When you design a paving stone mailbox surround in Arizona, you’re creating more than a decorative feature — you’re establishing a critical intersection between property aesthetics, postal regulations, and extreme climate performance. Your design decisions affect visibility compliance, vehicle impact resistance, and long-term material durability under relentless UV exposure and thermal cycling that regularly exceeds 100°F swings between night and day.

You need to account for specific clearance requirements dictated by USPS guidelines while simultaneously addressing how desert soil expansion affects foundation stability. The paving stone mail station area Arizona professionals specify must withstand not just the environmental assault but also potential vehicle strikes from distracted drivers navigating curbside approaches. These installations fail most often due to inadequate base preparation and material selection that doesn’t account for thermal expansion coefficients under sustained solar loading.

Material Performance Under Desert Thermal Stress

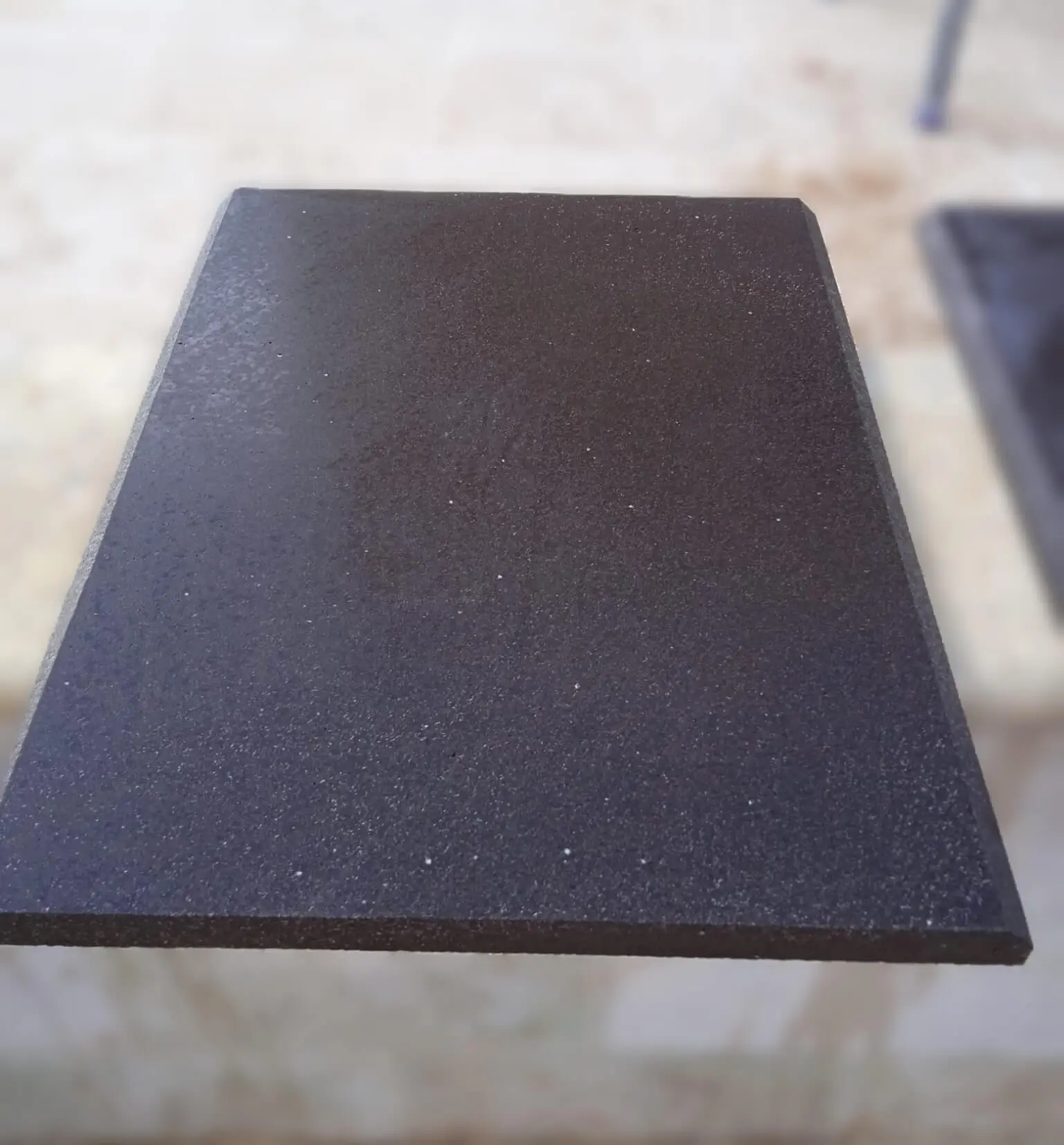

Your paving stone mailbox surround design Arizona project faces thermal conditions that create expansion and contraction cycles unknown in moderate climates. Surface temperatures on exposed pavers regularly reach 160-180°F during June through August, creating dimensional changes that affect joint integrity and structural alignment. You’ll need materials with thermal expansion coefficients below 6.0 × 10⁻⁶ per °F to maintain geometric stability.

The material you select must demonstrate interconnected pore structures that allow thermal energy dissipation without creating internal stress fractures. Porosity ranges between 4-7% provide optimal performance — below 4%, you risk thermal shock damage during monsoon season when surface temperatures drop 40°F in minutes. Above 7%, UV degradation accelerates as increased surface area exposes more material to photochemical breakdown.

- You should verify compressive strength exceeds 9,000 PSI for installations subject to vehicle proximity

- Your specification must address freeze-thaw resistance even in desert climates where Flagstaff installations experience 80+ annual freeze events

- You need to confirm slip resistance maintains DCOF ratings above 0.50 when dust accumulation creates surface film

- Abrasion resistance testing should demonstrate less than 3mm loss after 1,000 cycles per ASTM C1353

Color stability under UV exposure separates professional-grade materials from commodity products. You’ll observe that lighter tones reflect 55-65% of solar radiation, reducing surface temperature by 15-20°F compared to darker alternatives. This thermal performance directly impacts the longevity of your paving stone postal box feature Arizona installation.

Clearance Compliance and Postal Access Requirements

USPS regulations dictate specific dimensional constraints that directly affect how you configure your paving stone mailbox surround design Arizona layout. Mailbox height must position the bottom of the receptacle 41-45 inches above the roadway surface, with your surround design accommodating this requirement without creating visibility obstructions or vehicle hazards.

You need to maintain minimum 6-inch setback from the curb face to the nearest vertical element of your surround structure. For comprehensive material evaluation across applications, see trade paving slab pricing to compare performance specifications. Your horizontal clearance zone extends 15 feet in the direction of travel to prevent mail carrier vehicle conflicts with decorative elements.

The vertical clearance envelope requires you to keep decorative elements below 4 feet in height within 12 feet of the mailbox approach zone. Taller design elements create sight-line obstructions for both postal vehicles and residential traffic entering from driveways. Professional specifications account for these constraints during initial layout rather than discovering conflicts during installation.

Foundation Depth Requirements

Your foundation must extend below the frost line even in southern Arizona locations where freezing occurs infrequently. Minimum excavation depth should reach 18 inches in Phoenix-area installations, increasing to 24-30 inches in Flagstaff and higher elevations where soil moisture freezing creates heave forces.

Compacted aggregate base thickness affects long-term settlement patterns. You’ll achieve optimal stability with 8-10 inch base layers compacted in 3-4 inch lifts to 95% modified Proctor density. The base material should be Class 2 aggregate or equivalent, with particle gradation that prevents migration into underlying soils.

Vehicle Impact Resistance Design

When you position a paving stone mailbox surround design Arizona installation at the curbside, you’re creating a structure subject to potential vehicle strikes from distracted drivers, delivery trucks, and snow plows in northern regions. Your design must balance aesthetic objectives with breakaway characteristics that prevent catastrophic damage to vehicles and occupants.

Frangible design principles require you to avoid rigid mass concentrations above 8 inches from grade level. Mortared joints and solid masonry cores create dangerous projectile conditions during vehicle impacts. Instead, you should specify dry-laid construction methods that allow individual pavers to displace without generating large debris fields.

- You need to position vertical elements like columns or pillars at minimum 24 inches behind the mailbox post location

- Your base course should incorporate geogrid reinforcement to maintain structural integrity while allowing controlled failure modes

- Edge restraint systems must be designed to release under lateral loads exceeding 500 pounds

- You should avoid decorative caps or coping stones that could become airborne projectiles during impacts

The paving stone mail station area Arizona codes require takes into account local traffic patterns and roadway geometry. Installations on curved roadways or blind approach zones need additional setback distances to account for vehicle tracking paths during normal operation.

Soil Expansion and Moisture Management

Arizona soil conditions present unique challenges that affect how you design subsurface drainage and base stability for your paving stone address marker base Arizona installation. Clay content in valley soils creates expansion coefficients reaching 0.05-0.08 during moisture absorption, generating uplift forces that displace poorly designed structures.

You’ll need to verify soil classification through testing before specifying foundation details. Expansive soils classified as CH or MH under the Unified Soil Classification System require removal and replacement with non-expansive materials, or installation of moisture barriers that prevent seasonal wetting cycles. The replacement depth should extend 12-18 inches below your aggregate base layer.

Drainage design becomes critical in areas subject to sheet flow during monsoon events. Your surround design must incorporate positive drainage that directs water away from the mailbox foundation at minimum 2% grade. You should avoid creating collection basins within the paver field that allow water infiltration into base layers.

Subsurface Moisture Barriers

When you encounter expansive soils, geotextile barriers installed below the aggregate base prevent capillary moisture migration from underlying clay layers. You’ll want to specify woven geotextiles with puncture resistance exceeding 400 pounds and UV stabilization for edge exposures.

The barrier should extend 24 inches beyond the paver perimeter on all sides to intercept lateral moisture movement. Overlap joints require minimum 18-inch overlap with seams oriented perpendicular to the predominant drainage direction. You need to ensure warehouse delivery schedules account for these specialty materials that may not stock locally.

Thermal Expansion Joint Detailing

Your paving stone mailbox surround design Arizona specifications must incorporate expansion joints at intervals that accommodate the extreme temperature differentials characteristic of desert climates. Daily temperature swings of 50-60°F create dimensional changes requiring 1/8 to 3/16 inch movement capacity per 10 feet of paver field length.

You should position expansion joints at maximum 12-foot intervals in Arizona installations, reducing to 10 feet where continuous solar exposure exceeds 8 hours daily. The joint material needs compressibility characteristics that allow 25-30% compression without extrusion or permanent deformation. Closed-cell foam backer rod provides optimal performance when sized to 125% of joint width.

- Joint width should measure 3/8 to 1/2 inch to accommodate thermal movement without creating trip hazards

- You need to seal joints with polyurethane or silicone sealants rated for ±50% movement capability

- Your sealant selection must demonstrate UV stability exceeding 1,500 hours in accelerated weathering tests

- You should avoid rigid joint fillers like mortar or grout that create stress concentrations during thermal cycling

The paving stone entry feature Arizona professionals design includes isolation joints where the paver field intersects rigid elements like mailbox posts or decorative columns. These joints prevent stress transfer that causes cracking and displacement during differential movement cycles.

Color Selection for Visibility and Heat Management

When you specify paver colors for a paving stone mailbox surround design Arizona application, you’re balancing aesthetic preferences against thermal performance and visibility requirements. Light-colored materials in cream, tan, and light gray ranges reflect 55-70% of incident solar radiation, reducing surface temperatures by 18-25°F compared to dark alternatives.

Visibility considerations require sufficient contrast between the surround structure and adjacent landscaping to prevent vehicle encroachment. You’ll achieve optimal visibility with materials that maintain at least 30% luminance contrast against surrounding soil and vegetation. This becomes particularly important during dust storm conditions when airborne particulates reduce visibility to less than 100 feet.

Color fastness under UV exposure affects long-term appearance retention. You should verify that selected materials demonstrate less than 3 Delta E color shift after 2,000 hours of accelerated UV exposure testing. Integral color systems perform better than surface-applied pigments, which often fade to 60% of original intensity within 3-5 years in Arizona sun exposure.

Installation Timing and Environmental Conditions

Your installation schedule for a paving stone mailbox surround design Arizona project should avoid periods of temperature extremes that compromise material handling and base preparation quality. Optimal installation windows occur during spring months of March through May and fall periods of October through November when temperatures range between 65-85°F.

Summer installations during June through September require modified procedures to address ambient temperatures exceeding 105°F. You’ll need to schedule work during early morning hours before 10:00 AM when surface temperatures remain below 95°F. Material storage must provide shade coverage to prevent thermal expansion prior to installation that creates dimensional inconsistencies.

Winter installations in northern Arizona locations face different constraints related to ground freezing and precipitation. You should avoid excavation and base compaction when soil temperatures drop below 40°F, as frozen ground particles prevent proper compaction and create voids that collapse during spring thaw cycles.

Moisture Content Management

Base aggregate moisture content during compaction directly affects density achievement and long-term stability. You need to maintain moisture content between 4-6% of optimum as determined by modified Proctor testing. Below 4%, you’ll encounter difficulty achieving 95% density targets. Above 6%, excess moisture creates pumping conditions that degrade base performance.

Testing protocols require you to verify moisture content through field testing at 500 square foot intervals during placement. Nuclear density gauge readings provide real-time feedback, though sand cone testing remains the accepted verification method for dispute resolution.

Utility Coordination and Underground Clearances

Before you excavate for a paving stone mailbox surround design Arizona foundation, you must verify underground utility locations through state-mandated notification services. Arizona Blue Stake requires 48-hour advance notice prior to excavation, with marked locations valid for 15 working days from the mark date.

Common utility conflicts at curbside mailbox locations include water service lines, irrigation systems, electrical service to streetlights, and fiber optic communication cables. Your excavation must maintain minimum 18-inch horizontal clearance from marked utility locations unless you expose and hand-dig around actual infrastructure.

Gas line proximity requires special attention, as many residential services transition from steel to plastic materials at property lines near typical mailbox locations. You should hand-expose suspected gas line locations rather than risking mechanical excavation that could damage plastic piping and create explosive hazards.

Edge Restraint Specification and Installation

Your paving stone mailbox surround design Arizona installation requires perimeter edge restraints that prevent lateral migration while accommodating thermal expansion movements. Rigid concrete haunching creates stress concentrations during thermal cycling, leading to edge spalling and joint separation within 18-24 months.

Flexible edge restraint systems using aluminum or steel channels with anchoring spikes provide optimal performance. You’ll need restraints with minimum 1/8-inch thickness and 4-inch vertical leg depth to contain standard 2-3/8 inch thick pavers. Spike spacing should not exceed 16 inches on center, reducing to 12 inches on curves with radii less than 6 feet.

- You should position edge restraints to allow 1/4-inch expansion gap between the restraint face and paver edge

- Your spike penetration must reach 8 inches into compacted base material for adequate pullout resistance

- Edge restraint joints require 3/8-inch gaps at 10-foot intervals to accommodate thermal expansion of the restraint system itself

- You need to verify that truck delivery schedules align with installation progress to prevent material storage complications

Bulk Stone Pavers Arizona Applications Guidance

At Citadel Stone, we provide technical guidance for specifying bulk stone pavers in Arizona across the state’s diverse climate zones. When you evaluate material requirements for your paving stone mailbox surround design Arizona project, you’re addressing conditions that range from Yuma’s extreme heat to Flagstaff’s freeze-thaw cycles. This section outlines how you would approach specification decisions for six representative municipalities.

Your material selection process should account for local climate data, soil conditions, and installation environment characteristics specific to each location. The following city-specific considerations demonstrate how you would adapt your paving stone mailbox surround design Arizona specifications to optimize performance and longevity across varied regional conditions.

Phoenix Heat Considerations

In Phoenix, you’ll encounter extreme thermal stress with summer surface temperatures reaching 180°F on exposed pavers. Your specification should address materials with thermal expansion coefficients below 5.5 × 10⁻⁶ per °F and UV stability exceeding 2,000 hours. You need base preparation that extends 18 inches deep with Class 2 aggregate compacted to 95% density. The urban heat island effect amplifies standard thermal calculations by 8-12°F, requiring you to account for this delta in expansion joint spacing. Light-colored materials reflecting 60-65% of solar radiation reduce maintenance requirements and extend service life to 25-30 years under proper installation protocols.

Tucson Monsoon Performance

Tucson installations require you to emphasize drainage design due to intense monsoon events delivering 2-3 inches of rainfall in 60-minute periods. Your paving stone entry feature Arizona design should incorporate 3% minimum grade directing water away from the mailbox foundation. You’ll want base layers with 40% void space to handle infiltration rates exceeding 8 inches per hour during peak events. Caliche layers common at 12-18 inch depths create impermeable barriers requiring removal or perforation. At Citadel Stone, we recommend verifying soil percolation rates before finalizing base specifications, as clay content variations affect drainage performance significantly across Tucson’s basin topography.

Scottsdale Aesthetic Standards

When you design for Scottsdale locations, you’re addressing elevated aesthetic expectations common in premium residential developments. Your material selection should emphasize color consistency with Delta E variation below 2.0 between production lots. You need to specify premium-grade pavers with tight dimensional tolerances of ±1/16 inch to achieve the precise joint spacing expected in high-end applications. Surface finishes should balance slip resistance requirements with visual refinement — honed finishes with DCOF ratings of 0.52-0.56 meet both criteria. Lighting integration often accompanies these installations, requiring you to coordinate conduit placement during base preparation phases.

Flagstaff Freeze Protection

Flagstaff’s elevation creates freeze-thaw conditions requiring you to specify materials with absorption rates below 5% and verified ASTM C1645 compliance. You’ll need foundation depths reaching 30 inches to extend below the 24-inch frost line typical at 7,000-foot elevations. Your base preparation should incorporate open-graded aggregate allowing moisture drainage that prevents ice lens formation during freeze cycles. De-icing salt exposure from winter road treatments requires you to select materials with demonstrated chloride resistance. Snow load considerations affect decorative element design, limiting vertical features to heights that prevent snow accumulation exceeding 40 pounds per square foot.

Sedona Color Integration

Sedona design review standards often require you to coordinate paver colors with the region’s distinctive red rock formations. Your material selection should incorporate warm earth tones in terracotta, rust, and amber ranges that complement rather than contrast with natural surroundings. You need to account for Oak Creek Canyon’s microclimate effects, where elevation changes of 1,000 feet within project areas create temperature differentials of 10-15°F. Soil conditions transition from red clay to decomposed sandstone within short distances, requiring you to verify bearing capacity through testing rather than assumptions based on visual assessment.

Yuma Extreme Conditions

Yuma represents the most severe thermal environment in Arizona, with your paving stone mail station area Arizona installation facing ambient temperatures exceeding 120°F for extended periods. You should specify materials proven in similar extreme-heat applications with surface temperature performance verified above 185°F. Thermal expansion calculations must account for 70°F daily temperature swings during summer months. Wind-driven sand abrasion accelerates surface wear, requiring you to verify abrasion resistance below 2mm loss per ASTM C1353 testing. Installation scheduling becomes critical — you’ll need to limit work to October through April when temperatures permit proper base compaction and material handling without heat-related quality compromises.

Maintenance Protocols for Longevity

Your paving stone mailbox surround design Arizona installation requires periodic maintenance to achieve projected 25-30 year service life. Joint sand replenishment becomes necessary every 18-24 months as wind erosion and rain wash-out gradually deplete original fill levels. You should specify polymeric sand for initial installation, which provides superior retention compared to standard silica sand.

Sealer application every 3-5 years helps maintain color stability and reduces efflorescence formation in areas with alkaline soil conditions. You’ll want to use penetrating sealers rather than film-forming products, as topical coatings degrade rapidly under UV exposure and create slippery surfaces when wet. Application should occur when surface temperatures range between 50-80°F to ensure proper penetration and curing.

Pressure washing removes accumulated dust and organic growth that creates slip hazards and staining. You need to limit pressure to 1,500 PSI maximum to prevent joint sand displacement and surface erosion. Annual cleaning during spring months prepares surfaces for summer monsoon season when clean joints facilitate proper drainage.

Cost Factors and Budget Planning

When you budget for a paving stone mailbox surround design Arizona project, you need to account for material costs ranging from $8-18 per square foot for premium-grade pavers suitable for curbside exposure. Labor installation costs typically add $12-22 per square foot depending on design complexity and site access constraints. Your total project investment for a typical 50-60 square foot mailbox surround ranges from $1,000-2,400 installed.

Base preparation represents 35-40% of total installation cost but provides the foundation for long-term performance. You’ll encounter additional expenses for utility locating services ($150-300), soil testing in expansive clay areas ($200-400), and permitting fees where jurisdictions regulate curbside structures ($50-200). These ancillary costs often surprise project budgets when not anticipated during planning phases.

Material waste factors should account for 8-12% overage to accommodate cutting waste and future repairs. You need to purchase extra material from the same production lot to ensure color consistency for replacement pavers that may be needed years after initial installation. Warehouse storage of reserve materials prevents the color-matching difficulties common when trying to source replacement units from different production runs.

Common Installation Failures

The most frequent failure mode in paving stone postal box feature Arizona installations involves inadequate base compaction that leads to settlement and misalignment within 12-24 months. You’ll observe this as progressive tilting toward the roadway or vertical displacement creating trip hazards. Prevention requires you to verify 95% modified Proctor density through field testing rather than relying on visual assessment of base quality.

Edge restraint failure occurs when you undersize restraint systems or space anchoring spikes too far apart. The lateral forces generated during thermal expansion push pavers outward, creating spreading conditions that open joints and allow base migration. You should inspect edge restraints annually and reset any sections showing displacement before progressive failure develops.

- Joint sand depletion from inadequate initial compaction or use of standard silica sand instead of polymeric products

- Drainage failures from insufficient grade or blocked drainage paths allowing water accumulation in base layers

- Thermal cracking from rigid mortar joints that prevent expansion movement during temperature cycling

- Efflorescence formation from groundwater wicking through inadequate moisture barriers in expansive soil conditions

Regulatory Compliance Verification

Your paving stone mailbox surround design Arizona project may require permits from local building departments depending on structure height and proximity to public right-of-way. You should verify requirements with jurisdiction authorities before beginning installation, as regulations vary significantly between municipalities. Some jurisdictions regulate any structure within 10 feet of the property line, while others exempt mailbox surrounds below specific dimensions.

Homeowners association design review represents another layer of approval for properties within planned communities. You’ll need to submit design drawings showing dimensions, materials, colors, and placement for architectural committee review. Approval timelines range from 2-6 weeks depending on meeting schedules and committee responsiveness.

Americans with Disabilities Act compliance becomes relevant when your mailbox surround affects pedestrian path of travel along sidewalks. You must maintain 36-inch minimum clear width for accessible passage, with surface transitions limited to 1/4-inch vertical displacement to prevent wheelchair and mobility device hazards.

Professional Specification

Your professional approach to specifying a paving stone mailbox surround design Arizona installation requires you to balance competing performance requirements while maintaining compliance with postal regulations and local codes. You’ve seen how thermal stress, soil conditions, and vehicle impact considerations affect design decisions that determine long-term success. The material selection process demands you to verify compressive strength, thermal expansion characteristics, and UV stability through testing data rather than relying on generic product literature.

Installation quality depends on your attention to base preparation details, edge restraint specification, and drainage design that addresses Arizona’s unique combination of extreme heat and intense monsoon precipitation. You should approach these projects with the understanding that curbside exposure creates demanding service conditions requiring materials and methods proven in similar applications. For additional installation insights, review Stable paving stone foundations support outdoor shade structures effectively before you finalize your project documents. Citadel Stone’s reach establishes it as regional paving wholesalers in Arizona network.