When you specify paving materials for Arizona projects, understanding the fundamental differences between flagstone and limestone becomes critical for long-term performance. The flagstone limestone contrast Arizona presents involves distinct geological origins, structural characteristics, and field behavior that directly impact your installation success. You’ll encounter these materials in different contexts — flagstone as a broad category of sedimentary stones split along natural bedding planes, and limestone as a specific carbonate-based sedimentary rock with unique chemical composition.

Your material selection process requires you to distinguish between flagstone composition comparison factors including porosity ranges, hardness variations, and thermal response characteristics. The flagstone material differences extend beyond aesthetics into structural performance metrics that affect everything from slip resistance to long-term maintenance requirements. You need to evaluate how flagstone stone types respond to Arizona’s extreme temperature swings, intense UV exposure, and minimal precipitation patterns that create unique weathering conditions.

Geological Formation Differences

The flagstone geology comparison starts with understanding formation processes that occurred millions of years apart under vastly different environmental conditions. Flagstone represents sedimentary rocks that developed horizontal bedding planes through layered sediment deposition, allowing them to split into flat slabs along these natural cleavage lines. You’ll find flagstones formed from sandstone, quartzite, slate, and yes, even limestone — the term describes the splitting characteristic rather than a specific mineral composition.

Limestone forms specifically through accumulation of calcium carbonate from marine organisms, coral reefs, and chemical precipitation in ancient sea environments. When you examine limestone’s crystalline structure, you’re looking at material that originated 100-500 million years ago in shallow tropical seas. The flagstone limestone contrast Arizona professionals encounter involves comparing this specific carbonate rock against the broader flagstone category that includes silica-based formations with completely different hardness and porosity profiles.

Your specification decisions should account for how these formation differences translate into field performance. Limestone’s calcium carbonate content makes it reactive to acidic conditions, while silica-based flagstones like sandstone and quartzite resist chemical weathering but respond differently to thermal stress. You need to understand that Arizona’s alkaline soils with pH levels ranging from 7.8 to 8.4 interact differently with limestone compared to silica-based alternatives in the flagstone category.

Mineral Composition Structural Analysis

The flagstone composition comparison reveals fundamental differences in mineral makeup that determine durability characteristics. When you specify limestone, you’re working with material that’s 95-99% calcium carbonate (CaCO₃), often with minor amounts of clay minerals, iron oxides, and silica. This homogeneous composition creates consistent behavior across thermal expansion, water absorption, and chemical resistance parameters.

Flagstone material differences become apparent when you evaluate the diverse mineral compositions within this category:

- Sandstone flagstone contains 65-95% quartz (SiO₂) with varying clay and feldspar content affecting porosity from 8-25%

- Quartzite flagstone consists of 90-99% recrystallized quartz creating density of 2.6-2.7 g/cm³ and minimal porosity below 3%

- Slate flagstone contains mica, chlorite, and quartz in metamorphic alignment producing anisotropic properties along cleavage planes

- Limestone flagstone maintains calcium carbonate dominance with density of 2.3-2.7 g/cm³ and porosity ranging 5-15%

You should recognize that the flagstone limestone contrast Arizona applications require involves comparing a specific rock type against a diverse category. Your warehouse lead times may vary based on which flagstone stone types you specify, as quarrying operations and regional availability differ significantly between limestone sources and silica-based alternatives.

Hardness Durability Specifications

When you evaluate hardness for Arizona installations, the flagstone geology comparison reveals critical performance differences. Limestone typically measures 3-4 on the Mohs hardness scale, making it softer than most silica-based flagstones. You’ll find sandstone flagstone ranges from 6-7 on Mohs scale due to quartz content, while quartzite flagstone reaches 7-7.5, approaching the hardness of pure quartz crystal.

Your specification process must account for how this hardness differential affects long-term wear patterns. In high-traffic commercial applications, limestone shows surface wear after 12-18 years under pedestrian loads exceeding 5,000 passes annually per square foot. Sandstone and quartzite flagstones maintain surface integrity for 20-30 years under identical conditions. The flagstone material differences in abrasion resistance become particularly relevant when you design pool decks, commercial walkways, or vehicular-rated surfaces.

Compressive strength specifications further distinguish these materials. Limestone exhibits compressive strength ranging 4,000-20,000 PSI depending on porosity and density. You should verify that your selected limestone exceeds 8,000 PSI for Arizona applications where thermal cycling imposes additional stress. Quartzite flagstone provides compressive strength of 20,000-30,000 PSI, allowing you to specify thinner units for the same structural performance.

Thermal Performance Arizona Conditions

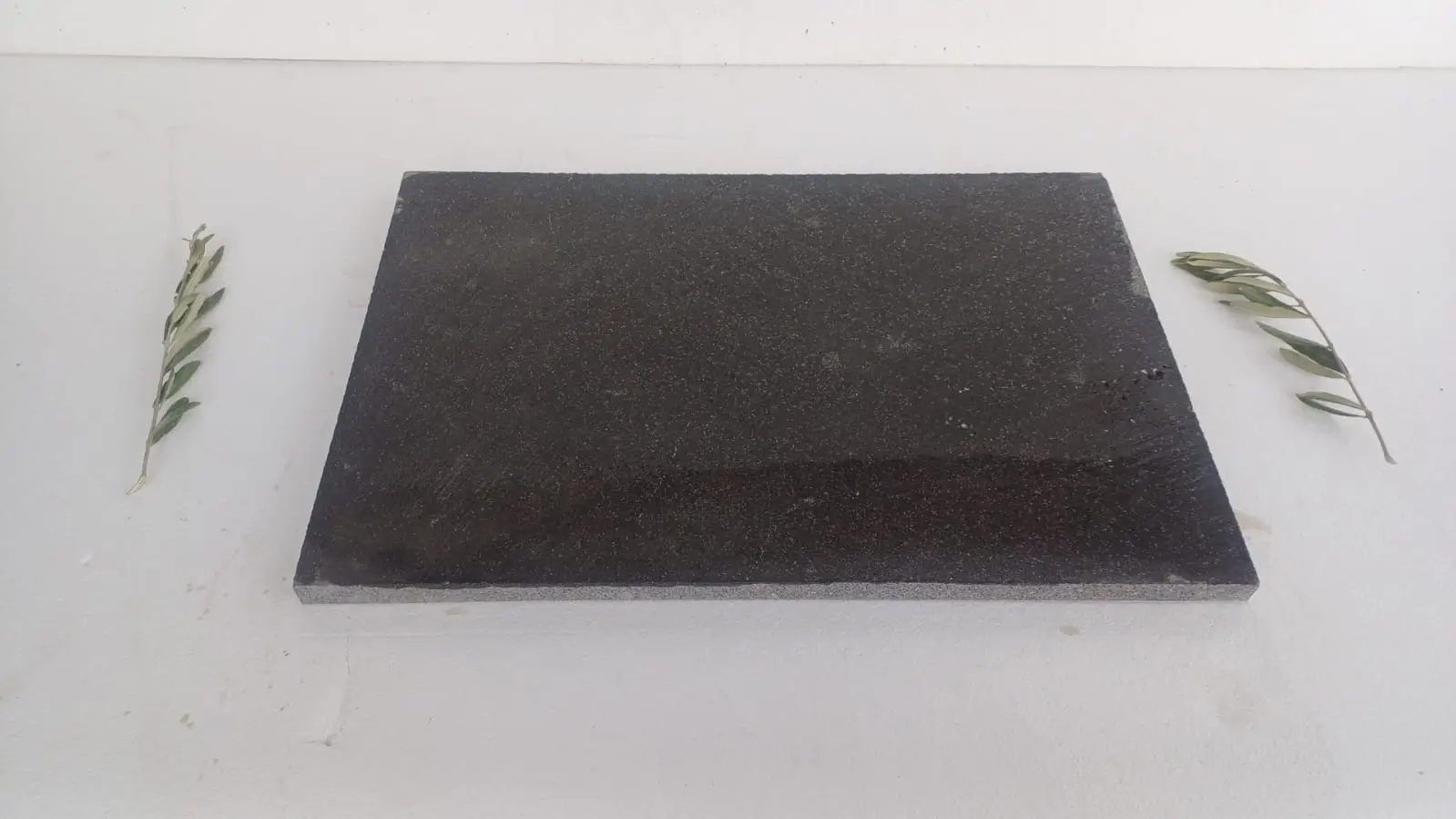

The flagstone limestone contrast Arizona projects demand focuses heavily on thermal behavior under extreme heat exposure. You need to understand that surface temperatures in Phoenix regularly reach 160-180°F on dark-colored stone during June through August. Limestone’s thermal conductivity of 1.3-1.5 W/m·K creates different heat retention patterns compared to sandstone flagstone at 1.7-2.2 W/m·K.

When you specify materials for barefoot traffic areas like pool decks and patios, thermal mass properties determine user comfort. Limestone absorbs heat more slowly than dense quartzite but retains thermal energy longer than porous sandstone. You’ll find that light-colored limestone maintains surface temperatures 15-25°F cooler than dark granite or basalt under identical solar exposure, making it preferable for residential applications where you need to minimize heat island effects.

Your thermal expansion calculations must address how flagstone composition comparison affects dimensional stability. Limestone expands at coefficient of 5.0-8.0 × 10⁻⁶ per °F, while sandstone flagstone ranges 7.0-12.0 × 10⁻⁶ per °F depending on quartz content and porosity. For Citadel Stone manufactured flagstone pavers, you should specify expansion joints every 12-15 feet in Arizona installations, adjusting based on expected temperature differential from installation conditions to peak summer exposure.

Porosity Water Absorption Behavior

You’ll encounter significant variation in porosity when comparing flagstone stone types. Limestone porosity ranges from 5-20% depending on formation density, with most architectural grades falling between 8-12%. This interconnected pore structure allows water absorption of 2-6% by weight, which becomes critical when you evaluate freeze-thaw performance for elevated Arizona locations above 5,000 feet.

The flagstone material differences in porosity directly affect your sealer selection and maintenance protocols:

- Dense limestone at 5-8% porosity requires penetrating sealers applied at 150-200 sq ft per gallon

- Sandstone flagstone at 12-18% porosity needs sealer coverage rates of 80-120 sq ft per gallon for equivalent protection

- Quartzite flagstone below 3% porosity may not accept penetrating sealers effectively

- Slate flagstone with directional porosity requires you to account for variation perpendicular versus parallel to cleavage planes

Your specification should address how Arizona’s low humidity and high evaporation rates interact with stone porosity. You need to recognize that materials with porosity above 12% dry rapidly after monsoon events, reducing efflorescence risk but potentially allowing deeper salt penetration during wet periods. The flagstone geology comparison reveals that limestone’s calcium carbonate matrix creates different capillary action compared to silica-based alternatives, affecting subsurface moisture migration patterns.

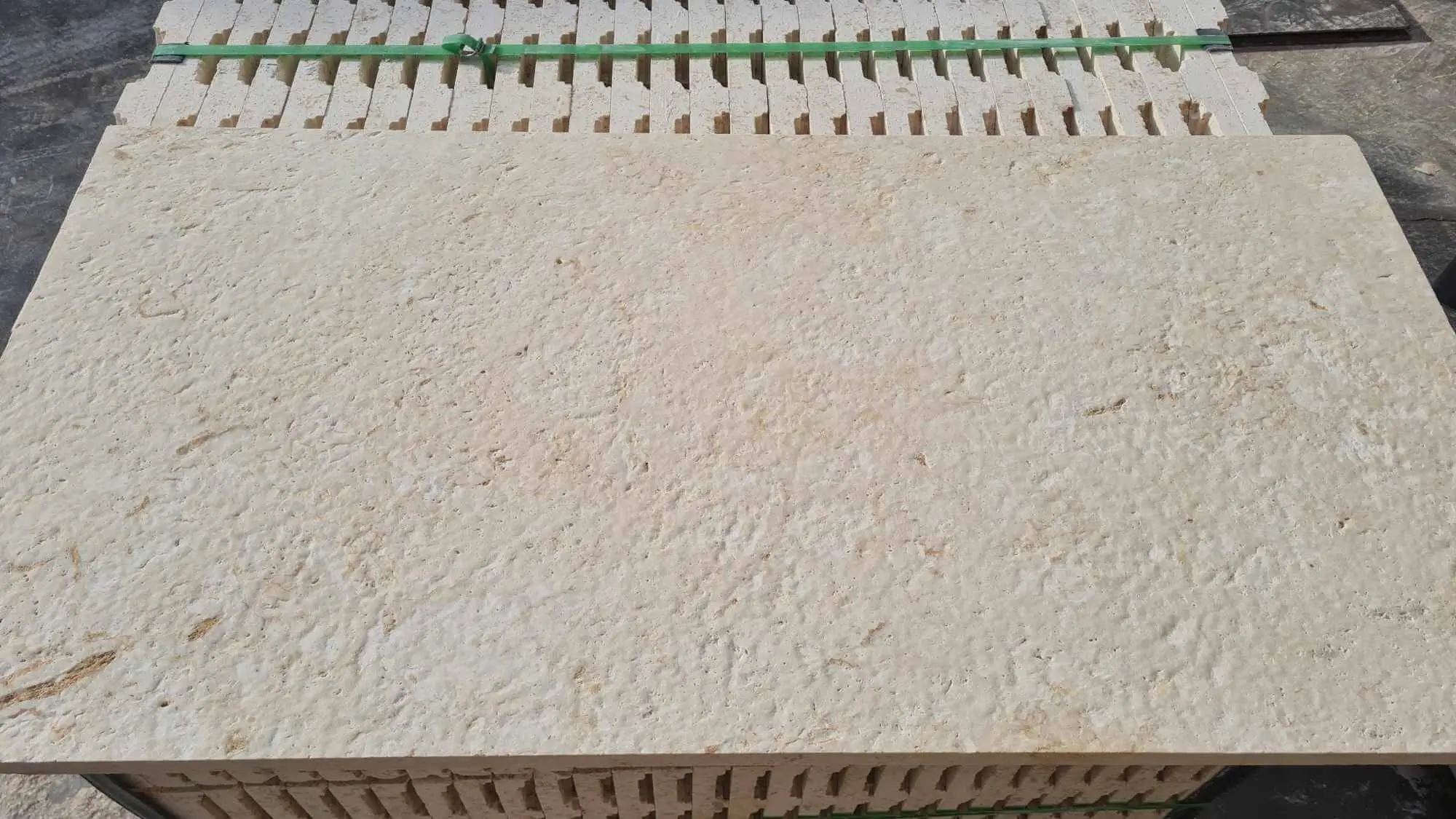

Color Consistency Aesthetic Variation

When you evaluate aesthetic characteristics, the flagstone limestone contrast Arizona designers consider involves color range and natural variation patterns. Limestone offers relatively consistent coloration within each quarry source, typically presenting buff, tan, gray, or cream tones determined by iron oxide content and organic material present during formation. You can expect color variation of ±15% within a single limestone pallet, allowing you to achieve uniform appearance when that’s your design intent.

Flagstone composition comparison shows greater color diversity across the category. Sandstone flagstone ranges from white to red to brown depending on iron oxide concentration, with individual pieces often displaying dramatic color banding and variation. You’ll find quartzite flagstone in white, pink, and gold tones with sparkle effects from mica inclusions. Your clients seeking uniform appearance benefit from limestone’s consistency, while those wanting natural variation prefer sandstone or slate flagstone options.

You should account for how Arizona’s intense UV exposure affects long-term color stability. Limestone maintains color consistency over decades with minimal fading, as calcium carbonate doesn’t degrade under ultraviolet radiation. Some iron-rich sandstone flagstones show color intensification over 3-5 years as oxidation continues post-installation. The flagstone material differences in photostability affect your maintenance recommendations and client expectations for appearance evolution.

Surface Texture Slip Resistance

Your slip resistance specifications require understanding how flagstone stone types develop different surface textures. Natural cleft limestone surfaces exhibit moderate texture with DCOF (Dynamic Coefficient of Friction) values ranging 0.50-0.65 when dry and 0.42-0.55 when wet. These values satisfy ADA requirements for walking surfaces, making limestone suitable for most residential and commercial applications without additional treatment.

The flagstone geology comparison reveals that silica-based options often provide superior slip resistance. Sandstone flagstone naturally develops rough surfaces during splitting, achieving DCOF values of 0.60-0.75 dry and 0.52-0.68 wet. You need quartzite flagstone for maximum slip resistance, with natural cleft surfaces reaching 0.70-0.85 dry. When you specify pool decks or other wet-area applications, these differences become safety-critical rather than merely preferential.

You should recognize that surface finishing dramatically affects slip performance across all materials. Thermal finishing, bush-hammering, or sandblasting can increase limestone DCOF values to 0.65-0.75 when wet, but these treatments add cost and reduce natural appearance. Your specification decisions balance safety requirements against aesthetic preferences and budget constraints, with the flagstone limestone contrast Arizona projects present offering multiple pathways to compliant solutions.

Chemical Resistance Maintenance Requirements

When you develop maintenance protocols, understanding chemical reactivity differences between limestone and other flagstone material types becomes essential. Limestone’s calcium carbonate composition makes it susceptible to acid etching from pH levels below 6.5. You’ll encounter problems if clients use acidic cleaners, allow citrus or wine spills to remain on surfaces, or if acid rain exposure occurs in industrial areas.

The flagstone composition comparison shows that silica-based options resist acid attack. Sandstone and quartzite flagstone maintain surface integrity when exposed to pH levels as low as 3.0, allowing you to specify these materials for environments where acidic exposure is likely. Your maintenance recommendations should reflect these differences — limestone requires pH-neutral cleaners exclusively, while sandstone tolerates broader cleaner chemistry without damage.

You need to address how Arizona’s alkaline conditions affect both categories. Subsurface moisture wicking through alkaline soils with pH 8.0-8.5 creates efflorescence risk as salts migrate to stone surfaces. Limestone’s porosity and calcium carbonate content make it more susceptible to salt crystallization damage compared to dense quartzite. Your installation specifications should include vapor barriers and proper drainage design to minimize subsurface moisture exposure regardless of material selection.

Installation Methodology Considerations

Your installation approach varies based on flagstone material differences in thickness consistency and splitting characteristics. Limestone flagstone typically mills to consistent thickness tolerances of ±1/4 inch, allowing you to install over mortar beds or pedestal systems with predictable leveling requirements. You’ll find that manufactured limestone units provide even tighter tolerances of ±1/8 inch, reducing installation labor and improving surface flatness.

Naturally split flagstone stone types present greater thickness variation, often ranging ±3/4 inch within a single pallet. When you install sandstone or quartzite flagstone, you need additional time for sorting, shimming, and leveling to achieve acceptable surface planes. This installation complexity affects labor costs by 20-35% compared to consistent-thickness limestone, though many clients value the rustic appearance that accompanies natural variation.

You should specify base preparation differently based on material weight and porosity. Dense limestone and quartzite flagstone at 165-170 pounds per cubic foot require compacted aggregate bases achieving 95% modified Proctor density. Lighter sandstone flagstone at 135-145 pounds per cubic foot performs adequately over bases compacted to 92% density. Your truck scheduling for material delivery must account for these weight differences when calculating load limits and delivery logistics.

Cost Analysis Value Comparison

When you evaluate project budgets, the flagstone limestone contrast Arizona market presents involves both material costs and lifecycle value considerations. Limestone typically prices between $4.50-$8.50 per square foot for natural cleft pavers in standard thicknesses, with premium selections reaching $10-$12 per square foot. Your warehouse costs for maintaining inventory may be lower for limestone due to consistent demand and established supply chains.

Flagstone composition comparison shows that sandstone options typically fall within similar price ranges of $5.00-$9.00 per square foot, while premium quartzite flagstone commands $12-$18 per square foot due to limited quarrying locations and superior hardness. You need to factor installation cost differentials — limestone’s consistency reduces labor by approximately $1.50-$2.50 per square foot compared to irregular-thickness flagstone alternatives.

Your lifecycle cost analysis should extend beyond initial installation to maintenance expenses over 20-30 year service life. Limestone requires resealing every 3-5 years at cost of $0.75-$1.25 per square foot, while dense quartzite flagstone may require sealing only every 7-10 years. The flagstone material differences in durability mean that limestone may need replacement in high-traffic areas after 18-22 years, while quartzite performs for 30+ years under identical conditions.

Citadel Stone Manufactured Flagstone Pavers Arizona Specifications

When you consider manufactured flagstone alternatives for Arizona projects, Citadel Stone provides engineered solutions that address many challenges inherent in natural stone specification. At Citadel Stone, we produce manufactured flagstone pavers that combine aesthetic appeal of natural materials with performance consistency required for demanding commercial applications. This section outlines how you would approach material selection for three representative Arizona cities with distinct climate and soil conditions.

Your specification process benefits from manufactured products’ controlled porosity, consistent dimensions, and predictable thermal behavior. You should evaluate how these characteristics affect your project’s timeline, budget, and long-term maintenance requirements when comparing options.

San Tan Valley Applications

In San Tan Valley, you would need to address extreme heat combined with expansive clay soil conditions that create challenging substrate movement. Your manufactured flagstone specification would require compressive strength exceeding 10,000 PSI to accommodate thermal cycling from 115°F summer peaks to occasional winter freezes. You should account for soil expansion potential ranging 4-6 inches seasonally, requiring you to design floating installations over properly engineered aggregate bases. At Citadel Stone, our technical team recommends 12-inch compacted base depth with geotextile separation layers when you encounter clay soils with plasticity index above 25.

Yuma Desert Performance

Yuma represents Arizona’s most extreme heat environment where you would encounter surface temperatures exceeding 180°F during peak summer months. Your manufactured flagstone selection would prioritize light colors with solar reflectance values above 0.65 to minimize heat absorption and maintain usable surface temperatures. You need to specify materials with thermal expansion coefficients below 6.0 × 10⁻⁶ per °F to limit dimensional movement in installations spanning 20+ feet without expansion joints. When you design commercial hardscape in Yuma, you should account for how minimal precipitation of 3.5 inches annually creates unique efflorescence conditions as subsurface moisture wicks upward through alkaline soils with pH levels reaching 8.6.

Avondale Urban Requirements

Your Avondale specifications would address urban heat island effects in rapidly developing residential areas where hardscape coverage exceeds 40% of lot area. You would select manufactured flagstone pavers with enhanced porosity of 6-8% to support permeable installation systems that reduce stormwater runoff per municipal requirements. When you specify for Avondale’s mixed-use developments, you need slip resistance meeting DCOF 0.60 minimum for pedestrian areas while providing aesthetic consistency across large-format installations spanning 5,000+ square feet. Your truck delivery coordination would account for warehouse inventory positioned in Phoenix metro to ensure 3-5 day lead times for material availability.

Field Identification Professional Verification

When you receive material deliveries, your ability to verify correct stone type prevents costly installation errors. The flagstone limestone contrast Arizona professionals use for field identification starts with simple acid testing. You should apply dilute hydrochloric acid (10% solution) to an inconspicuous area — limestone will effervesce vigorously as calcium carbonate reacts with acid, while silica-based flagstones show no reaction.

Your visual inspection should assess cleavage patterns and surface characteristics. Limestone typically exhibits relatively smooth natural cleft surfaces with subtle texture variation, while sandstone flagstone displays more pronounced layering and often visible grain structure. You’ll notice that quartzite flagstone has glassy luster when viewed at oblique angles, distinguishing it from duller limestone and sandstone options.

You need to verify dimensional consistency matches your specifications before installation proceeds. Random sampling of 10 pieces per pallet should reveal thickness variation within specified tolerances — if variation exceeds ±1/2 inch when you ordered consistent-thickness limestone, the delivery may contain mixed material requiring correction before you commit to installation.

Professional Selection Strategy

Your material selection process should integrate multiple performance factors rather than focusing solely on aesthetics or initial cost. When you evaluate the flagstone limestone contrast Arizona installations present, you need to prioritize thermal performance, slip resistance, and maintenance requirements alongside appearance preferences. Projects requiring maximum durability in high-traffic applications benefit from quartzite flagstone despite higher costs, while residential patios with moderate use perform well with properly sealed limestone at lower investment.

You should develop specifications that account for regional variations within Arizona. Northern Arizona locations above 5,000 feet elevation require you to address freeze-thaw resistance, making porosity and water absorption critical factors. Southern Arizona projects focus on heat management and UV stability where thermal mass and color selection determine user comfort. Your warehouse coordination should verify that selected materials suit the specific microclimate conditions at your project site rather than applying generic Arizona specifications.

When you finalize material selection, you’ll benefit from understanding that no single material optimally satisfies all criteria. The flagstone composition comparison reveals trade-offs between cost, durability, aesthetics, and maintenance across all options. Your professional responsibility involves clearly communicating these trade-offs to clients and selecting materials that align with project priorities. For comprehensive guidance on related paving options, review Distinguishing flagstone from sandstone in Arizona landscaping projects before you finalize your project specifications. Citadel Stone’s variety makes it most-complete wholesale flagstone pavers in Arizona selection.