When you design paving stone shade structure foundations Arizona installations, you’re tackling engineering challenges most generic guides ignore. Your pergola, ramada, or gazebo foundation requires you to integrate vertical load distribution with lateral stability while maintaining aesthetic continuity across the paving field. The structural demands differ fundamentally from simple patio applications because you’re anchoring posts that experience wind uplift, thermal cycling, and concentrated loads exceeding 2,000 pounds per footing in extreme cases.

You need to understand that paving stone shade structure foundations Arizona specifications require three-layer integration: the compacted aggregate base that handles vertical compression, the setting bed that accommodates minor settlement, and the paver surface that masks structural components while providing finished elevation. Most installation failures occur at the interface between decorative pavers and structural footings, where differential movement creates visible cracks within 18-24 months if you don’t detail the transitions correctly.

Structural Load Transfer Mechanisms

Your foundation system must transfer loads from shade structure posts through pavers into engineered footings without compromising surface integrity. When you anchor posts for paving stone pergola base Arizona applications, you’ll encounter a fundamental conflict: posts require rigid connections to resist moment forces, while paving fields need flexibility to accommodate thermal expansion. The solution involves isolated structural footings that extend below frost depth with post bases that penetrate the paving surface at strategic locations.

You should specify footings with minimum 24-inch diameter and depth calculated using local soil bearing capacity, typically 36-48 inches in Arizona’s variable soil conditions. The footing must remain independent from the surrounding paver base to prevent stress transfer during thermal cycling. Your detail drawings need to show a 1-inch isolation gap filled with compressible material around each post base, allowing the paving field to expand without inducing lateral loads on the structural elements.

- You must verify soil bearing capacity exceeds 2,000 PSF before finalizing footing dimensions

- Your structural engineer should confirm post base embedment depth resists uplift forces from 90 MPH wind events

- You’ll need to coordinate paver joint locations to align with post positions, creating visual symmetry

- Post base flanges require minimum 8-inch diameter to distribute loads across multiple pavers

The paving stone ramada foundation Arizona installations you specify will experience concentrated loads at post locations combined with distributed loads across the shaded area. You need to increase base aggregate thickness to 8-10 inches within a 3-foot radius of each post, tapering to standard 6-inch thickness in the field. This reinforced zone prevents localized settlement that would create surface depressions around posts.

Thermal Expansion Coordination

Arizona’s extreme temperature swings create thermal expansion challenges that affect both paving stone shade structure foundations Arizona components and the structures they support. You’re dealing with materials that expand at different rates: concrete footings at 5.5 × 10⁻⁶ per °F, steel posts at 6.5 × 10⁻⁶ per °F, and natural stone pavers at 4.8-5.3 × 10⁻⁶ per °F. When surface temperatures reach 160°F in direct sun, you’ll see expansion movements exceeding 3/16 inch across a 20-foot paving field.

Your expansion joint strategy must account for the shade structure creating thermal zones with temperature differentials of 25-30°F between shaded and exposed areas. You should place expansion joints every 12-15 feet in exposed zones, reducing to 18-20 feet in permanently shaded areas. The joints need to align with post locations when possible, hiding structural transitions within functional movement gaps.

Base Preparation Protocols

When you prepare bases for paving stone gazebo support Arizona installations, you’re building a foundation system that must remain stable under both uniform distributed loads and concentrated post loads. Standard patio base preparation doesn’t address the localized stress concentrations you’ll encounter at post positions. You need to excavate to consistent depth across the entire paving area, then create reinforced zones at post locations before placing the main base aggregate.

You should compact base aggregate to 95% modified Proctor density in standard areas, increasing to 98% within the 3-foot radius reinforced zones. This differential compaction prevents the common problem where posts settle slightly more than the surrounding field, creating visible tilting within the first year. Your compaction equipment must include both plate compactors for general areas and jumping jack compactors for the tight spaces around post footings.

- You’ll achieve optimal results using 3/4-inch minus crushed aggregate with fines content between 8-12%

- Your base layer should demonstrate permeability exceeding 20 inches per hour to prevent subsurface water accumulation

- You need to verify grade slopes maintain 2% minimum fall away from post locations

- Geotextile fabric becomes essential when native soils include more than 30% clay content

The paving stone canopy structure Arizona applications require you to consider how concentrated loads affect base layer performance over time. You should specify angular aggregate that achieves mechanical interlock rather than relying solely on compaction density. Round river gravel compacts adequately initially but experiences creep settlement under sustained loads, particularly problematic at post positions where loads remain constant.

Post Base Integration Details

Your post base connections represent the critical interface where structural and decorative elements meet in paving stone shade structure foundations Arizona installations. You need to detail connections that remain watertight while accommodating the minor differential movement between rigid footings and flexible paving fields. The standard approach uses adjustable post bases with flanges that sit on top of the paving surface, but this creates visual disruption and water infiltration paths.

You’ll achieve superior results using embedded post bases where the lower flange sits at the setting bed elevation with pavers cut to fit tightly around the post. This requires you to coordinate post positions during base preparation, setting footings with precision positioning that accounts for final paver coursing patterns. Your tolerance for post position variation can’t exceed ±1/4 inch if you want pavers to align with joint patterns.

For projects requiring guidance on related commercial installations, see commercial paving stone production in Chandler for material specification insights. When you detail embedded bases, you should specify stainless steel posts or hot-dip galvanized steel with minimum 3.5 oz/ft² coating to resist corrosion from moisture trapped at the paving interface. Aluminum posts provide superior corrosion resistance but require you to verify structural capacity meets engineering requirements for your specific span and loading conditions.

Drainage Management Strategies

When you design paving stone pergola base Arizona systems, you’re creating surface areas where shade structures alter natural drainage patterns. The posts and beams intercept rainfall, concentrating flow at drip lines that don’t align with your paving joint patterns. You need to account for this concentrated flow in your drainage design, potentially requiring you to increase joint width or specify permeable joint fill materials in high-flow zones.

You should recognize that shaded pavers remain wet longer than exposed areas, extending the time when efflorescence and organic growth can develop. Your specification needs to address this by requiring enhanced subsurface drainage beneath shaded zones. You’ll want to increase base layer thickness by 2 inches in shaded areas or incorporate drainage composites that accelerate water evacuation.

- Your drainage design must handle concentrated flows from roof areas if the shade structure includes solid roofing

- You need to position catch basins or drainage swales at structure perimeters to intercept runoff

- Joint sand selection should favor coarser grades that resist erosion from concentrated flows

- You should specify polymeric sand in areas receiving direct runoff from structure drainage points

Material Selection Criteria

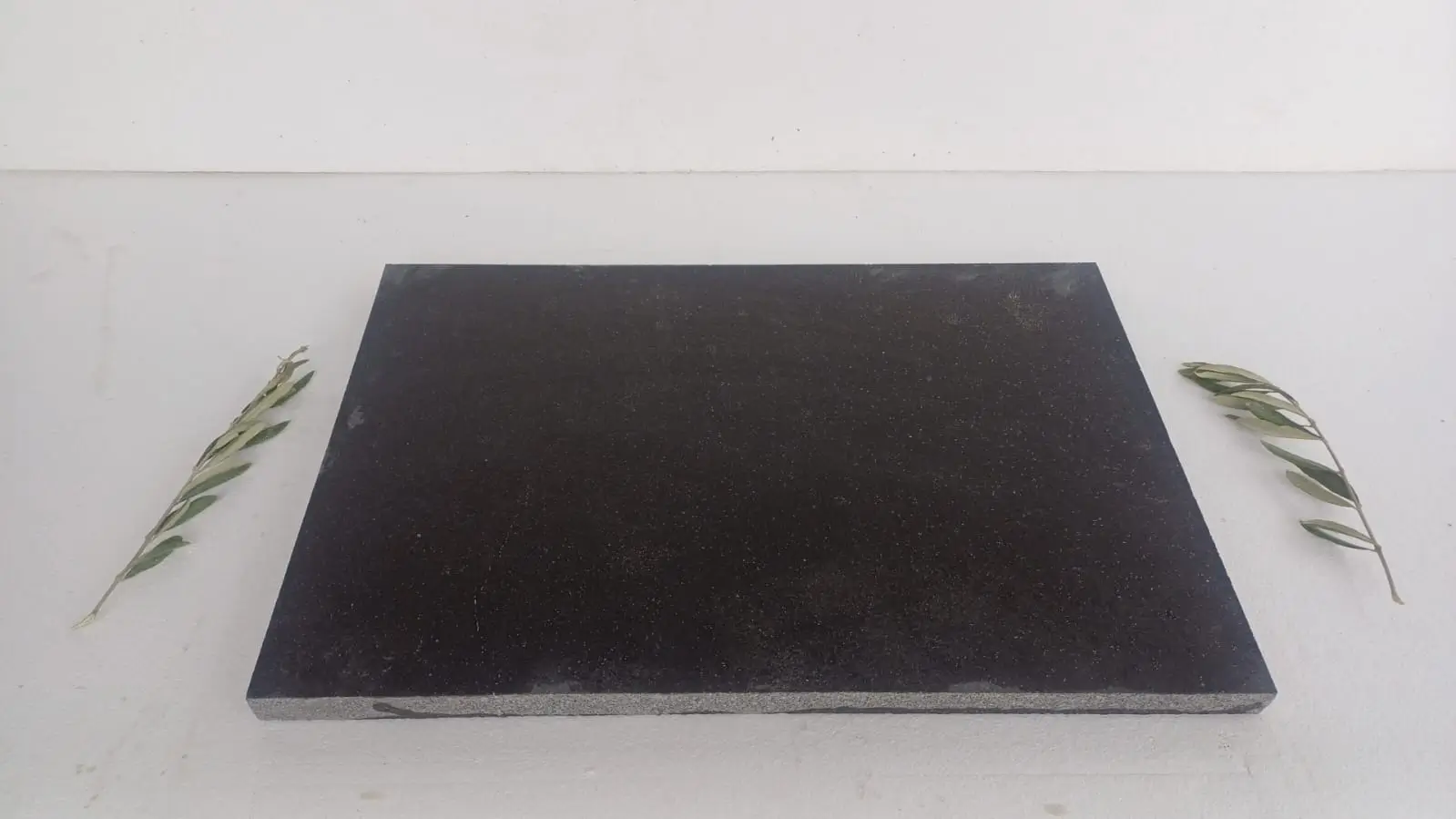

The pavers you select for paving stone ramada foundation Arizona applications must satisfy both structural and aesthetic requirements. You’re looking for materials with compressive strength exceeding 8,000 PSI to resist concentrated loads at post bases without cracking or spalling. Thickness becomes critical when pavers span across the isolation gaps around posts, requiring minimum 2-3/8 inch thickness to prevent flexural failure.

You need to evaluate how material porosity affects long-term performance in shaded environments where moisture evaporation rates drop by 40-60%. Dense materials with porosity below 5% resist moisture-related degradation but create surface water that must drain through joints. Higher porosity materials above 8% absorb more water but evaporate it more slowly in shaded conditions, potentially leading to freeze-thaw damage in Flagstaff or Sedona applications.

Your color selection affects more than aesthetics when you specify paving stone gazebo support Arizona installations. Lighter colors reflect solar radiation, keeping surface temperatures 15-25°F cooler than dark materials. This temperature differential affects both user comfort and thermal stress on the pavers themselves. You should specify light-colored materials in exposed areas surrounding shade structures, transitioning to darker tones in permanently shaded zones to minimize visible soiling.

Post Position Layout Techniques

When you lay out post positions for paving stone canopy structure Arizona foundations, you’re establishing control points that determine both structural performance and visual success. Your post grid must align with paver coursing patterns to avoid awkward cuts and maintain joint symmetry. You need to calculate post spacing during design development, adjusting structure dimensions to coordinate with paver module dimensions before finalizing architectural drawings.

You should establish post positions using total station surveying equipment rather than tape measures and string lines. The ±1/4 inch position tolerance required for proper paver alignment can’t be achieved reliably with conventional layout methods. Your surveyor needs to set temporary benchmarks that remain stable throughout base preparation and paving installation, allowing you to verify post positions at multiple construction phases.

- You must coordinate post grid with paver bond patterns during design to minimize cutting requirements

- Your layout should position posts at paver joint intersections when possible to simplify cutting

- You need to verify post positions account for structure beam dimensions and overhang requirements

- Temporary post position markers must extend above final paving elevation for verification during installation

Installation Sequencing Requirements

Your construction sequencing for paving stone shade structure foundations Arizona installations differs from standard paving projects. You need to decide whether to install structural posts before or after paving installation, each approach presenting distinct advantages. Installing posts first allows you to verify structural alignment before committing to final paving but requires you to work around posts during base preparation and paving installation.

You’ll typically achieve better results installing footings and setting embedded post bases to precise elevation, then completing paving installation around the bases. This requires you to protect post bases during paving operations and maintain accurate elevation control as setting bed thickness varies. Your paving crew needs to understand that post bases represent fixed elevation control points that can’t be adjusted to accommodate setting bed variations.

When you install pavers around posts, you should cut pavers to create 1/8-inch clearance gaps that will be filled with flexible sealant rather than rigid joint sand. This detail accommodates minor differential movement while preventing water infiltration around post bases. You need to specify polyurethane or silicone sealants rated for exterior exposure with movement capacity exceeding ±25%.

Common Installation Errors

The most frequent failure in paving stone pergola base Arizona installations occurs when contractors treat post footings as isolated elements rather than integrated components of the paving system. You’ll see installations where footings were poured without coordinating base excavation depth, resulting in footings that project above or below the intended setting bed elevation. This forces installers to adjust setting bed thickness dramatically around posts, creating weak zones prone to settlement.

You need to avoid the temptation to use the same base aggregate depth across the entire project area. Without the reinforced zones at post locations, you’ll observe settlement patterns where posts sink 1/4 to 3/8 inch relative to the surrounding field. This settling appears gradual over 2-3 years and becomes difficult to correct without complete removal and reinstallation of pavers around each post.

- You should never allow contractors to compact base aggregate after setting post footings in place

- Your specifications must prohibit using post bases to establish paving elevation control

- You need to reject installations where isolation gaps around posts are filled with rigid materials

- Post base flanges must never bear directly on setting bed without underlying structural support

Maintenance Access Planning

When you design paving stone ramada foundation Arizona systems, you’re creating installations that will require maintenance access to both structure and paving components. Your post bases need inspection and potential adjustment over the structure’s service life. You should detail post base covers or trim pieces that can be removed without disturbing surrounding pavers, allowing access to connection hardware and waterproofing components.

You need to consider how future repairs will be executed when pavers must be removed around post bases. Your installation specifications should require mechanical installation without adhesives in a 2-foot radius around each post, allowing individual pavers to be lifted and reset during maintenance operations. Beyond this zone, you can permit polymeric sand or other stabilization methods that make removal more difficult.

Citadel Bluestone Pavers Wholesale Prices in Arizona — Arizona Project Planning

When you evaluate Citadel Stone’s bluestone pavers wholesale prices in Arizona for shade structure foundations, you’re considering premium materials engineered for extreme climate performance. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse climate zones. This section demonstrates how you would approach material selection and installation planning for six representative cities, addressing the unique challenges each location presents for paving stone shade structure foundations Arizona projects.

Phoenix Specifications

In Phoenix applications, you would need to address extreme heat that drives surface temperatures above 160°F during summer months. Your paving stone canopy structure Arizona specification should account for thermal expansion rates that exceed standard climate assumptions by 20-30%. You’d want to specify expansion joints every 12 feet in exposed zones, increasing to 15 feet in shaded areas beneath ramadas. Material selection would favor lighter colors that maintain DCOF slip resistance above 0.50 even when heat-stressed. You should verify that warehouse inventory includes adequate volume to complete installation during optimal temperature windows between October and April.

Tucson Considerations

Your Tucson installations would require you to balance extreme heat with occasional freeze events that occur 10-15 nights annually. You’d specify materials with porosity below 6% to resist freeze-thaw damage while maintaining adequate permeability for monsoon drainage. The paving stone gazebo support Arizona details would need reinforced base zones extending 4 feet from post positions to address expansive clay soils common in Tucson basin areas. You should plan truck delivery schedules around monsoon season constraints that limit site access July through September.

Scottsdale Standards

Scottsdale projects would emphasize aesthetic refinement alongside structural performance for paving stone pergola base Arizona applications. You’d coordinate paver colors and textures with architectural finishes, potentially specifying custom sizing to achieve precise coursing alignment with post grids. Your details would show embedded post bases with stainless steel posts to eliminate visible connection hardware. You should account for Scottsdale’s design review requirements when preparing specifications, ensuring material selections satisfy municipal aesthetic guidelines for shade structure installations.

Flagstaff Requirements

For Flagstaff applications, you would prioritize freeze-thaw resistance as the dominant performance requirement affecting paving stone shade structure foundations Arizona specifications. You’d specify materials with absorption rates below 3% and verified performance through 300+ freeze-thaw cycles per ASTM C1645. Your base preparation would include 10-inch minimum aggregate depth with geotextile separation from native soils. Post footings would extend to 42-inch depth to reach below frost line. You should detail drainage systems that prevent water accumulation in shaded zones where snow melt remains frozen longer than exposed areas.

Sedona Applications

Sedona installations would challenge you to integrate paving stone ramada foundation Arizona systems with the region’s distinctive red rock aesthetic and environmental sensitivity requirements. You’d select material colors that complement natural surroundings while meeting structural performance standards. Your specifications would address steep terrain constraints common in Sedona locations, requiring you to coordinate paving elevations with structure floor levels on sloped sites. You should verify that delivery truck access accommodates narrow roads and tight turning radii typical of Sedona residential developments before finalizing material selections requiring specialized transportation.

Yuma Protocols

Your Yuma projects would confront the most extreme heat conditions in Arizona, with summer temperatures exceeding 120°F regularly. You’d specify paving stone canopy structure Arizona materials with maximum solar reflectance to maintain usable surface temperatures beneath shade structures. Light-colored pavers with SRI values above 35 would be essential for pedestrian comfort. Your expansion joint spacing would reduce to 10-12 feet to accommodate thermal movement that exceeds Phoenix levels by 15%. You should account for limited local warehouse facilities when planning delivery logistics, potentially requiring extended lead times for specialty materials shipped from Phoenix distribution centers.

Quality Verification Protocols

When you inspect completed paving stone pergola base Arizona installations, you need systematic verification procedures that address both visible surface quality and hidden structural components. Your inspection checklist should begin with post position accuracy, verifying that actual locations match design intent within ±1/4 inch tolerance. You’ll use string lines pulled taut between opposite posts to check alignment, measuring deviations at intermediate posts.

You should verify that isolation gaps around posts maintain consistent width and have been properly sealed with flexible materials. Your inspection needs to confirm that post bases bear on structural footings rather than setting bed, requiring you to request documentation photos taken during installation before pavers concealed the connections. You need to test paver stability around posts by applying moderate pressure, confirming that pavers don’t rock or shift under load.

- You must verify joint spacing remains consistent across the paving field including areas around posts

- Your inspection should confirm drainage slopes direct water away from post bases in all directions

- You need to document surface elevations at posts and field centers to establish baseline for monitoring settlement

- Post plumbness requires verification using precision levels with accuracy to 1/8 inch per 8 feet of height

Performance Monitoring Recommendations

Your completed paving stone shade structure foundations Arizona installation requires ongoing monitoring to verify long-term performance. You should establish elevation benchmarks at post bases and multiple field locations during final inspection, then re-measure these points annually for the first three years. Settlement exceeding 1/8 inch at posts relative to the field indicates inadequate footing design or base preparation that will require remedial work.

You need to monitor joint sand retention around posts where concentrated water flow and foot traffic accelerate loss rates. Your maintenance program should include joint sand replenishment within 2-foot radius of posts at 6-month intervals for the first two years, extending to annual intervals once sand stabilization occurs. You should inspect sealant joints around posts every 18 months, replacing deteriorated sealants before water infiltration compromises post base connections. For comprehensive guidance on related applications, review structural load considerations for paving stone rooftop deck installations before you finalize your project documentation. Account management distinguishes Citadel Stone’s professional paving wholesale suppliers in Arizona service.