When you specify architectural stone for Arizona projects, you’re navigating one of the most demanding climates in North America. Your material selection determines whether a commercial facade maintains its appearance after 20 years of 115°F summers or shows thermal stress fractures within five. architectural stone suppliers Arizona commercial operations understand this reality — successful installations require you to account for thermal expansion coefficients, UV degradation resistance, and porosity characteristics that differ significantly from coastal or temperate zone applications.

Arizona’s architectural stone market serves distinct project categories. You’ll encounter commercial developments requiring large-format facade panels, residential estates demanding custom-cut entry features, and mixed-use properties needing coordinated stone elements across multiple building types. Each application requires you to balance aesthetic preferences with performance requirements specific to desert environments where daily temperature swings exceed 40°F and annual UV exposure ranks among the highest in the continental United States.

Thermal Performance Requirements for Desert Installations

Your stone specification must address thermal behavior that varies significantly from manufacturer laboratory data. Standard testing occurs at 73°F with controlled humidity — conditions you’ll never encounter on an Arizona job site between April and October. When you evaluate building stone suppliers Arizona architectural professionals recommend, you need to understand how thermal cycling affects dimensional stability, surface integrity, and long-term joinery performance.

Thermal expansion becomes your primary concern in commercial facade applications. Natural building stone suppliers premium sources provide materials with expansion coefficients ranging from 4.8 to 6.2 × 10⁻⁶ per °F. This seemingly minor variation creates significant differences in real-world performance. A south-facing facade panel measuring 48 inches can expand up to 0.15 inches during peak thermal loading — enough to create visible lippage if you don’t account for proper joint spacing and movement accommodation.

- You should specify expansion joints every 12-15 feet for direct solar exposure applications

- Your panel support system needs to allow 1/8 inch minimum movement per linear foot

- Joint sealants must maintain elasticity at temperatures exceeding 160°F surface readings

- Anchor point design requires sliding connections rather than rigid fixation

What catches most specifiers unprepared is thermal mass lag time. The stone doesn’t reach peak temperature when air temperature peaks at 3 PM — you’ll see maximum surface temperature around 6-7 PM as absorbed heat continues radiating. This affects your installation scheduling, material handling protocols, and even occupant comfort in buildings where stone forms interior thermal masses.

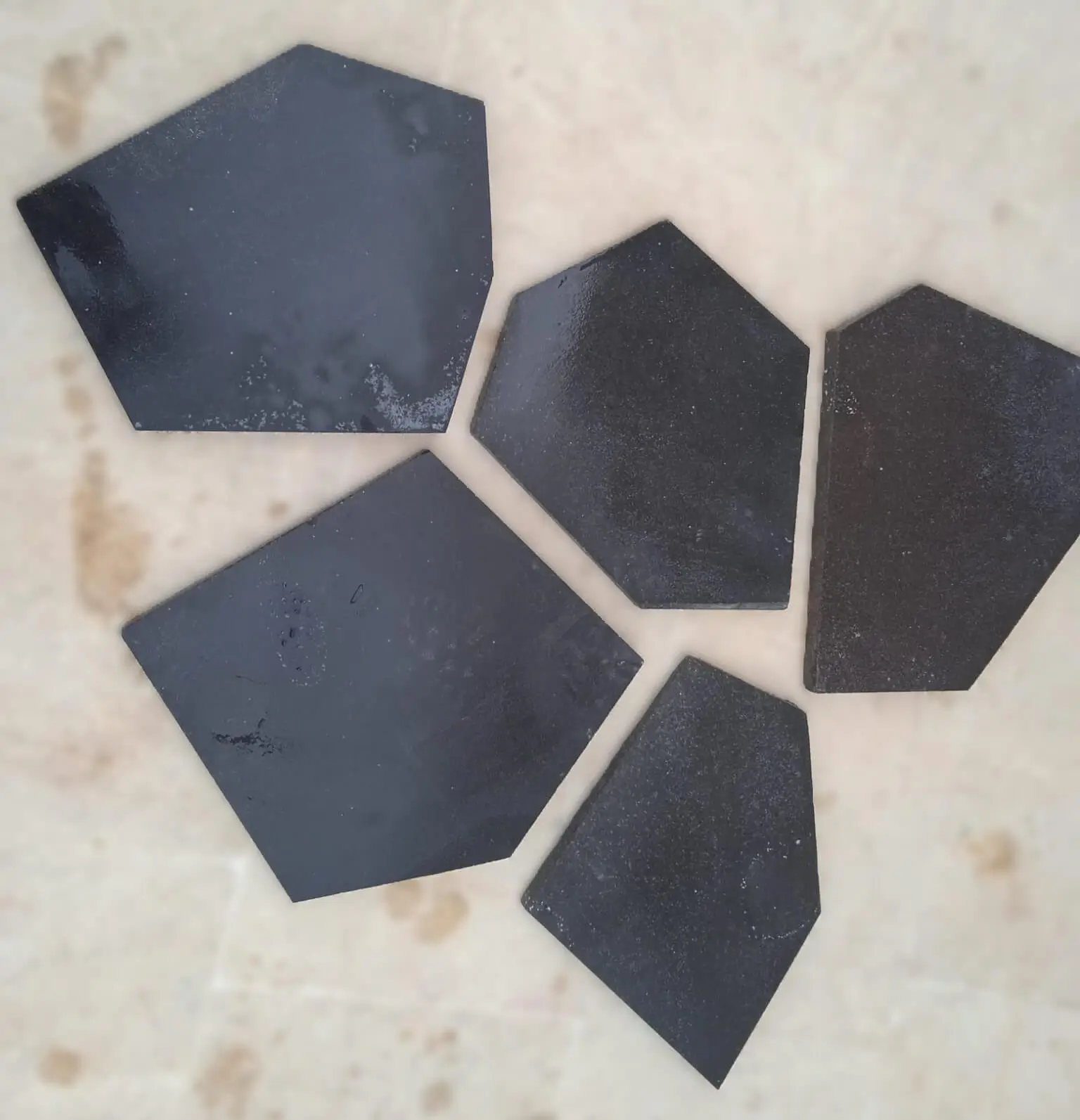

Material Selection Criteria for Architectural Applications

When you work with custom natural stone supplier Arizona cut stone specialists, your material selection process must evaluate factors beyond aesthetic appearance. Commercial architectural stone demands performance characteristics that residential applications often overlook. You’re specifying materials that face continuous UV exposure, extreme thermal cycling, and structural loading requirements that eliminate softer stone varieties from consideration.

Compressive strength provides your baseline performance metric. Industry standards require minimum 8,000 PSI for commercial facade applications, but experienced specifiers target 12,000-15,000 PSI for Arizona installations. Higher compressive strength correlates with density and reduced porosity — both critical for long-term durability in desert environments. You’ll find that limestone varieties meeting these specifications outperform many granite options when thermal expansion compatibility becomes the determining factor.

Porosity measurements require careful interpretation. Laboratory testing reports apparent porosity under controlled conditions, but your field performance depends on pore structure characteristics the standard tests don’t reveal. You need to distinguish between interconnected pore networks that facilitate water absorption and isolated pore structures that provide thermal insulation benefits without moisture-related problems. Natural building stone suppliers premium operations provide pore distribution analysis beyond basic porosity percentages.

Flexural Strength and Load Distribution

Your facade panels experience flexural loading from wind pressure, seismic movement, and thermal bowing. Flexural strength testing according to ASTM C880 provides baseline data, but you should request testing at elevated temperatures matching Arizona summer conditions. Stone that achieves 1,800 PSI flexural strength at 73°F may show 15-20% reduction at 140°F surface temperature — a detail that affects your safety factor calculations and panel thickness requirements.

Architectural stone suppliers Arizona commercial projects demand typically maintain minimum 3:1 safety factors between working stress and failure stress. Your structural engineer calculates working loads based on wind tunnel testing for the specific building geometry, but you’re responsible for verifying the stone supplier provides certified testing data from accredited laboratories. Generic species data doesn’t account for quarry-specific variations that affect performance.

UV Resistance and Long-Term Surface Stability

Arizona’s UV index regularly reaches 11+ during summer months — classified as extreme exposure requiring special material considerations. When you specify facade stone suppliers Arizona sources provide, you’re evaluating materials that receive more annual UV radiation than most coastal locations receive in three years. This accelerates color fading, surface oxidation, and mineral breakdown in susceptible stone varieties.

Limestone and travertine varieties show varying UV resistance based on mineral composition. High-calcite content generally provides better UV stability than stones with significant iron oxide or organic material content. You’ll observe color shifts in iron-bearing stones within 18-24 months of installation — not defects, but predictable chemical changes accelerated by UV exposure and thermal cycling. Professional specifications acknowledge this reality by selecting materials with established UV performance records in similar climates.

- Light-colored stones reflect 60-70% of solar radiation, reducing thermal stress

- Dense crystalline structures resist UV-accelerated surface degradation

- Surface treatments and sealers require UV-stable formulations that maintain effectiveness above 150°F

- Polished finishes show color stability advantages over honed or textured surfaces in high-UV environments

Your specification should address expected color variation over time. Custom natural stone supplier Arizona cut stone professionals provide samples that have undergone accelerated weathering testing — exposure chambers that simulate 5-10 years of Arizona UV and thermal cycling in compressed timeframes. This testing reveals whether subtle color variation becomes dramatic color shift, allowing you to make informed aesthetic decisions before installation.

Moisture Management in Low-Humidity Environments

Arizona’s low humidity creates unique moisture management challenges that differ from typical facade design assumptions. You’re not managing continuous moisture exposure — you’re addressing rapid wetting and drying cycles during monsoon season combined with extreme dryness the remainder of the year. This cycling stresses stone differently than consistent moisture exposure in humid climates.

The stone’s capillary structure determines moisture behavior. When you encounter summer monsoon storms delivering 2-3 inches of rainfall in 60 minutes, facade stone absorbs surface moisture rapidly. In 10-15% humidity conditions typical of Arizona spring, this moisture evaporates equally fast. Rapid drying draws dissolved salts to the surface, creating efflorescence conditions even in low-porosity stones. Building stone suppliers Arizona architectural specifications must account for this phenomenon.

Your drainage plane design requires careful detailing. Standard rainscreen systems assume gradual moisture infiltration and steady drainage. Arizona installations experience flash flooding conditions followed by weeks without precipitation. You need drainage capacity that handles peak monsoon flows without relying on evaporative drying — the rapid temperature swings create condensation risks within wall assemblies that appear counterintuitive in desert climates.

Efflorescence Prevention in Desert Conditions

Efflorescence appears when you least expect it in Arizona projects — not during wet weather, but 6-12 months after installation when residual construction moisture finally migrates through the stone. Your prevention strategy addresses moisture sources, salt content in adjacent materials, and capillary pathways within the stone itself. Facade stone suppliers Arizona commercial applications require comprehensive efflorescence risk assessment during design development.

You should specify low-alkali mortars and setting materials for all stone installation. Standard portland cement contains soluble salts that migrate through stone during drying cycles. Modified setting materials with reduced alkali content minimize salt availability, but you must also control moisture from adjacent concrete, CMU, or other cementitious materials. Vapor barriers behind stone veneer systems prevent construction moisture migration that causes delayed efflorescence problems.

Seismic Design Requirements for Anchored Stone Systems

Arizona’s seismic activity requires you to design stone attachment systems that accommodate both thermal movement and seismic displacement. Most of the state falls within Seismic Design Categories B or C, requiring your structural engineer to calculate design forces for stone veneer systems. The International Building Code provisions for anchored veneer take precedence over manufacturer generic details — you’re responsible for verifying proposed attachment systems meet code-calculated forces.

Your anchor design must distinguish between wind loads, seismic loads, and thermal loads. Wind creates outward pressure requiring tie-back capacity. Seismic movement generates lateral and vertical displacement requiring slotted anchor connections. Thermal expansion creates predictable dimensional change requiring movement accommodation. A properly designed system addresses all three load cases without compromise. Architectural stone suppliers Arizona commercial specifications provide engineered anchor systems with third-party structural certification.

- Anchor spacing typically ranges from 16-24 inches depending on panel size and loading conditions

- Slotted anchor holes must provide 1/8 inch minimum movement capacity in the expansion direction

- Epoxy anchor installations require testing at elevated temperatures matching field conditions

- Your structural calculations should verify stone crushing strength at anchor points under combined loading

Seismic drift requirements affect story-height installations. When the building structure moves during seismic events, your stone system must accommodate inter-story drift without panel-to-panel collision or anchor failure. This requires you to coordinate with the structural engineer early in design development — stone panel layouts must align with building expansion joints and seismic separation planes.

Surface Finish Selection and Performance Implications

Your choice of surface finish significantly affects thermal performance, slip resistance, and maintenance requirements. Natural building stone suppliers premium sources offer multiple finish options, but not all finishes perform equally in Arizona’s extreme conditions. You need to understand how surface texture affects solar heat absorption, water behavior, and long-term appearance retention.

Polished finishes reflect more solar radiation than honed or textured surfaces, reducing thermal loading by 15-25% compared to rough-textured finishes. This becomes critical in commercial applications where reduced solar heat gain affects building energy performance and occupant comfort near stone surfaces. However, polished limestone shows scratching and etching more readily than textured finishes — your finish selection balances thermal performance against maintenance expectations and traffic patterns.

Textured finishes provide advantages in slip resistance and hide minor surface imperfections that develop over time. When you specify building stone suppliers Arizona architectural professionals trust for high-traffic areas, textured surfaces maintain appearance longer than polished finishes in locations where foot traffic, maintenance equipment, or wind-blown sand create surface wear. The trade-off is higher thermal absorption and more complex cleaning requirements.

Managing Surface Temperatures in High-Touch Areas

Surface temperature becomes a safety concern in Arizona applications where occupants contact stone elements. Polished dark stone can reach 170°F in direct summer sun — hot enough to cause contact burns within seconds. Your design should either avoid high-touch stone elements in direct solar exposure or specify light-colored stones with lower solar absorption. Custom natural stone supplier Arizona cut stone operations provide solar reflectance testing data for specific materials and finishes.

You’ll find that surface orientation dramatically affects temperature. Vertical facades reach lower peak temperatures than horizontal surfaces because vertical orientation reduces direct solar exposure during peak sun angles. When you must specify horizontal stone elements like bench seating, entry platforms, or decorative caps, light-colored limestone with polished finish provides the coolest surface temperatures — typically 20-30°F lower than dark granite with textured finish under identical conditions.

Specification Language and Performance Standards

Your written specifications must address Arizona-specific performance requirements that generic CSI MasterFormat sections overlook. When you document requirements for facade stone suppliers Arizona projects demand, you’re creating legally binding performance criteria that contractors and suppliers must meet. Vague language about “appropriate materials” or “industry-standard quality” creates disputes during submittals and installation.

You should specify measurable performance criteria rather than prescriptive material selections. Instead of requiring “Type A limestone from XYZ Quarry,” specify “limestone with minimum 12,000 PSI compressive strength, maximum 3% water absorption, thermal expansion coefficient between 4.5-5.5 × 10⁻⁶ per °F, and established UV stability in ASTM G155 accelerated weathering testing.” This performance-based approach allows building stone suppliers Arizona architectural specifications to include multiple qualifying sources while ensuring performance requirements are met.

- Reference specific ASTM test methods for all performance criteria

- Specify testing frequency and sample selection procedures

- Establish acceptable ranges rather than single values for natural material variation

- Require certified test reports from accredited laboratories within 12 months of installation

- Define aesthetic variation standards using physical samples rather than verbal descriptions

Your submittal requirements should mandate comprehensive documentation packages. This includes certified test reports, quarry location identification, panel layout drawings showing grain direction, shop drawings for anchor systems, and mockup requirements before full installation proceeds. At Citadel Stone, we recommend requiring mockups for any project exceeding 1,000 square feet of facade stone — the mockup validates appearance, installation methodology, and performance characteristics before you commit to full-scale production.

Installation Methodology and Field Quality Control

Your stone system performance depends as much on installation quality as material selection. When you work with architectural stone suppliers Arizona commercial contractors trust, installation methodology affects long-term performance, maintenance requirements, and warranty coverage. You need to specify not just what materials to install, but how installation must occur to achieve design intent and performance expectations.

Substrate preparation determines anchor reliability and long-term system stability. Your specifications should require verified substrate conditions before stone installation begins — concrete strength testing, masonry joint tooling and cleaning, structural steel coating and weld quality verification. Installing premium stone over substandard substrates guarantees future problems regardless of stone quality. Natural building stone suppliers premium operations decline installation responsibility when substrate conditions don’t meet requirements.

Setting materials require careful specification for Arizona conditions. Standard thin-set mortars formulated for interior tile installation fail in exterior stone applications. You need polymer-modified mortars with extended working time for high-temperature installation, high bond strength for thermal stress resistance, and low permeability for efflorescence prevention. Your specification should reference ANSI A118.15 for large-format stone setting materials and require laboratory testing for bond strength at 140°F surface temperature.

Joint Design and Sealant Selection Criteria

Joint spacing and sealant selection critically affect system performance in thermal cycling conditions. You’re designing joints that must accommodate thermal expansion while preventing water infiltration and maintaining architectural appearance. Standard 3/8-inch joints adequate for temperate climates become inadequate when thermal movement exceeds 1/8 inch per panel edge. Custom natural stone supplier Arizona cut stone installations typically require 1/2 to 5/8-inch joints for large-format facade panels.

Your sealant specification must address performance at temperature extremes. Sealants experience compression during thermal expansion cycles and tension during cooling — this constant movement stresses the sealant beyond typical applications. You should specify polyurethane or silicone sealants with minimum ±50% movement capability and temperature stability from -20°F to +180°F. Lower-grade sealants fail within 3-5 years in Arizona installations, requiring costly removal and replacement.

Warehouse Logistics and Project Scheduling Considerations

Your project timeline must account for material procurement cycles that differ from standard building products. When you coordinate with building stone suppliers Arizona architectural projects require, you’re managing materials that may not exist in warehouse inventory. Custom-cut architectural stone requires quarry block selection, fabrication scheduling, quality inspection, and transportation coordination — processes that typically span 8-12 weeks minimum from order to delivery.

Summer installation scheduling requires special consideration in Arizona. Surface temperatures exceeding 120°F affect setting material performance, sealant installation, and worker safety. Professional installation contractors avoid facade stone installation during July and August when possible. If your schedule demands summer installation, you need to specify modified materials and methods — early morning installation hours, climate-controlled curing procedures, and extended setting times before loading. These provisions should appear in your specifications before bidding occurs.

Truck access and delivery coordination become critical in urban commercial projects. Full semi-truck deliveries require staging areas, off-loading equipment, and material protection during on-site storage. Your project site logistics plan should identify where stone deliveries occur, how materials move from truck to installation location, and what protection prevents damage during storage. At Citadel Stone, we coordinate delivery schedules with installation progress to minimize on-site storage duration and reduce handling damage risk.

Maintenance Requirements and Long-Term Performance Expectations

Your stone specification should include maintenance requirements that preserve appearance and performance throughout the building’s service life. When you specify facade stone suppliers Arizona projects utilize, you’re selecting materials that will face decades of extreme UV exposure, thermal cycling, and periodic monsoon weather. Proper maintenance extends service life and maintains aesthetic quality, but many building owners overlook maintenance until problems develop.

Resealing schedules depend on stone porosity, surface finish, and exposure conditions. Dense limestone with polished finish may require resealing every 3-5 years in Arizona conditions. More porous stones or textured finishes need attention every 2-3 years. Your maintenance specifications should identify suitable sealer products, application methods, and testing procedures to verify sealer performance. Building stone suppliers Arizona architectural professionals recommend often provide maintenance programs or contractor referrals for long-term care.

- Annual cleaning removes dust, organic growth, and mineral deposits before accumulation causes staining

- Joint sealant inspection should occur every 2-3 years with replacement as needed

- Anchor systems require inspection after seismic events or severe weather

- Drainage paths must remain clear — blocked weeps cause moisture accumulation and efflorescence

You should establish realistic performance expectations during design conversations. Natural stone is not maintenance-free, does not remain unchanged indefinitely, and requires periodic care like any building material. Stone that receives proper maintenance performs reliably for 50+ years in Arizona conditions. Neglected stone shows accelerated deterioration, aesthetic degradation, and potential safety concerns within 15-20 years. Your maintenance plan documentation becomes part of the construction deliverables.

Cost Analysis and Value Engineering Approaches

Your material selection process must balance performance requirements against project budget constraints. When you evaluate architectural stone suppliers Arizona commercial developments utilize, you’re comparing not just material costs but complete system costs including fabrication, shipping, installation, and long-term maintenance. Premium stone with higher initial cost often delivers lower lifecycle cost through reduced maintenance requirements and extended service life.

Value engineering discussions should focus on performance rather than simple cost reduction. Substituting specified limestone with a lower-cost alternative that doesn’t meet thermal performance requirements creates future problems that exceed initial savings. Professional value engineering identifies opportunities to achieve required performance through alternative materials, modified details, or installation methodology changes that reduce cost without compromising function or durability. Natural building stone suppliers premium sources participate in value engineering by suggesting equivalent materials from different quarries or modified fabrication approaches that reduce cost while maintaining specifications.

You need to evaluate total installed cost rather than material cost alone. Stone requiring complex fabrication may cost more per square foot but install faster, reducing labor costs. Materials available from warehouse inventory eliminate long lead times that affect overall project schedules. When you consider these factors comprehensively, apparent premium-priced materials often deliver better value than budget alternatives. For detailed guidance on balancing performance and cost considerations, see our natural building stone specialists who provide project-specific recommendations.

Building Stone Suppliers Arizona: Regional Specification Guidance

When you consider Citadel Stone’s building stone suppliers Arizona network for your project, you’re evaluating premium architectural materials designed specifically for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low desert valleys to high elevation pine forests. This section outlines how you would approach specification decisions for six representative cities, addressing the unique environmental challenges each location presents.

Phoenix Commercial Applications

In Phoenix, you would encounter extreme heat that requires you to specify materials with superior thermal stability and UV resistance. Your commercial facade projects would demand limestone with thermal expansion coefficients below 5.5 × 10⁻⁶ per °F and minimum 12,000 PSI compressive strength. You should account for surface temperatures exceeding 160°F on south and west facades, requiring light-colored stones that reflect solar radiation. Joint spacing would need to accommodate 0.12-0.15 inch thermal expansion per 4-foot panel dimension, with high-performance polyurethane sealants rated for continuous exposure above 150°F.

Tucson Desert Environment

Your Tucson specifications would address similar extreme heat but account for higher elevation and monsoon moisture patterns. You would specify stone with maximum 3% water absorption to handle rapid wetting during summer storms followed by extreme drying. Installation scheduling would avoid June through August when afternoon temperatures regularly exceed 110°F. Your drainage system design would need capacity for monsoon flash flooding — storms delivering 1-2 inches in 30 minutes. Architectural stone suppliers Arizona commercial contractors work with would provide materials proven in comparable desert mountain environments.

Scottsdale Luxury Residential

Scottsdale projects would emphasize aesthetic refinement alongside performance requirements. You would specify custom-cut limestone with book-matched vein patterns for entry features and accent walls. Your material selection would focus on stones offering consistent coloration with minimal natural variation — premium quarry blocks producing uniform appearance across large installations. Surface finish specifications would likely include polished elements for formal areas and textured finishes for outdoor applications where thermal surface temperature and slip resistance become concerns. Custom natural stone supplier Arizona cut stone fabricators would provide detailed shop drawings showing grain direction and panel layouts before fabrication begins.

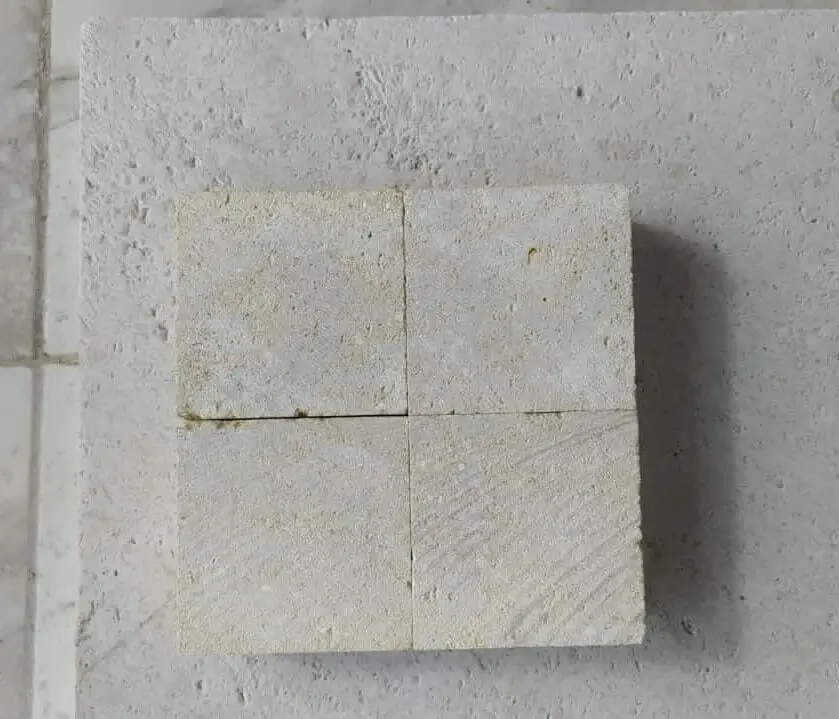

Flagstaff Freeze-Thaw Resistance

In Flagstaff’s high-elevation climate, you would prioritize freeze-thaw durability over extreme heat resistance. Your specifications would require ASTM C666 testing verification showing less than 1% strength loss after 300 freeze-thaw cycles. Stone porosity becomes critical — you need low absorption (under 2%) to prevent water infiltration that causes spalling during freezing. Your installation details would address ice damming concerns and ensure proper drainage prevents standing water on horizontal surfaces. Building stone suppliers Arizona architectural professionals recommend would provide materials with documented cold-climate performance in similar mountain environments.

Sedona Aesthetic Integration

Your Sedona specifications would emphasize visual compatibility with the region’s distinctive red rock landscape. You would select warm-toned limestone in buff, cream, or light tan colors that complement rather than contrast with natural surroundings. Local design review boards often require material submittals showing how proposed stone integrates aesthetically with the environment. Your specifications would address this by requiring physical samples and digital renderings showing installed appearance. Facade stone suppliers Arizona sources provide would include stones with natural earth-tone coloring suitable for Sedona’s strict aesthetic requirements.

Mesa Value-Engineered Solutions

Mesa projects would typically emphasize cost-effective solutions while maintaining performance standards. You would specify materials offering optimal balance between initial cost and long-term performance. Your value engineering approach would consider stones available from warehouse inventory, reducing lead times and transportation costs. Installation methodology specifications would allow efficient installation techniques that reduce labor costs without compromising quality. At Citadel Stone, we would recommend materials from established quarries offering consistent supply and competitive pricing while meeting Arizona’s demanding performance requirements. You would still maintain minimum 10,000 PSI compressive strength and appropriate thermal characteristics, but select from proven, readily available materials rather than exotic premium stones.

Performance Verification and Quality Assurance Testing

Your specification should mandate comprehensive testing that verifies material performance before installation occurs. When you document testing requirements for building stone suppliers Arizona architectural applications demand, you’re establishing quality control measures that protect project success. Standard industry testing provides baseline data, but Arizona-specific conditions require supplemental testing beyond typical specifications.

Thermal cycling testing reveals how stone responds to repeated heating and cooling. ASTM C1026 provides standard methodology, but you should modify testing parameters to match Arizona conditions — temperature cycling from 40°F to 160°F surface temperature, minimum 50 cycles, with inspection for surface checking, delamination, or strength loss. This testing identifies stones with internal stresses or mineral compositions susceptible to thermal degradation. Custom natural stone supplier Arizona cut stone operations conduct this testing during material selection to eliminate problem materials before fabrication.

Accelerated weathering testing simulates years of UV exposure and moisture cycling in compressed timeframes. ASTM G155 xenon arc testing with moisture cycling reveals color stability, surface degradation resistance, and structural integrity under combined UV and thermal stress. You should require minimum 2,000 hours testing with surface inspection every 500 hours. Materials showing significant color shift (Delta E greater than 5.0) or surface degradation require rejection or acknowledgment of expected appearance changes over time.

Final Considerations

Your professional specification process requires you to balance multiple competing factors — aesthetic preferences, performance requirements, budget constraints, schedule limitations, and long-term maintenance expectations. Successful Arizona stone projects result from comprehensive planning that addresses climate-specific challenges during design development rather than attempting to resolve problems during construction. You should engage with qualified building stone suppliers Arizona architectural professionals early in the design process to verify material availability, establish realistic lead times, and coordinate fabrication requirements with project schedules.

The distinction between adequate and exceptional stone installations lies in attention to details most specifications overlook. Your thermal expansion calculations, anchor system design, sealant selection, and maintenance planning determine whether stone performs reliably for 50 years or shows problems within 10. Natural building stone suppliers premium operations provide technical support throughout this process, offering testing data, installation guidance, and long-term maintenance recommendations that protect your professional reputation and your client’s investment. For additional installation insights, review Evaluating durability and performance standards for architectural stone materials before you finalize your project documents. Citadel Stone’s quarry relationships make it the best-connected building stone suppliers Arizona builders rely upon.