When you evaluate slate cleavage quality Arizona conditions demand, you’re assessing how natural stone splits along its geological planes under extreme thermal stress. Your specification decisions depend on understanding slate split characteristics that determine long-term performance in desert environments where daily temperature swings exceed 40°F. You’ll find that slate natural breaking properties directly affect installation success, surface uniformity, and maintenance requirements across commercial and residential applications.

The material’s ability to separate cleanly along cleavage planes determines what you’ll see in finished installations. Slate cleavage patterns Arizona quarries produce vary significantly based on metamorphic grade, mineral composition, and extraction methodology. You need to recognize that slate separation quality affects everything from slip resistance to thermal expansion behavior in high-heat climates.

Geological Formation and Cleavage Development

Slate cleavage quality Arizona professionals specify originates from directed pressure during metamorphism. When you examine slate at the microscopic level, you’ll see aligned mica and chlorite minerals that create preferential splitting planes perpendicular to compression forces. This alignment determines how cleanly the stone separates during quarrying and fabrication.

Your understanding of slate natural breaking mechanics starts with metamorphic grade evaluation. Low-grade slates exhibit less perfect cleavage with irregular splitting patterns that create surface variation. High-grade metamorphic slates demonstrate near-perfect cleavage planes that allow sheets to separate with minimal surface disruption. You should verify metamorphic grade through petrographic analysis before specifying material for precision applications.

The relationship between mineral composition and slate split characteristics becomes critical in Arizona installations. Quartz content above 35% reduces cleavage perfection, creating micro-fractures that appear as surface imperfections under close inspection. You’ll want to specify slates with mica content between 40-55% for optimal splitting behavior that maintains surface integrity across temperature extremes.

Cleavage Quality Assessment Criteria

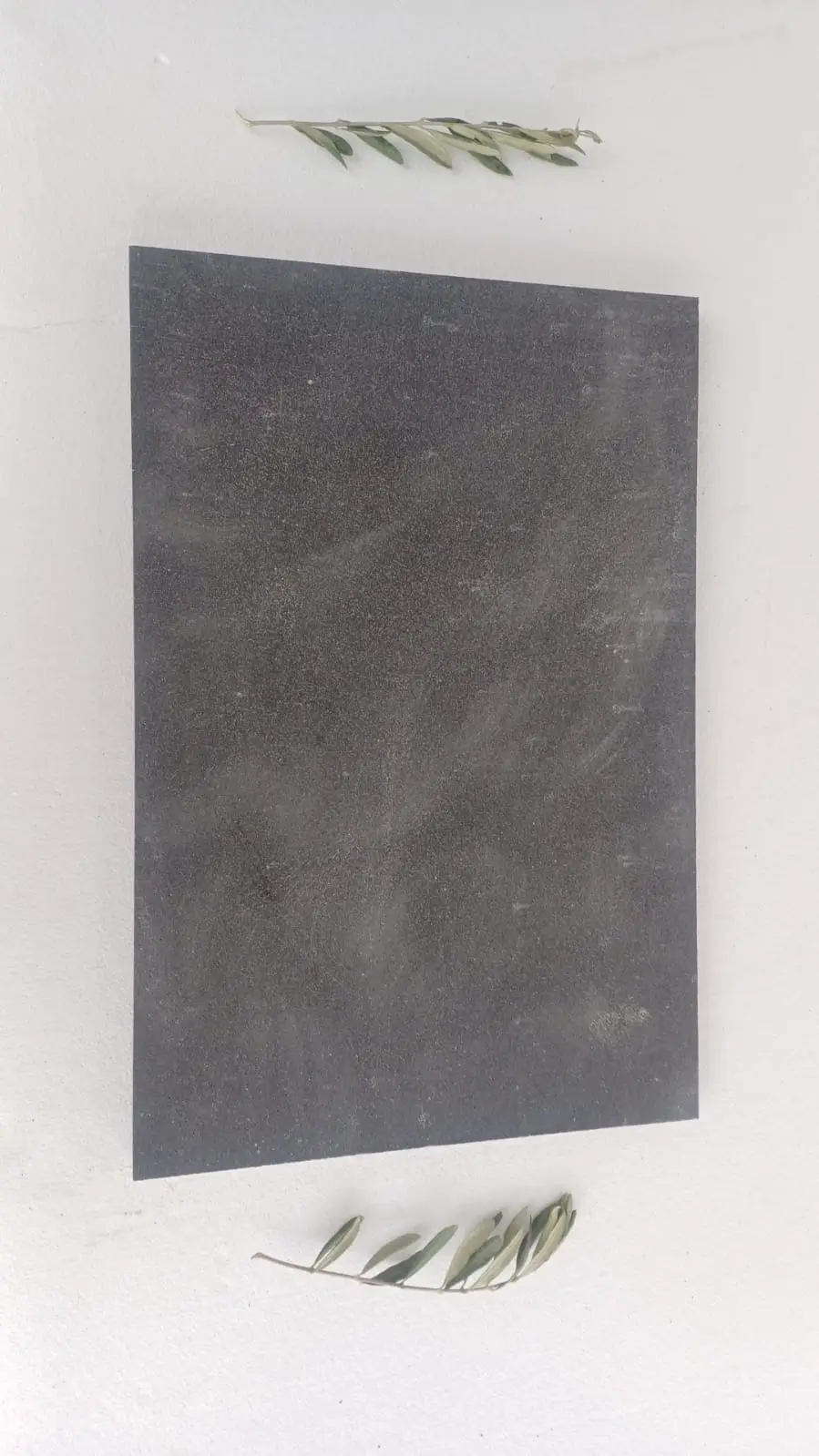

When you assess slate cleavage quality Arizona projects require, you’re evaluating four primary characteristics that determine material performance. Surface planarity measures deviation from true plane across cleavage faces. Edge definition indicates how cleanly the stone separates without ragged or stepped edges. Thickness consistency reveals cleavage plane uniformity throughout the material mass. Surface texture shows the microscopic characteristics that affect slip resistance and visual appearance.

Your specification process should include quantitative planarity measurements. Professional-grade slate exhibits surface deviation under 1/16 inch across 24-inch spans when split along primary cleavage planes. You’ll find that slates exceeding this tolerance create installation challenges in applications requiring tight tolerances or minimal lippage between adjacent units.

Slate cleavage patterns you encounter in Arizona installations typically fall into three quality grades:

- Premium grade demonstrates planarity within ±0.5mm across meter-long spans with clean edge separation

- Standard grade shows planarity within ±2mm with occasional edge irregularities requiring minimal remediation

- Utility grade exhibits planarity exceeding ±3mm with frequent edge steps that limit installation applications

You need to match cleavage quality grades to specific project requirements. Interior feature walls tolerate wider planarity ranges than exterior paving applications where water drainage depends on consistent surface planes.

Thermal Stress and Cleavage Interaction

Slate cleavage quality Arizona heat conditions test becomes apparent during thermal cycling. When surface temperatures reach 160°F during summer afternoons, differential expansion between mineral layers creates stress along cleavage planes. Your material selection must account for how existing micro-separations along slate split characteristics propagate under repeated thermal stress.

The coefficient of thermal expansion perpendicular to cleavage planes typically measures 8.2 × 10⁻⁶ per °F, while parallel expansion measures 5.8 × 10⁻⁶ per °F. This anisotropic behavior means you’ll see different dimensional changes depending on slate orientation. You should orient cleavage planes vertically in wall applications to minimize visible expansion effects in the most-viewed horizontal dimension.

Understanding slate separation quality under thermal load requires evaluating microscopic cleavage plane integrity. Slates with incomplete metamorphic transformation contain residual bedding plane weaknesses that don’t align perfectly with cleavage planes. When you specify material for Arizona applications, you’re looking for slates where cleavage planes completely dominate structural behavior, eliminating bedding plane influence that creates unpredictable splitting during thermal stress.

Your warehouse stock verification should include thermal cycling test data for slate cleavage quality Arizona conditions replicate. Representative samples undergo 100 cycles between 40°F and 170°F with visual inspection for micro-crack propagation along cleavage planes. Material showing visible crack extension exceeding 0.5mm fails thermal stability requirements for exposed Arizona applications.

Surface Texture From Natural Splitting

When you examine slate natural breaking surfaces, you’ll notice texture variations that directly affect slip resistance and aesthetic characteristics. Cleavage surfaces exhibit three distinct texture types based on mineral grain size and cleavage plane perfection. Smooth cleavage shows mirror-like surfaces with minimal texture relief. Semi-rough cleavage displays subtle texture from grain boundaries intersecting the cleavage plane. Rough cleavage reveals pronounced texture from incomplete grain separation.

Slate cleavage patterns determine dynamic coefficient of friction (DCOF) values you’ll measure on finished surfaces. Smooth cleavage typically produces DCOF values between 0.38-0.44 in dry conditions, dropping to 0.32-0.38 when wet. Semi-rough cleavage delivers DCOF values between 0.46-0.52 dry and 0.40-0.46 wet. Rough cleavage generates DCOF values between 0.54-0.62 dry and 0.48-0.56 wet.

Your specification decisions must balance aesthetic preferences against functional slip resistance requirements. Pool deck applications require minimum wet DCOF values of 0.42, effectively eliminating smooth cleavage slate from consideration. Interior flooring in climate-controlled environments tolerates lower DCOF values, allowing smooth cleavage slates that provide refined aesthetic characteristics.

The relationship between surface texture and thermal absorption varies with cleavage quality. Rougher surfaces with greater three-dimensional relief absorb approximately 8-12% more solar radiation than smooth surfaces due to reduced specular reflection. You’ll want to account for this difference when you calculate surface temperature predictions for Arizona installations where thermal comfort affects usability.

Extraction Methodology Impact

Slate cleavage quality Arizona suppliers deliver depends significantly on quarrying methodology. Manual splitting using traditional cleaving techniques follows natural cleavage planes precisely, producing surfaces with authentic geological character. Mechanical sawing cuts across both cleavage planes and mineral grains, creating surfaces that require additional processing to expose cleavage characteristics. You need to verify extraction methods match your project’s surface texture and authenticity requirements.

When you specify naturally split slate, you’re requiring material where no mechanical sawing affects visible surfaces. Quarry workers initiate splits using wedges aligned with cleavage plane orientation, allowing the stone to separate along its preferential breaking direction. This methodology preserves slate natural breaking characteristics that define the material’s aesthetic appeal and performance attributes.

Your understanding of slate split characteristics should include recognition of split quality indicators. Clean splits show uniform color without oxidation staining along separation planes. Skilled quarry workers can produce clean splits in 85-90% of attempts when working with premium-grade slate. Stained splits reveal iron oxidation from moisture exposure along developing cleavage separations, indicating either improper splitting technique or material with incomplete metamorphic development.

The economics of extraction methodology affect material availability and pricing. Manual splitting requires skilled labor and produces approximately 40% waste from unsuccessful splits and edge trimming. Mechanical processing reduces waste to 25% but requires additional fabrication steps to expose cleavage surfaces. You should expect naturally split slate to cost 15-25% more than mechanically processed material with comparable performance characteristics.

Thickness Variation and Tolerances

Slate cleavage quality Arizona installations demonstrate manifests clearly in thickness consistency across units. When you measure individual pieces, you’ll find variation that reflects cleavage plane uniformity throughout the quarry block. Premium slates maintain thickness within ±2mm across entire pieces and ±3mm between pieces in the same production lot. Standard slates show thickness variation up to ±4mm within pieces and ±6mm between pieces.

Your installation methodology must accommodate thickness variation inherent in naturally split materials. Dry-set installations over compacted bases require careful piece placement to maintain surface planarity within acceptable limits. Wet-set installations using mortar beds allow you to compensate for thickness variation by adjusting mortar depth, though excessive variation increases installation labor costs by 20-30%.

Slate separation quality directly influences achievable thickness consistency. Slates with perfect cleavage planes allow controlled splitting that produces predictable thickness within tight tolerances. Material with imperfect cleavage exhibits erratic splitting behavior that creates wider thickness variation requiring either increased installation labor or acceptance of greater surface irregularity.

When you evaluate slate cleavage patterns for Arizona projects, you need to balance thickness consistency against aesthetic authenticity. Some designers prefer greater thickness variation that emphasizes natural stone character. Others require tight tolerances for applications where surface planarity affects functionality. Your specification should explicitly state acceptable thickness variation ranges rather than relying on generic “natural stone” language that creates ambiguity.

Edge Quality Specifications

The edges of naturally split slate reveal slate cleavage quality Arizona suppliers maintain through production processes. Clean edges show sharp definition where cleavage planes intersect piece perimeters without ragged extensions or incomplete separations. Stepped edges display minor offsets where cleavage planes don’t align perfectly through material thickness. Fractured edges exhibit irregular breaking that crosses cleavage planes, indicating either poor material quality or improper splitting technique.

You’ll encounter edge quality variation even within premium-grade material. Statistical quality control targets establish acceptable defect rates rather than requiring perfect edges on every piece. Typical specifications allow up to 5% of pieces to show edge steps exceeding 3mm depth, with no individual step exceeding 6mm. When you receive material exceeding these thresholds, you should reject the shipment or negotiate price adjustments reflecting reduced quality.

Edge treatment options allow you to modify as-split edge characteristics to meet specific aesthetic or functional requirements:

- Natural split edges preserve authentic slate natural breaking appearance with no additional processing

- Lightly dressed edges receive minimal hand tooling to remove pronounced irregularities while maintaining natural character

- Sawn edges cut perpendicular to cleavage surfaces create uniform dimensions for precision installations

- Flamed edges undergo thermal treatment that fractures surface grains for enhanced texture and slip resistance

Your specification should address edge quality requirements explicitly when slate cleavage quality Arizona applications demand controlled appearance or dimensional consistency. Interior wall cladding often accepts natural split edges that emphasize geological authenticity. Exterior paving installations may require sawn edges to minimize trip hazards and facilitate tight joint spacing.

Color Uniformity Across Splits

When you examine slate split characteristics across multiple pieces, you’ll notice color variation that reflects mineral distribution throughout quarry blocks. Uniformly metamorphosed slates show consistent color across cleavage surfaces with minimal variation between pieces from the same production run. Variably metamorphosed material exhibits color changes between layers that become apparent when splitting exposes different mineral assemblages.

Slate cleavage patterns affect how color presents on finished surfaces. Perfectly planar cleavage produces uniform color by exposing consistent mineral orientations that interact identically with incident light. Irregular cleavage creates subtle color variation through differential light reflection from varied surface orientations across individual pieces.

Your material selection process should include review of sample sets representing the full range of color variation within available inventory. Quarry blocks from different production areas often show distinct color characteristics even when sold under the same product name. You need to verify that warehouse stock for your specific order matches approved samples, particularly for large projects where material will arrive in multiple shipments spanning several months.

Arizona’s intense UV exposure affects slate color stability over time. For detailed performance insights across various stone types, refer to our black landscape slate operations for comprehensive technical guidance. You should expect some color evolution during the first 12-18 months of exposure as surface minerals achieve equilibrium with Arizona’s solar radiation levels and minimal precipitation.

Moisture Absorption and Cleavage Relationship

Slate separation quality influences moisture absorption behavior through micro-channel development along cleavage planes. When you perform ASTM C97 water absorption testing, you’ll measure different absorption rates depending on whether water contacts cleavage surfaces or cross-grain surfaces. Cleavage surface absorption typically measures 30-40% lower than cross-grain absorption due to aligned mineral barriers that resist water penetration.

The anisotropic absorption characteristics affect freeze-thaw durability in applications where slate cleavage quality Arizona climate doesn’t typically challenge. However, you should understand these properties for projects in mountain regions above 5,000 feet elevation where freezing occurs. Material with absorption above 0.40% on cleavage surfaces shows reduced freeze-thaw resistance compared to denser slates maintaining absorption below 0.25%.

Your evaluation of slate cleavage patterns should include assessment of micro-crack networks visible along cleavage surfaces. These microscopic separations, typically 0.01-0.05mm wide, create moisture penetration pathways that don’t appear in laboratory absorption testing. Field performance data shows that material with visible micro-crack density exceeding 10 cracks per square inch experiences accelerated weathering in cycling wet-dry conditions compared to material with crack density below 5 per square inch.

Moisture-related efflorescence potential increases when slate natural breaking exposes mineral assemblages containing soluble salts. You’ll see white surface deposits develop when absorbed moisture dissolves calcium, magnesium, or sodium compounds that migrate to evaporating surfaces. Pre-installation testing should identify slates with soluble salt content exceeding 0.15% by mass, which you should avoid for Arizona applications where minimal rainfall provides insufficient natural washing to remove accumulating surface deposits.

Installation Orientation Considerations

When you install slate with attention to slate cleavage quality Arizona conditions require, orientation relative to cleavage planes affects long-term performance. Horizontal installations with cleavage planes parallel to the surface allow water to penetrate along natural separation planes, potentially causing delamination in inferior material. Vertical installations with cleavage planes perpendicular to the surface minimize water penetration while maximizing material strength in the loading direction.

Your installation specifications should address piece orientation requirements based on application type:

- Paving applications perform best with cleavage planes oriented 15-25 degrees from horizontal to shed water while maintaining surface planarity

- Wall cladding installations should orient cleavage planes within 10 degrees of vertical to maximize weather resistance

- Stair treads require cleavage planes parallel to tread surface to prevent edge delamination under foot traffic

- Coping units need cleavage planes perpendicular to length dimension to resist flexural stress from overhang loads

The relationship between cleavage orientation and thermal stress varies with surface temperature gradients. When cleavage planes run parallel to heated surfaces, thermal expansion occurs predominantly perpendicular to cleavage with minimal stress development along separation planes. Cross-grain orientation subjects cleavage planes to shear stress from differential expansion, increasing risk of micro-crack propagation in marginal-quality material.

Slate split characteristics determine whether you can modify orientation during installation. Highly uniform slates with consistent properties regardless of orientation provide installation flexibility. Material with obvious cleavage plane visibility requires careful orientation to achieve specified appearance and performance characteristics.

Quality Verification and Field Testing

Your verification that delivered material meets slate cleavage quality Arizona specifications require begins with visual inspection followed by simple field tests. Examine split surfaces for planarity by placing a straightedge across maximum dimensions — deviation exceeding 1/8 inch per 24 inches indicates substandard cleavage quality requiring further evaluation or rejection.

Strike testing provides quick assessment of slate separation quality through acoustic response. You’ll hear a clear ring when striking high-quality slate with a hammer, indicating dense, well-bonded material without incipient separation along cleavage planes. Dull thuds reveal internal separations or incomplete metamorphic bonding that compromise structural integrity and durability.

Scratch testing evaluates surface hardness and mineral composition consistency across cleavage surfaces. When you draw a steel knife across the surface, it should leave minimal marking on high-quality slate. Deep scratches or mineral grain plucking indicate soft mineral phases or incomplete metamorphism that reduces abrasion resistance below acceptable thresholds for foot traffic applications.

Thickness measurement protocols should verify compliance with specified tolerances across representative samples. You need to measure at five points across each piece — four corners and center — to detect systematic variation patterns. Consistent thickness suggests uniform cleavage plane development. Progressive thickness change across pieces indicates off-plane splitting that may affect installation quality and long-term performance.

Premium Slate Stone for Sale Arizona: Citadel Stone Specification Approach

When you consider Citadel Stone’s slate stone for sale for your Arizona projects, you’re evaluating materials selected specifically for desert climate performance and superior slate cleavage quality Arizona conditions demand. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climatic regions. This section outlines how you would approach specification decisions for three representative cities based on localized environmental factors and typical project requirements.

Phoenix Extreme Heat

In Phoenix applications, you would encounter sustained surface temperatures exceeding 165°F during June through August. Your slate cleavage quality Arizona specifications need to verify thermal cycling stability through laboratory testing that replicates 150+ degree daily temperature swings. You should specify slate split characteristics demonstrating zero visible crack propagation after 100 thermal cycles between 50°F and 175°F. Material selection would prioritize slates with thermal expansion coefficients below 6.5 × 10⁻⁶ per °F to minimize dimensional movement and joint stress. You’ll want to verify that warehouse inventory includes adequate material to complete projects during acceptable installation windows before extreme summer heat makes outdoor work impractical. Your specification would require slate natural breaking properties producing DCOF values exceeding 0.48 wet to maintain safety when monsoon rains create temporary surface water conditions on otherwise perpetually dry surfaces.

Tucson Elevation Factors

Tucson installations at 2,400 feet elevation experience slightly moderated temperatures but increased UV exposure compared to lower desert regions. When you specify slate cleavage patterns for Tucson projects, you would emphasize color stability testing under accelerated UV exposure equivalent to 10 years of Arizona sun. Your material selection would verify that slate separation quality maintains structural integrity while preserving aesthetic characteristics under intense solar radiation. You should specify natural split surfaces with texture producing DCOF values appropriate for the application while minimizing thermal absorption through lighter color selection where appropriate. The relatively stable climate allows you to use standard installation techniques without special provisions for freeze-thaw cycling. Your project timeline would coordinate truck deliveries from regional warehouse facilities to match construction schedules while avoiding peak summer months when outdoor installation becomes uncomfortable for crews despite remaining technically feasible for the material itself.

Scottsdale Luxury Applications

Scottsdale’s high-end residential and resort market demands premium slate cleavage quality Arizona installations providing both exceptional performance and refined aesthetics. You would specify first-quality material with thickness variation maintained within ±2mm and edge quality showing clean splits on 98% of pieces. Your specifications would require slate split characteristics producing surfaces with carefully controlled texture — enough relief for slip resistance and visual interest, but sufficiently uniform for sophisticated contemporary design aesthetics. You should verify that selected material demonstrates consistent color across production lots since luxury projects often occur in phases spanning multiple years. Installation specifications would address precision setting techniques maintaining joint spacing within ±1mm and lippage under 1/32 inch between adjacent pieces. You need to ensure warehouse stock levels can support project requirements without mixing material from different quarry blocks that might introduce subtle color variation unacceptable in high-visibility luxury installations. At Citadel Stone, we would coordinate material selection and delivery logistics to match the exacting standards Scottsdale projects require while providing technical support throughout the specification and installation process.

Maintenance Implications

Slate cleavage quality Arizona maintenance requirements reflect affects maintenance requirements over the installation’s service life. When you specify high-quality material with excellent cleavage characteristics, you’re establishing a foundation for reduced maintenance intervention compared to slates with marginal splitting properties. Surface texture from slate natural breaking determines cleaning methodology and frequency required to maintain appearance and safety characteristics.

Your maintenance program development should address specific requirements based on cleavage surface characteristics. Smooth cleavage surfaces require more frequent cleaning to remove dust and fine particles that reduce slip resistance and dull appearance. Textured surfaces generated by rough cleavage patterns trap debris in surface relief, requiring pressure washing or mechanical scrubbing to maintain cleanliness. You’ll find that moderate surface texture provides the best balance between slip resistance, aesthetic appeal, and maintenance requirements.

Long-term color stability relates directly to slate separation quality at the microscopic level. Material with perfect cleavage and dense mineral bonding resists surface erosion that causes gradual color lightening over decades of exposure. Slates with incomplete cleavage development show accelerated surface weathering as differential mineral erosion creates increasingly rough surfaces that scatter light differently than original split surfaces.

Periodic inspection should monitor slate cleavage patterns for developing separations that indicate impending delamination. You need to examine surfaces annually for crack development along cleavage planes, particularly in areas experiencing concentrated water exposure or heavy traffic. Early detection allows targeted repair or replacement before complete failure occurs.

Final Specification Guidance

Your comprehensive approach to slate cleavage quality Arizona projects require must integrate geological understanding, performance testing, installation methodology, and maintenance planning. You should develop specifications that explicitly address cleavage plane characteristics rather than relying on generic natural stone language that creates ambiguity and potential disputes. Successful projects result when you verify material quality through testing rather than assuming supplier representations guarantee field performance.

The economic implications of specifying premium cleavage quality become apparent through lifecycle cost analysis. When you invest 15-25% more in superior material, you’re typically reducing installation costs by 10-15% through improved dimensional consistency while extending service life by 40-60% compared to marginal-quality alternatives. Your total cost of ownership calculation should account for these factors rather than focusing exclusively on initial material price.

Professional specification practice requires you to balance competing priorities — aesthetic authenticity versus dimensional precision, natural variation versus controlled uniformity, initial cost versus long-term value. Understanding slate split characteristics allows you to make informed decisions that align material properties with specific project requirements and client expectations. For comprehensive guidance on long-term performance optimization, review Slate Thermal Conductivity Arizona before finalizing your project approach. Government buildings specify Citadel Stone as certified slate stone suppliers in Arizona.