Arizona’s winter climate presents unique challenges when you’re specifying paving materials for exterior applications. While most professionals associate salt damage with northern freeze-thaw states, you’ll encounter de-icing scenarios in elevated Arizona communities that demand careful material selection. Understanding paving stone salt damage prevention Arizona protocols protects your installations from premature deterioration caused by chemical exposure.

When you evaluate paving stone de-icer effects Arizona installations experience, you need to account for temperature fluctuations that occur at elevations above 5,000 feet. Flagstaff sees 100+ nights below freezing annually, while Sedona and higher elevations in the Phoenix metro area require occasional ice management. Your specification decisions determine whether installations maintain structural integrity through 15-20 winter seasons or require replacement within 8-10 years due to chemical degradation.

Chemical Interaction Mechanisms

Salt-based de-icers create specific deterioration patterns you should understand before specifying materials. When sodium chloride contacts porous stone surfaces, you’re introducing hygroscopic compounds that attract and retain moisture within the material matrix. This moisture retention accelerates freeze-thaw damage by maintaining saturation levels that exceed the critical threshold for crystallization pressure.

You’ll observe that calcium chloride and magnesium chloride variants present different risk profiles. Calcium chloride penetrates deeper into pore structures due to its smaller molecular size, creating subsurface deterioration you won’t detect until spalling occurs. Magnesium chloride reacts with certain mineral compositions to form expansive compounds that generate internal pressures exceeding 2,000 PSI — well above the tensile strength of most paving materials.

- Sodium chloride creates surface-level scaling when concentrations exceed 3% by weight

- Calcium chloride penetration reaches 8-12mm depth in materials with porosity above 6%

- Magnesium chloride forms brucite in alkaline conditions, causing subsurface expansion

- Potassium acetate alternatives reduce crystallization pressure by 40-50% compared to chloride salts

Your material specifications must address pore size distribution, not just total porosity. Materials with interconnected pores above 50 microns diameter allow deeper de-icer penetration, while those with predominantly closed or smaller pore structures resist chemical intrusion more effectively.

Material Selection Criteria

When you’re evaluating paving stone chemical resistance Arizona conditions demand, you need to prioritize density and mineral composition over aesthetic preferences. Dense materials with water absorption rates below 3% by weight provide superior resistance to chemical penetration. You should verify absorption rates through ASTM C97 testing rather than relying on product literature that may reflect ideal laboratory conditions.

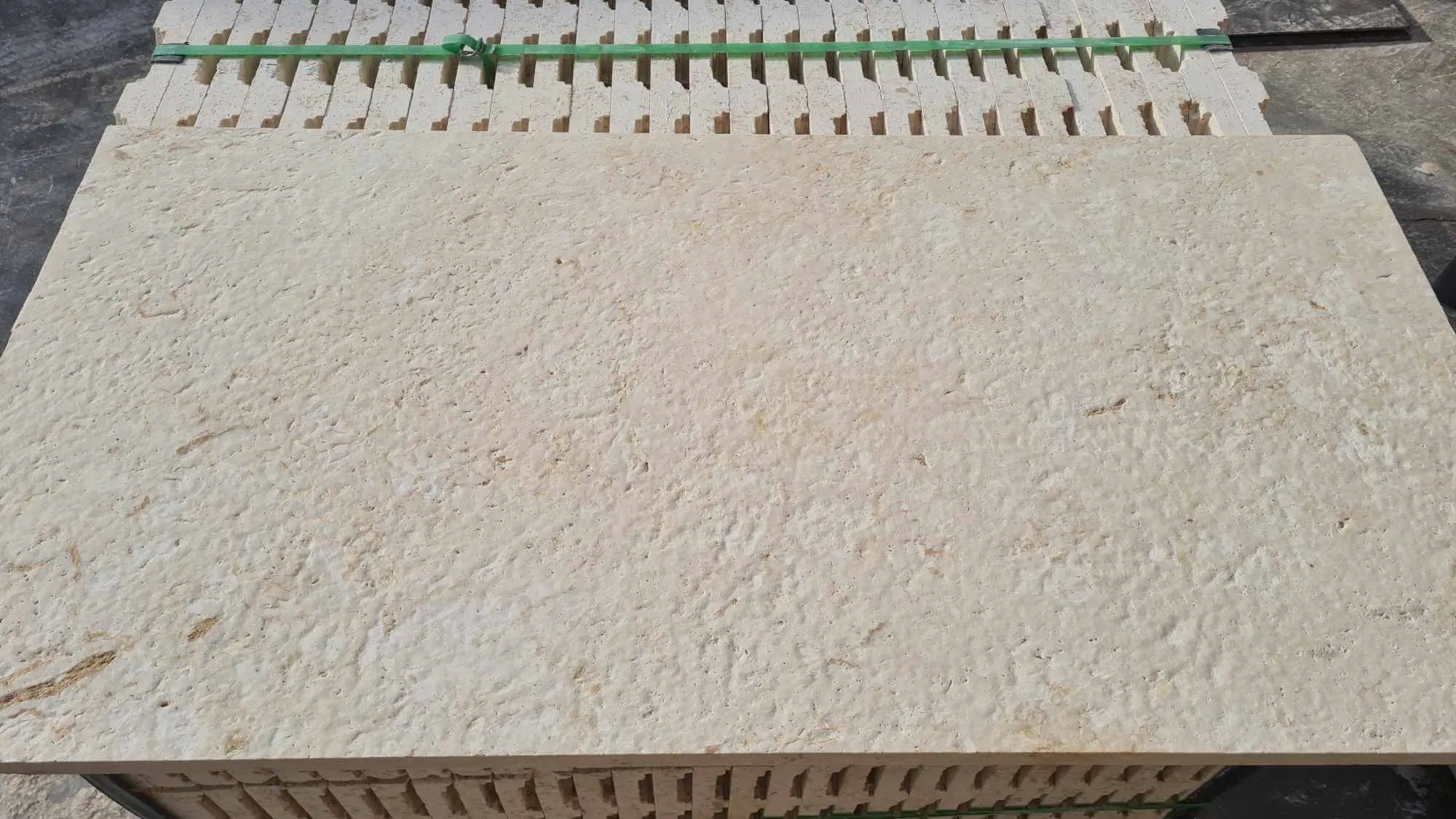

Mineral composition determines how aggressively different de-icers attack the stone matrix. Limestone and travertine contain calcium carbonate that reacts directly with acidic de-icers and certain chloride compounds, creating soluble calcium salts that leach from the surface. You’ll see this manifest as pitting and surface recession rates of 0.5-1.2mm annually in high-exposure areas.

Siliceous materials — granite, quartzite, and certain sandstones — offer superior paving stone chemical resistance Arizona professionals should consider for de-icing zones. These materials resist direct chemical reaction, though you still need to account for physical deterioration from salt crystallization within pore spaces. Your specification should target materials with:

- Compressive strength exceeding 12,000 PSI for freeze-thaw and salt exposure zones

- Water absorption below 2.5% by weight per ASTM C97

- Acid resistance rating of 95% or higher per ASTM C267

- Closed or fine pore structure with minimal interconnected porosity

You’ll find that engineered pavers often outperform natural stone in salt-exposure applications. High-density concrete pavers manufactured to ASTM C936 standards achieve water absorption rates of 1.5-2.0% with compressive strengths exceeding 8,000 PSI. When you compare lifecycle costs, engineered options with integral sealers frequently deliver better value in de-icing zones.

Protective Treatment Protocols

Implementing paving stone winter protection Arizona installations require starts with surface preparation that ensures proper sealer penetration and adhesion. You need to verify the substrate reaches moisture content below 4% before treatment application — higher moisture levels trap water beneath the sealer, creating conditions for subsurface deterioration you won’t detect until significant damage occurs.

Penetrating sealers provide superior protection compared to film-forming topical products for paving stone salt damage prevention Arizona applications. Silane/siloxane formulations chemically bond within the pore structure, creating hydrophobic barriers that repel water and dissolved salts while maintaining vapor permeability. You should specify products with active solids content of 20-40% for adequate protection depth.

Application timing affects sealer performance more than most specifications acknowledge. You’ll achieve optimal penetration when you apply treatments to surfaces at 60-80°F ambient temperature with substrate temperatures within the same range. Your installation schedule should account for 48-72 hour cure times before exposure to moisture or chemical contact.

- Initial sealer application should occur immediately after installation and joint stabilization

- Reapplication intervals of 24-36 months maintain protective effectiveness in de-icing zones

- Surface cleaning before resealing requires pH-neutral cleaners to avoid chemical residue

- Test panels verify sealer compatibility with specific stone types before full application

For projects requiring bulk paving wholesale materials in Tempe, you should coordinate sealer application timing with material delivery schedules to ensure proper cure time before installation.

Installation Design Considerations

Your installation design directly influences how effectively paving stone ice melt damage Arizona environments can cause affects long-term performance. Slope requirements in de-icing zones should increase from the standard 2% minimum to 3-4% to accelerate drainage and reduce the duration of chemical contact with paving surfaces.

Joint spacing and filling materials require modification when you’re designing for salt exposure. Wider joints — 6-8mm instead of the standard 3-5mm — allow for greater drainage capacity and reduce the potential for salt accumulation in joint sand. You should specify polymeric sand products with chemical resistance additives that resist degradation from chloride exposure.

Subsurface drainage becomes critical for paving stone salt damage prevention Arizona professionals must implement. Your base design should incorporate drainage layers that prevent de-icer solutions from accumulating at the paver-bedding interface. A minimum 100mm crushed stone base layer with permeability exceeding 500 inches per hour ensures adequate drainage capacity.

- Edge restraints must be non-corrosive materials rated for chloride exposure

- Bedding sand should be coarse-graded with minimal fines to maintain permeability

- Geotextile separation fabric prevents base contamination while allowing chemical drainage

- Perimeter drains should be positioned to capture and redirect de-icer runoff

You’ll notice that installations without proper subsurface drainage show accelerated deterioration patterns within 3-5 years of initial installation. The warehouse stock you select should include adequate base materials to meet enhanced drainage specifications.

Alternative De-Icing Strategies

When you’re addressing paving stone winter protection Arizona projects require, you should evaluate de-icing alternatives that reduce chemical exposure while maintaining safety performance. Sand and fine aggregate treatments provide traction without introducing salts, though you’ll need to account for increased spring cleanup requirements and potential joint contamination.

Calcium magnesium acetate (CMA) formulations offer significantly reduced reactivity with stone materials compared to chloride-based products. Testing demonstrates CMA creates 75-80% less surface degradation over equivalent exposure periods. Your project budget should account for CMA costs that run 2-3 times higher than sodium chloride, though lifecycle cost analysis frequently favors the higher initial investment.

Heated paving systems eliminate de-icing chemical requirements entirely by maintaining surface temperatures above freezing during precipitation events. You’ll find that hydronic systems embedded in concrete base layers or electric cable systems within bedding layers provide reliable performance. Initial installation costs run $45-75 per square foot, but you eliminate ongoing chemical damage and reduce long-term maintenance requirements by 60-70%.

Climate Zone Specifications

Arizona’s elevation-dependent climate zones require you to tailor paving stone de-icer effects Arizona specifications based on site-specific conditions. Areas above 6,000 feet elevation experience freeze-thaw cycles that mirror northern climates, demanding comprehensive salt-damage prevention protocols. You should implement full protective measures including penetrating sealers, enhanced drainage, and alternative de-icing strategies.

Mid-elevation zones between 3,500-6,000 feet present intermittent freeze conditions that create challenging specification decisions. You’ll encounter 15-40 annual freeze-thaw cycles that justify protective treatments, though less aggressive protocols may suffice compared to high-elevation installations. Your material selections can include moderately porous options with water absorption rates of 3-4% when combined with regular sealer maintenance.

- High desert elevations require materials with water absorption below 2.5% for optimal longevity

- Transitional zones benefit from semi-annual sealer inspections and spot treatment

- Low desert areas below 2,500 feet rarely justify comprehensive salt-damage prevention measures

- Microclimate assessment identifies localized cold zones requiring upgraded specifications

You need to account for urban heat island effects that create temperature variations within metro areas. North-facing installations in Scottsdale at 1,500 feet elevation may experience freeze conditions that south-facing sites at the same elevation never encounter.

Maintenance Program Development

Establishing effective maintenance protocols for paving stone ice melt damage Arizona prevention requires you to implement seasonal inspection and treatment schedules. Fall preparation should include comprehensive cleaning to remove accumulated organic debris and mineral deposits that interfere with sealer performance. You’ll achieve best results using pH-neutral cleaners with surfactant concentrations of 3-5%.

Your pre-winter inspection should document existing damage and identify areas requiring repair before freeze conditions arrive. Joint sand levels need verification and replenishment to maintain 90-95% fill capacity — inadequate joint filling allows lateral movement during freeze-thaw cycles that accelerates edge spalling. Surface sealer effectiveness requires water-drop testing; properly sealed surfaces should show beading behavior with contact angles exceeding 90 degrees.

Post-winter assessment protocols you implement should document salt damage progression and guide specification modifications for future installations. Systematic photography from consistent positions allows quantitative comparison across seasons. You should measure surface recession at marked reference points using depth micrometers accurate to 0.01mm to detect deterioration rates before visible damage appears.

- Spring cleaning must remove all residual de-icing chemicals within 30 days of final application

- Annual sealer inspection identifies areas requiring spot treatment before comprehensive reapplication

- Joint stabilization verification prevents lateral displacement that compromises structural integrity

- Documentation provides warranty support and guides long-term performance optimization

Performance Monitoring Methods

When you’re tracking paving stone chemical resistance Arizona installations demonstrate over time, you need quantitative assessment methods that detect deterioration before remediation costs escalate. Surface hardness testing using Mohs picks or Rebound Schmidt hammers establishes baseline values you can compare during annual inspections. Hardness reductions exceeding 15% indicate chemical attack has compromised surface integrity.

Chloride ion concentration testing in joint sand and surface deposits reveals de-icer accumulation patterns. You can extract samples using vacuum methods and submit for ion chromatography analysis. Concentrations exceeding 500 ppm suggest inadequate drainage or excessive application rates requiring corrective action.

Ultrasonic pulse velocity testing provides non-destructive assessment of subsurface deterioration you can’t detect visually. This technique measures sound wave transmission speed through the material — velocities decreasing more than 10% from baseline indicate internal damage progression. Professional testing services offer this capability, or you can acquire portable units for in-house assessment programs.

Specification Language Examples

Your project specifications for paving stone salt damage prevention Arizona applications should include explicit performance requirements and testing protocols. Generic references to “chemical resistance” don’t provide adequate guidance for material suppliers or installation contractors. You need quantified criteria that establish clear acceptance thresholds.

Effective specification language should state: “Paving materials shall exhibit water absorption not exceeding 2.5% by weight per ASTM C97 testing. Contractor shall provide certified test results from samples representing actual production lot. Materials exceeding specified absorption limits shall be rejected.” This approach eliminates ambiguity and provides enforcement mechanisms.

- Surface sealers shall be penetrating silane/siloxane formulations with minimum 30% active solids content

- Sealer application shall achieve water contact angles exceeding 90 degrees verified by field testing

- Joint sand shall be polymeric formulation with chemical resistance certification for chloride exposure

- Base aggregate shall achieve permeability of 500+ inches per hour per ASTM D2434

You should specify truck delivery schedules that prevent extended storage periods before installation. Materials stored outdoors for more than 60 days may experience moisture absorption that complicates sealer application and initial performance.

Common Specification Mistakes

One critical error you’ll want to avoid involves specifying aesthetic characteristics without addressing performance requirements for paving stone winter protection Arizona conditions demand. Projects that prioritize appearance over chemical resistance frequently require premature replacement when salt damage becomes visually unacceptable within 6-8 years.

Inadequate attention to drainage design represents another specification failure that compromises even properly selected materials. You can specify the most chemically resistant paving available, but if your installation allows de-icer solutions to pond on the surface or accumulate in the base layer, deterioration accelerates beyond material capabilities to resist.

Sealer specifications that reference generic “waterproofing” treatments without chemical composition requirements lead to inappropriate product selection. Film-forming acrylics and epoxies trap moisture and fail rapidly in freeze-thaw conditions. Your specifications must explicitly require breathable penetrating formulations with proven performance in similar exposure conditions.

- Failing to specify sealer reapplication intervals creates maintenance gaps that void material warranties

- Omitting base material permeability requirements allows inadequate drainage substrate installation

- Generic references to “appropriate” materials without quantified performance criteria invite substitutions

- Ignoring edge restraint corrosion resistance leads to structural failure from hardware degradation

Cost-Benefit Analysis Framework

When you’re evaluating investments in paving stone ice melt damage Arizona prevention measures, you need comprehensive lifecycle cost analysis that accounts for material premiums, protective treatments, and avoided replacement expenses. Initial cost differentials between standard and chemically resistant materials typically range from $2-6 per square foot, while comprehensive sealer programs add $1.50-2.50 per square foot including initial treatment and biennial reapplication.

Your analysis should compare these prevention costs against replacement scenarios. Full paving replacement in salt-damaged installations averages $18-28 per square foot including demolition, disposal, and reinstallation. If prevention measures extend service life from 10 years to 20 years, you’ll realize net present value benefits of $8-15 per square foot at typical discount rates.

Maintenance cost reductions from damage prevention provide additional value you should quantify. Installations without salt damage require 40-50% less annual maintenance compared to deteriorating installations that need ongoing repairs, joint stabilization, and surface treatments. Over 20-year evaluation periods, these maintenance savings contribute $3-5 per square foot to lifecycle value.

Citadel Stone — Leading Paving Wholesale Suppliers in Arizona Expertise

When you’re sourcing materials for salt-exposed applications across Arizona’s diverse climate zones, you need suppliers with technical expertise in paving stone salt damage prevention Arizona protocols. At Citadel Stone, we provide detailed specification guidance for hypothetical installations throughout the state’s varying elevation and exposure conditions. This section outlines how you would approach material selection and protective treatment specifications for six representative Arizona communities.

Arizona’s elevation range from 70 feet in Yuma to over 7,000 feet in Flagstaff creates dramatically different de-icing requirements you must address through site-specific specifications. You’ll find that warehouse inventory selection should account for regional climate variations that determine appropriate material characteristics and treatment protocols.

Flagstaff Specifications

In Flagstaff’s high-elevation environment at 7,000 feet, you would specify materials meeting the most stringent chemical resistance criteria. Your material selections should target water absorption below 2.0% with compressive strength exceeding 14,000 PSI. The city experiences over 100 annual freeze-thaw cycles and regular de-icing applications that demand comprehensive paving stone winter protection Arizona protocols. You would implement penetrating sealer programs with initial application and 24-month reapplication intervals. Base design should incorporate enhanced drainage layers with permeability exceeding 600 inches per hour, and you would specify heated edge zones for critical pedestrian areas to minimize chemical exposure entirely.

Sedona Applications

For Sedona installations at 4,500 feet elevation, you would balance aesthetic requirements for this tourism-focused community with moderate salt-exposure protection. Your specifications could accommodate materials with water absorption rates of 2.5-3.0% when combined with robust sealer protocols addressing paving stone de-icer effects Arizona intermittent freeze conditions create. You would recommend silane/siloxane treatments with 30% active solids applied before winter season onset. North-facing installations and shaded canyon areas would receive upgraded material specifications matching Flagstaff criteria, while sun-exposed areas could utilize standard protection protocols. Joint spacing of 6-7mm would optimize drainage while maintaining the refined appearance this market demands.

Phoenix Considerations

Phoenix metro area installations at 1,100 feet elevation rarely require comprehensive salt-damage prevention, though you would address localized microclimate conditions in north-facing courtyards and shaded building perimeters. Your material specifications could include moderately porous options with water absorption up to 5% for most applications. You would implement basic penetrating sealer treatments for premium installations where any minor deterioration would be unacceptable. The focus in Phoenix shifts from chemical resistance to thermal cycling durability and UV stability, though you should maintain awareness of occasional freeze events that occur every 3-5 years requiring temporary de-icing measures.

Prescott Requirements

At 5,400 feet elevation, Prescott represents transitional climate conditions where you would implement moderate paving stone chemical resistance Arizona specifications. Your material selections should target water absorption below 3.5% with annual sealer inspection and spot treatment protocols. You would encounter 40-60 freeze-thaw cycles annually requiring attention to paving stone ice melt damage Arizona prevention, though less aggressive than Flagstaff requirements. Base preparation should include 125mm crushed stone layers with permeability of 500+ inches per hour. You would specify polymeric joint sand with chemical resistance additives and recommend alternative de-icing strategies using calcium magnesium acetate for premium installations where chemical exposure reduction justifies the cost premium.

Scottsdale Projects

Scottsdale’s desert environment at 1,250 feet elevation typically doesn’t require comprehensive salt-damage prevention, though your specifications for luxury residential and commercial projects should include protective measures that ensure long-term aesthetic performance. You would recommend optional penetrating sealer treatments that provide stain resistance benefits beyond chemical protection. Material selection could prioritize aesthetic characteristics while maintaining minimum water absorption below 6%. Your installation design should address thermal expansion from extreme temperature cycling rather than freeze-thaw concerns. North-facing installations in elevated areas of north Scottsdale above 2,500 feet would receive upgraded attention to occasional freeze conditions requiring modified specifications.

Tucson Parameters

For Tucson installations at 2,400 feet elevation, you would implement minimal salt-damage prevention protocols focused on occasional freeze events that occur 10-15 times annually. Your material specifications could accommodate water absorption rates up to 5% for most applications, with upgraded requirements for north-facing exposures and elevated foothill areas above 3,000 feet. You would recommend basic penetrating sealer treatments for installations where any surface deterioration would be problematic, though comprehensive protocols aren’t typically justified by exposure frequency. Joint design should emphasize thermal expansion accommodation rather than chemical resistance, though you would specify adequate drainage to prevent the rare de-icer accumulation that could occur during winter storm events.

Regulatory Compliance Considerations

Your specifications must address environmental regulations governing de-icer runoff and chemical discharge into storm water systems. Many Arizona municipalities have adopted restrictions on chloride concentrations in surface water, requiring you to implement best management practices that capture and treat de-icer solutions before they enter drainage systems.

The Arizona Department of Environmental Quality establishes water quality standards you need to consider when specifying de-icing protocols for paving stone salt damage prevention Arizona applications. Chloride concentrations exceeding 250 mg/L in surface water discharge may trigger reporting requirements and remediation obligations. Your installation design should incorporate collection systems that prevent direct discharge to sensitive water bodies.

Americans with Disabilities Act (ADA) compliance requirements affect your ability to use certain alternative de-icing methods. Sand and aggregate traction treatments may create accessible route maintenance challenges that require more frequent cleaning than chloride-based products. You should evaluate heated paving systems as ADA-compliant solutions that eliminate both chemical exposure and traction material complications.

Implementation Priorities

Successful paving stone winter protection Arizona installations require you to prioritize protective measures based on project-specific risk factors and performance requirements. Your implementation strategy should begin with accurate climate assessment including elevation, aspect, shading patterns, and microclimate influences that determine actual freeze-thaw exposure.

Material selection represents your primary defense against chemical damage, and you should invest specification effort here before relying solely on protective treatments. Dense, low-porosity materials with proven chemical resistance provide baseline performance that supplemental sealers enhance but cannot replace. Your budget allocation should prioritize material upgrades over treatment programs when cost constraints require trade-off decisions.

Installation quality control ensures that properly specified materials achieve their performance potential. You need to verify base permeability, joint spacing accuracy, sealer application rates, and drainage function before accepting installations. Field testing during construction costs far less than post-installation remediation when specification non-compliance creates performance failures.

For comprehensive guidance on heritage and restoration applications requiring specialized attention to material authenticity and preservation standards, review Authentic heritage paving materials for Arizona historic preservation projects before you finalize your project specifications. Project coordination comes from Citadel Stone’s organized bulk paver stones in Arizona logistics.