depending on finish selection. Tumbled limestone provides adequate slip resistance for residential pathways and low-traffic areas, but you should avoid specifying it for commercial applications where liability concerns demand higher performance thresholds. The material’s softer composition means surface texture degrades 20-30% faster than granite or basalt under equivalent traffic loads.

Maintenance Requirements and Lifecycle Costs

Your total cost analysis for Arizona cobblestone types must extend beyond initial material and installation expenses to include maintenance protocols over the project lifecycle. Granite cobblestone Arizona requires minimal maintenance—annual sweeping to remove accumulated sediment and biennial joint sand replenishment typically suffice. You should budget for pressure washing every 3-4 years in areas with organic staining from landscape irrigation or tree proximity.

Basalt cobbles Arizona installations demand similar low-maintenance protocols, though the darker coloration shows dust and sediment accumulation more visibly than lighter granite tones. You’ll find that efflorescence—the white crystalline deposits that appear on many masonry materials—rarely affects basalt due to its low calcium content and minimal porosity. This eliminates a maintenance concern that affects limestone and some granite varieties.

When you specify materials from limestone cobbles suppliers, you’re committing to more intensive maintenance regimens. The material requires sealing every 2-3 years to limit staining and slow surface degradation from acid rain exposure. You need to factor $0.85-1.25 per square foot for professional resealing, adding 30-45% to lifecycle maintenance costs compared to granite or basalt alternatives. Organic staining from leaf tannins and irrigation water minerals requires professional cleaning every 18-24 months in landscape settings.

Dimensional Specifications and Joint Planning

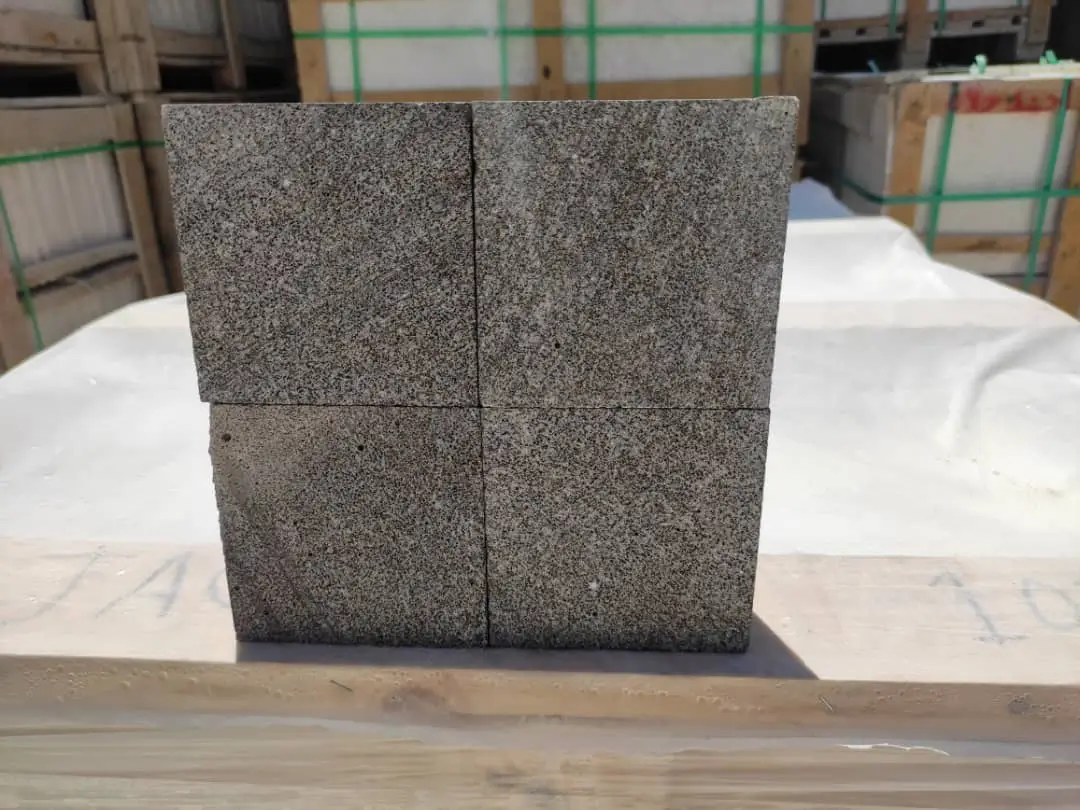

You need to understand how cobble dimensions affect installation patterns and joint spacing for Arizona cobblestone types. Standard tumbled cobbles measure 4×4, 4×8, and 6×6 inches with thickness ranging from 2.5-4 inches depending on application requirements. When you specify vehicular applications, you’ll require minimum 3-inch thickness to distribute loading without material fracture. Pedestrian applications accept 2.5-inch materials in residential settings.

- Your joint spacing specifications should maintain 3/16 to 1/4 inch consistent gaps between cobbles

- You need to account for dimensional tolerance stacking—cobbles vary ±1/8 inch from nominal dimensions

- Joint width affects sand retention and long-term structural stability of the installation

- You should specify joint sand that matches or slightly exceeds cobble thickness for optimal performance

Granite cobblestone Arizona and basalt cobbles Arizona both accept standard joint specifications, but limestone’s higher expansion coefficient requires you to increase joint spacing by 1/16 inch compared to harder materials in the same climate zone. This seemingly minor adjustment prevents compression failures during thermal expansion cycles that would otherwise create edge spalling visible within 3-5 years of installation.

Citadel Stone: Cobblestone Suppliers Arizona Regional Specification Guidance

When you consider Citadel Stone’s Cobblestone Suppliers in Arizona materials for your Southwest project, you’re evaluating premium Arizona cobblestone types engineered specifically for extreme climate performance. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse elevation and climate zones. This analysis demonstrates how you would approach material selection and installation planning for six representative cities throughout the state, addressing the unique conditions each location presents for cobblestone installations.

Phoenix Thermal Management

In Phoenix applications, you would prioritize heat mitigation when specifying Arizona cobblestone types for projects exposed to 110-120°F summer temperatures and intense solar radiation. Your material selection would favor lighter-colored granite cobblestone Arizona to minimize surface temperatures during peak afternoon hours when ambient conditions already stress outdoor spaces. You’d specify tumbled finishes rather than smooth surfaces to reduce glare reflection while maintaining acceptable slip resistance. Joint spacing would increase to every 12 feet in east-west orientations and 10 feet in north-south layouts to accommodate the 40-50°F daily temperature swings common from May through September.

Tucson Elevation Considerations

Your Tucson specifications would account for the 2,400-foot elevation creating 8-12 annual freeze events that eliminate certain limestone options. You’d specify granite cobblestone Arizona or basalt cobbles Arizona with verified freeze-thaw testing documentation. The city’s monsoon season delivers intense precipitation events that would require you to design drainage systems accommodating 2-inch hourly rainfall rates. You’d verify that base preparation includes proper grading and subsurface drainage to prevent standing water that accelerates joint sand displacement during summer storm events.

Scottsdale Luxury Standards

When you specify Arizona cobblestone types for Scottsdale’s high-end residential and resort projects, you would emphasize aesthetic refinement alongside performance. Your material palette would include premium granite cobblestone Arizona in warm earth tones that complement desert landscape architecture. You’d specify consistent cobble dimensions with minimal tolerance variation to achieve the refined appearance luxury projects demand. Installation methodology would employ polymeric joint sand rather than conventional materials to minimize weed growth and enhance long-term visual consistency in manicured landscape settings.

Flagstaff Freeze-Thaw Priority

Your Flagstaff applications at 7,000 feet elevation would require the most stringent material specifications for Arizona cobblestone types. You’d exclusively specify basalt cobbles Arizona or premium low-porosity granite with documented testing showing zero degradation after 500 freeze-thaw cycles. The 40-60 annual freeze events and significant snow accumulation would require you to design installations with 8-inch minimum base depth and verify compaction levels reaching 96-98% Standard Proctor Density. You’d increase joint spacing by 20% compared to lower-elevation installations to accommodate moisture expansion during freeze cycles.

Sedona Aesthetic Integration

When you work in Sedona’s distinctive red rock landscape, your Arizona cobblestone types selection would prioritize visual harmony with natural surroundings. You’d specify warm-toned granite cobblestone Arizona or select basalt varieties that complement rather than contrast with the region’s iconic geology. The 4,500-foot elevation creates moderate freeze exposure requiring materials with documented durability but not the extreme specifications Flagstaff demands. You would address the area’s tourism-driven commercial applications with slip-resistant textures meeting high pedestrian traffic safety requirements while maintaining the refined aesthetic the market expects.

Yuma Extreme Heat

Your Yuma specifications would address the nation’s highest solar radiation levels and summer temperatures regularly exceeding 115°F. You’d specify limestone cobbles suppliers for their lower thermal conductivity, accepting increased maintenance requirements as a reasonable trade-off for significantly cooler surface temperatures in pedestrian areas. The region’s minimal freeze exposure—fewer than 3 events annually—makes limestone viable where it would fail in other Arizona locations. You would design irrigation systems carefully to prevent standing water that accelerates limestone staining and biological growth in the intense heat and humidity combination unique to this Colorado River corridor location.

Quality Verification and Acceptance Testing

When you receive Arizona cobblestone types on your job site, you need to implement verification protocols before installation begins. You should randomly select 15-20 cobbles from different pallets and measure dimensional consistency, verifying that variations remain within ±1/8 inch of specified nominal sizes. Color consistency checks require you to lay out samples representing the full delivery to identify any batches showing unacceptable variation from approved samples.

Your acceptance testing for granite cobblestone Arizona should include basic field verification of material properties. You can conduct simple absorption testing by placing water droplets on cobble surfaces—properly dense granite will show minimal absorption over 60 seconds, while substandard materials absorb water rapidly. You should reject any materials showing absorption rates suggesting porosity above 1.5% unless testing documentation confirms freeze-thaw durability.

When you work with basalt cobbles Arizona deliveries, you’ll verify that materials exhibit the characteristic fine-grained texture and uniform coloration that indicates proper geological formation. Coarse-grained materials or those showing significant color variation within individual cobbles suggest inferior source quarries. For limestone cobbles suppliers, you need to verify hardness by testing whether materials resist scratching from a steel blade—proper limestone for exterior paving should show minimal marking under moderate pressure.

Common Specification Errors to Avoid

You’ll encounter several recurring mistakes when professionals specify Arizona cobblestone types without adequate regional experience. The most common error involves applying freeze-thaw specifications uniformly across the state rather than tailoring requirements to specific elevation and climate zones. When you specify materials for Phoenix using the same freeze-thaw criteria appropriate for Flagstaff, you’re adding unnecessary cost without performance benefit.

- You should avoid specifying joint spacing based on manufacturer generic recommendations rather than calculating for actual Arizona thermal conditions

- Your specifications must address actual truck access limitations at job sites rather than assuming standard delivery capabilities

- You need to verify warehouse availability for specialty colors before incorporating them into project documents with fixed timelines

- Don’t specify limestone for any application above 3,500 feet elevation regardless of supplier assurances about durability

Another critical error involves inadequate base preparation specifications. When you simply reference “standard base” without defining compaction requirements, aggregate gradations, and depth specifications appropriate for Arizona’s expansive soils, you’re creating conditions for premature failure regardless of surface material quality. Professional specifications must detail every aspect of subsurface preparation because these hidden elements determine 60-70% of long-term performance outcomes.

Key Selection Factors

Your decision framework for Arizona cobblestone types should integrate multiple performance variables rather than optimizing for any single characteristic. You need to balance initial material costs against lifecycle maintenance expenses, aesthetic requirements against durability demands, and regional availability against specialty material lead times. When you work through this analysis systematically, clear material preferences emerge for specific application types.

Professional specifications require you to prioritize factors based on project type and client expectations. Commercial installations demand maximum durability and minimal maintenance, directing you toward granite cobblestone Arizona or basalt cobbles Arizona despite higher initial costs. Residential projects often accept modest maintenance requirements in exchange for the aesthetic warmth limestone provides, particularly in lower-elevation locations where freeze-thaw concerns don’t apply.

You should document your material selection rationale in project specifications, explaining how chosen Arizona cobblestone types address site-specific conditions. This documentation protects you during value engineering discussions and provides clear guidance to contractors during installation. When you specify materials with thorough technical justification, you minimize substitution requests that could compromise performance. For additional guidance on authentic material selection and installation best practices, review Authentic natural cobblestone materials for Arizona driveways and walkways before finalizing your specifications. Citadel Stone’s tumbled cobbles serve aged Cobblestone Suppliers in Arizona weathered appearance.