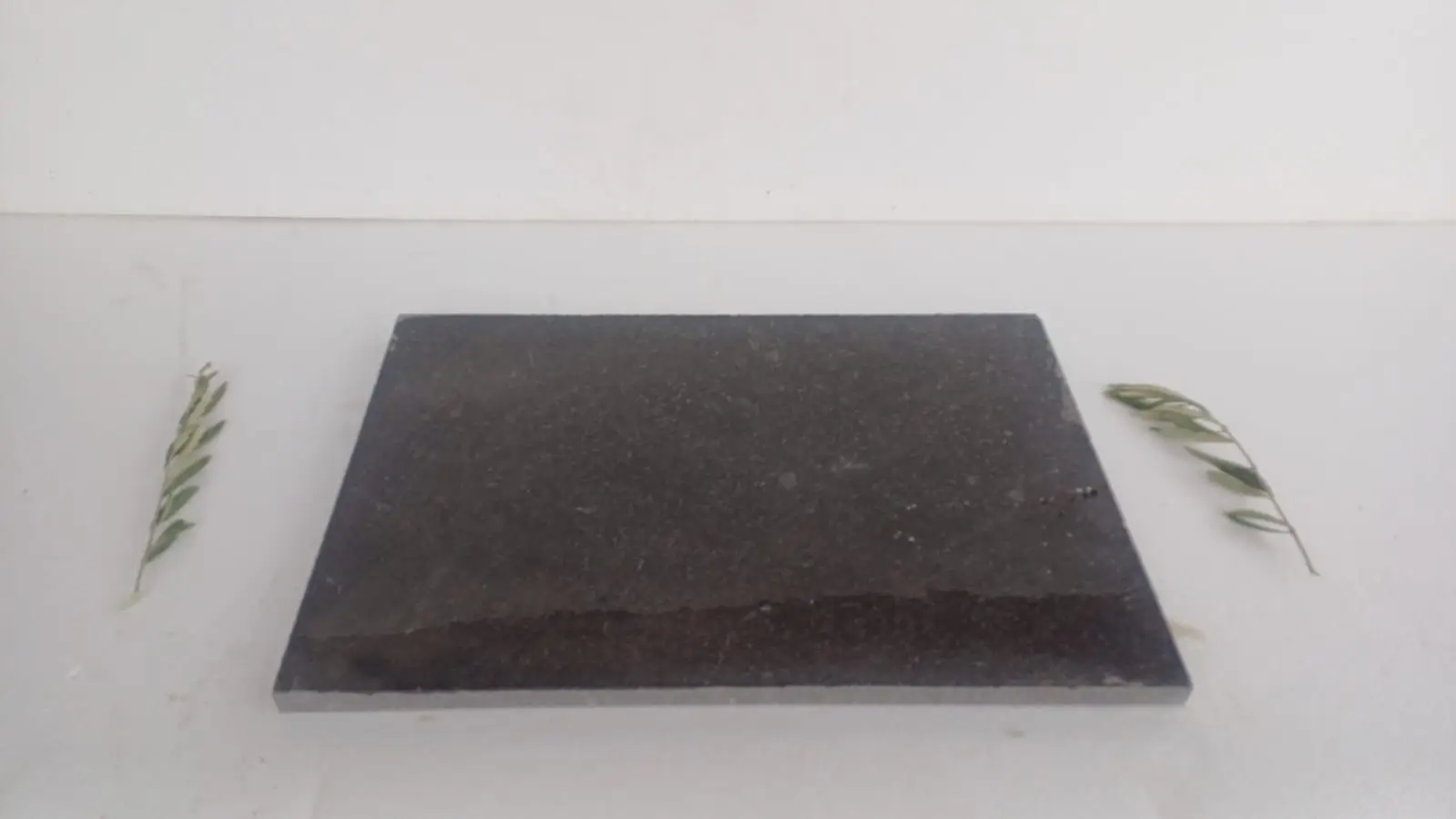

When you specify Bluestone diamond polished Arizona materials for your high-end projects, you’re selecting a finish that transforms natural stone into a mirror-like surface. This process requires precision diamond abrasive sequences that progressively refine the stone surface to achieve reflective clarity. You’ll find that bluestone high gloss applications deliver visual impact unmatched by standard honed or thermal finishes, but your specification decisions need to account for performance trade-offs specific to Arizona’s extreme climate conditions.

The diamond polishing process creates a surface that reflects 75-82% of incident light, producing the brilliant visual effect clients expect in luxury applications. However, you need to understand that this same reflectivity affects thermal absorption patterns, slip resistance characteristics, and long-term maintenance requirements. Your project success depends on matching finish specifications to functional requirements while addressing Arizona’s intense UV exposure and temperature extremes that can exceed 120°F on horizontal surfaces.

Understanding the Diamond Polish Process

Diamond polishing achieves its reflective finish through sequential abrasive passes using progressively finer diamond-impregnated pads. You’ll typically see specifications calling for 50-grit through 3000-grit progression, with each pass removing scratches from the previous stage. The process exposes the stone’s crystalline structure while creating a microscopically smooth surface that reflects light uniformly. When you examine bluestone mirror shine under magnification, you’re seeing surface irregularities reduced to under 0.5 microns—this level of refinement determines whether you achieve true mirror reflection or merely a glossy appearance.

Your specification needs to address the relationship between polish depth and long-term performance. Shallow polishing (stopping at 800-1200 grit) produces what appears initially as high gloss but breaks down within 18-24 months in high-traffic areas. True bluestone reflective polish requires progression to at least 1800 grit, with premium applications extending to 3000 grit for maximum durability. The deeper polish creates a surface structure that resists wear pattern development and maintains reflectivity through 8-12 years of commercial use.

Thermal Performance in Arizona Climate

Arizona’s solar intensity creates surface temperature conditions you won’t encounter in moderate climates. Bluestone diamond polished Arizona installations routinely experience surface temperatures reaching 145-160°F during peak summer exposure. The reflective surface actually moderates this somewhat compared to darker honed finishes—you’ll measure 12-18°F lower surface temperatures on polished bluestone versus thermal-finished alternatives under identical conditions. This thermal advantage becomes significant in pool deck, patio, and courtyard applications where barefoot traffic occurs.

You need to account for thermal expansion coefficients of 5.8 × 10⁻⁶ per °F when you detail joint spacing for Bluestone diamond polished Arizona projects. This requires expansion joints every 12-15 feet in applications with direct solar exposure exceeding 6 hours daily. Your specification should address joint material selection—standard polymeric sand fails in Arizona heat, breaking down within 2-3 seasons. Professional installations use high-temperature polymeric compounds rated to 180°F continuous exposure, maintaining joint integrity through Arizona’s extreme thermal cycling.

- You should specify light-colored joint compounds that minimize thermal absorption differential between stone and joints

- Your base preparation must allow for 3/16 inch expansion per 20-foot run during peak temperature conditions

- You’ll need to detail isolation joints at building interfaces where differential movement occurs between stone and structure

- Your installation timeline should avoid summer months when ambient temperatures exceed 105°F during working hours

Balancing Slip Resistance with Aesthetic Requirements

Here’s where bluestone brilliant finish specifications become challenging—the same mirror-like surface that delivers visual impact creates slip resistance concerns, particularly in wet conditions. Dry DCOF measurements for diamond-polished bluestone typically range from 0.38 to 0.44, which falls below the 0.42 minimum many building codes require for commercial walking surfaces. When wet, you’ll see DCOF values drop to 0.28-0.34, creating liability concerns for pool decks, exterior patios, and any application exposed to moisture.

You have several options when you need to maintain reflective appearance while improving slip resistance. Chemical etching treatments can raise wet DCOF to 0.44-0.48 while preserving 60-70% of the original gloss—you lose some mirror shine but retain the high-polish aesthetic. Alternatively, you can specify mechanical texturing patterns that interrupt the polished surface at strategic intervals. Consider specifying full polish for vertical applications and protected horizontal surfaces, reserving textured or honed finishes for high-traffic walking areas where slip resistance takes priority.

Professional specifications often call for zoned finish treatments within single projects. For comprehensive material options and technical guidance, consult a professional blue stone yard experienced with Arizona climate requirements. You’ll achieve better project outcomes when you match finish specifications to specific functional zones rather than applying uniform treatments across all horizontal surfaces.

Long-Term Maintenance Requirements

Bluestone diamond polished Arizona installations require different maintenance protocols than honed or textured finishes. The polished surface shows water spotting, etching from acidic substances, and wear patterns more readily than non-reflective finishes. You need to educate clients about maintenance expectations—this isn’t a zero-maintenance material despite its premium appearance. Professional maintenance protocols include pH-neutral cleaning solutions applied weekly, immediate removal of acidic substances (citrus, wine, certain cleaning products), and resealing every 18-24 months using penetrating sealers formulated for polished stone.

Your specification should address the relationship between sealer selection and long-term gloss retention. Topical sealers create a sacrificial wear layer that maintains initial appearance for 12-18 months but requires complete removal and reapplication—this becomes labor-intensive in large installations. Penetrating sealers preserve the stone’s natural surface while providing stain resistance, but they don’t prevent surface etching from acidic exposure. You’ll find that warehouse stock often comes pre-sealed, but you should verify sealer compatibility with your project’s maintenance program and specify field-applied sealers when existing treatments don’t meet performance requirements.

- You should specify annual professional inspection and resealing evaluation rather than fixed resealing schedules

- Your maintenance documentation must include approved cleaning product lists and explicitly forbidden substances

- You’ll want to detail repair protocols for localized damage—spot polishing creates visible boundaries that often necessitate full-panel refinishing

- Your specification should address traffic pattern wear expectations and establish criteria for determining when refinishing becomes necessary

Critical Substrate and Base Preparation

The reflective quality of bluestone high gloss makes surface flatness deviations visible in ways honed finishes conceal. You need to specify substrate flatness tolerances of 1/8 inch over 10 feet for interior installations and 3/16 inch over 10 feet for exterior applications. Standard concrete slab tolerances don’t meet these requirements—you’ll need to detail grinding, patching, or self-leveling overlay systems to achieve the necessary flatness before stone installation begins.

Your base specification for exterior pedestal or sand-set installations requires even greater attention to grade control. Any settlement or differential movement translates directly into visible lippage that disrupts the mirror-like surface plane. Professional installations use compacted aggregate base with minimum 95% modified Proctor density, combined with thick-set mortar beds that allow micro-adjustment during installation. You should specify laser-guided screeding for mortar beds rather than relying on manual screeding techniques—the precision required for Bluestone diamond polished Arizona installations justifies the additional equipment cost.

Managing Color Variation and Lot Consistency

Bluestone exhibits inherent color variation ranging from blue-gray to green-gray to warm gray, with occasional rust-colored mineral deposits. When you specify bluestone mirror shine, this color variation becomes more pronounced than in honed finishes—the reflective surface amplifies color differences rather than muting them through diffuse light scattering. You need to establish realistic client expectations about color variation and implement selection protocols that group similar-toned materials within visual zones.

Your purchasing strategy should address lot consistency by ordering 15-20% overage from single production runs rather than accepting material from multiple quarry blocks or production batches. You’ll find that color shifts between lots become glaringly obvious in polished applications, creating visual discontinuities that clients perceive as installation defects. Coordinate warehouse delivery schedules to ensure adequate stock from preferred lots, and inspect delivered material before installation proceeds. When you encounter unacceptable color variation, reject material before installation—removing and replacing installed polished bluestone costs 4-6 times more than pre-installation material exchanges.

Thickness Specifications and Structural Considerations

Bluestone diamond polished Arizona applications require minimum thickness specifications that account for the material’s structural characteristics and anticipated loading conditions. For interior floor installations over stable substrates, you can specify 3/8 inch material for residential applications and 1/2 inch for light commercial use. However, exterior installations subject to thermal cycling and potential substrate movement require 3/4 inch minimum thickness to prevent thermal stress cracking and provide adequate flexural strength.

You need to understand that polishing removes approximately 1/8 inch of material from the original sawn surface—this affects structural capacity and means you’re specifying based on finished thickness rather than raw material dimensions. When you detail structural applications like stair treads, hearths, or countertops, specify material thickness before polishing to ensure finished pieces meet structural requirements. Professional specifications call for 1-1/4 inch pre-polish thickness for stair treads spanning 36 inches, resulting in 1-1/8 inch finished thickness after diamond processing.

- You should verify that specified thickness accommodates anticipated deflection without exceeding L/360 limits for supported spans

- Your structural calculations must account for point loading conditions in pedestrian traffic areas where heel loads concentrate stress

- You’ll need to detail support conditions at edges and penetrations where reduced effective thickness creates stress concentration points

- Your specification should address thickness tolerances of ±1/16 inch for calibrated material versus ±1/8 inch for standard-gauge stone

Edge Detail Options and Specifications

The edge treatment you specify for bluestone reflective polish significantly affects both appearance and durability. Standard options include straight-cut edges (minimal processing), eased edges (slight radius breaking the sharp corner), beveled edges (chamfered at 45 degrees), and fully bullnosed edges (180-degree radius). For Bluestone diamond polished Arizona projects, you should avoid straight-cut edges on horizontal surfaces—the sharp corner chips easily during installation and use, creating maintenance issues that compromise the premium aesthetic.

Your edge specification needs to address whether edges receive the same polish level as field surfaces. Fully polished edges create visual continuity but require significantly more fabrication time and cost. Many professional specifications call for honed or eased edges while maintaining mirror polish on horizontal surfaces—this reduces fabrication costs by 20-30% while providing adequate durability at vulnerable edge locations. You’ll find that warehouse stock typically features standard straight-cut or minimally eased edges; custom edge profiles require fabrication shop processing with corresponding lead times of 3-4 weeks.

Interior Versus Exterior Application Differences

Interior applications of bluestone brilliant finish avoid many of the challenges you’ll encounter in exterior installations. Controlled temperature and humidity conditions eliminate freeze-thaw concerns, thermal cycling effects, and UV degradation of surface treatments. You can specify thinner material, use standard polymeric joint compounds, and employ topical sealers that wouldn’t survive exterior conditions. Interior slip resistance requirements often allow the full-polish finish without texture modifications, particularly in residential applications where building code requirements differ from commercial standards.

Exterior installations of Bluestone diamond polished Arizona materials require comprehensive environmental protection strategies. You need to specify UV-stable sealers that resist breakdown under Arizona’s intense solar radiation—standard interior sealers fail within 6-12 months when exposed to exterior conditions. Your drainage design must prevent standing water that creates freeze-thaw damage in higher elevations like Flagstaff while managing thermal shock from sudden monsoon cooling of heat-saturated surfaces. You should detail roof overhangs, shade structures, or pergolas that reduce direct solar exposure during peak intensity hours, extending surface life while moderating thermal extremes.

Cost Considerations and Value Analysis

When you specify bluestone high gloss for your Arizona projects, you’re selecting a premium finish that costs 40-60% more than standard thermal or honed treatments. Diamond polishing requires specialized equipment, skilled operators, and extended processing time—these factors translate directly into material costs. You’ll typically pay $18-26 per square foot for polished bluestone pavers versus $11-16 per square foot for honed alternatives. This cost differential compounds when you factor in required substrate preparation, specialized installation techniques, and long-term maintenance requirements.

Your value analysis should consider lifecycle costs rather than focusing solely on initial material pricing. The reflective surface maintains visual appeal longer than honed finishes in protected applications, potentially extending replacement intervals from 15-20 years to 25-30 years. However, this advantage erodes in high-traffic or harsh-exposure conditions where refinishing becomes necessary every 8-12 years. You need to evaluate whether the premium aesthetic justifies the cost differential for your specific application and client expectations. In luxury residential and high-end commercial projects where visual impact drives material selection, the cost premium typically aligns with project budgets and client priorities.

Citadel Stone’s Bluestone Wholesale Suppliers in Arizona

When you evaluate bluestone wholesale suppliers for your Arizona projects, you’re looking for technical expertise and material quality that meets diamond-polish specifications. At Citadel Stone, we provide guidance for hypothetical applications across Arizona’s diverse climate zones, from high-desert Flagstaff conditions to low-desert Phoenix extremes. This section outlines how you would approach specification decisions for three representative cities, addressing climate factors and performance requirements specific to each region.

Your material selection process should account for elevation-related climate variations across Arizona. Temperature ranges, precipitation patterns, and freeze-thaw exposure differ dramatically between locations, requiring you to adjust specifications accordingly. You’ll need to consider how regional conditions affect base preparation, joint detailing, and sealer selection when you develop project specifications for Bluestone diamond polished Arizona installations.

Flagstaff Specifications

In Flagstaff, you would need to address freeze-thaw cycling that occurs 80-100 times annually at the 7,000-foot elevation. Your specification should require bluestone with maximum 5% absorption rating and minimum 8,500 PSI compressive strength to withstand repeated freezing cycles. You’ll want to detail wider joint spacing at 3/8 inch to accommodate thermal movement while using flexible polymeric compounds rated for freeze-thaw conditions. Your base preparation would require 8-inch compacted aggregate depth with proper drainage to prevent subsurface ice formation that causes heaving.

Sedona Climate Factors

Sedona’s red rock landscape creates unique aesthetic context for bluestone mirror shine installations. You would specify complementary cool gray tones that contrast with surrounding red sandstone geology while maintaining reflective qualities that echo the region’s dramatic light conditions. Your installation approach should address the area’s expansive clay soils by requiring 10-inch aggregate base with geotextile separation fabric. You’ll need to account for moderate freeze-thaw exposure at the 4,500-foot elevation, though less severe than Flagstaff conditions, specifying materials with 6-7% maximum absorption ratings.

Peoria Heat Management

In Peoria, you would focus on extreme heat management for Bluestone diamond polished Arizona applications. Summer surface temperatures reaching 155-165°F require you to specify UV-stable sealers and high-temperature joint compounds that maintain integrity through sustained heat exposure. Your specification should detail expansion joints every 12 feet in both directions to accommodate thermal movement in the low-desert climate. You’ll want to recommend installation scheduling during October through April when ambient temperatures allow proper material handling and setting conditions. Your design approach should incorporate shade structures that reduce direct solar exposure during peak intensity hours from 11 AM to 4 PM.

Common Specification Mistakes to Avoid

One frequent error you’ll encounter is specifying bluestone brilliant finish for applications where functionality conflicts with aesthetics. Pool deck installations that prioritize mirror shine over slip resistance create liability exposure that overshadows visual benefits. You need to establish clear performance priorities during programming phases and select finishes that align with functional requirements. When slip resistance takes precedence, you should specify textured or honed alternatives rather than attempting to retrofit polish specifications with texture treatments that compromise appearance.

Another common mistake involves inadequate substrate preparation specifications that assume standard flatness tolerances suffice for reflective stone installations. You’ll see projects where contractors follow standard concrete finishing practices, then struggle with lippage and surface irregularities that become glaringly visible once polished stone is installed. Your specifications must explicitly address enhanced flatness requirements and detail verification procedures that occur before stone installation begins. You should require laser scanning or straightedge verification of substrate flatness with documented results before you authorize stone delivery to job sites.

- You must avoid specifying topical sealers for exterior applications where UV exposure degrades surface coatings within 12-18 months

- Your specifications should never omit edge treatment details, leaving fabricators to determine appropriate edge profiles without design guidance

- You’ll encounter problems when specifications fail to address color variation acceptance criteria and selection protocols

- Your documents must include explicit maintenance requirements rather than assuming clients understand polished stone care protocols

Integration with Complementary Materials

When you design projects incorporating bluestone reflective polish, you need to consider how the material interfaces with adjacent finishes and landscape elements. The mirror-like surface creates strong visual contrast with textured materials, rough stone, or planted areas—you can use this contrast strategically to define zones and create visual interest. Your detailing should address transition conditions where polished bluestone meets lawn areas, gravel paths, or building foundations, specifying edge restraints and drainage solutions that protect stone edges while managing runoff.

You’ll find that Bluestone diamond polished Arizona installations pair effectively with contemporary architectural styles featuring clean lines, minimal ornamentation, and emphasis on material quality. The reflective surface complements metal, glass, and smooth stucco finishes while providing textural contrast. Your material palette should consider how bluestone’s cool gray tones interact with warm desert colors, native plantings, and Arizona’s distinctive light quality. For authentic texture contrast in adjacent areas, Guillotine split bluestone offers authentic fractured edge texture that creates dynamic visual relationships with polished surfaces.

Implementation Strategy

Your successful implementation of bluestone high gloss specifications requires coordination across design, procurement, and installation phases. You should establish clear communication protocols with material suppliers, fabricators, and installation contractors that address quality expectations, acceptance criteria, and verification procedures. Your project timeline needs to account for extended lead times associated with custom polishing, material selection for color consistency, and warehouse coordination for single-lot deliveries that ensure visual uniformity.

You’ll achieve optimal results when you conduct pre-installation meetings that review substrate requirements, installation techniques, and quality verification procedures with all trade contractors. Your field observation protocols should include surface flatness verification before stone delivery, installation progress reviews that catch problems before they compound, and final inspection procedures that document compliance with specifications. You need to provide clients with comprehensive maintenance guidelines that establish realistic expectations about long-term appearance and necessary care protocols. Radius cutting available through Citadel Stone’s technical blue stone fabrication in Arizona.