When you’re specifying flagstone quartzite recognition Arizona protocols for high-performance hardscape installations, you need to understand that not all flagstone delivers the same structural integrity. Quartzite represents one of the hardest natural stones available, and your ability to identify it accurately determines whether your project withstands decades of desert extremes or requires costly replacement within ten years. You’ll encounter numerous stone varieties labeled as flagstone in Arizona’s material supply chain, but quartzite’s unique crystalline structure and mineral composition set it apart from sedimentary alternatives that lack comparable durability.

Your recognition process starts with understanding what separates quartzite from softer sandstone or limestone flagstone options. The geological transformation from sandstone to quartzite involves extreme heat and pressure that fuses quartz grains into an interlocking crystalline matrix. This metamorphic process creates flagstone hard stone identification characteristics you can verify through field testing protocols. When you examine potential quartzite specimens, you’re evaluating material that formed under conditions exceeding 300°F and pressures equivalent to burial depths of 15,000 feet or more.

Geological Formation Factors

Quartzite formation requires specific geological conditions that directly impact the flagstone mineral identification features you’ll use during material selection. The parent sandstone must contain at least 90% quartz content before metamorphism begins. During transformation, silica cement between original quartz grains recrystallizes under pressure, eliminating the porous structure typical of sedimentary stone. You should understand this process because it explains why quartzite flagstone exhibits superior resistance to water absorption compared to sandstone alternatives that retain sedimentary porosity.

The degree of metamorphism determines final material properties you’ll measure during flagstone quartzite recognition Arizona verification procedures. Partially metamorphosed specimens show transitional characteristics between sandstone and true quartzite. You can identify these intermediate stones through scratch testing and fracture pattern analysis. True quartzite breaks through quartz grains rather than around them, creating the conchoidal fracture patterns that distinguish metamorphic from sedimentary stone. Your specification documents should require verification of complete metamorphism to ensure you’re sourcing genuine quartzite rather than metaquartzite or quartzitic sandstone.

Visual Identification Characteristics

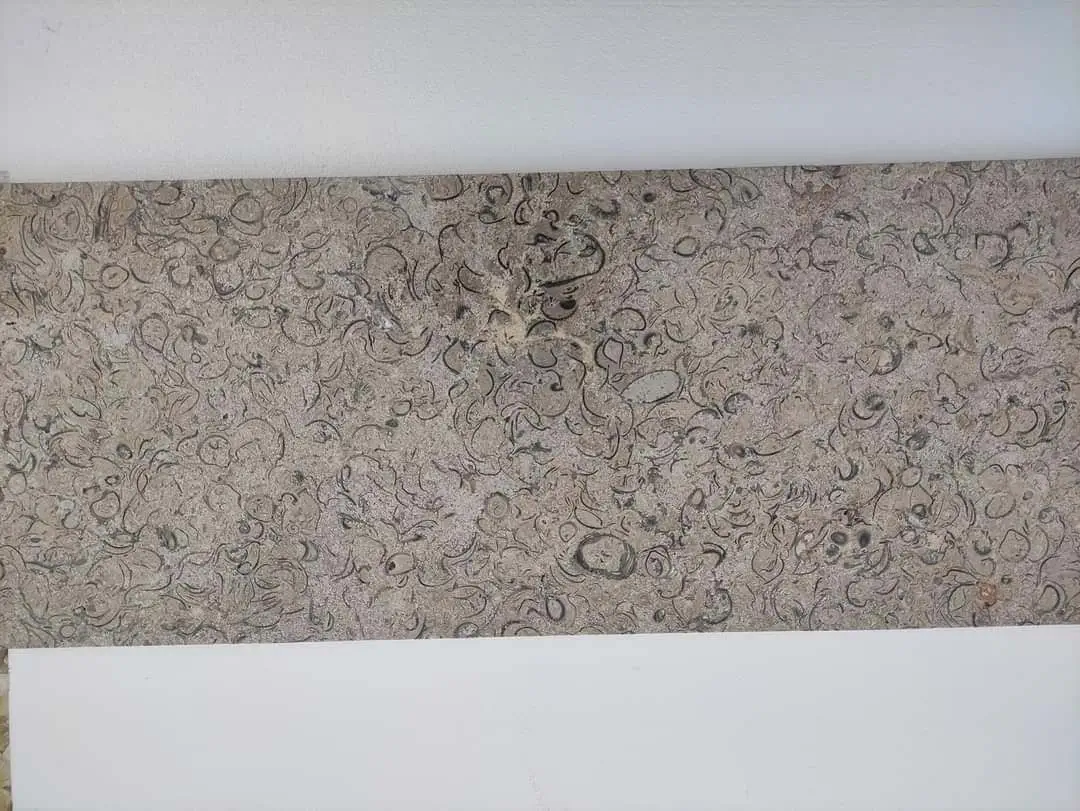

When you conduct flagstone quartzite recognition Arizona assessments in the field, visual inspection provides your first verification layer. Quartzite exhibits a sugary, crystalline appearance on freshly broken surfaces that differs markedly from the granular texture of sandstone. You’ll observe this by examining edges and fracture faces rather than weathered surfaces, which can mislead identification. The crystalline structure reflects light with a subtle sparkle caused by individual quartz crystal faces catching direct illumination at varying angles.

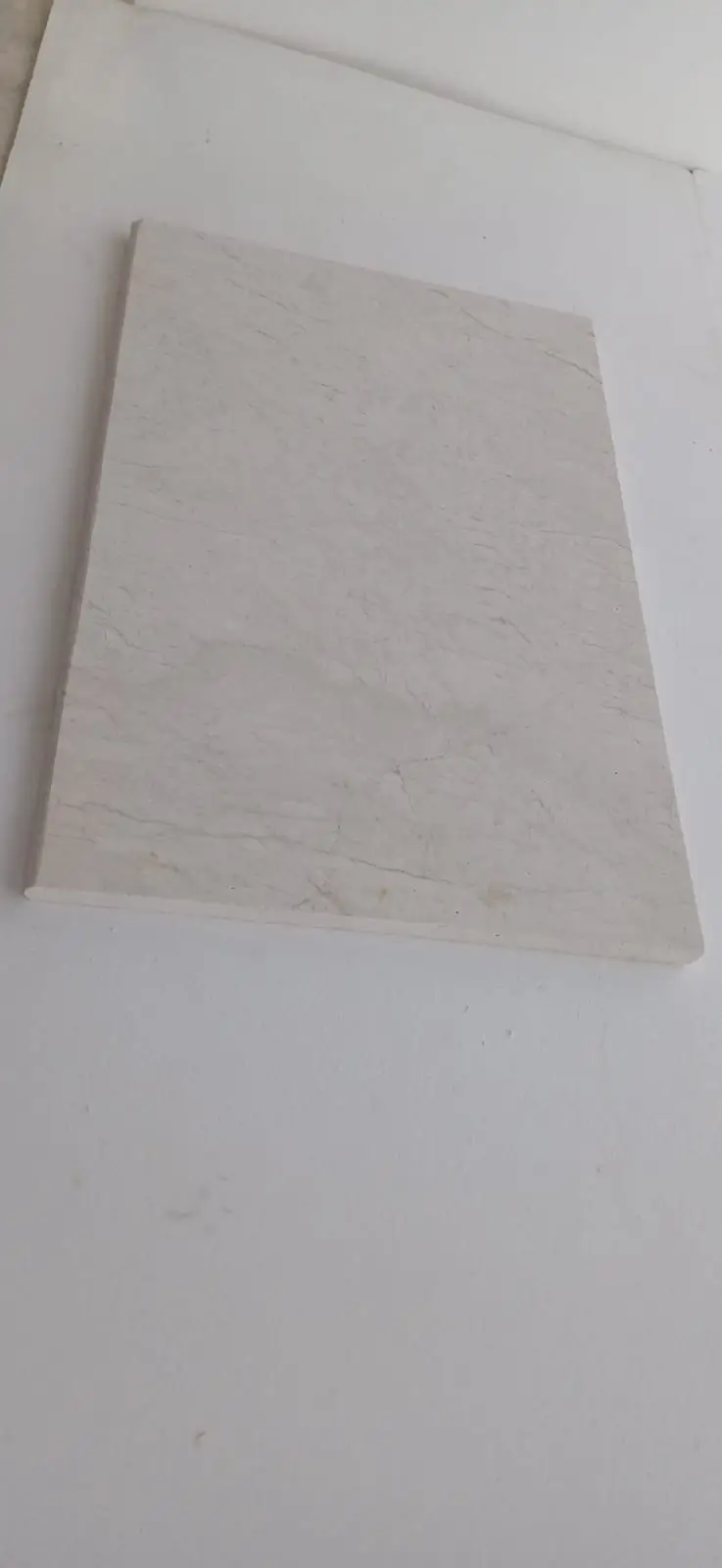

Color alone doesn’t confirm quartzite identity, but certain color patterns indicate probable metamorphic origin. Pure quartzite ranges from white to gray, while iron oxide impurities create red, pink, or yellow tones. You should note that color banding typically appears more defined in quartzite than sandstone due to differential mineral concentration during metamorphism. For flagstone hard stone identification purposes, examine whether color layers show sharp or gradual transitions. Sharp boundaries between color bands suggest metamorphic reorganization, while diffuse transitions indicate sedimentary deposition patterns more common in sandstone.

Surface Texture Analysis

Your tactile assessment reveals important flagstone stone hardness indicators that separate quartzite from alternatives. Run your hand across a fresh break surface and you’ll detect a glassy smoothness in quartzite that contrasts with sandstone’s gritty texture. This difference stems from the fused crystalline structure versus loose grain boundaries. When you evaluate warehouse inventory, request access to broken or cut edges rather than relying solely on weathered faces that may have altered surface characteristics from prolonged exposure.

Translucency Testing

Thin quartzite sections often exhibit slight translucency when backlit, a property absent in opaque sandstone. You can perform this test on slab edges typically 1-2 inches thick. Hold a bright LED flashlight against the edge and observe whether any light transmits through the stone. This flagstone mineral identification technique works best with lighter-colored specimens, as iron-rich varieties may appear opaque despite quartzite composition. The test doesn’t definitively confirm identity alone but provides supporting evidence when combined with other recognition methods.

Hardness Verification Protocols

Flagstone stone hardness represents your most reliable quartzite indicator because metamorphic fusion creates measurably superior scratch resistance. You should conduct Mohs hardness testing as standard practice during flagstone quartzite recognition Arizona procedures. Quartzite rates 7 on the Mohs scale, matching pure quartz hardness, while sandstone typically rates 6-6.5. This single-point difference translates to dramatic performance variations in abrasion resistance and long-term surface preservation.

Your field testing requires a systematic approach using common hardness reference materials. A steel knife blade rates approximately 5.5 on the Mohs scale and will scratch sandstone with moderate pressure but cannot mark true quartzite. For flagstone hard stone identification, attempt to scratch an inconspicuous area using a fresh knife blade at a 45-degree angle with firm downward pressure. Sandstone shows a visible groove, while quartzite remains unmarked or produces only metal streak from the blade itself. You can remove metal streaks with a cloth, revealing undamaged stone beneath.

- Glass plates rate 5.5 Mohs and scratch easily against quartzite edges

- Quartzite scratches porcelain tile rated 6-7 Mohs depending on composition

- Steel files rated 6.5 Mohs produce minimal effect on quartzite surfaces

- Sandstone and limestone show obvious damage from all these test materials

Acid Reaction Testing

When you need to distinguish quartzite from carbonate-based flagstone varieties, acid testing provides immediate confirmation. Quartzite consists of silicon dioxide and shows zero reaction to dilute hydrochloric acid, while limestone or dolomitic flagstone fizzes vigorously. This flagstone mineral identification test takes seconds and requires only a small dropper bottle of 10% hydrochloric acid solution available at masonry supply outlets. Apply a single drop to a clean, unweathered area and observe for bubbling or effervescence.

Your interpretation must account for surface contamination that can produce false positives. Desert flagstone sometimes accumulates calcium carbonate deposits from groundwater or dust, creating a reactive surface layer over non-carbonate stone. For accurate flagstone quartzite recognition Arizona results, you should clean the test area with water and allow complete drying, then scratch through any potential coating to expose fresh stone before applying acid. True quartzite remains completely inert regardless of how long acid contacts the surface.

Density and Porosity Evaluation

Quartzite’s metamorphic fusion creates exceptional density that you can verify through comparative weight assessment. When you lift similarly sized flagstone samples, quartzite feels noticeably heavier than sandstone of equivalent dimensions. Typical quartzite density ranges from 160-165 pounds per cubic foot, while sandstone averages 140-150 pounds per cubic foot. This 10-15% density difference becomes apparent when you handle multiple specimens during material selection at supplier yards.

Porosity testing reveals another critical distinction for flagstone stone hardness and durability prediction. You can perform a simple water absorption test by placing drops on a flat, dry surface and timing how long moisture remains visible. Sandstone absorbs water within 30-90 seconds as liquid penetrates interconnected pore spaces. Quartzite shows minimal absorption over several minutes because metamorphic recrystallization eliminated most porosity. For projects requiring freeze-thaw resistance or stain prevention, this low porosity makes quartzite the superior specification choice.

Fracture Pattern Recognition

The way stone breaks under impact provides definitive evidence for flagstone quartzite recognition Arizona protocols. Quartzite exhibits conchoidal fracturing similar to glass, creating smooth, curved break surfaces with sharp edges. When you examine broken quartzite, you’ll see that fractures pass directly through quartz grains rather than following grain boundaries. This transgranular fracture pattern contrasts sharply with sandstone’s intergranular fracture, where breaks follow cement boundaries between individual sand grains.

Your assessment requires examining fresh breaks rather than weathered edges. Request that suppliers break a small sample piece or provide access to recently split material. Look for the characteristic conchoidal ripple marks that radiate from the impact point. These semi-circular ridges represent stress waves propagating through the homogeneous crystalline structure. Sandstone breaks with rougher, more irregular surfaces that reflect its granular composition. This flagstone hard stone identification criterion works regardless of color, weathering, or surface finish.

Sound Resonance Testing

Experienced stone professionals use acoustic properties for quick flagstone mineral identification in the field. When you strike quartzite with a metal object, it produces a clear, high-pitched ring that sustains briefly before fading. This resonance results from the dense, uniform crystalline structure that conducts sound waves efficiently. Sandstone produces a dull thud with no sustained resonance because its porous structure and grain boundaries dampen vibration rapidly.

You can standardize this test by suspending a flagstone sample from one corner using wire or cord, then tapping the opposite edge with a metal tool. The suspended mounting eliminates damping from contact with other surfaces, allowing free vibration. For flagstone quartzite recognition Arizona purposes, the quality of resonance provides reliable preliminary identification that you should confirm through hardness and acid testing. Dense limestone can also ring when struck, which is why you must combine acoustic testing with chemical verification to rule out carbonate stone.

Weathering Resistance Indicators

When you evaluate existing installations, weathering patterns reveal long-term performance differences between quartzite and alternative flagstone materials. Quartzite maintains sharp edges and crisp surface detail even after decades of exposure to Arizona’s intense UV radiation and temperature cycling. You’ll observe that sandstone weathers with rounded edges, surface pitting, and grain loss that accelerates over time. These deterioration patterns result from weaker intergranular bonds that fail under thermal stress and moisture cycling.

Your forensic assessment of older hardscapes provides practical data for material specification decisions. Examine 10-15 year old installations and document edge condition, surface integrity, and whether foot traffic has created worn pathways. Quartzite shows minimal change beyond surface dirt accumulation, while sandstone exhibits measurable thickness loss in high-traffic zones. For professional guidance on durable material options, see Citadel Stone’s flagstone dealer services for comprehensive selection criteria. This performance history demonstrates why flagstone stone hardness verification matters during initial material selection rather than after installation failure.

Thermal Expansion Characteristics

Quartzite’s crystalline structure produces specific thermal expansion behavior that affects installation design in Arizona’s extreme temperature environment. The material expands at approximately 5.8 × 10⁻⁶ per degree Fahrenheit, lower than most sandstone varieties that range from 6.5-7.5 × 10⁻⁶ per degree Fahrenheit. When you calculate joint spacing requirements, this difference impacts long-term installation stability. Summer surface temperatures regularly exceed 160°F on dark-colored flagstone, creating expansion forces that can crack inadequately jointed installations.

Your specification must account for the directional properties of thermal expansion in flagstone applications. Quartzite derived from directionally bedded sandstone may show anisotropic expansion, meaning expansion rates vary depending on orientation relative to original bedding planes. You should request information about quarrying orientation and incorporate this data into layout planning. Professional installations orient flagstone to minimize differential expansion across individual pieces, reducing stress concentration at joints and connection points.

Commercial Mislabeling Concerns

The commercial stone market frequently mislabels materials, making independent flagstone quartzite recognition Arizona verification essential for your projects. Suppliers sometimes apply the term quartzite to hard sandstone or quartzitic sandstone that hasn’t undergone complete metamorphism. These intermediate materials cost less than true quartzite but lack equivalent durability. You protect project outcomes by conducting on-site verification rather than relying solely on supplier descriptions or product literature.

Your due diligence should include reviewing geological source data when available. True quartzite originates from specific metamorphic formations that you can verify through quarry location research. Materials sourced from sedimentary formations cannot represent genuine quartzite regardless of hardness or appearance. For flagstone mineral identification purposes, request documentation of geological source and conduct independent testing of representative samples. The cost of verification testing represents a small fraction of potential replacement expenses if inferior material fails prematurely in your installation.

- Request quarry location and geological formation documentation from suppliers

- Conduct independent hardness testing on random samples from each delivery

- Verify acid reaction results match quartzite’s inert response

- Document fracture patterns and acoustic properties in acceptance records

- Maintain test results as warranty protection against material substitution

Citadel Stone: Flagstone Dealers in Arizona — Quartzite Specification Guidance

When you evaluate flagstone dealers for Arizona projects, you need suppliers who understand material verification protocols and can provide documented quartzite specifications. At Citadel Stone, we maintain inventory selection processes that verify flagstone stone hardness and mineral composition before material enters our distribution system. This section outlines how you would approach flagstone quartzite recognition Arizona requirements across three representative cities with distinct climate challenges and installation conditions.

Arizona’s geographic diversity creates varying performance requirements that affect your material selection decisions. Extreme heat, minimal precipitation, and intense solar radiation characterize the desert environment, but elevation differences and urban heat island effects modify local conditions significantly. You should consider these regional factors when specifying quartzite flagstone to ensure optimal performance throughout your project’s service life.

Yuma Heat Specifications

In Yuma, you would encounter the nation’s most intense solar radiation combined with summer temperatures exceeding 120°F. Your quartzite specification needs to address thermal shock resistance as daily temperature swings reach 40-50°F between night and midday. You should verify that flagstone hard stone identification confirms material capable of withstanding these cycles without developing thermal fractures. Light-colored quartzite would provide thermal reflectivity advantages, reducing surface temperatures by 20-30°F compared to darker alternatives. Your installation design should incorporate expansion joints every 12-15 feet to accommodate thermal movement in this extreme environment.

Mesa Urban Applications

When you plan Mesa installations, you need to account for urban heat island effects that amplify already extreme desert temperatures. Your flagstone mineral identification process should verify quartzite’s low porosity characteristics because reduced water absorption minimizes staining from urban pollutants and irrigation system minerals. You would specify material with minimum Mohs hardness rating of 7 to ensure durability under heavy pedestrian traffic common in commercial developments. Mesa’s alkaline soils require you to verify complete quartzite composition through acid testing, as carbonate stones deteriorate rapidly in contact with local groundwater that frequently exceeds pH 8.5.

Gilbert Residential Standards

Your Gilbert project specifications would emphasize flagstone quartzite recognition Arizona protocols that verify aesthetic consistency alongside structural performance. Residential clients typically prioritize color uniformity and surface finish quality while requiring you to ensure long-term durability. You should conduct fracture pattern analysis to confirm transgranular breaks characteristic of true quartzite, as this indicates material that will maintain sharp edges and clean appearance throughout decades of exposure. Gilbert’s master-planned communities often mandate specific design standards that require you to provide documented verification of material properties. Your specification package should include density measurements, hardness test results, and acid reaction documentation to satisfy architectural review requirements. You would recommend light-colored quartzite varieties that coordinate with regional architecture while providing superior thermal performance in Gilbert’s exposed residential settings.

Quality Verification Documentation

Your professional practice should include systematic documentation of all flagstone quartzite recognition Arizona testing procedures. Photographic records of fracture patterns, written results of hardness testing, and witnessed acid reaction tests create a verification trail that protects against material substitution during project execution. You should establish acceptance criteria before material delivery and conduct random sample testing on each truck shipment to confirm consistency with approved specimens.

Testing frequency depends on project scale and material sourcing. For large projects exceeding 5,000 square feet, you should test at least three random samples per delivery load. Smaller residential projects may require testing only initial samples plus random verification of subsequent deliveries. Your documentation should include test date, specific location within the delivery from which samples were drawn, and results of all verification procedures. This record establishes baseline quality standards that you can reference if performance issues emerge during the warranty period.

Specification Language Recommendations

When you write formal project specifications, precise language ensures contractors source appropriate materials matching your design intent. Generic terms like “hard flagstone” or “durable natural stone” leave interpretation gaps that lead to unsuitable material substitution. Your specifications should explicitly state “metamorphic quartzite flagstone” and include verifiable performance criteria that contractors must demonstrate through testing before installation begins.

Effective specification language includes measurable parameters you can verify in the field. Require minimum Mohs hardness of 7.0, maximum water absorption under 1% by weight, and density not less than 160 pounds per cubic foot. State that material must show no reaction to 10% hydrochloric acid and must exhibit conchoidal fracture patterns when broken. These specific criteria enable objective flagstone hard stone identification that eliminates ambiguity about acceptable materials. At Citadel Stone, we recommend including sample approval procedures that require you to physically approve representative specimens before bulk material ordering proceeds.

Maintenance Performance Expectations

Quartzite flagstone requires minimal maintenance compared to sedimentary alternatives, but you should establish realistic expectations with clients regarding long-term care requirements. The material’s low porosity resists staining from organic debris, food spills, and irrigation water minerals. You’ll find that routine sweeping and occasional rinsing with water maintains appearance indefinitely in most residential applications. Commercial installations with heavy foot traffic may require annual pressure washing to remove ground-in dirt from texture variations in the stone surface.

Your maintenance recommendations should address joint sand retention, which affects long-term installation stability more than stone deterioration. Quartzite’s durability means the surrounding installation components typically determine service life rather than stone failure. You should specify polymeric sand for joints in high-traffic areas to minimize loss from foot traffic and water erosion. Expect to add supplemental joint sand every 3-5 years in residential applications and annually in commercial settings. This maintenance addresses installation system requirements rather than stone deterioration, reflecting quartzite’s superior longevity compared to alternatives requiring surface sealing and periodic replacement.

Performance Advantages

Understanding quartzite’s performance advantages helps you justify material selection decisions when project budgets create pressure to specify less expensive alternatives. The metamorphic stone delivers measurably superior outcomes across multiple criteria that affect both immediate installation success and long-term ownership costs. Your cost analysis should account for lifecycle performance rather than only initial material pricing, as quartzite’s durability eliminates replacement expenses that make softer stone ultimately more costly.

Slip resistance represents one area where flagstone stone hardness directly impacts safety performance. Quartzite’s crystalline texture provides superior traction in wet conditions compared to smooth-grained sandstone that becomes slippery when moisture films form on the surface. You can specify flamed or thermal finishes that enhance this natural slip resistance without compromising structural integrity. Arizona’s intense sun creates surface temperatures that make slip resistance crucial around pools and water features where barefoot traffic predominates. The material’s ability to maintain texture through decades of exposure ensures consistent safety performance throughout your installation’s service life. For additional context on comparative material properties, review Physical property differences between flagstone and slate materials before finalizing your specification documents. As a leading supplier of premium natural stone, Citadel Stone delivers high-quality flagstone to homeowners and contractors across Arizona, including Phoenix, Scottsdale, and Tucson.