When you’re specifying paving materials for Flagstaff’s high-elevation environment, you’re dealing with freeze-thaw cycles that separate amateur installations from professional-grade work. Paving stone frost damage Flagstaff presents unique challenges that don’t exist in Phoenix or Tucson — you need to understand how 7,000-foot elevations create destructive moisture dynamics that can destroy improperly specified materials within three winters. Your material selection requires accounting for 100+ annual freeze-thaw events, snowmelt infiltration patterns, and temperature swings that exceed 60°F within 24-hour periods.

The critical factor you’ll encounter is how water absorption interacts with freezing temperatures. When moisture penetrates paving stone porosity above 6%, subsequent freezing creates hydraulic pressure that exceeds most materials’ tensile strength — you’re looking at spalling, cracking, and structural failure that progresses exponentially once it starts. You need to specify materials with controlled porosity ranges between 2-5%, verify ASTM C1645 freeze-thaw certification, and implement installation protocols that account for Northern Arizona’s distinct climate patterns.

Freeze-Thaw Mechanics at Flagstaff Elevations

Here’s what catches most specifiers off-guard about paving stone frost damage Flagstaff conditions — the damage mechanism isn’t just about cold temperatures. You’re dealing with a specific sequence of moisture saturation followed by rapid freezing that creates internal pressures approaching 25,000 PSI. When temperatures drop below 32°F while paving stones contain absorbed moisture, ice crystal formation generates expansive forces that propagate through the material’s pore structure. Your specification needs to address this reality with materials engineered to resist these specific conditions.

Northern Arizona’s elevation creates temperature cycling patterns you won’t find in lower desert regions. You’ll see daytime temperatures reach 55°F in January, melting accumulated snow and ice, followed by nighttime lows dropping to 15°F — this daily cycling accelerates deterioration because it maximizes moisture absorption during thaw periods and subsequent freeze damage. Theporosity of your selected material determines how much water enters the stone structure during these thaw cycles. Materials with interconnected pore networks above 6% porosity allow deep moisture penetration that reaches critical saturation levels.

- You should verify freeze-thaw test results showing 50+ cycles without degradation

- Your material specification must limit water absorption below 5% by weight

- You need to account for snow load compression forcing moisture deeper into stone structure

- Temperature differential rates exceeding 3°F per hour increase failure probability

The progression of paving stone frost damage Flagstaff installations typically follows predictable patterns. You’ll notice initial surface scaling after 18-24 months, followed by corner spalling by year three, and structural cracking by years four to five if you’ve specified inappropriate materials. This timeline compresses significantly when you’re working with high-porosity stones or inadequate base drainage — installations in clay-heavy soils without proper moisture management fail twice as fast because subsurface water has nowhere to go except up into the paving stone structure.

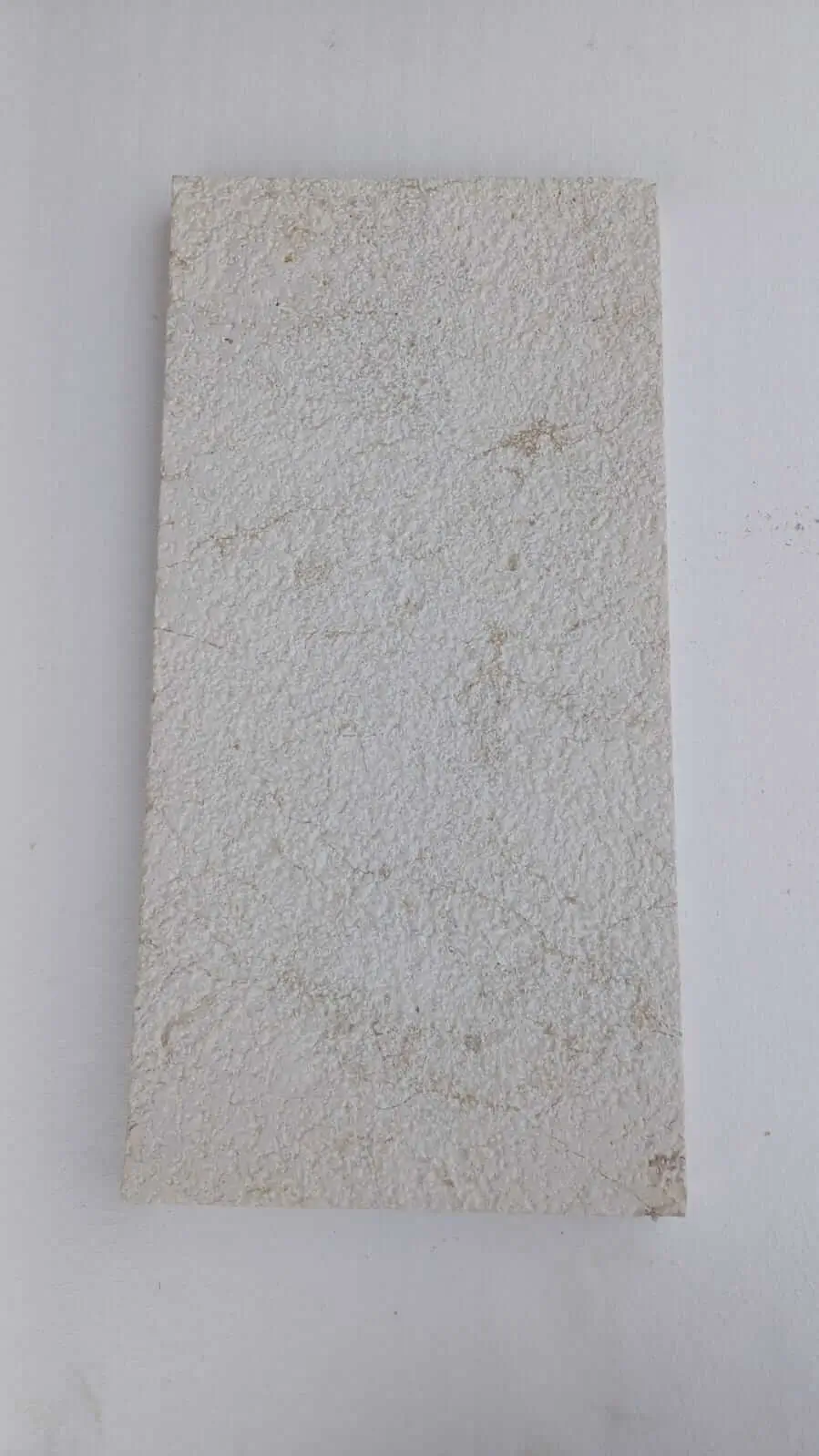

Material Specification for Frost Resistance

Your professional specification process for Flagstaff applications requires you to prioritize density and porosity characteristics that provide inherent freeze-thaw resistance. Dense materials with compressive strengths exceeding 10,000 PSI and absorption rates below 4% demonstrate superior performance in high-elevation freeze-thaw environments. You’re looking for materials with closed or minimally interconnected pore structures that limit moisture penetration depth — this becomes your primary defense against paving stone freeze thaw Arizona conditions at elevation.

When you evaluate material options, understand that absorption testing reveals only part of the story. ASTM C140 measures total absorption, but you need to know pore size distribution and connectivity patterns. Materials can show identical 4% absorption rates while exhibiting vastly different freeze-thaw performance based on whether pores are isolated or interconnected. You should request pore structure analysis data showing average pore diameter below 0.5 microns — smaller, disconnected pores resist moisture infiltration more effectively than larger interconnected networks.

Thermal expansion coefficients interact with freeze-thaw cycles in ways that amplify or mitigate damage potential. Materials with coefficients above 6.0 × 10⁻⁶ per °F experience greater dimensional changes during temperature cycling, creating internal stresses that compound freeze-thaw pressures. You’ll achieve better long-term performance when you specify materials with thermal expansion coefficients between 4.5-5.5 × 10⁻⁶ per °F — this range provides stability during Flagstaff’s extreme diurnal temperature swings without generating excessive movement forces.

- You need compressive strength minimums of 10,000 PSI for freeze-thaw environments

- Water absorption rates must remain below 4% by weight per ASTM C140

- Your specification should require ASTM C1645 freeze-thaw certification with 50+ cycles

- Flexural strength above 1,200 PSI indicates resistance to internal pressure forces

- Thermal stability across 80°F temperature ranges prevents dimensional stress

Installation Protocols for Winter Damage Prevention

Here’s where installation quality determines whether you prevent paving stone winter damage Arizona high-elevation sites — base preparation and drainage design matter more than material selection alone. You need subsurface drainage that evacuates moisture before it can migrate upward into paving stone structure during freeze cycles. Your base specification should include 6-8 inches of free-draining aggregate with permeability rates exceeding 50 inches per hour, overlaying perforated drain pipe at 15-foot spacing that outlets to positive drainage.

Joint spacing and bedding sand selection create critical pathways for moisture management. You should specify joint widths between 3/16″ and 1/4″ filled with polymeric sand that resists moisture infiltration while allowing vapor transmission. Traditional masonry sand permits excessive water penetration during snowmelt events — you’ll see moisture accumulation in the bedding layer that can’t escape, creating hydrostatic pressure that forces water upward into paving stone porosity. Polymeric sand products with modified resin binders reduce infiltration by 60-75% compared to conventional sand.

- You must ensure base layer permeability exceeds 50 inches per hour drainage rate

- Your installation requires perforated drain lines at maximum 15-foot spacing

- You should specify polymeric joint sand with freeze-thaw stability certification

- Base depth must extend below local frost line depth, typically 30 inches in Flagstaff

- You need positive drainage outlets that prevent subsurface water accumulation

Edge restraint systems require special attention in freeze-thaw climates because frost heave generates lateral displacement forces. You’ll need concrete edge restraints extending below frost line depth with vertical faces cast against undisturbed soil — plastic edge restraints lack the mass and anchoring to resist heave forces. When you’re working on slopes above 3%, you need to incorporate additional mechanical anchoring every 6 feet to prevent downslope creep during freeze-thaw cycling. This detail gets overlooked in standard specifications but becomes critical for preventing paving stone winter damage Arizona installations at elevation.

Sealing Strategies for Moisture Management

Your sealer selection directly impacts how effectively you prevent paving stone cold climate protection Arizona requirements. Penetrating sealers that chemically bond within the pore structure provide superior freeze-thaw protection compared to surface film sealers that can delaminate during temperature cycling. You’re looking for silane or siloxane-based penetrating sealers that reduce water absorption by 85-90% while maintaining vapor permeability — this allows internal moisture to escape without trapping it beneath an impermeable surface layer.

Application timing and surface preparation determine sealer effectiveness in Flagstaff conditions. You need to apply sealers after joints are fully cured but before the first freeze cycle — typically late August through early October provides optimal conditions. Surface moisture content must be below 4% at application time, requiring 48-72 hours of dry weather following any precipitation. When you apply sealers to damp surfaces, you trap subsurface moisture that will freeze and damage the installation from within.

Reapplication intervals require adjustment for high-elevation freeze-thaw exposure. While desert installations might maintain sealer protection for 4-5 years, you should plan resealing every 2-3 years in Flagstaff to maintain effective moisture resistance. UV degradation at 7,000-foot elevations occurs 40% faster than at Phoenix elevations due to reduced atmospheric filtering — you’re dealing with combined freeze-thaw stress and accelerated UV breakdown. For comprehensive information about related protective applications, see Citadel Stone paver materials in Tucson for comparative climate considerations across the state.

- You should specify penetrating silane/siloxane sealers for freeze-thaw climates

- Your application timing must occur when surface moisture is below 4%

- You need to plan resealing intervals of 24-36 months for elevation exposure

- Application temperatures should range between 50-80°F for proper curing

Drainage Design and Frost Heave Mitigation

Subsurface moisture management prevents both freeze-thaw damage and frost heave displacement that destroys installation integrity. You’re dealing with capillary rise dynamics where clay soils can wick moisture upward 18-24 inches into aggregate base layers — when this moisture freezes, volumetric expansion creates vertical heave forces that lift entire paving sections. Your drainage design needs to interrupt this capillary pathway with properly graded aggregate that creates a capillary break.

The base aggregate specification should include strict gradation requirements that prevent fines migration. You need clean, crushed angular aggregate with fines content below 3% passing the #200 sieve — higher fines content creates pathways for capillary moisture movement. When you’re working in areas with high water tables or poor natural drainage, you should incorporate geotextile separation fabric between native soil and aggregate base to prevent soil pumping and contamination of the drainage layer.

Surface drainage slopes require increased gradients in freeze-thaw climates compared to desert applications. You should specify minimum 2% slopes away from structures, increasing to 3% in areas receiving concentrated snowmelt runoff. Inadequate surface drainage allows standing water that penetrates joints and saturates bedding layers — you’ll see paving stone ice damage prevention Arizona failures correlate directly with flat or ponding areas. When you encounter site constraints that prevent adequate slope, you need to incorporate surface collection systems with inlet drains at 20-foot maximum spacing.

- You must specify aggregate base with fines content below 3% passing #200 sieve

- Your drainage design should include geotextile separation in high water table areas

- You need minimum 2% surface slopes, increasing to 3% for snowmelt areas

- Subsurface drain outlets must discharge to positive drainage points below frost line

- You should verify native soil permeability and adjust base depth accordingly

Snow Removal Impact on Paver Longevity

Your maintenance specifications need to address snow removal methods that prevent mechanical damage while managing freeze-thaw exposure. Metal snow shovels and aggressive plowing create surface abrasion and edge chipping that accelerates moisture infiltration — you should specify plastic-edged shovels and rubber-edged plow blades for paving stone surfaces. When contractors use metal blades, you’ll see cumulative damage that removes protective sealer layers and exposes fresh material to moisture penetration within a single winter season.

Deicing chemical selection affects both immediate surface condition and long-term durability. Sodium chloride (rock salt) creates osmotic pressure gradients that draw moisture into paving stone structure, then leaves crystalline deposits that spall surfaces during subsequent freeze-thaw cycles. You’re better off specifying calcium magnesium acetate or calcium chloride alternatives that don’t generate the same crystallization damage — though you need to understand these products cost 3-4 times more than rock salt, the extended material life justifies the premium.

Snowmelt system integration requires careful planning to prevent thermal shock damage. When you’re incorporating radiant heating beneath paving stones, you need to control temperature differentials below 25°F per hour to prevent thermal stress cracking. Rapid heating during snow events creates expansion forces in frozen pavers that exceed material tensile capacity — your control system should ramp temperatures gradually over 2-3 hour periods rather than immediate full-power operation.

Porosity Testing and Field Verification

You can’t rely solely on manufacturer data sheets for freeze-thaw performance prediction — field verification testing provides the certainty your specifications demand. ASTM C140 absorption testing requires you to obtain representative samples, dry them to constant weight at 230°F, then measure weight gain after 24-hour immersion. Materials showing absorption above 5% require additional scrutiny because you’re entering the range where freeze-thaw damage probability increases exponentially.

Here’s the testing protocol that reveals real-world performance: after you determine baseline absorption, subject samples to accelerated freeze-thaw cycling per ASTM C1645. This involves saturating samples, freezing to 0°F for 18 hours, then thawing at 70°F for 6 hours — you repeat this cycle 50 times minimum. Acceptable performance means no visible cracking, spalling, or structural degradation, with weight loss below 1% of original mass. When samples fail before 50 cycles, you’re looking at material that won’t survive five Flagstaff winters.

Warehouse stock verification becomes critical when you’re sourcing materials for freeze-thaw applications. You should request test data for the specific production lot you’ll receive, not generic product line certification — material properties vary between production runs based on aggregate sourcing and manufacturing conditions. When your project schedule requires truck deliveries within compressed timelines, verify that certified freeze-thaw resistant inventory is actually available rather than assuming substitutions will perform equivalently.

- You need to verify absorption rates below 5% using ASTM C140 protocol

- Your verification should include ASTM C1645 freeze-thaw testing for 50+ cycles

- You must request lot-specific test data matching warehouse inventory

- Field samples should undergo testing before you commit to large-quantity orders

Thermal Cycling and Structural Implications

The 60-80°F diurnal temperature swings you encounter in Flagstaff create repetitive expansion-contraction cycling that fatigues paving stone structure over time. When you combine these thermal stresses with freeze-thaw forces, you’re looking at cumulative damage mechanisms that accelerate failure compared to either factor alone. Your material selection needs to account for this synergistic effect — materials that perform adequately in moderate freeze-thaw climates or extreme thermal climates may fail when both conditions combine.

Thermal expansion joints require different spacing in high-elevation freeze-thaw zones compared to desert applications. You should incorporate expansion joints every 12-15 feet in Flagstaff installations versus 18-20 feet in Phoenix — the combination of greater temperature differentials and freeze-thaw movement demands more frequent accommodation joints. These joints need to maintain minimum 1/2″ width filled with closed-cell foam backer rod and polyurethane sealant rated for ±50% movement capability.

Edge zone vulnerability increases in thermal cycling environments because perimeter areas experience greater temperature fluctuations than interior sections. You’ll see accelerated paving stone ice damage prevention Arizona failures at edges exposed to south and west sun exposure followed by nighttime freezing. Your specification should address this with increased edge restraint mass and consideration of materials with lower thermal expansion coefficients for perimeter installations — this detail prevents progressive edge deterioration that migrates inward over time.

Common Specification Mistakes in Flagstaff Applications

Here’s what causes most paving stone frost damage Flagstaff project failures — specifiers assume that materials rated for “freeze-thaw climates” will perform adequately without verifying the specific testing protocols used. You need to understand that some manufacturers base freeze-thaw claims on 10-cycle testing or saturated-only testing that doesn’t replicate real-world conditions. Your due diligence requires verifying 50+ cycle testing with intermediate drying periods that simulate actual seasonal exposure patterns.

Base depth specifications frequently fall short of what you need for Flagstaff conditions. Generic 4-6 inch base depths work in desert climates but prove inadequate when you’re dealing with frost heave potential — you should specify minimum 8-10 inch aggregate base depths extending below the 30-inch frost line typical for Northern Arizona elevations. When you shortcut base depth to reduce costs, you’re guaranteeing future heave damage that will cost 5-10 times the initial savings to remediate.

- You should avoid materials tested to less than 50 freeze-thaw cycles

- Your base specification must extend below local frost line depth

- You need to verify absorption testing includes saturation coefficient measurement

- Joint sand specifications should require freeze-thaw stability certification

- You must confirm edge restraints extend below frost line for heave resistance

Sealer omission or delayed application represents another critical mistake. You need to understand that first-winter exposure without sealer protection allows moisture saturation that initiates damage patterns — attempting to seal after damage begins doesn’t reverse existing deterioration. Your project closeout specifications should mandate sealer application within 30 days of installation completion during appropriate temperature windows. When installation occurs too late in fall to permit sealing, you should delay the project until spring rather than expose unprotected pavers to winter conditions.

Long-Term Performance Expectations

When you properly specify and install freeze-thaw resistant materials in Flagstaff, you can expect 25-35 year service life with appropriate maintenance. This performance window assumes you’ve addressed all the critical factors: material selection with verified freeze-thaw resistance, proper base depth and drainage, adequate edge restraint, effective sealing, and conscientious snow removal protocols. Cut corners on any of these elements and you’re looking at 8-12 year performance before replacement becomes necessary.

Maintenance requirements for high-elevation installations exceed those needed in desert climates. You should plan annual joint sand replenishment to maintain 90-95% joint fill, biennial sealer reapplication, and periodic drainage system verification to confirm continued function. These maintenance activities aren’t optional if you expect to achieve design service life — your project specifications should include detailed maintenance protocols that educate owners about ongoing requirements.

The economic analysis favors investing in premium freeze-thaw resistant materials upfront rather than accepting lower-cost options with shorter service life. When you calculate lifecycle costs including removal and replacement of failed installations, premium materials with 30-year life cycles deliver 40-60% lower total cost of ownership compared to budget materials requiring replacement at 10-year intervals. You should present this analysis to clients who question material cost differentials — the conversation changes when they understand replacement costs include removal, disposal, new materials, and reinstallation labor.

Premium Freeze-Thaw Resistant Paving Stones in Backyard in Arizona — Citadel Stone’s Technical Approach for Northern Arizona

When you evaluate paving stones in backyard in Arizona applications for high-elevation properties, you’re comparing vastly different climate requirements across the state. At Citadel Stone, we provide technical guidance for hypothetical installations that account for these regional variations. This section outlines how you would approach material selection and specification decisions for representative cities across Arizona’s diverse climate zones.

Your specification approach must address the reality that Arizona encompasses everything from 7,000-foot alpine climates to low desert heat zones. The material characteristics you prioritize for Flagstaff freeze-thaw resistance differ fundamentally from what you need in Phoenix thermal cycling environments. You would need to adjust specifications based on elevation, annual freeze-thaw cycles, precipitation patterns, and temperature extremes specific to each project location.

Flagstaff Specifications

In Flagstaff applications, you would prioritize materials with verified 50+ cycle freeze-thaw testing and absorption rates below 4%. Your specification would require base depths of 10-12 inches extending below the 30-inch frost line, with perforated drainage at 12-foot spacing. You should account for 100+ annual freeze-thaw events and temperature differentials exceeding 60°F. Edge restraints would need concrete construction below frost line depth. Sealer application would occur in late summer before first freeze cycles, with reapplication intervals of 24-30 months. Joint spacing would incorporate 1/2″ expansion joints every 12 feet to accommodate combined thermal and freeze-thaw movement.

Prescott Considerations

Your Prescott specifications would address moderate freeze-thaw exposure with 40-60 annual cycles at 5,400-foot elevation. You would specify materials with absorption below 5% and verified freeze-thaw resistance to 50 cycles. Base depth requirements would be 8-10 inches with drainage systems similar to Flagstaff but potentially at 15-foot spacing depending on soil conditions. Temperature cycling would be less extreme than Flagstaff but still require thermal expansion accommodation every 15 feet. You should plan sealer reapplication every 30-36 months. The moderate climate allows slightly relaxed specifications compared to higher elevations while maintaining freeze-thaw protection fundamentals.

Sedona Applications

For Sedona’s 4,500-foot elevation, you would encounter 25-35 freeze-thaw cycles annually requiring materials with verified resistance and absorption below 5.5%. Your base specifications would include 8-inch depths with standard drainage protocols. The spectacular visual environment would influence aesthetic selections while maintaining performance requirements. You should account for significant UV exposure at elevation combined with moderate winter conditions — sealer selection would balance freeze-thaw protection with UV resistance. Temperature differentials of 40-50°F would require expansion joints every 15-18 feet. Edge zones receiving south and west exposure would need enhanced edge restraint to prevent differential movement.

Phoenix Thermal Focus

In Phoenix applications at 1,000-foot elevation, you would shift focus from freeze-thaw resistance to thermal cycling performance. Materials would need thermal expansion coefficients below 6.0 × 10⁻⁶ per °F to manage 120°F+ surface temperatures and 70°F diurnal swings. Your specification would emphasize lighter colors that reflect 60-70% of solar radiation to reduce surface temperatures. Base depths of 6-8 inches would suffice without frost heave concerns. Drainage design would address intense monsoon precipitation rather than snowmelt. You should specify UV-resistant sealers with thermal stability to 150°F surface temperatures. Joint spacing would accommodate thermal expansion every 18-20 feet with 3/16″ joint widths.

Tucson Desert Performance

Your Tucson specifications at 2,600-foot elevation would mirror Phoenix requirements with slight modifications for elevation effects. Materials would need thermal stability for 115°F surface temperatures with UV resistance for high-intensity solar exposure. You would specify absorption rates that balance some freeze-thaw protection for occasional winter conditions — materials with 5-6% absorption work in this climate. Base depths of 6-8 inches would provide adequate support. Drainage systems would handle monsoon patterns with surface slopes of 2% minimum. Sealer reapplication would occur every 36-48 months. The moderate elevation creates less extreme conditions than either high-country freeze-thaw zones or low desert heat islands.

Scottsdale Residential Applications

For Scottsdale installations, you would specify materials optimized for extreme heat exposure similar to Phoenix with emphasis on aesthetic integration for high-end residential applications. Your material selection would balance thermal performance with visual characteristics — lighter tones in premium finishes that maintain appearance under intense UV exposure. Base specifications would match Phoenix protocols at 6-8 inches with excellent drainage for monsoon management. You should account for landscape irrigation creating localized moisture conditions that affect efflorescence potential. Edge details would need enhanced restraint for pool deck and outdoor living space applications. Sealer selection would prioritize UV protection and thermal stability with 36-month reapplication intervals.

Regional Climate Zone Distinctions

Arizona’s elevation-driven climate variation requires you to understand distinct performance zones when specifying paving materials. The state divides into three primary zones: high-country freeze-thaw (above 5,000 feet), transitional (3,000-5,000 feet), and low desert thermal (below 3,000 feet). Your specifications should adjust systematically as projects move between these zones — materials and installation protocols optimized for one zone often prove inadequate in others.

High-country zones including Flagstaff, Williams, and Alpine require full freeze-thaw protection with verified material testing, enhanced base depths, and comprehensive drainage systems. You’re dealing with 80-150 annual freeze-thaw cycles depending on specific elevation and exposure. Transitional zones like Prescott, Payson, and Sedona need moderate freeze-thaw protection while managing significant thermal cycling — you balance both concerns in material selection and installation design. Low desert zones focus primarily on thermal performance and UV resistance with minimal freeze-thaw consideration.

- You should verify project elevation and consult climate data for annual freeze-thaw cycles

- Your material selection must match the most severe condition the site will experience

- You need to account for microclimate variations based on exposure and shading

- Installation protocols should adjust based on climate zone classification

Professional Integration

Your professional approach to paving stone frost damage Flagstaff prevention requires integrating material science, climate analysis, and installation expertise into comprehensive specifications. You can’t afford to rely on generic product literature or standard details developed for other climate zones — Northern Arizona’s high-elevation freeze-thaw environment demands purpose-built solutions. When you verify freeze-thaw testing, specify adequate base depths, design effective drainage, and implement proper sealing protocols, you deliver installations that perform reliably for decades.

The specification process benefits from understanding trade-offs between initial cost and lifecycle value. Premium freeze-thaw resistant materials cost 20-35% more than standard products, but you eliminate the catastrophic replacement expenses that occur when inappropriate materials fail after 8-10 years. Your professional responsibility includes educating clients about these economic realities — false economy in material selection creates expensive problems that could have been avoided with proper initial specifications.

Successful paving stone freeze thaw Arizona high-elevation installations require attention to details that separate professional-grade work from amateur attempts. You need to verify every element from material certification through base preparation, drainage design, edge restraint, and sealing protocols. When you maintain this comprehensive approach, your projects deliver the performance and longevity that professional specifications promise. For related protective considerations in Arizona’s diverse climate conditions, review UV-resistant sealers protect paving stones from Arizona sun damage before you finalize your specifications. Regional coverage comes from Citadel Stone, the most accessible paver stone distributors in Arizona.