When you specify natural stone for Arizona projects, understanding flagstone travertine differences Arizona presents becomes critical to your selection process. You’ll encounter distinct textural qualities and structural characteristics that directly impact performance, aesthetics, and long-term durability. These materials might appear similar at first glance, but their formation processes create fundamental differences you need to recognize before committing to project specifications.

Your material selection affects everything from surface temperature management to slip resistance ratings. Flagstone travertine differences Arizona manifests in pore structure, density variations, and thermal behavior—factors that influence installation methods and maintenance protocols. You should evaluate how flagstone texture comparison reveals practical implications for foot traffic patterns and weather exposure in desert climates.

Formation Geology & Structural Implications

The geological origins of these materials create the flagstone material contrasts you’ll observe in field applications. Travertine forms through rapid calcium carbonate precipitation at hot springs and limestone caves, creating a layered structure with interconnected porosity ranging from 15-25%. This formation process produces the characteristic banding and voids you’ll see throughout the material. Your specifications need to account for this inherent porosity when you’re evaluating structural load requirements.

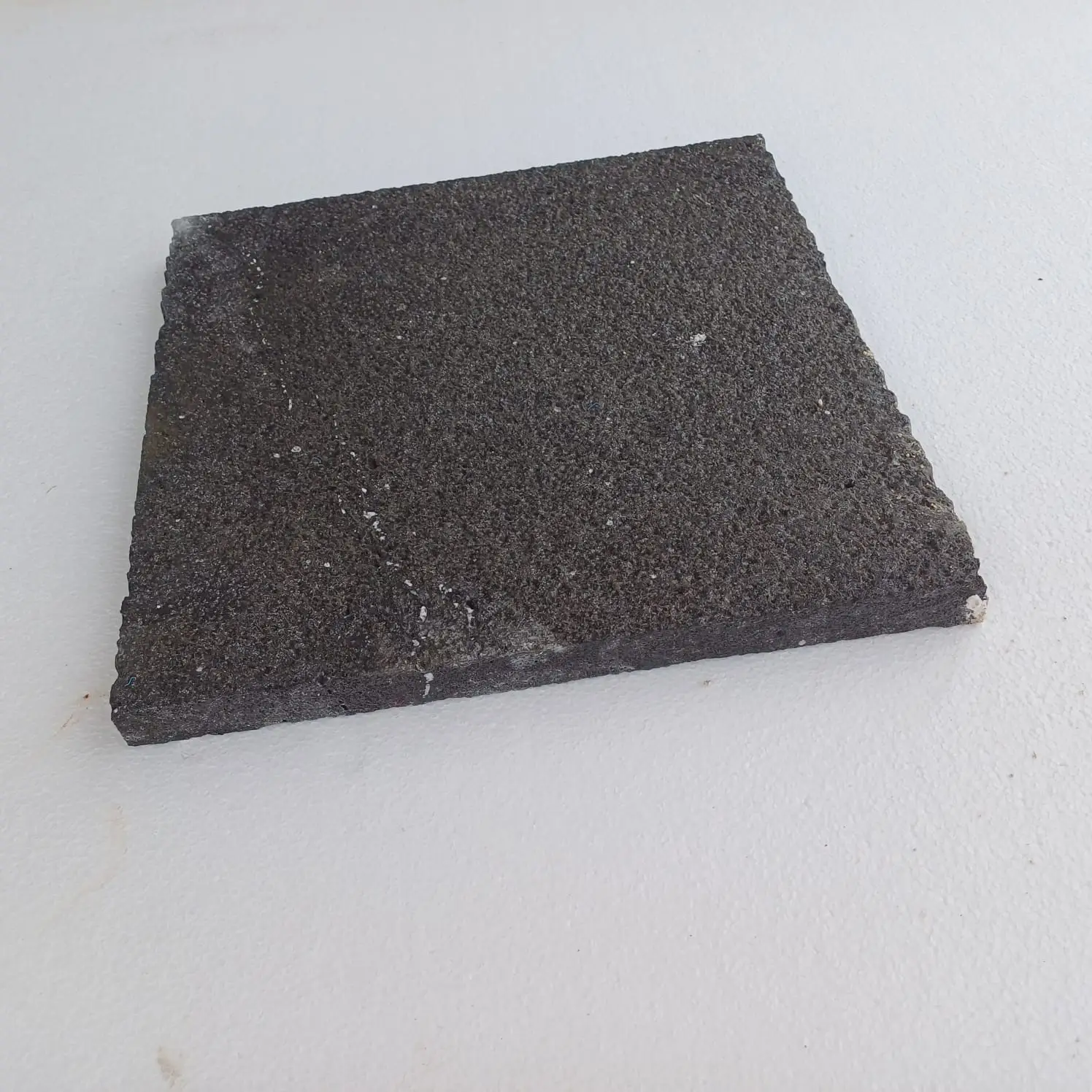

Flagstone encompasses metamorphic varieties like quartzite and slate that formed under intense heat and pressure over millions of years. When you examine flagstone structure differences, you’ll notice denser crystalline matrices with porosity typically below 3-5%. This fundamental contrast affects compressive strength, water absorption, and freeze-thaw resistance. You’ll find that flagstone varieties achieve compressive strengths of 18,000-25,000 PSI, while travertine typically ranges from 8,000-12,000 PSI.

The metamorphic transformation that creates flagstone produces interlocking mineral crystals that resist weathering and maintain structural integrity under extreme conditions. You should recognize that this density difference translates directly to installation substrate requirements—travertine demands more robust base preparation to prevent deflection and cracking under point loads.

Surface Texture & Tactile Characteristics

Your flagstone texture comparison begins with surface morphology that affects both aesthetics and functionality. Travertine exhibits natural voids and pitting across its surface—characteristics you’ll need to address through filling and sealing protocols or accept as design features. These surface irregularities create texture variation that influences slip resistance but also affects cleaning difficulty and debris accumulation.

Flagstone presents cleaner, more uniform surface planes with natural cleft textures or sawn finishes. When you specify flagstone for high-traffic applications, you’re working with material that maintains consistent texture without the void-filling requirements travertine demands. The flagstone stone variations you’ll encounter relate more to mineral composition and color rather than structural voids.

Surface preparation options differ significantly between these materials. You can achieve honed, brushed, or tumbled finishes on both, but travertine’s porosity means you’ll see more dramatic texture changes with each finishing method. Your selection of surface treatment directly impacts the final slip resistance coefficient—critical data for pool decks and wet-area applications where DCOF ratings must meet or exceed 0.50.

Thermal Mass & Heat Retention Properties

Understanding flagstone travertine differences Arizona requires you to evaluate thermal behavior in extreme desert conditions. Travertine’s lighter color palette reflects 65-75% of solar radiation, reducing peak surface temperatures by 15-20°F compared to darker materials. Your barefoot-friendly pool deck specifications should prioritize this reflectivity when surface contact temperature matters.

The material’s porosity affects thermal mass performance in ways most generic specifications overlook. Travertine’s interconnected void structure allows air circulation within the material, moderating heat retention. You’ll observe faster cooling rates after sunset—typically 30-40% quicker temperature drop compared to dense flagstone varieties. This characteristic becomes valuable when you’re designing evening-use outdoor spaces.

Flagstone’s higher density creates superior thermal mass for applications where you want heat retention and gradual temperature modulation. Dense quartzite flagstone stores thermal energy throughout the day and releases it slowly overnight. When you’re specifying materials for thermal comfort in transitional seasons, this heat retention extends usable hours for outdoor spaces. You need to match these thermal characteristics to your project’s specific microclimate and usage patterns.

Porosity Profiles & Water Management

The flagstone material contrasts become most apparent when you examine water absorption and drainage behavior. Travertine’s 15-25% porosity means you’re specifying material that absorbs significant moisture during rain events. This absorption affects freeze-thaw performance in northern Arizona elevations above 5,000 feet. Your Flagstaff and Sedona projects require different sealing protocols than Phoenix installations specifically because of elevation-related freeze cycles.

You should verify that your travertine selections undergo proper sealing before installation in areas experiencing more than 10 annual freeze-thaw cycles. Unprotected travertine can experience spalling and surface degradation when absorbed moisture expands during freezing. Testing shows that properly sealed travertine performs adequately in these conditions, but you need to specify annual resealing in your maintenance documentation.

Flagstone structure differences manifest in dramatically lower water absorption—typically 1-3% for dense metamorphic varieties. When you’re working on projects where minimal moisture penetration matters for structural or aesthetic reasons, flagstone provides superior performance. You’ll also find that lower porosity translates to reduced efflorescence potential and fewer organic staining issues from algae and mildew growth in shaded areas.

Dimensional Stability & Expansion Coefficients

Your technical specifications must address how flagstone travertine differences Arizona affect dimensional stability across Arizona’s extreme temperature swings. Travertine exhibits thermal expansion coefficients around 4.7 × 10⁻⁶ per °F—relatively moderate expansion that you can accommodate with standard joint spacing. You’ll need 3/16″ to 1/4″ joints for typical travertine installations, with expansion joints every 20-25 feet in areas exceeding 6 hours of daily direct solar exposure.

Flagstone varieties demonstrate expansion coefficients ranging from 5.1 to 6.8 × 10⁻⁶ per °F depending on mineral composition. When you’re specifying quartzite flagstone, you’re working with material requiring slightly wider expansion accommodation. Your joint spacing should increase to 1/4″ to 5/16″ with expansion joints every 15-18 feet in full-sun applications. This detail often gets missed in standard specifications but prevents long-term edge spalling and displacement.

The relationship between thermal expansion and installation substrate becomes critical in Arizona applications. You need to ensure your base preparation allows lateral movement without restriction. Rigid mortar-set installations over concrete substrates require proper slip-sheet membranes to prevent restraint that leads to cracking. This consideration applies regardless of material choice but becomes more critical with higher-expansion flagstone varieties.

Slip Resistance & Safety Performance

When you evaluate flagstone texture comparison for safety-critical applications, you’re examining how surface morphology translates to friction coefficients. Travertine’s natural surface texture with voids and irregularities typically achieves DCOF ratings of 0.50-0.58 when dry, adequate for most residential applications. The challenge emerges in wet conditions where these ratings can drop to 0.38-0.44—below the 0.42 minimum threshold for safe pedestrian traffic.

Your specifications should require surface treatments that maintain wet DCOF above 0.50 for pool decks and water-feature surrounds. Brushed or tumbled finishes on travertine enhance slip resistance but reduce the material’s naturally smooth aesthetic. You’ll need to balance safety requirements against design intent, often specifying different finishes for wet versus dry zones within the same project.

Flagstone stone variations provide broader slip resistance options based on natural cleft textures. You can achieve wet DCOF ratings of 0.55-0.68 with naturally textured flagstone surfaces without additional treatment. This inherent slip resistance makes flagstone the preferred specification for commercial applications where safety standards demand higher performance thresholds. You should document slip resistance testing results in your submittal requirements to verify field performance matches specifications.

Installation Methodology & Base Requirements

Understanding flagstone travertine differences Arizona extends to installation protocols that accommodate each material’s structural characteristics. Travertine’s lower density and higher porosity mean you need more substantial base preparation to prevent deflection under load. Your specifications should require compacted aggregate base depths of 6-8 inches for pedestrian applications, increasing to 10-12 inches for vehicular traffic. This exceeds typical flagstone requirements by 30-40%.

The base material composition affects long-term performance differently for these materials. You’ll want to specify crushed granite or limestone aggregate with fines content between 8-12% for optimal compaction and drainage. When you’re working with expansive clay soils common in Phoenix and Peoria, your base preparation requires geotextile separation fabric to prevent soil migration into the aggregate layer. For guidance on related paving options, see our flagstone distribution division for comprehensive comparison data.

Your setting bed specifications differ between materials based on thickness tolerances. Travertine tiles with 1/4″ thickness variation require thicker mortar beds or adjustable pedestals to achieve level finished surfaces. Flagstone varieties typically exhibit tighter thickness tolerances of ±1/8″, simplifying installation and reducing labor costs. You should account for these installation time differences when you’re developing project schedules and budget estimates.

Durability Performance & Service Life Expectations

When you specify materials for Arizona’s harsh environment, you need realistic performance expectations for flagstone travertine differences Arizona. Travertine installations demonstrate 20-30 year service life in protected residential applications with proper sealing maintenance performed biennially. You’ll see accelerated wear in high-traffic commercial settings where foot traffic exceeds 500 daily users—surface pitting and void enlargement become visible within 8-12 years.

Environmental factors specific to Arizona accelerate travertine degradation in ways you need to anticipate. The combination of intense UV exposure, extreme temperature cycling, and low humidity creates surface microcracking that compounds over time. Your maintenance specifications should include annual inspection protocols and remedial sealing when you observe surface chalking or increased water absorption.

- You should expect flagstone to deliver 40-60 year service life in similar applications with minimal maintenance

- Your flagstone installations resist UV degradation and maintain structural integrity through decades of thermal cycling

- Dense metamorphic varieties demonstrate negligible wear even in commercial applications exceeding 2,000 daily users

- You’ll find that flagstone requires resealing only every 3-5 years compared to annual or biennial treatments for travertine

The cost-per-year calculation favors flagstone despite higher initial material costs. When you evaluate lifecycle economics, flagstone’s extended service life and reduced maintenance requirements typically result in 30-40% lower total ownership costs over 30-year analysis periods.

Color Stability & Patina Development

Your aesthetic specifications need to account for how flagstone material contrasts affect long-term appearance. Travertine’s beige, cream, and walnut colorations remain relatively stable under Arizona sun exposure, experiencing only subtle lightening over 10-15 years. This color stability makes travertine predictable for projects where you need to match existing installations or maintain consistent appearance across phased construction.

Flagstone structure differences produce varied color stability depending on mineral composition. Iron-rich quartzite develops attractive rust-tone patinas that deepen over time—an aging characteristic you should present to clients as a design feature rather than degradation. Slate varieties maintain stable gray tones with minimal UV-related fading. When you’re selecting flagstone, you’ll want to review long-term exposure samples that demonstrate realistic patina development.

Surface sealing affects color presentation differently between these materials. Travertine benefits from color-enhancing sealers that deepen natural tones and create richer appearance—an aesthetic upgrade you can specify for premium projects. Flagstone’s denser surface accepts both natural-look and color-enhancing sealers, giving you greater aesthetic control. You should prepare mock-up samples with your specified sealer to confirm appearance meets design intent before proceeding with full installation.

Maintenance Protocols & Service Requirements

When you develop maintenance specifications for flagstone travertine differences Arizona, you’re creating protocols that dramatically affect long-term performance. Travertine demands more intensive maintenance regimes to preserve appearance and structural integrity. Your maintenance documentation should specify annual cleaning with pH-neutral stone soap, biennial resealing, and quarterly inspection for void deterioration and surface damage.

The material’s porosity makes travertine susceptible to organic staining from landscape irrigation overspray and decomposing vegetation. You’ll need to specify irrigation system design that minimizes water contact with stone surfaces and establish maintenance protocols for immediate cleanup of organic debris. These requirements add operational costs your clients need to understand during material selection.

Flagstone maintenance protocols demand less frequent intervention. You can specify cleaning on an as-needed basis—typically annually for appearance rather than preservation. Resealing intervals extend to 3-5 years depending on traffic levels and exposure conditions. When you’re working with clients who want minimal maintenance obligations, flagstone stone variations provide clear advantages despite higher initial investment.

Cost Analysis & Value Proposition

Your budget development requires understanding how flagstone texture comparison translates to installed costs. Travertine material costs range from $8-$15 per square foot for standard grades, with premium filled and honed varieties reaching $18-$22. Installation labor adds $6-$10 per square foot depending on pattern complexity and site conditions. You’re looking at total installed costs of $14-$32 per square foot for typical residential applications.

Flagstone material pricing varies widely based on type and sourcing. You’ll see standard cleft quartzite at $12-$18 per square foot, with premium color selections reaching $20-$28. Installation labor runs slightly lower at $5-$9 per square foot due to more consistent thickness tolerances. Your total installed costs range from $17-$37 per square foot—approximately 15-20% higher than comparable travertine installations.

The value proposition extends beyond initial installation when you factor maintenance costs and replacement timelines. Your lifecycle cost analysis should include biennial sealing at $1.50-$2.50 per square foot for travertine versus 3-5 year intervals for flagstone. Over a 30-year period, these maintenance cost differentials can offset the initial price premium flagstone commands. You need to present these complete lifecycle economics to clients making value-based decisions.

Citadel Stone — Leading Flagstone Distributors in Arizona

When you consider Citadel Stone’s flagstone distributors for your Arizona project, you’re evaluating premium materials designed for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse regions, from high-desert elevations to low-desert valleys. This section outlines how you would approach specification decisions for three representative cities, considering how flagstone travertine differences Arizona affect material selection and installation protocols.

Flagstaff Elevation Considerations

You would need to prioritize freeze-thaw resistance for Flagstaff installations at 7,000 feet elevation where annual freeze cycles exceed 120 events. Your specifications should require dense quartzite flagstone with porosity below 2% to prevent moisture-related spalling. The material’s compressive strength above 20,000 PSI ensures structural integrity through repeated freeze-thaw cycling. You’d want to specify 1/4″ joint spacing with polymeric sand that remains flexible during temperature extremes ranging from -10°F winter lows to 90°F summer highs. At Citadel Stone, we would recommend additional sealing protocols for joints and edges where moisture infiltration risk concentrates during spring snowmelt periods.

Sedona Aesthetic Integration

Your Sedona specifications would emphasize color coordination with the region’s distinctive red rock landscape. You should select iron-rich quartzite flagstone varieties in rust, terra cotta, and amber tones that complement rather than contrast with surrounding geology. The moderate elevation of 4,500 feet means you’d face fewer freeze-thaw concerns than Flagstaff but still need to account for 30-40 annual freeze cycles. Your installation design should incorporate natural, irregular patterns that reflect Sedona’s organic aesthetic rather than geometric formality. You would specify brushed surface finishes that enhance slip resistance while maintaining the refined appearance high-end residential clients expect in this premium market.

Peoria Heat Management

In Peoria’s low-desert environment, you would need to address extreme heat management where summer temperatures regularly exceed 115°F. Your specifications should prioritize lighter-colored flagstone varieties that reflect solar radiation and minimize surface temperatures. You’ll want to account for thermal expansion with 5/16″ joint spacing and expansion joints every 15 feet in areas receiving full-day sun exposure. The material selection should balance heat reflectivity with durability under intense UV exposure that degrades lesser materials within 10-12 years. You would specify testing to verify your selected flagstone maintains DCOF slip resistance above 0.50 even when surface temperatures reach 140-150°F during peak afternoon conditions common in July and August.

Application-Specific Selection Framework

Your material selection process for flagstone travertine differences Arizona should follow a systematic evaluation framework that matches material characteristics to project requirements. Start by defining your performance priorities using weighted criteria that reflect client values and site conditions. When thermal management ranks highest, travertine’s reflectivity provides clear advantages. When durability and minimal maintenance drive decisions, flagstone delivers superior long-term value.

Traffic loading and usage intensity directly affect material appropriateness. You should specify travertine for light residential applications where aesthetic qualities outweigh durability concerns. Your commercial and high-traffic specifications favor flagstone’s structural strength and wear resistance. Pool decks and wet-area applications require careful slip resistance evaluation—you’ll often find flagstone’s natural texture eliminates the need for additional surface treatments travertine requires.

Climate and elevation factors demand location-specific specifications. You need to account for freeze-thaw cycling, temperature extremes, UV exposure intensity, and precipitation patterns when you’re making material selections. Your northern Arizona specifications at elevations above 5,000 feet should default to low-porosity flagstone unless specific design requirements justify travertine’s aesthetic characteristics with appropriate performance mitigation through enhanced sealing protocols.

Professional Specification Documentation

Your construction documents need comprehensive material specifications that eliminate ambiguity and ensure contractor compliance. When you specify either material, include detailed requirements for compressive strength, porosity percentage, thickness tolerances, and slip resistance ratings. You should reference applicable ASTM standards—C1528 for slip resistance, C170 for compressive strength, C97 for water absorption—and specify minimum performance thresholds.

Surface finish specifications require precise language that contractors can execute consistently. Don’t rely on subjective terms like “smooth” or “textured.” Instead, you should specify measurable finish characteristics: honed to 220-grit equivalent, brushed with 0.030″ average profile depth, or natural cleft with ±0.125″ surface variation. Include sample approval procedures that require you to review and accept material samples before full procurement.

Your installation specifications should detail base preparation requirements, setting bed composition, joint spacing dimensions, and expansion joint locations. You need to specify sealer products by manufacturer and product number rather than generic descriptions. Include maintenance procedures in your specification package so building owners receive clear guidance for long-term care. This documentation becomes particularly important when you’re working with materials like travertine that demand regular maintenance to preserve performance and appearance.

Long-Term Performance Verification

Your professional responsibility extends beyond initial specification to include performance verification protocols that confirm materials deliver expected results. You should establish inspection procedures at 1-year, 3-year, and 5-year intervals that document condition, identify maintenance needs, and verify your specifications achieved intended performance. This verification process provides valuable feedback that improves your future specifications and demonstrates professional accountability.

When you conduct performance inspections, evaluate specific condition indicators relevant to flagstone material contrasts. Look for surface spalling, void enlargement, edge chipping, color fading, slip resistance degradation, and joint sand loss. Document findings with photographs and measurements that create baseline data for ongoing monitoring. You’ll find that systematic performance tracking across multiple projects builds expertise that distinguishes your professional practice.

The data you collect from performance verification informs lifecycle cost modeling and helps clients understand the long-term implications of material selection decisions. When you can demonstrate that flagstone installations you specified 10-15 years ago maintain excellent condition while comparable travertine projects required remedial work, you’re providing compelling evidence for specification recommendations. For additional installation insights, review Quartzite flagstone mineral composition and hardness testing methods before you finalize your project documents. Transform your outdoor living spaces with durable, hand-selected flagstone from Citadel Stone, the trusted source for competitive pricing and statewide delivery throughout Arizona.