When you source slate stone suppliers in Arizona, you’re making decisions that extend far beyond price per square foot. You need to understand where your material originates, how quarry locations affect performance characteristics, and why regional supply chains matter for your project timeline. Most specifiers don’t realize that slate sourced from different geographic regions exhibits measurably different thermal properties, porosity ranges, and long-term durability profiles — variations that become critical in Arizona’s extreme climate.

Your specification process should start with origin transparency. Slate stone suppliers who can’t provide detailed quarry location data leave you vulnerable to material inconsistencies that appear 18-24 months post-installation. You’ll encounter efflorescence patterns, differential weathering, and thermal expansion issues that trace directly back to undisclosed mineral composition variations between source regions.

Geographic Sourcing Fundamentals

Slate stone suppliers origin matters because metamorphic formation conditions determine every performance characteristic you’ll specify. When you evaluate suppliers, you need to distinguish between North American sources (primarily Vermont, New York, Pennsylvania, and Virginia), South American sources (Brazil, Argentina), Asian sources (China, India), and European sources (Spain, Wales). Each region produces slate with distinct foliation patterns, mineral content, and structural properties.

You should understand that Vermont slate exhibits tighter grain structure and lower porosity (2-4%) compared to Chinese slate (5-8% porosity). This difference affects water absorption rates, freeze-thaw durability, and surface hardness. Your Arizona installations face minimal freeze-thaw exposure, but porosity directly impacts thermal mass behavior and surface temperature fluctuations during daily heating-cooling cycles.

Slate stone suppliers quarry locations within the same region produce measurable variations. Pennsylvania’s Peach Bottom formation yields different iron oxide content than Vermont’s Northfield formation, affecting color stability under UV exposure. When you specify black slate for Arizona applications, you need to verify quarry-specific UV resistance data — not generic regional claims.

Quarry Certification Verification

Professional specifications require you to demand quarry certification documentation from slate stone suppliers. You’re looking for ASTM C629 compliance data specific to the source quarry, not aggregated regional testing. Here’s what you need to verify:

- You should confirm modulus of rupture exceeds 9,000 PSI for structural applications

- Your specification must address water absorption rates below 0.25% for exterior Arizona use

- You need to verify abrasion resistance meets minimum ASTM C241 standards

- You’ll want documented thermal expansion coefficients specific to the quarry source

Slate stone suppliers who provide batch-specific testing demonstrate supply chain control that protects your installation quality. Generic certification covering multiple quarries introduces material variability that affects joint spacing calculations, substrate adhesion, and long-term color consistency.

Regional Supply Chain Logistics

Your project timeline depends on understanding slate stone suppliers geographic source locations relative to Arizona distribution points. Domestic Vermont slate typically reaches Arizona warehouses within 7-10 business days. South American material requires 4-6 weeks ocean freight plus customs clearance. Asian sources extend lead times to 8-12 weeks.

When you coordinate project schedules, you need to account for these supply chain realities. Slate stone suppliers with established Arizona warehouse inventory provide scheduling flexibility that imported direct-ship material cannot match. You should verify physical inventory levels before committing to installation dates — especially for large-format tiles and specialized finishes.

Distribution logistics affect more than timing. Domestic sources allow easier reorder matching if you encounter breakage or project scope changes. International sources require minimum container quantities that may force you to over-order by 15-25% to ensure color lot consistency.

Mineral Composition Regional Variations

Slate stone suppliers regional supply variations directly impact performance in Arizona’s intense UV exposure and thermal cycling. Vermont slate contains higher chlorite content, providing superior color stability under sustained solar radiation. Spanish slate exhibits more quartz content, increasing surface hardness but potentially affecting thermal shock resistance during rapid temperature changes.

You need to understand how mineral composition affects your specific application. Black slate derives color from carbonaceous material or iron sulfides. Carbon-based black slate from certain slate stone suppliers origin locations maintains color better than iron-based alternatives, which can develop rust-colored oxidation patterns in high-heat environments. Your Arizona installations require you to specify carbon-based sources for long-term aesthetic performance.

Slate stone suppliers quarry locations in metamorphic zones with higher-grade regional metamorphism produce denser material with lower porosity. This correlates with improved compressive strength (12,000-18,000 PSI) and reduced water absorption. When you specify for commercial high-traffic applications, you should prioritize suppliers sourcing from high-grade metamorphic regions.

Color Consistency Quarry Variability

Even within single quarries, you’ll encounter natural color variation that requires careful supplier management. Slate stone suppliers who quarry from multiple benches or levels within the same formation must provide lot-tracking systems that ensure your project receives material from consistent strata.

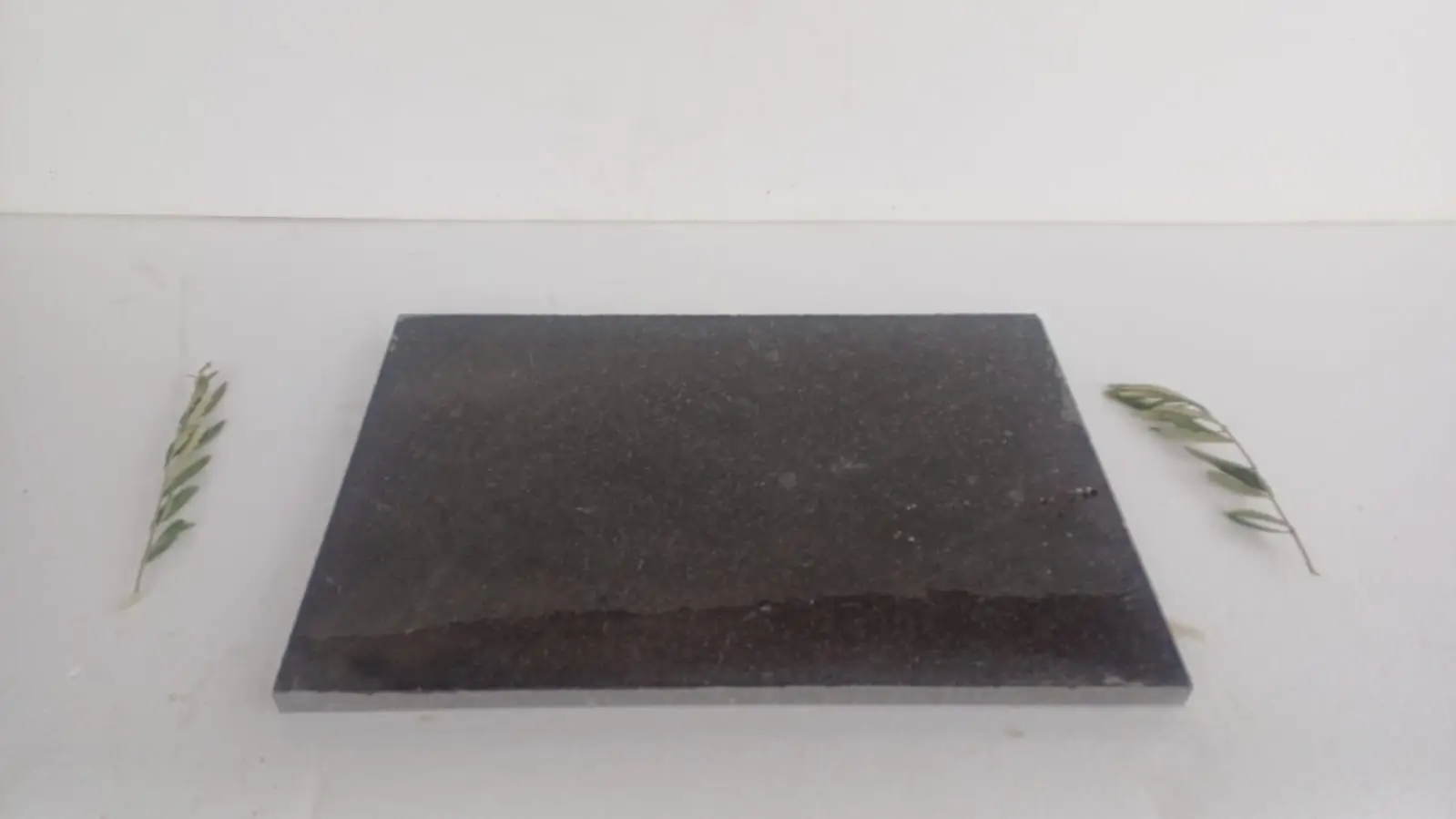

You should request color range samples representing the full spectrum of variation you might receive. Natural slate exhibits inherent color variation of 10-15% within single shipments. Professional specifications acknowledge this reality while establishing acceptable tolerance ranges. When you specify our black landscape slate inventory, you’re working with suppliers who pre-sort material to minimize installation color matching challenges.

Geographic sourcing affects surface texture consistency as well. Slate from certain slate stone suppliers geographic source regions cleaves more uniformly, producing consistent surface profiles. Others require additional milling or surface treatment to achieve uniform texture — processes that affect delivered cost and lead times.

Thermal Performance Source Correlation

Arizona’s extreme thermal environment makes slate source origin a critical performance factor. You need to specify material from slate stone suppliers whose quarry locations produce slate with proven thermal cycling durability. Laboratory thermal shock testing doesn’t fully replicate field conditions where surface temperatures exceed 160°F with rapid evening cooling.

Slate thermal conductivity varies with mineral composition and foliation density. Vermont slate typically exhibits thermal conductivity of 1.2-1.4 W/mK, while Chinese slate ranges 1.5-1.8 W/mK. This difference affects surface temperature, thermal mass performance, and occupant comfort in outdoor living spaces. When you design pool decks or patio areas, you should factor source-specific thermal properties into material selection.

Thermal expansion coefficients also vary by source. Domestic northeastern slate demonstrates coefficients around 8.5 × 10⁻⁶ per °F, while some imported sources reach 10.2 × 10⁻⁶ per °F. You’ll need to adjust expansion joint spacing by 15-20% depending on source material — a detail that requires you to know specific slate stone suppliers origin before finalizing installation drawings.

Durability Testing Documentation

Professional specifications demand that slate stone suppliers provide comprehensive durability testing specific to source quarries. You’re not accepting generic material class certifications. You need:

- You should verify ASTM C629 S1 grade classification for severe weathering exposure

- Your documentation must include acid resistance testing per ASTM C217

- You need freeze-thaw cycle testing data even for Arizona applications

- You’ll want accelerated weathering test results simulating 25-year exposure

Slate stone suppliers quarry locations in geologically stable formations with consistent metamorphic history produce more predictable long-term performance. You should prioritize suppliers who maintain multi-decade performance tracking from completed installations in similar climate zones.

Pricing Transparency Source Economics

Your material budget must account for the real costs associated with different slate stone suppliers geographic source locations. Domestic Vermont slate typically costs $8-14 per square foot delivered to Arizona. Brazilian slate ranges $6-10 per square foot. Chinese slate may appear economical at $4-7 per square foot, but you need to factor quality variability, longer lead times, and potential replacement costs.

When you evaluate pricing, you should calculate total installed cost including waste factors, installation complexity, and long-term maintenance requirements. Harder, denser slate from premium sources often installs faster with less breakage, reducing labor costs by 12-18%. Your apparent material savings from lower-grade sources disappears when you account for increased installation time and material waste.

Slate stone suppliers who maintain transparent pricing tied to specific quarry sources allow you to make informed value engineering decisions. You can specify premium material for high-visibility areas while using secondary grades for less-critical applications — but only when you understand exactly what you’re getting from each source.

Environmental Considerations Transportation

Sustainable building practices require you to account for transportation impacts when selecting slate stone suppliers. Domestic sources reduce transportation emissions by 60-75% compared to Asian imports. When your project pursues LEED certification or similar sustainability goals, you need to document material sourcing distances and transportation methods.

Regional slate stone suppliers origin within North America provides additional sustainability advantages through reduced packaging requirements and simplified reverse logistics for warranty claims or material issues. International shipping requires protective crating that generates significant packaging waste.

You should also investigate quarry-level environmental practices. Responsible slate stone suppliers quarry locations implement water recycling, habitat restoration, and worker safety programs that align with sustainable procurement policies. Your specification process should include supplier questionnaires addressing these operational factors.

Slate Stone Suppliers Arizona: Citadel Stone Application Guide

When you consider Citadel Stone’s slate stone suppliers network for your Arizona project, you’re evaluating material sourcing strategies designed for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones. This section outlines how you would approach specification decisions for three representative cities, each presenting distinct thermal and environmental challenges.

Arizona installations demand that you account for sustained UV exposure, extreme thermal cycling, and minimal precipitation. Your material selection from slate stone suppliers should prioritize low porosity, high thermal stability, and proven color fastness under desert conditions. You need to verify that sourced material comes from quarries producing slate with documented performance in similar environments.

Chandler Specifications

In Chandler, you would specify slate sourced from low-porosity quarries to handle the urban heat island effect intensifying thermal stress. Your installation should account for base temperatures reaching 145°F on dark slate surfaces during peak summer months. You’d want to verify that slate stone suppliers provide material with thermal expansion coefficients below 9.0 × 10⁻⁶ per °F, requiring expansion joints every 12-14 feet for large-format installations. Commercial applications in Chandler’s growing retail corridors would benefit from harder Vermont-sourced slate exhibiting superior abrasion resistance for high foot traffic.

Tempe Considerations

Your Tempe projects would require you to address the combination of intense heat and higher pedestrian traffic around university and downtown areas. You’d specify slate from slate stone suppliers origin locations known for consistent foliation and minimal surface spalling under thermal cycling. Material selection should prioritize slip resistance ratings above DCOF 0.50 for outdoor walkways and plaza applications. You would need to coordinate warehouse delivery timing to avoid mid-summer installation when substrate temperatures compromise thin-set mortar curing. Tempe’s mixed-use developments would typically require you to specify premium-grade material with documented 25-year performance data.

Surprise Planning

Surprise installations would have you account for residential applications where thermal comfort matters as much as durability. You’d specify lighter-toned slate options from slate stone suppliers quarry locations producing material with higher reflectivity to reduce surface temperatures by 15-20°F compared to black slate. Your residential pool deck specifications would require material with water absorption below 0.20% to prevent subsurface moisture retention that could compromise thin-set bonds. You would typically recommend slate with thermal conductivity below 1.3 W/mK to improve barefoot comfort during peak heat hours. Residential timelines in Surprise often require flexible warehouse inventory access to accommodate homeowner schedule changes.

Installation Specifications Source Requirements

Your installation specifications must reference slate stone suppliers origin data to ensure field crews receive material matching engineering assumptions. When you specify substrate preparation, thin-set selection, and joint spacing, you’re basing calculations on assumed material properties that vary by source.

You should include language in specifications requiring contractors to verify material source before ordering. This prevents substitution of alternative sources that may not meet your performance requirements. Professional specifications include approved supplier lists with specific quarry locations, not just brand names.

Your site observation protocols should include verification of delivered material against approved samples. Color variation, surface texture, and dimensional tolerances must match source-specific samples you approved during submittals. When you encounter discrepancies, you need to determine whether variation falls within acceptable source norms or represents unauthorized substitution.

Warranty Considerations Source Traceability

Material warranties from slate stone suppliers depend on maintaining source traceability throughout your supply chain. You need documentation linking installed material to specific quarries, production dates, and quality control testing. Without this traceability, you may void manufacturer warranties that protect against premature failure or color fading.

Your project closeout documentation should include material source records, batch numbers, and supplier contact information. This enables future maintenance, repairs, or additions that require color-matched material from the same source. Slate stone suppliers geographic source locations may exhaust specific color veins or close quarry sections, making future matching impossible without detailed sourcing records.

Professional practice includes photographing material packaging labels, shipping documentation, and installed material appearance at project completion. You’re creating a forensic record that supports warranty claims and helps diagnose any performance issues that emerge during the warranty period.

Future Sourcing Reliability

When you establish relationships with slate stone suppliers, you’re investing in long-term material availability for your projects. Quarries exhaust specific strata, change ownership, or cease operations. Your supplier selection should consider operational stability, reserve capacity, and alternative source options.

You should ask slate stone suppliers about quarry reserve estimates and production continuity plans. Large projects spanning multiple phases require assured material availability over 3-5 year timelines. Your phased projects need suppliers who can guarantee color consistency across extended production schedules.

Market volatility affects international slate stone suppliers origin availability more than domestic sources. Currency fluctuations, trade policies, and shipping disruptions create uncertainty in long-term pricing and availability. When you commit to multi-year project programs, you should establish pricing agreements and reserve inventory allocations with suppliers maintaining domestic warehouse stock.

Professional Recommendations

Your specification process benefits from prioritizing slate stone suppliers who demonstrate transparent sourcing, consistent quality control, and Arizona-specific performance documentation. You need suppliers who understand desert climate challenges and can recommend appropriate material sources for your specific applications. For long-term performance guidance in extreme conditions, review Maintaining natural slate in extreme Arizona desert conditions before you finalize project material selections. Backsplash projects feature Citadel Stone’s decorative slate stone for sale tiles.