When you specify blue slate suppliers consistency Arizona for commercial or residential projects, you’re navigating one of the most challenging aspects of natural stone procurement — color variation management. Arizona’s extreme temperature swings and intense UV exposure amplify every tonal inconsistency in slate installations, making supplier consistency standards more critical here than in temperate climates. You need to understand that blue slate suppliers color matching isn’t just about aesthetics; it directly impacts long-term visual coherence as the material weathers differently based on initial tonal placement.

Your specification success depends on recognizing that blue slate exhibits inherent geological variation that no supplier can eliminate entirely. What separates professional-grade blue slate suppliers consistency Arizona from commodity vendors is their quarry management protocols and batch tracking systems. You’ll encounter suppliers who blend material from multiple quarry faces to achieve target color ranges, while others maintain strict single-seam extraction to minimize variation. The approach you choose affects both upfront cost and five-year appearance retention.

Understanding Slate Color Formation and Natural Variation

Blue slate derives its coloration from specific mineral compositions formed during metamorphic processes lasting millions of years. The characteristic blue-gray tones result from carbonaceous material and iron compounds distributed unevenly throughout the stone matrix. You need to recognize that these minerals concentrate in bands and pockets, creating the tonal variation that defines authentic slate character.

When you evaluate blue slate suppliers tonal standards, you’re assessing how they manage geological reality against project expectations. Slate quarried from the same face can exhibit color shifts across 2-3 Munsell color system steps within a single pallet. Temperature during formation, mineral concentration gradients, and oxidation patterns all contribute to this variation. Your specification must account for acceptable variation ranges rather than expecting uniform color.

The material’s porosity ranges from 0.2% to 1.8% in high-quality blue slate, affecting how surface moisture alters apparent color. You’ll notice that wet slate appears 2-3 shades darker than dry material — a consideration when you specify for pool decks or fountain surrounds in Arizona’s monsoon-affected regions. Professional blue slate suppliers consistency Arizona should provide both wet and dry color samples for outdoor applications.

Supplier Grading Systems and Quality Tiers

Professional blue slate suppliers implement grading systems that categorize material into quality tiers based on color consistency, surface characteristics, and dimensional tolerances. You should understand these classifications before you commit to pricing structures that may not align with your project’s visual requirements.

- Premium grade maintains color variation within 1-1.5 Munsell steps across an entire shipment, representing the top 15-20% of quarry output

- Standard grade allows 2-2.5 step variation, comprising 50-60% of production with predictable tonal ranges

- Economy grade includes 3+ step variation with occasional color outliers, suitable for rustic applications where variation enhances design intent

- Select grade represents custom sorting for specific color concentrations, adding 25-40% to base material cost

When you specify premium grade blue slate suppliers shade uniformity, you’re paying for extensive hand-sorting and potentially 60-70% quarry waste. This isn’t arbitrary markup — it reflects labor-intensive culling processes where workers evaluate each piece against color standards. Standard grade provides better value for most Arizona installations where some variation creates visual interest without appearing haphazard.

You’ll find that blue slate suppliers tonal standards vary significantly between domestic and imported material. North American quarries typically offer tighter color control due to more homogeneous geological formations, while Asian sources may exhibit wider variation compensated by lower cost. Your decision should factor in the total installed cost including sorting labor, not just the per-square-foot material price.

Batch Consistency and Lot Tracking Requirements

Professional procurement requires you to implement batch tracking from quarry extraction through installation. Blue slate suppliers consistency Arizona depends on lot number documentation that connects your purchased material to specific quarry locations and extraction dates. Without this traceability, future material matching for repairs or expansions becomes nearly impossible.

You should require suppliers to provide batch certificates showing color range documentation with Munsell notation or equivalent color system references. These certificates establish baseline expectations and provide recourse if delivered material falls outside specified parameters. Request sample boards representing the full color range of your specific lot before you authorize warehouse release for shipment.

Temperature and humidity in warehouse storage affect slate appearance, particularly for material stored longer than 90 days. You need to verify that your supplier maintains climate-controlled warehouses in Arizona rather than outdoor storage yards where thermal cycling can alter surface characteristics. Material stored above 140°F (common in uncovered Arizona yards during summer) may exhibit accelerated oxidation that shifts blue tones toward gray-brown.

Your specification should mandate that all material ships from a single production lot whenever possible. When projects exceed single-lot availability, you’ll need to implement blending protocols where installers draw from multiple pallets simultaneously. This prevents creating distinct zones of tonal variation that become obvious after installation. For projects requiring staged deliveries, consider the challenges in matching subsequent shipments to initial installations. Blue slate suppliers color matching capabilities decline as time between shipments increases, with quarry face conditions changing seasonally.

Color Matching Testing Methods and Acceptance Standards

Objective color assessment requires standardized testing beyond subjective visual evaluation. You should implement spectrophotometric analysis for projects where tight color control justifies the testing cost. Spectrophotometers measure reflected light across the visible spectrum, providing numerical values that eliminate interpretation ambiguity.

For most Arizona projects, you can rely on visual comparison protocols using controlled lighting conditions. Natural daylight evaluation at solar noon provides the most accurate representation of installed appearance, though you should also verify color under evening LED landscape lighting if applicable. Blue slate exhibits metamerism — color appearance changes under different light sources — making multi-light evaluation essential for projects with varied lighting conditions.

- Test panels should include minimum 25 square feet of installed material representing the full color range from your specific lot

- Panel evaluation should occur at project site under actual lighting and adjacent material conditions

- Acceptance criteria must define maximum allowable color variation using reference standards, not subjective language

- Wet testing simulates post-rain appearance, revealing undertones not visible in dry material

You’ll achieve better consistency by accepting natural variation and designing installations that celebrate rather than fight slate’s inherent character. Specify blue slate suppliers hue selection that provides multiple related tones instead of attempting impossible uniformity. Random pattern layouts with intentionally mixed tones often deliver more cohesive results than attempts at forced consistency.

When you encounter material outside specification ranges, document issues immediately with photography under consistent lighting. Your acceptance or rejection decisions should reference the original batch certificates and sample boards. For projects utilizing our wholesale slate division, pre-delivery sample approval processes prevent costly field rejections and project delays.

Regional Quarry Characteristics Affecting Consistency

North American slate quarries in Vermont, New York, and Pennsylvania produce blue slate with distinct regional characteristics that affect consistency expectations. Vermont slate typically exhibits deeper blue tones with minimal green undertones, while Pennsylvania material often shows more gray influence. You need to understand these regional signatures when you specify sources for multi-phase projects requiring future material matching.

Chinese and Indian slate dominates lower-price market segments, offering wider color variation within individual shipments. These sources provide cost advantages of 40-60% compared to domestic material, but require more rigorous sorting protocols. Blue slate suppliers consistency Arizona using imported material should demonstrate established relationships with specific overseas quarries rather than spot-purchasing from variable sources.

Quarry depth affects color consistency in ways most specifications don’t address. Surface-level extraction often yields more weathered material with oxidized surface characteristics, while deeper mining produces fresher blue tones. You should verify whether your supplier sources from active deep faces or surface reclamation operations. Material from consistent quarry depths provides better batch-to-batch matching for phased projects.

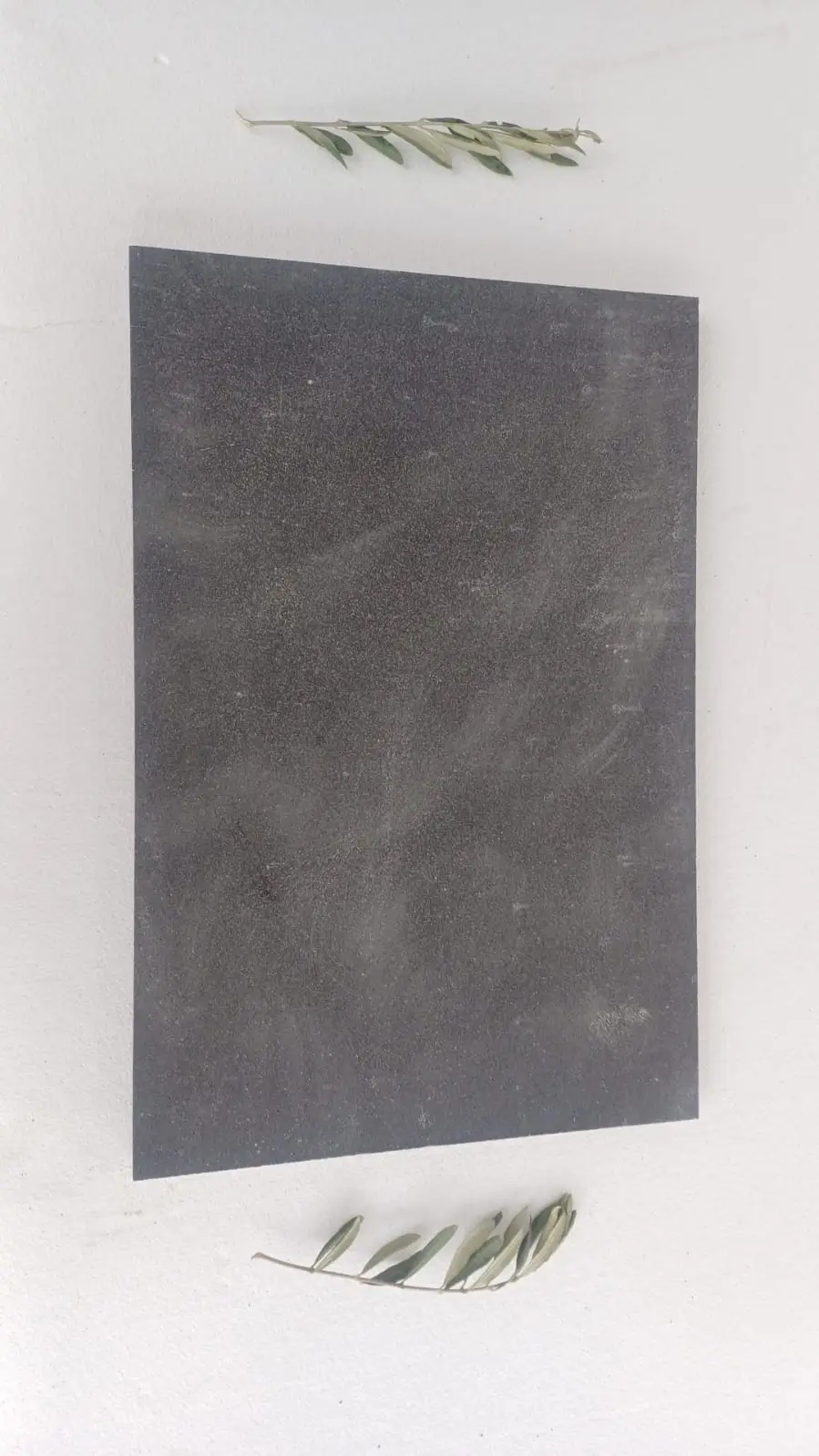

Surface Finish Impact on Perceived Color Consistency

The surface finish you specify dramatically affects perceived color uniformity even when underlying stone color remains constant. Natural cleft surfaces emphasize texture over color, helping disguise tonal variations through shadow play and light reflection patterns. You’ll find that cleft-finish blue slate tolerates wider color variation than honed or polished surfaces where tonal differences become more apparent.

Honed finishes flatten surface texture, making color variation more visible by eliminating the texture-based visual distraction of cleft surfaces. When you specify honed blue slate, you need tighter blue slate suppliers shade uniformity standards to prevent installations that appear blotchy rather than varied. Thermal finishing creates micro-texture that slightly darkens apparent color while maintaining natural slate character — a useful middle ground between cleft and honed aesthetics.

- Cleft surfaces tolerate 2.5-3 step color variation while maintaining visual coherence

- Honed surfaces require sub-2 step variation for professional appearance

- Thermal finishes allow 2-2.5 step variation with texture compensating for color differences

- Polished surfaces demand premium-grade material with maximum 1.5 step variation

Your finish selection should align with available material grades and project budget realities. Specifying honed finish with economy-grade material creates inevitable appearance problems, while cleft finish with premium material may represent unnecessary cost. Blue slate suppliers tonal standards typically tier pricing by finish as well as grade, with polished material requiring the most stringent color control.

Environmental Exposure Effects on Long-Term Color Stability

Arizona’s environmental conditions affect blue slate color stability differently than temperate climates. UV radiation at 7,000+ foot elevations in Flagstaff exceeds Phoenix intensity by 15-20%, accelerating any photodegradation of iron compounds that contribute to blue coloration. You need to account for elevation-specific weathering patterns when you specify for mountain versus desert installations.

Thermal cycling between 30°F winter nights and 110°F summer days in many Arizona locations stresses slate microstructure, potentially opening fissures that alter light reflection and apparent color. Material with higher porosity shows more rapid color evolution, typically shifting toward lighter gray tones as surface oxidation progresses. Your specification should acknowledge that installed slate color will evolve 0.5-1 Munsell steps over 5-7 years under Arizona exposure.

Monsoon moisture introduces temporary color darkening that becomes permanent if organic growth establishes in slate’s porous structure. You’ll see this most in shaded north-facing installations where moisture retention supports algae colonization. Blue slate suppliers hue selection should consider whether project orientation and exposure create conditions for biological staining that will override original color specifications.

Specification Language Requirements for Color Control

Vague specification language like “uniform blue slate” or “minimal color variation” creates disputes and field rejections. You need precise, measurable language that defines acceptable variation ranges using recognized color systems. Professional specifications reference Munsell color notation or provide physical samples representing minimum and maximum acceptable variation boundaries.

Your specification should include phrases like: “Blue slate shall exhibit color range between Munsell 5B 4/1 and 5B 6/1, with no more than 15% of pieces falling outside this range.” This provides objective acceptance criteria that both supplier and installer can verify. Include requirements for sample panel approval before full installation proceeds.

- Define color range using Munsell notation or equivalent standardized system

- Specify maximum percentage of pieces allowed outside primary color range

- Require batch certificates with lot numbers and color range documentation

- Mandate sample panel approval representing full delivered color range

- Establish lighting conditions for color evaluation and acceptance testing

You should address phased delivery scenarios explicitly, requiring that all material for each project phase derives from the same production lot when possible. For projects spanning multiple phases over months or years, include provisions for future material matching or acknowledge that exact matching may not be achievable. This protects both parties from unrealistic expectations about blue slate suppliers color matching capabilities across time gaps.

Cost Implications of Consistency Standards

Tighter color consistency correlates directly with higher material cost due to increased quarry waste and sorting labor. You’ll pay 25-35% premium for premium-grade material compared to standard grade, and 50-70% premium compared to economy grade. These differentials reflect the reality that achieving uniform color requires rejecting significant portions of quarried material.

Your budget decisions should weigh material cost against potential field rejection costs. Specifying economy-grade material for projects requiring tight consistency often results in 20-30% field rejection rates, negating initial savings. Conversely, specifying premium grade for rustic applications where variation enhances design represents poor value engineering.

Consider warehouse stocking realities when you evaluate cost-consistency tradeoffs. Suppliers maintaining large inventories can blend material from multiple shipments to achieve consistent color ranges, but this requires warehouse space and carrying costs reflected in pricing. Blue slate suppliers consistency Arizona with local warehouses typically charge 8-12% more than direct-ship suppliers, but provide better color control and faster delivery response for supplemental material needs.

Installation Strategies for Managing Variation

Skilled installation practices minimize the visual impact of inherent color variation. You should require installers to blend material from multiple pallets simultaneously rather than installing pallet-by-pallet. This prevents creating distinct color zones that emphasize variation rather than distributing it evenly.

Pre-sorting material into light, medium, and dark groups allows intentional distribution patterns. You might concentrate lighter tones in high-visibility areas while placing darker pieces in peripheral zones, or create subtle gradients that make variation appear intentional. Random placement without pre-sorting often creates unintended clustering of similar tones that looks haphazard.

- Draw material simultaneously from minimum three pallets during installation

- Pre-sort into tonal groups if creating intentional gradients or patterns

- Dry-lay critical areas before setting to evaluate color distribution

- Reserve pieces outside specification range for cuts and edge conditions

Your installation specification should mandate dry-layout approval for representative sections before full installation proceeds. This catch-point allows color distribution adjustments before mortar or adhesive makes changes costly. For large projects, require daily progress photos showing overall color distribution, not just close-up detail shots that hide broader pattern issues.

Quality Control Documentation and Traceability

Comprehensive documentation protects your interests throughout procurement and installation. You need batch certificates, sample boards, test panel photos, and acceptance documentation creating an audit trail for any future issues. This documentation becomes essential if you need to source matching material for repairs or additions years after initial installation.

Batch certificates should include quarry location, extraction date, lot numbers, and color range data. Request digital copies stored in project files along with physical samples representing the delivered material’s color range. These samples provide future matching references that remain stable while installed material evolves through weathering.

Photographic documentation should capture material appearance under consistent lighting at multiple project stages: delivery, sample panel approval, installation progress, and final completion. You’ll want both overview shots showing color distribution patterns and detail images showing individual piece variation. Include color reference cards in photos to establish baseline comparisons.

Citadel Stone’s Approach to Blue Slate Suppliers Consistency Arizona Projects

When you consider Citadel Stone’s blue slate suppliers consistency Arizona capabilities for your project, you’re evaluating quarry-direct relationships that support predictable color range management. At Citadel Stone, we maintain specification-grade material selections appropriate for Arizona’s demanding environmental conditions. This section outlines how you would approach blue slate suppliers shade uniformity considerations for three representative Arizona cities with distinct climate challenges and design preferences.

Arizona’s geographic diversity creates varying requirements for slate specification from low-desert installations to high-elevation mountain communities. You need to account for regional temperature ranges, precipitation patterns, and UV exposure intensities when you develop color consistency standards. The hypothetical scenarios below demonstrate how professional specifications adapt blue slate suppliers tonal standards to local conditions.

Yuma Desert Conditions

In Yuma’s extreme desert environment where summer temperatures exceed 120°F, you would specify blue slate with minimal iron content to reduce oxidation-driven color shift. Your color consistency standards should anticipate 0.5-1 step lightening over initial years as intense UV exposure affects surface minerals. You’d want suppliers demonstrating batch consistency across multiple deliveries since project phasing often extends due to summer heat construction limitations. Local contractors recommend cleft-finish material since texture compensates for any color evolution while providing superior slip resistance for pool surrounds and outdoor living spaces common in Yuma residential projects.

Mesa Suburban Applications

Mesa’s established neighborhoods and commercial corridors create demand for blue slate matching existing installations during renovation projects. You would prioritize suppliers with extensive inventory depth allowing color matching to material installed 10-15 years prior. Your specification should acknowledge that exact matching proves difficult, recommending transition zones or pattern changes that incorporate both existing and new material. Blue slate suppliers hue selection for Mesa projects typically emphasizes medium blue-gray tones that complement the area’s prevalent desert landscaping palette. You’d verify warehouse stock availability before committing to project schedules since Mesa’s strong construction market creates periodic material shortages during peak building seasons.

Gilbert Premium Residential

Gilbert’s luxury home market demands premium-grade blue slate suppliers shade uniformity with tight color control appropriate for high-visibility outdoor entertainment spaces. You would specify maximum 1.5-step variation with sample panel approval requirements before full installation proceeds. Your procurement strategy should include contingency material orders of 12-15% beyond calculated needs, allowing field sorting that removes any pieces outside acceptable range. Gilbert projects typically justify the premium material cost since homeowner expectations include minimal visible variation. You’d coordinate delivery timing carefully since many Gilbert properties have limited staging areas, requiring just-in-time material arrival that depends on reliable supplier lead times and consistent truck access scheduling.

Maintenance and Long-Term Color Preservation

Proper maintenance protocols extend color stability and minimize divergence from original appearance. You should implement cleaning schedules that remove organic material before biological growth establishes, particularly in irrigated landscape areas where moisture supports algae development. Pressure washing at 1,500-2,000 PSI annually removes surface contamination without damaging slate structure.

Sealer application affects both color appearance and long-term stability. Color-enhancing sealers darken slate by 1-2 tones while making existing variation less apparent — useful for installations where delivered material exceeded desired variation ranges. You’ll need to reapply sealers every 2-4 years depending on UV exposure and foot traffic intensity. Natural finish maintenance allows slate to weather authentically, accepting gradual color evolution as part of the material’s character.

Arizona’s alkaline soils and hard water create efflorescence risk that manifests as white haze obscuring slate’s blue tones. You need drainage design preventing subsurface salt migration to slate surfaces. When efflorescence appears, acidic cleaners remove deposits, but recurrence indicates ongoing moisture and salt transport requiring base-level remediation beyond surface treatment.

Future Material Matching Considerations

Planning for future repairs or expansions requires realistic expectations about material matching possibilities. You should retain physical samples from original installation along with complete batch documentation. Even with perfect documentation, quarry conditions change over years, making exact matching difficult or impossible for projects requiring material additions more than 3-5 years after initial installation.

Your specification approach for phased projects should anticipate matching challenges by incorporating design strategies that make future additions visually distinct rather than attempting seamless integration. Border changes, pattern shifts, or intentional color contrasts provide better long-term solutions than assuming suppliers can match aged material. Blue slate suppliers consistency Arizona professionals understand these limitations and recommend designs accommodating them from initial planning stages.

Final Considerations

Your success with blue slate procurement depends on understanding that natural stone variation represents inherent material character rather than quality deficiency. You achieve better project outcomes by designing installations that celebrate variation within defined parameters rather than fighting geological reality. Working with suppliers demonstrating transparent grading systems, comprehensive batch tracking, and realistic consistency guarantees provides the foundation for professional results. For additional guidance on long-term performance management, review Slate maintenance techniques for arid Arizona desert conditions before you finalize your material selections and installation specifications. Terraced gardens use Citadel Stone’s structural slate walling stone suppliers in Arizona.