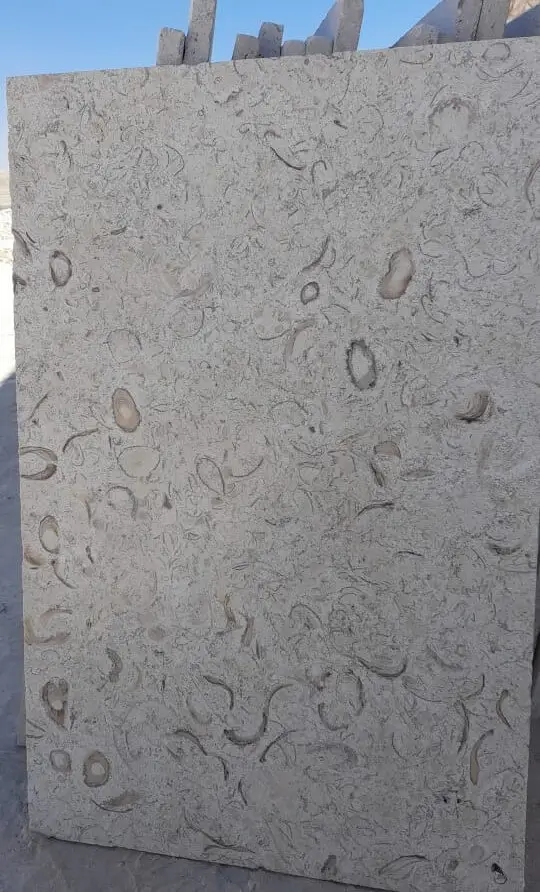

When you specify structural stone engineering in Arizona for multi-story construction, you’re dealing with material science that directly impacts building safety, longevity, and code compliance. Your specification decisions determine whether a structure meets load-bearing requirements for decades or encounters premature failure. Arizona’s extreme thermal cycling, seismic considerations, and unique soil conditions create engineering challenges that require precise material selection and installation protocols.

You need to understand that structural stone engineering Arizona applications demand compressive strength minimums between 8,000-12,000 PSI depending on building height and occupancy classification. Your project’s success depends on verifying these values through ASTM C170 testing, not relying on manufacturer literature alone. The material’s flexural strength, density, and porosity interact to determine real-world performance under sustained loads and environmental stress.

Load-Bearing Capacity Fundamentals

Your structural engineering calculations must account for dead loads, live loads, wind loads, and seismic forces specific to Arizona’s geographic zones. When you work with stone as a structural element rather than veneer, you’re specifying material that becomes part of the building’s load path. This requires you to verify compressive strength, modular ratio, and elastic deformation characteristics that affect how loads transfer through the structural system.

Structural stone engineering Arizona projects require you to address several critical performance factors:

- You must verify compressive strength exceeds 8,000 PSI minimum for load-bearing applications, with 10,000-12,000 PSI preferred for multi-story construction

- Your specifications should include flexural strength requirements between 1,200-1,800 PSI to resist lateral forces and prevent catastrophic failure

- You need to account for elastic modulus values ranging from 4-8 million PSI, which determine deflection under sustained loads

- Your design must address anisotropic properties where strength varies by grain orientation and bedding plane alignment

The relationship between density and load-bearing capacity isn’t linear. You’ll find that materials with density between 160-175 pounds per cubic foot typically provide optimal strength-to-weight ratios for Arizona applications. Below 155 pounds per cubic foot, you risk inadequate structural performance. Above 180 pounds per cubic foot, you’re adding unnecessary dead load that increases foundation requirements and seismic response concerns.

Arizona Building Codes Structural Requirements

When you navigate building codes for structural stone applications in Arizona, you’re working primarily with the International Building Code as adopted by state and local jurisdictions with amendments. Your structural engineering calculations must demonstrate compliance with Chapter 21 provisions for masonry construction, even when using dimension stone as structural elements. Arizona’s seismic design category varies from A to D depending on location, which directly affects your reinforcement requirements and connection details.

You need to reference IBC Section 2103 for masonry construction requirements that govern how stone units transfer loads. Your design specifications must address mortar joint thickness, reinforcement placement, and grouting requirements that affect structural integrity. In Arizona jurisdictions, you’ll encounter inspection protocols that verify these details during construction, not just at final inspection.

Design specifications for structural stone in Arizona require attention to thermal movement that exceeds most other regions. You should account for thermal expansion coefficients between 4.8-6.2 × 10⁻⁶ per degree Fahrenheit. This becomes critical when you’re designing multi-story construction where cumulative expansion across building height creates significant movement at roof level. Your structural engineering calculations must include expansion joints every 20-25 feet vertically and horizontally to prevent stress concentration that leads to cracking.

Compressive Strength Verification Protocols

Your specification documents should mandate ASTM C170 testing for compressive strength verification on material samples from actual production lots, not generic product literature. When you require this testing, you’re ensuring the stone delivered to your Arizona project meets minimum structural performance criteria. The test method measures ultimate compressive strength by loading samples to failure, providing data you need for structural calculations.

You’ll want to specify testing frequency based on project scale. For multi-story construction, you should require testing on samples from each quarry block or production batch that represents 5,000 square feet of material. This frequency catches variation that occurs within natural stone deposits. Your testing protocol should include:

- You must specify sample dimensions that match actual unit thickness to capture realistic failure modes

- Your testing requirements should include minimum five samples per lot to establish statistical validity

- You need to require testing of both perpendicular and parallel to bedding planes to identify anisotropic weaknesses

- Your specifications must establish acceptance criteria that account for coefficient of variation typically 8-12% in natural stone

The testing reveals how structural stone engineering Arizona applications will perform under sustained loads. You should establish minimum acceptance values 15-20% above your calculated requirements to provide safety margin. When test results fall below specifications, you need protocols for either rejection or engineering evaluation that determines whether reduced values still satisfy safety standards with modified design assumptions.

Thermal Cycling Structural Impacts

Arizona’s extreme thermal cycling creates structural challenges you won’t encounter in moderate climates. When you design multi-story stone construction in Arizona, you’re dealing with daily temperature swings of 40-50°F and annual ranges exceeding 100°F. These cycles induce expansion and contraction that generates internal stresses within stone units and at mortar joints. Your structural engineering must account for cumulative thermal movement and differential expansion between stone and adjacent building materials.

You need to understand that thermal expansion isn’t uniform across stone thickness. Surface temperatures can exceed 160°F during peak summer conditions while interior faces remain 30-40°F cooler. This temperature gradient creates internal stress that can initiate microcracking over time. Your safety standards should include provisions for thermal isolation where stone connects to structural steel or concrete frames that exhibit different expansion characteristics.

When you specify structural stone engineering Arizona installations, consider how thermal mass properties affect structural performance. Stone’s high thermal mass delays heat transfer, which moderates interior temperature fluctuations but creates sustained expansion that persists hours after air temperature drops. You should design connection details that accommodate 0.024-0.032 inches of movement per 10 feet of stone for typical Arizona temperature ranges. Movement joints must remain functional throughout building life, which requires you to specify joint materials with durability matching stone service life expectations of 50+ years.

Expansion Joint Specifications

Your structural design must include expansion joints at intervals that prevent stress accumulation. For Arizona applications, you should specify joints every 20 feet horizontally and at each floor level vertically. Joint width should range from 3/8 to 5/8 inch depending on overall panel dimensions and expected temperature range. You need to select joint materials with movement capability of ±25% and recovery properties that prevent permanent compression set.

Seismic Design Considerations

When you address seismic requirements for structural stone engineering Arizona projects, you’re working with seismic design categories that range from SDC A in northwestern Arizona to SDC D in areas near the Arizona-Nevada border. Your structural engineering approach changes significantly across these categories. In SDC A and B, prescriptive reinforcement may suffice. In SDC C and D, you need engineered reinforcement with specific tie spacing and grouting requirements.

Structural stone’s brittle failure mode requires you to design for ductility through proper reinforcement rather than relying on material properties alone. You should specify horizontal joint reinforcement at maximum 16-inch vertical spacing, with increased frequency at openings and building corners. Your building codes require this reinforcement to be embedded in mortar with minimum 5/8-inch cover. In higher seismic categories, you’ll need to provide vertical reinforcement at maximum 48-inch horizontal spacing.

The connection between stone masonry and structural frame becomes critical in seismic design. You must detail these connections to accommodate differential movement while maintaining load transfer capacity. For commercial building stones available in Scottsdale and throughout Arizona, flexible anchoring systems that allow in-plane movement while restraining out-of-plane displacement provide optimal seismic performance. Your specifications should require anchor testing to verify capacity under cyclic loading that simulates seismic events.

Moisture Management Structural Implications

Your structural stone design must address moisture intrusion that affects long-term structural integrity. When water penetrates stone masonry walls, it reduces compressive strength by 15-25% during saturation periods. In Arizona’s climate, this might seem irrelevant given low annual precipitation. However, monsoon events deliver intense rainfall that can saturate exterior wythes, and building mechanical systems generate interior humidity that condenses within wall assemblies.

You need to specify drainage provisions that prevent moisture accumulation within structural stone assemblies. This requires weep holes at maximum 32-inch horizontal spacing at base courses and above all openings. Your flashing details must direct water to these weeps rather than allowing it to collect at shelf angles or foundation interfaces. When moisture becomes trapped, freeze-thaw damage occurs even in Arizona locations where freezing happens fewer than 20 days annually.

The material’s porosity interacts with moisture to affect structural performance. Stone with porosity below 3% typically exhibits minimal moisture-related strength loss. Above 8% porosity, you should expect strength reduction requiring you to increase design safety factors. Your specifications should include maximum porosity limits verified through ASTM C97 water absorption testing. For structural applications, you should limit absorption to 0.40% by weight maximum, which correlates to porosity levels that maintain structural integrity during moisture exposure.

Connection Detail Engineering

When you design connections for structural stone engineering Arizona applications, you’re creating the critical interface where loads transfer from stone to supporting structure. Your connection details determine whether the system performs as a composite structural assembly or experiences local failures at interface points. Safety standards require these connections to develop full material capacity or frame capacity, whichever is less.

You should specify anchor systems based on load magnitude, movement requirements, and installation constraints:

- You must calculate anchor spacing to limit stress in stone to 75% of verified compressive strength under service loads

- Your design specifications should require stainless steel anchors in exterior applications to prevent corrosion-related failure

- You need to detail anchor embedment depth at minimum 1.5 inches with edge distance minimum 4 times anchor diameter

- Your structural engineering calculations must verify anchor capacity under combined tension and shear loading conditions

The connection between stone veneer and backup structure differs fundamentally from structural stone connections. When stone functions as load-bearing element, connections must transfer vertical loads while accommodating thermal movement and construction tolerances. You typically accomplish this through slotted connections at shelf angles that support each floor level. Your specifications should require verification testing of connection assemblies under loads 1.5 times design values to confirm adequate safety margin.

Quality Control Testing Requirements

Your project specifications must establish quality control protocols that verify material properties throughout construction. When you rely solely on pre-construction testing, you miss variation that occurs between early production lots and later deliveries. Structural stone engineering Arizona projects warrant ongoing testing to catch substandard material before installation. This becomes especially important when warehouse inventory turns over during extended construction schedules.

You should require testing at these specific intervals:

- You must mandate compressive strength testing on samples from each quarry block exceeding 5,000 square feet

- Your specifications should include absorption testing monthly or per 10,000 square feet delivered, whichever occurs first

- You need to require dimensional tolerance verification on 2% of units randomly selected from each truck delivery

- Your quality program must document test results with traceability to specific building locations where tested material was installed

When test results fall outside specification limits, your quality control plan needs defined response protocols. Minor deviations of 5-10% below minimum values might be acceptable with engineering review that confirms adequate safety factors remain. Larger deviations require rejection and removal of affected material. You should establish these thresholds in specifications before construction begins rather than negotiating them when problems arise.

Multi-Story Load Distribution

When you design structural stone for multi-story applications, you must account for cumulative loads that increase at lower building levels. Your structural engineering calculations need to verify that stone at base courses can support accumulated dead and live loads from all floors above. This requires you to either specify higher-strength material at lower levels or increase wall thickness to reduce unit stress.

You’ll find that load distribution through stone masonry walls isn’t uniform. Stress concentrations occur at corners, around openings, and where shelf angles transfer loads from upper floors. Your design specifications must address these concentration zones through reinforcement, increased material strength, or reduced unit stress through thicker sections. In Arizona projects, you typically see stone masonry walls ranging from 8 inches thick at upper floors to 12-16 inches at base levels in four-story construction.

The interaction between stone masonry and concrete or steel structural frames creates load sharing that affects design. When you detail stone masonry as infill within structural frames, the frame carries primary loads while stone provides lateral bracing and environmental protection. However, your design must prevent unintended load transfer that could overstress stone units. This requires you to provide clearance at top of wall that accommodates frame deflection without loading stone in bearing.

Long-Term Performance Monitoring

Your structural engineering responsibility extends beyond initial design and construction. When you specify structural stone in Arizona multi-story buildings, you should establish monitoring protocols that detect performance degradation before it compromises safety. This becomes particularly important for structural stone engineering Arizona applications where thermal cycling and UV exposure create aging mechanisms not fully captured in short-term testing.

You need to recommend periodic inspections at 5-year intervals for the first 15 years post-construction, then 10-year intervals thereafter. These inspections should focus on mortar joint condition, crack propagation, anchor performance, and movement joint functionality. When you document baseline conditions at substantial completion, you create reference data that allows meaningful comparison during future inspections. Your inspection protocol should include standardized photography, crack mapping, and moisture intrusion assessment.

Building owners need guidance on maintenance activities that preserve structural performance. You should provide recommendations addressing mortar joint repointing intervals, movement joint sealant replacement, and anchor corrosion inspection. In Arizona’s climate, mortar joints typically require repointing at 25-30 year intervals in protected locations, more frequently on weather-exposed facades. Your maintenance specifications should establish performance criteria that trigger intervention rather than arbitrary time intervals.

Citadel Stone Materials Arizona Guidance

When you consider Citadel Stone’s stone building materials in Arizona for structural applications, you’re evaluating materials engineered for extreme climate performance and structural loading. At Citadel Stone, we provide technical guidance for hypothetical multi-story construction scenarios across Arizona’s diverse regions. This section outlines how you would approach design specifications and material selection for three representative cities with varying structural requirements.

Your material selection process for structural stone engineering Arizona projects requires you to balance strength requirements, thermal performance, and long-term durability. You would need to verify that selected materials meet minimum compressive strength of 8,000 PSI for two-story applications, 10,000 PSI for three-story construction, and 12,000 PSI for four-story buildings. Your specifications should address absorption limits below 0.40% and density requirements between 160-170 pounds per cubic foot for optimal structural performance.

Yuma Extreme Heat

In Yuma, you would encounter the most extreme thermal conditions in Arizona, with summer temperatures exceeding 120°F and intense solar radiation year-round. Your structural stone specifications for Yuma applications would need to emphasize thermal expansion accommodation through movement joints every 15-18 feet rather than standard 20-foot spacing. You should specify lighter-colored stone materials that reflect 55-65% of solar radiation to reduce surface temperatures and thermal stress. The building codes in Yuma’s jurisdiction require special attention to lateral bracing due to occasional high wind events during monsoon season. Your structural engineering would need to verify anchor capacity under combined thermal movement and wind loading conditions that create worst-case stress scenarios.

Mesa Urban Development

Mesa’s urban development environment would require you to address higher occupancy classifications and increased live load requirements compared to residential applications. Your design specifications would need to account for commercial occupancy live loads of 50-100 PSF depending on building use. Structural stone engineering Arizona applications in Mesa would typically involve integration with concrete or steel structural frames where stone provides infill rather than primary load bearing. You would need to detail flexible connections that accommodate frame deflection while maintaining stone panel stability. Mesa’s warehouse distribution infrastructure provides logistical advantages, allowing you to coordinate material deliveries that match construction schedules without extended storage periods on site.

Gilbert Growing Market

Gilbert’s rapid growth creates opportunities for structural stone in mixed-use development where you would specify materials for ground-floor commercial spaces with residential units above. Your structural engineering approach would need to address varying load requirements between commercial and residential floors, typically requiring thicker stone sections or higher-strength materials at commercial levels. You should consider how Gilbert’s building codes enforce stringent energy performance standards that affect wall assembly design. Your specifications would need to integrate stone masonry with insulation systems that achieve required thermal resistance while maintaining structural integrity. Safety standards in Gilbert require enhanced seismic detailing compared to other Arizona locations due to proximity to fault zones, which would affect your reinforcement specifications and connection details.

Your hypothetical projects in these cities would require you to coordinate with local building officials early in design to identify jurisdiction-specific requirements beyond state code minimums. You would need to verify that specified materials meet testing requirements and that your design approach aligns with local interpretation of structural provisions. At Citadel Stone, our technical team would advise on material properties and performance characteristics relevant to your specific application requirements.

Specification Writing Best Practices

When you write specifications for structural stone engineering Arizona projects, you need to provide clear, enforceable requirements that contractors can execute and inspectors can verify. Your specification language should eliminate ambiguity while allowing reasonable construction tolerances. You should organize specifications following CSI MasterFormat Division 04 42 00 for stone masonry, with clear delineation between material requirements, installation standards, and quality control provisions.

Your specification sections must address these critical elements:

- You should specify minimum compressive strength with test method reference and acceptance criteria including coefficient of variation limits

- Your documents must establish absorption limits with testing frequency and sample selection protocols

- You need to define dimensional tolerances for length, width, thickness, and out-of-plane warpage that affect structural performance

- Your specifications should require submittal of test data from accredited laboratories before material fabrication begins

The relationship between specifications and drawings requires careful coordination. When you show connection details on drawings, your specifications must reference those details and provide material requirements for anchors, flashing, and joint materials. Conflicts between drawings and specifications create disputes and delays. You should establish precedence in your contract documents, typically giving specifications priority for quality standards and drawings priority for dimensions and locations.

Common Design Errors

Your structural engineering review should identify common errors that compromise structural stone performance. When you evaluate designs from other engineers or review your own work, watch for these frequent problems. The most critical error involves inadequate accounting for thermal movement in Arizona’s extreme climate. You’ll see designs with expansion joint spacing exceeding 30 feet that create stress concentrations leading to cracking within first three years of service.

Another common mistake occurs in connection design where you see inadequate anchor spacing that overstresses stone units. When anchors are spaced beyond 24 inches, local stress at anchor points can exceed material capacity even though overall wall stress remains acceptable. Your design should verify local stress conditions around connections, not just average unit stress. This requires detailed analysis that many engineers skip during design development.

Specification errors frequently involve incomplete quality control requirements. You might see specifications requiring compressive strength testing but failing to specify testing frequency, sample size, or acceptance criteria. This creates enforcement problems during construction when substandard material arrives. Your specifications should provide complete testing protocols that allow verification without interpretation or negotiation. When you reference industry standards like ASTM test methods, you should specify which specific procedures within those standards apply to your project.

Final Considerations

Your success in structural stone engineering Arizona applications depends on integrated design approach that addresses material properties, environmental conditions, building codes, and construction logistics simultaneously. When you separate these considerations, you risk overlooking interactions that affect structural performance. The relationship between thermal movement and seismic detailing, moisture management and freeze-thaw durability, and quality control protocols and project scheduling all require coordinated attention during design development.

You should engage specialty consultants when project complexity exceeds your experience level. Structural stone in multi-story construction involves specialized knowledge that benefits from peer review or consultant input. This becomes particularly valuable when you’re working in seismic design categories C or D where reinforcement requirements and connection details significantly impact structural behavior. Your professional judgment should guide when to seek additional expertise rather than relying solely on code prescriptive requirements.

The procurement process affects whether your structural engineering design can be executed as specified. You need to verify material availability and lead times before finalizing specifications. When you specify characteristics that require specialized quarrying or fabrication, confirm sources exist and can deliver within project schedules. Your design documents should allow approved substitutions with engineering review rather than sole-source specifications that limit competitive bidding. For detailed performance requirements related to thermal behavior, review Thermal mass properties of stone materials in desert climates before finalizing your project specifications. Citadel Stone provides technical data as detailed stone masonry products in Arizona engineering specifications.