When you design spa and hot tub surrounds in Arizona, you’re dealing with a unique combination of challenges that most standard paving specifications don’t address. The interaction between constant water splash, chemical exposure from sanitizers, and Arizona’s extreme temperature swings creates performance demands that require you to rethink conventional material selection. Your paving stone spa surrounds Arizona installations need to withstand surface temperatures exceeding 160°F while simultaneously handling pH levels ranging from 7.2 to 8.0 in chlorinated water exposure zones.

You’ll encounter three critical failure modes in poorly specified installations: chemical etching from bromine and chlorine contact, efflorescence migration from subsurface moisture, and thermal shock cracking from rapid temperature cycling. The splash zone extending 18-24 inches from the spa perimeter experiences the most aggressive exposure conditions. When you specify materials for these applications, you need to understand how porosity, surface finish, and chemical composition interact with sanitizer chemistry and thermal stress.

What separates successful paving stone hot tub perimeter Arizona projects from premature failures is your attention to how water infiltration patterns affect long-term performance. You should account for the fact that spa water contains 3-5 ppm chlorine or 4-6 ppm bromine continuously, creating a persistent chemical exposure scenario that accelerates material degradation in susceptible stone types. Your specification must address both the immediate splash contact zone and the secondary migration area where subsurface moisture carries dissolved chemicals through capillary action.

Chemical Exposure Performance Factors

The chemistry of spa and pool water creates specific material stress conditions you need to understand before you finalize specifications. Chlorine-based sanitizers maintain oxidation-reduction potential (ORP) levels between 650-750 mV, which actively oxidizes calcium carbonate and certain silicate minerals. When you evaluate paving stone chemical resistant surfaces Arizona applications, you’re looking for materials with minimal reactive mineral content and controlled porosity that limits chemical penetration depth.

Your material selection needs to account for pH fluctuations that occur during chemical balancing cycles. Spa water pH typically ranges from 7.2 to 7.8, but adjustment processes can temporarily expose surfaces to pH levels outside this range. You’ll see accelerated etching in high-calcium stones when pH drops below 7.0 during acid dosing, and efflorescence formation when pH exceeds 8.2 following alkalinity adjustment. The paving stone spa surrounds Arizona specifications must specify materials with acid resistance verified through ASTM C267 testing, showing less than 2% mass loss after 24-hour exposure to 10% hydrochloric acid solution.

- You should verify that chemical composition shows less than 15% calcium carbonate content for optimal sanitizer resistance

- Your porosity specifications need to target 3-6% absorption rates measured per ASTM C97 standards

- You need surface hardness ratings of at least 6.5 on Mohs scale to resist abrasive cleaning compound damage

- Your material must demonstrate pH stability across the 6.8-8.5 range without visible etching or discoloration

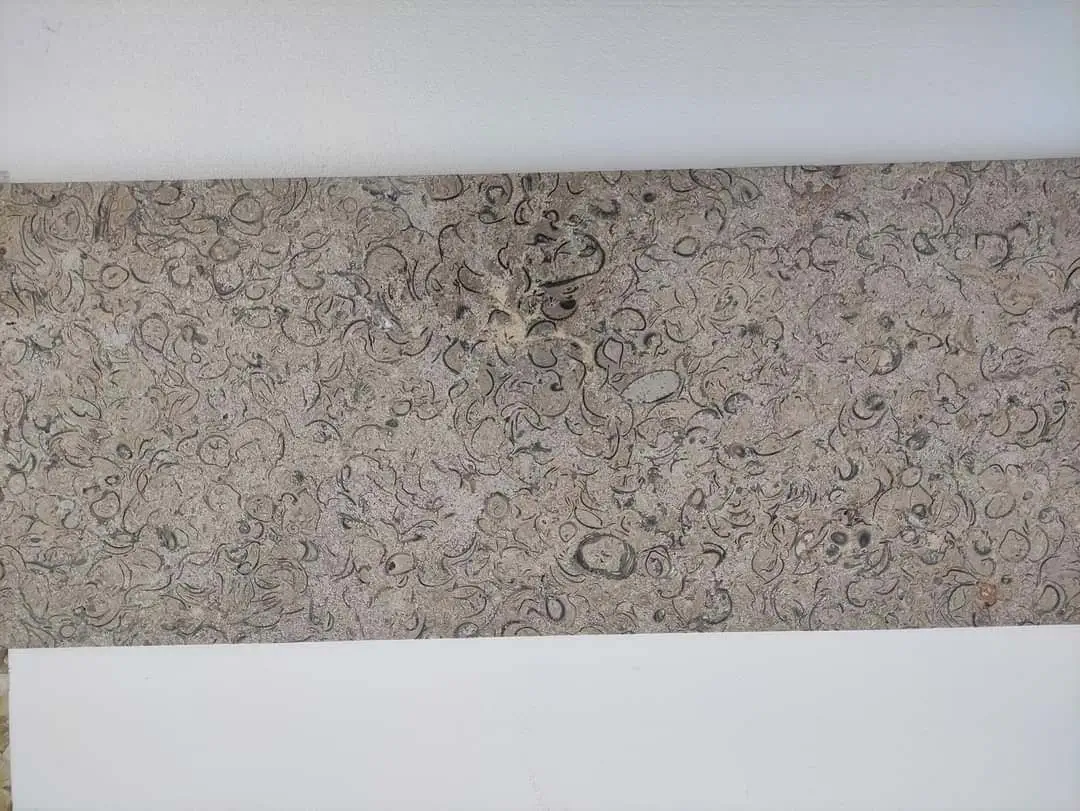

The interaction between sanitizer chemistry and mineral composition determines long-term appearance retention. You’ll find that high-silica materials with minimal carbonate content maintain original surface characteristics for 15-20 years in continuous chemical exposure, while limestone-based products show visible degradation within 3-5 years. When you specify paving stone chemical resistant surfaces Arizona installations, you’re selecting materials based on their mineralogical stability rather than just compressive strength ratings.

Splash Zone Material Requirements

Your paving stone water feature edges Arizona design must recognize that the splash zone experiences fundamentally different exposure conditions than the general deck area. Water droplets landing on hot surfaces create localized thermal shock events, with temperature differentials reaching 80-120°F within seconds. You need materials with thermal expansion coefficients below 6.0 × 10⁻⁶ per °F and thermal conductivity values that prevent extreme surface heating.

The splash pattern from spa jets extends 24-36 inches depending on jet configuration and operating pressure. When you calculate your layout, you should map the primary splash zone where surfaces receive direct water contact at least twice per operating cycle, and the secondary zone where occasional splash and drainage patterns create intermittent exposure. Your paving stone splash zone materials Arizona selections need to address both areas with appropriate material grades and surface treatments.

You’ll encounter a specific challenge with surface texture selection for these zones. Smooth finishes show chemical etching more prominently but are easier to clean and maintain. Textured surfaces hide minor degradation better but can accumulate sanitizer residue in surface irregularities, creating localized high-concentration exposure that accelerates deterioration. Professional specifications typically call for thermal finishes or light shot-blasting that provides 0.50-0.55 DCOF slip resistance while maintaining cleanability.

- You need to specify materials with water absorption rates below 5% to limit chemical penetration into the substrate

- Your surface finish should provide slip resistance above 0.48 DCOF when wet without creating residue-trapping texture

- You should require edge details that prevent standing water accumulation within 6 inches of the spa perimeter

- Your drainage slope must exceed 2% within splash zones to ensure rapid water evacuation

The subsurface preparation beneath splash zones requires your attention to details that standard paving specs often overlook. You need base materials with permeability coefficients exceeding 120 inches per hour to prevent subsurface saturation that causes efflorescence and joint deterioration. When you design drainage systems for paving stone hot tub perimeter Arizona projects, you’re creating a comprehensive moisture management strategy that addresses both surface runoff and subsurface infiltration.

Thermal Cycling Durability

Arizona’s temperature extremes create thermal stress conditions that compound chemical exposure challenges. Your paving stone spa surrounds Arizona installations experience surface temperatures ranging from 40°F on winter nights to 165°F on summer afternoons. When you add the rapid cooling effect of water splash on superheated surfaces, you’re creating thermal shock scenarios that test material integrity continuously.

The coefficient of thermal expansion becomes your critical specification parameter. Materials expanding more than 0.0007 inches per linear foot per 100°F temperature change will develop visible joint separation or internal stress fractures within 5-7 years. You need to specify expansion joint spacing that accommodates cumulative movement across seasonal temperature ranges while maintaining structural integrity during daily cycling events.

You’ll observe that thermal mass properties affect both surface comfort and material durability. High thermal mass materials moderate surface temperature but create greater internal stress during rapid cooling. Low thermal mass materials heat and cool quickly, reducing internal stress but creating uncomfortably hot surfaces during peak exposure. Your specification should balance these factors based on installation orientation and shade patterns. For comprehensive guidance on material performance across different applications, review trade paver stone pricing to understand regional availability and specification options.

- You should verify thermal expansion coefficients through ASTM C531 testing showing values below 5.8 × 10⁻⁶ per °F

- Your material must demonstrate freeze-thaw stability through 50 cycles per ASTM C1645 without spalling or cracking

- You need to specify joint spacing that accommodates 0.125 inches of movement per 20 linear feet

- Your edge restraint system must allow controlled expansion while preventing displacement

Porosity and Absorption Characteristics

When you evaluate paving stone water feature edges Arizona materials, porosity becomes the determining factor in chemical resistance and durability. The pore structure characteristics—total porosity, pore size distribution, and pore connectivity—control how deeply chemicals penetrate and how effectively water evacuates from the material matrix. You’re looking for materials with 4-7% total porosity consisting primarily of disconnected micropores rather than interconnected macropores.

Your specification should require porosity testing that goes beyond simple water absorption measurements. You need pore size distribution analysis showing that 70% or more of total porosity exists in pores smaller than 10 microns. This pore structure allows minimal water absorption while preventing deep chemical penetration. Materials with large interconnected pores absorb water rapidly but also allow sanitizers to penetrate deeply, creating internal chemical exposure that causes subsurface degradation.

The relationship between porosity and freeze-thaw durability matters even in Arizona’s generally mild climate. Flagstaff and higher elevation installations experience 40-60 freeze-thaw cycles annually. When you specify materials for these locations, you need critical saturation coefficients below 0.78, meaning the material cannot absorb enough water to cause freeze-related damage. You’ll find this specification becomes essential for paving stone spa surrounds Arizona projects at elevations above 5,000 feet.

- You should specify absorption testing per ASTM C97 showing results between 3.5% and 6.5% by weight

- Your material requires pore size analysis demonstrating micropore dominance for chemical resistance

- You need saturation coefficient verification below 0.80 for installations experiencing freeze-thaw exposure

- Your specification must address how absorption characteristics affect slip resistance when wet

Surface Finish Considerations

The surface finish you specify for paving stone splash zone materials Arizona applications directly affects chemical resistance, slip resistance, and long-term maintenance requirements. Polished finishes provide minimal texture for residue accumulation but show etching more prominently and offer inadequate wet slip resistance. Heavily textured finishes hide minor degradation and provide excellent traction but trap sanitizer residue in surface irregularities.

You’ll achieve optimal performance with thermal or flamed finishes that create microsurface texture without deep relief patterns. This finish type provides 0.50-0.58 DCOF slip resistance when wet while maintaining surface smoothness that prevents residue accumulation. The finish also helps mask minor etching that occurs over time, maintaining appearance longer than polished surfaces.

Your surface finish specification needs to account for how texture affects cleaning protocols. Smooth finishes allow simple spray-and-rinse maintenance, while textured surfaces require periodic scrubbing with pH-neutral cleaners to remove accumulated residue. You should specify finishes that balance safety requirements with practical maintenance capabilities for the installation’s intended use patterns.

- You need slip resistance verification showing minimum 0.48 DCOF wet readings per ANSI A326.3 testing

- Your finish should provide texture depth between 0.010 and 0.025 inches for optimal performance

- You should avoid heavily textured finishes that create residue traps requiring aggressive chemical cleaning

- Your specification must address how finish type affects long-term appearance retention

Joint Spacing and Edge Details

When you design paving stone hot tub perimeter Arizona installations, joint spacing becomes critical for managing both thermal expansion and chemical drainage. Standard 3/16-inch joints work adequately for general paving but prove insufficient for spa surrounds where thermal cycling and water infiltration create additional stress. You need joint widths of 1/4 to 3/8 inch within the primary splash zone to accommodate expansion and facilitate rapid drainage.

Your joint fill material selection matters as much as joint width. Traditional polymeric sand performs poorly in continuous chemical exposure, breaking down within 18-24 months and requiring replacement. You should specify resin-modified joint compounds specifically formulated for pool deck applications, with chemical resistance verified through accelerated aging tests in chlorinated water. These materials maintain integrity for 8-12 years in active splash zones.

Edge details at the spa perimeter require your careful attention to prevent water infiltration beneath the paving system. You need a positive seal between the spa shell and paving surface, typically achieved with closed-cell backer rod and polyurethane or polysulfide sealant rated for continuous water immersion. The detail must accommodate thermal movement while preventing water migration into the base layers where it can cause efflorescence and structural settlement.

- You should specify joint widths of 1/4 inch minimum within 24 inches of spa perimeter

- Your joint fill must demonstrate chemical stability in 5 ppm chlorine solution for 2,000 hours minimum

- You need edge sealant with movement capability of ±25% and UV resistance for Arizona sun exposure

- Your detail drawings must show proper drainage away from spa perimeter at minimum 2% slope

Efflorescence Prevention Strategies

Efflorescence presents a persistent challenge in paving stone chemical resistant surfaces Arizona installations where chemical-laden water repeatedly wets and dries on stone surfaces. The white crystalline deposits form when water-soluble salts migrate to the surface through capillary action and crystallize as moisture evaporates. You’re dealing with salts from multiple sources: the stone itself, setting bed materials, base aggregates, and dissolved chemicals in spa water.

Your primary prevention strategy involves controlling moisture movement through the paving system. You need to specify materials with low inherent salt content, verified through water-soluble sulfate testing showing less than 0.1% sulfate content. The base and setting materials require similar verification to prevent salt migration from subsurface layers. You should also require subsurface drainage systems that prevent groundwater wicking upward through the installation.

The interaction between spa chemicals and efflorescence becomes particularly problematic when calcium-based balancing compounds dissolve in splash water and then deposit on paving surfaces. You’ll see this most prominently around jets and overflow edges where splash intensity is highest. Your maintenance specifications need to address regular cleaning with pH-neutral products that remove deposits without adding additional salts to the system.

- You should specify materials with water-soluble salt content below 0.08% measured per ASTM C1580

- Your base materials require similar salt content verification to prevent subsurface migration

- You need drainage systems that maintain subsurface moisture levels below critical saturation points

- Your maintenance protocol must include quarterly cleaning with low-residue neutral cleaners

Comparative Material Performance

Different stone types demonstrate vastly different performance characteristics in paving stone spa surrounds Arizona applications. High-silica materials like quartzite and granite provide superior chemical resistance and minimal thermal movement, maintaining appearance and integrity for 20+ years in active splash zones. Limestone and travertine offer aesthetic appeal but suffer progressive degradation in chemical exposure, typically requiring replacement or extensive maintenance within 8-12 years.

You need to understand the trade-offs each material category presents. Granite provides exceptional durability and chemical resistance but limited color range and higher initial cost. Porcelain pavers offer outstanding chemical stability and color consistency but require specialized installation techniques and careful edge protection. Natural sandstone balances moderate chemical resistance with broad aesthetic options and mid-range pricing, performing adequately when properly sealed and maintained.

Your selection process should evaluate materials based on total lifecycle cost rather than initial installed price. A limestone installation at $18 per square foot requiring replacement after 10 years costs more over 20 years than a granite installation at $28 per square foot lasting 25+ years with minimal maintenance. You need to present these comparisons to clients when specifying paving stone water feature edges Arizona projects.

- You should evaluate chemical resistance through accelerated aging in pH-adjusted chlorinated water

- Your cost analysis must include maintenance requirements and expected service life

- You need to consider how material selection affects overall design aesthetics and project value

- Your specifications should address backup material availability for future repairs or additions

Installation Protocol Requirements

Proper installation makes the difference between 20-year performance and 5-year failure in paving stone splash zone materials Arizona applications. Your specifications must address installation procedures that standard paving protocols don’t cover. The base preparation requires compaction to 96% modified Proctor density with materials showing less than 5% fines passing the #200 sieve. You need this level of compaction stability to prevent differential settlement when the base experiences repeated wetting and drying cycles from splash infiltration.

The setting bed composition requires modification from standard paving applications. You should specify portland cement-modified sand at 1:6 cement to sand ratio for installations within 36 inches of the spa perimeter. This modified bed provides chemical resistance and bonding strength that pure sand beds cannot match in chemical exposure conditions. You’ll need to ensure proper curing with mist application before exposing the installation to spa chemicals.

Your installation timing specifications need to account for material temperature during placement. You should restrict installation to periods when ambient temperature remains between 50°F and 85°F and material temperature stays below 95°F. Installation during extreme heat causes premature setting of modified beds and prevents proper compaction of polymeric or resin joint fills.

- You need base compaction verification through nuclear density testing showing 96% modified Proctor minimum

- Your setting bed should incorporate portland cement at 1:6 ratio within primary splash zones

- You must specify 72-hour cure period before exposing installations to chemical-laden water

- Your quality control protocol should include joint fill density verification and edge seal inspection

Citadel Stone – Premium Paving Wholesalers in Arizona Regional Specifications

When you evaluate Citadel Stone’s paving wholesalers in Arizona inventory for spa and hot tub surround applications, you’re considering materials specifically selected for chemical exposure and thermal cycling performance. At Citadel Stone, we maintain technical documentation on chemical resistance, porosity characteristics, and thermal properties for each product line. This section provides hypothetical specification guidance for how you would approach material selection across six representative Arizona cities with distinct climate and installation challenges.

Your regional specification approach needs to account for elevation-related temperature variation, annual freeze-thaw cycle frequency, and local water chemistry characteristics. You’ll find that material selection criteria shift significantly between low-desert installations and high-elevation mountain communities. The following city-specific scenarios illustrate how you would modify specifications to address local performance requirements.

Phoenix Specifications

In Phoenix installations, you would prioritize thermal mass management and UV stability over freeze-thaw resistance. Your material selection would focus on light-colored options with solar reflectance values exceeding 0.45 to minimize surface temperatures that regularly reach 155-165°F. You’d specify thermal expansion accommodation with 1/4-inch joints throughout the splash zone and 3/8-inch expansion joints every 12 linear feet. The chemical exposure from high evaporation rates concentrating spa chemicals would require you to select materials with absorption below 4.5% and verified acid resistance. You should account for the urban heat island effect adding 8-12°F to ambient temperatures in central Phoenix locations.

Tucson Conditions

Your Tucson specifications would address the combination of intense UV exposure and alkaline soil conditions that affect subsurface drainage and efflorescence potential. You’d need to specify base materials with verified low sulfate content and subsurface drainage systems that prevent capillary rise from alkaline groundwater. The material selection would require UV stability testing showing less than 5% color shift after 2,000 hours accelerated weathering. You should design for surface temperatures approaching 160°F while maintaining slip resistance above 0.50 DCOF when wet. Chemical resistance specifications would mirror Phoenix requirements with emphasis on materials resistant to both chlorine and the bromine systems popular in Tucson’s spa market.

Scottsdale Applications

Scottsdale projects typically demand premium aesthetics combined with high performance standards. Your specifications would emphasize materials with consistent color variation patterns and tight dimensional tolerances below ±1/8 inch. You’d specify edge details with architectural-grade sealants and precision-cut coping transitions. The chemical exposure requirements would match Phoenix specifications, but you should add requirements for compatibility with automated chemical monitoring systems common in luxury installations. Surface finish specifications would need to balance the smooth contemporary aesthetics preferred in Scottsdale design with minimum 0.48 DCOF slip resistance. You’d verify warehouse stock levels for premium grades to ensure project timelines align with material availability.

Flagstaff Requirements

Your Flagstaff specifications would shift focus to freeze-thaw durability while maintaining chemical resistance for spa applications. You’d require materials with saturation coefficients below 0.75 and verified performance through minimum 100 freeze-thaw cycles per ASTM C1645. The combination of freezing temperatures and chemical exposure creates accelerated degradation conditions requiring you to specify materials with both low porosity and disconnected pore structures. You should account for snow load on surrounding areas and specify drainage systems that handle both meltwater and spa splash. Joint fill specifications would need to address freeze-thaw stability in addition to chemical resistance. Material color selection would consider how snow reflectance affects perceived color temperature.

Sedona Design

Sedona installations often require your specifications to address aesthetic integration with natural surroundings while meeting performance standards. You’d select materials with earth-tone coloration and textured finishes that complement red rock landscapes. The elevation at 4,500 feet creates moderate freeze-thaw exposure requiring saturation coefficients below 0.80 and joint systems that accommodate freeze expansion. Chemical resistance specifications would address the interaction between spa sanitizers and iron oxide content in red-toned materials. You should specify sealers that enhance color depth without creating slippery surfaces or interfering with chemical resistance. Drainage design would need to prevent staining of adjacent natural stone features from chemically treated runoff.

Mesa Standards

Your Mesa specifications would closely parallel Phoenix requirements with additional attention to clay soil subsurface conditions common in the area. You’d need to specify engineered base systems with minimum 8-inch depth of crushed aggregate over geotextile fabric to prevent clay infiltration and provide stable support. The material selection would prioritize chemical resistance and thermal stability matching Phoenix standards. You should design drainage systems that handle both spa splash and occasional monsoon flooding common in Mesa’s flat terrain. Edge restraint specifications would account for clay soil expansion during moisture events. Material sourcing from nearby warehouse facilities would allow you to minimize transportation costs while ensuring availability for your project timeline.

Maintenance and Longevity

Your long-term performance expectations for paving stone spa surrounds Arizona installations depend heavily on maintenance protocol implementation. You need to specify quarterly cleaning with pH-neutral cleaners specifically formulated for natural stone in chemical exposure environments. Standard pool deck cleaners often contain acids that accelerate etching in susceptible materials or alkaline compounds that contribute to efflorescence.

The resealing schedule you establish affects both appearance retention and chemical resistance. You should specify initial sealing 30-45 days after installation, allowing adequate cure time for setting beds and joint compounds. Subsequent resealing intervals range from 18 months for high-porosity materials to 36 months for dense, low-absorption stones. Your sealer selection must provide chemical resistance without creating slip hazards or interfering with material breathability.

You’ll need to address joint maintenance as a critical component of system longevity. Joint compound degrades over time from chemical exposure and mechanical erosion, requiring inspection every 24 months and renewal every 4-6 years. Your maintenance specifications should include procedures for joint cleaning, depth verification, and proper compound replacement techniques.

- You should specify quarterly cleaning with pH 7-8 neutral stone cleaners rated for chemical exposure

- Your resealing intervals need to account for material porosity and exposure intensity

- You must require biennial joint inspection and renewal every 4-6 years with compatible materials

- Your maintenance protocol should include annual edge seal inspection and repair as needed

Cost Analysis and Value

When you evaluate paving stone chemical resistant surfaces Arizona project costs, you need to analyze total lifecycle expenses rather than initial installation pricing. Material costs range from $12-$45 per square foot depending on stone type, finish, and dimensional specifications. Installation labor adds $8-$18 per square foot, with chemical-resistant installations at the higher end due to modified setting bed requirements and precision joint work.

Your cost analysis should project maintenance expenses over the expected service life. Basic maintenance averages $0.35-$0.65 per square foot annually, including cleaning, sealing, and joint inspection. Major maintenance events—joint renewal and comprehensive resealing—occur every 4-6 years at $3-$6 per square foot. You’ll find that higher-quality materials with lower maintenance requirements often prove more economical over 15-20 year timeframes despite elevated initial costs.

The replacement cost differential between material types becomes significant when you project 20-year ownership. A limestone installation requiring replacement at year 12 incurs demolition costs ($4-$7 per square foot), disposal fees, and complete reinstallation. A granite or porcelain installation lasting 25+ years avoids these mid-life replacement expenses, creating long-term value that justifies premium material selection.

- You need to calculate lifecycle costs including maintenance, sealing, and potential replacement over 20-year periods

- Your material comparison should factor annual maintenance costs ranging from $0.35 to $0.85 per square foot

- You should account for major maintenance events every 4-6 years at $3-$6 per square foot

- Your analysis must include replacement scenarios for materials with service lives under 15 years

Common Specification Mistakes

You’ll encounter recurring specification errors that compromise paving stone hot tub perimeter Arizona installation performance. The most common mistake involves specifying materials based solely on compressive strength without evaluating chemical resistance, porosity, or thermal properties. High compressive strength doesn’t predict performance in chemical exposure—you need comprehensive material characterization addressing the specific stress conditions spa surrounds experience.

Another frequent error occurs when you apply standard paving joint specifications to chemical exposure zones. The 3/16-inch joints with standard polymeric sand that work adequately for patios and walkways fail rapidly in spa splash zones. You need wider joints with chemically resistant fill materials specifically engineered for these applications. Failure to modify joint specifications leads to joint breakdown within 18-24 months and subsequent paving system deterioration.

You’ll also see specifications that overlook drainage design details specific to chemical-laden water. Standard 1.5% slope proves insufficient for spa surrounds where you need aggressive 2-3% slopes to ensure rapid water evacuation. Chemical residue accumulation in slowly draining areas accelerates material degradation and creates slip hazards from sanitizer films. Your drainage specifications must address both surface slope and subsurface permeability requirements.

- You must avoid specifying materials based on compressive strength alone without chemical resistance verification

- Your joint specifications need modification from standard paving details to address chemical exposure

- You should require minimum 2% drainage slopes within splash zones rather than standard 1.5% minimums

- Your specifications must address edge sealing details that standard paving installations omit

Key Performance Metrics

Your specification success depends on establishing measurable performance criteria that ensure long-term installation integrity. You need to define acceptance standards for material properties, installation quality, and post-installation performance. The critical metrics include absorption rates, slip resistance values, chemical resistance verification, and dimensional tolerances that collectively determine system performance.

Material absorption testing per ASTM C97 should show results between 3.5% and 6.5% by weight for optimal chemical resistance combined with freeze-thaw stability. You’ll verify slip resistance through DCOF testing showing minimum 0.48 wet readings per ANSI A326.3 protocols. Chemical resistance requires accelerated aging in pH-adjusted chlorinated water demonstrating less than 3% mass loss and no visible etching after 1,000-hour exposure.

Installation quality metrics include base compaction verification, joint width consistency, and surface plane tolerance. You should require nuclear density testing confirming 96% modified Proctor compaction, joint width measurements within ±1/32 inch of specification, and surface flatness within 1/8 inch per 10 feet. These measurable standards provide objective acceptance criteria and ensure installation quality that supports long-term performance. For additional guidance on protecting installations from environmental challenges, review Protecting paving stones from winter de-icing chemical damage before you finalize your maintenance protocols. Citadel Stone’s discounts make it economical wholesale paver stones in Arizona choice.